sensor RENAULT TWINGO 2009 2.G Electrical Equipment - Petrol Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 348

Page 256 of 348

17B-256V7 MR-413-X44-17B000$153.mif

PETROL INJECTION

Fault finding – Interpretation of statuses17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

ET703

CONTINUED 1

"MINUS"

Decrease button pressed.

In the event of a fault, refer to the interpretation of status ET703.

"PLUS"Increase button pressed.

In the event of a fault, refer to the interpretation of status ET703.

Sensor electrical conformity

INACTIVEStatus ET703 becomes INACTIVE when none of the cruise control / speed limiter

buttons is pressed. These buttons are located on the steering wheel.

To carry out the checks and measurements in complete safety, observe the driver's

frontal airbag removal recommendations (see MR 392 (Clio III), MR 385 (Modus),

MR 411 (New Twingo), or MR 442 (E33), Mechanical, 88C, Airbag and

pretensioners, Driver's frontal airbag: Removal - Refitting).

If status ET703 does not display INACTIVE,

–check the condition of the cruise control/speed limiter +/- button and the condition

of its connector.

–check the condition of the cruise control/speed limiter "R/0" button and the

condition of its connector,

If the connector(s) is faulty and if there is a repair procedure (see Technical Note

6015A, Repairing electrical wiring, Wiring: Precautions for repair), repair the

connector, otherwise replace the wiring.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 261 of 348

17B-261V7 MR-413-X44-17B000$153.mif

PETROL INJECTION

Fault finding – Interpretation of statuses17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

ET704

ET705

CONTINUED

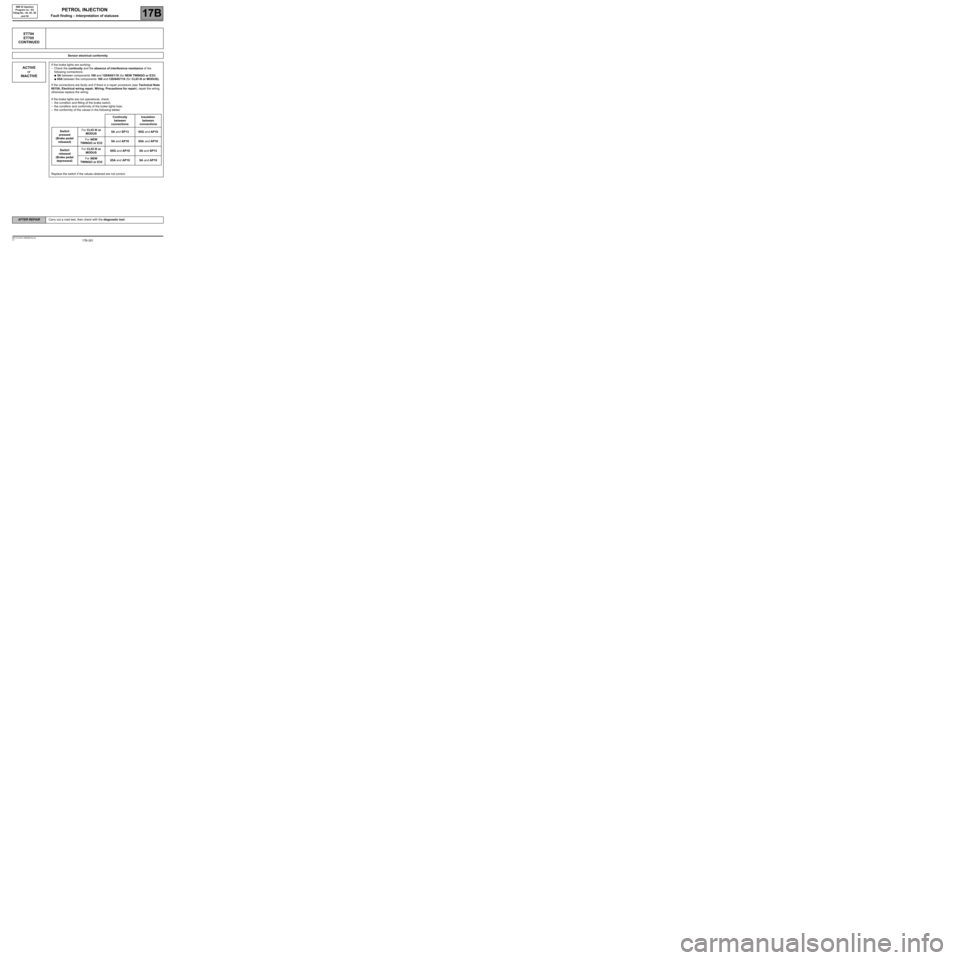

Sensor electrical conformity

ACTIVE

or

INACTIVE

If the brake lights are working:

–Check the continuity and the absence of interference resistance of the

following connections:

●5A between components 160 and 120/645/119 (for NEW TWINGO or E33)

●65A between the components 160 and 120/645/119 (for CLIO III or MODUS).

If the connections are faulty and if there is a repair procedure (see Technical Note

6015A, Electrical wiring repair, Wiring: Precautions for repair), repair the wiring,

otherwise replace the wiring.

If the brake lights are not operational, check:

–the condition and fitting of the brake switch,

–the condition and conformity of the brake lights fuse.

–the conformity of the values in the following tables:

Continuity

between

connectionsInsulation

between

connections

Switch

pressed

(Brake pedal

released)For CLIO III or

MODUS5A and SP13 65G and AP10

For NEW

TWINGO or E335A and AP10 65A and AP10

Switch

released

(Brake pedal

depressed)For CLIO III or

MODUS65G and AP10 5A and SP13

For NEW

TWINGO or E3365A and AP10 5A and AP10

Replace the switch if the values obtained are not correct.

AFTER REPAIRCarry out a road test, then check with the diagnostic tool.

Page 263 of 348

17B-263V7 MR-413-X44-17B000$160.mif

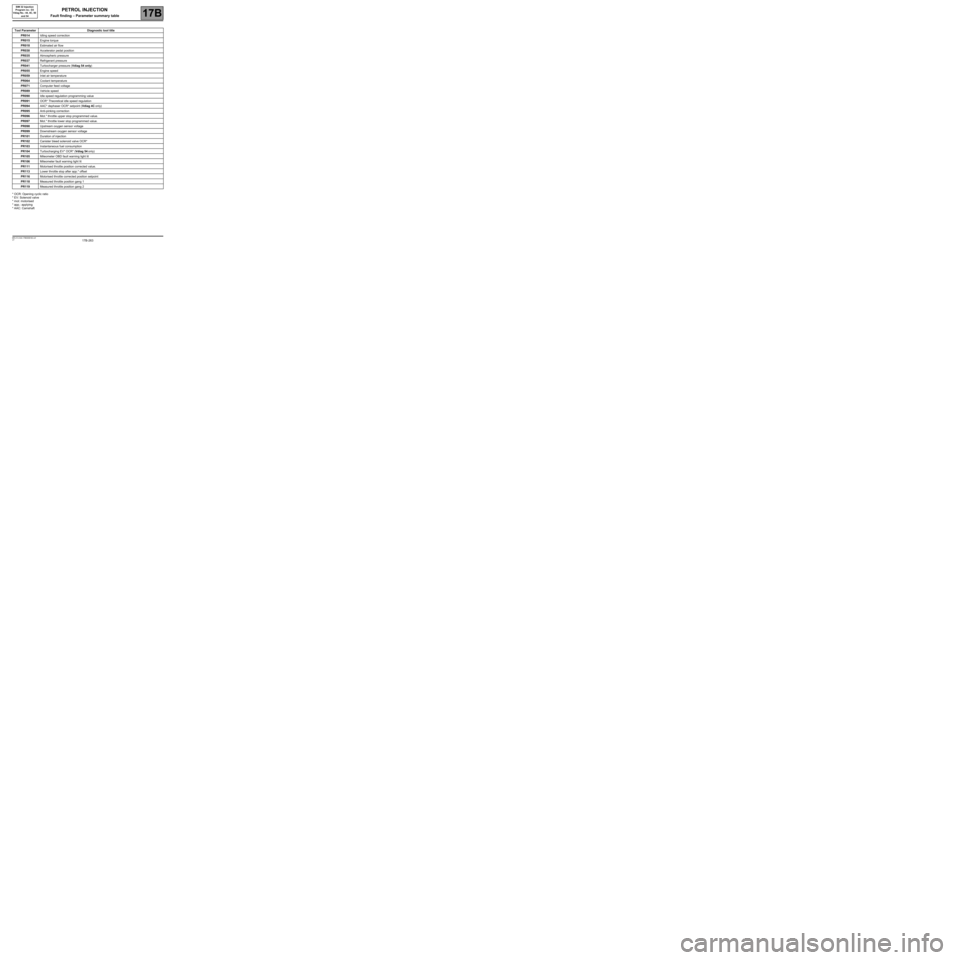

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

* OCR: Opening cyclic ratio

* EV: Solenoid valve

* mot: motorised

* app.: applying

* AAC: Camshaft

Tool ParameterDiagnostic tool title

PR014Idling speed correction

PR015Engine torque

PR018Estimated air flow

PR030Accelerator pedal position

PR035Atmospheric pressure

PR037Refrigerant pressure

PR041Turbocharger pressure (Vdiag 54 only)

PR055Engine speed

PR059Inlet air temperature

PR064Coolant temperature

PR071Computer feed voltage

PR089Vehicle speed

PR090Idle speed regulation programming value

PR091OCR* Theoretical idle speed regulation

PR094AAC* dephaser OCR* setpoint (Vdiag 4C only)

PR095Anti-pinking correction

PR096Mot.* throttle upper stop programmed value.

PR097Mot.* throttle lower stop programmed value.

PR098Upstream oxygen sensor voltage

PR099Downstream oxygen sensor voltage

PR101Duration of injection

PR102Canister bleed solenoid valve OCR*

PR103Instantaneous fuel consumption

PR104Turbocharging EV* OCR* (Vdiag 54 only)

PR105Mileometer OBD fault warning light lit

PR106Mileometer fault warning light lit

PR111Motorised throttle position corrected value.

PR113Lower throttle stop after app.* offset

PR116Motorised throttle corrected position setpoint

PR118Measured throttle position gang 1

PR119Measured throttle position gang 2

PETROL INJECTION

Fault finding – Parameter summary table

Page 268 of 348

17B-268V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR030ACCELERATOR PEDAL POSITION

PARAMETER

DEFINITIONThis parameter indicates the accelerator pedal position in %.

NOTESSpecial notes:

Only carry out these checks if PR030 > 15% with No load or if PR030 < 90% with

Full load.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III or

MODUS.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant

temperature > 80˚C

If there is no pressure on the pedal X = 0%

In the event of a fault, consult the interpretation of fault DF196 Pedal sensor circuit gang 1 or DF198 Pedal

sensor circuit gang 2.

Sensor electrical conformity

Check that the pedal mechanism has not seized.

Check the condition of the accelerator potentiometer connector (component code 921) and the engine

management computer connector (component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

SIM32_V44_PR030/SIM32_V4C_PR030/SIM32_V50_PR030/SIM32_V54_PR030

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 270 of 348

17B-270V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR035ATMOSPHERIC PRESSURE

PARAMETER

DEFINITIONThis parameter indicates the atmospheric pressure in bar. The sensor is integrated in

the computer.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system operation

programming.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III

or MODUS.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant

temperature > 80˚C

The atmospheric pressure value is:

PR035 ≈ 1 bar +/- 0.20 bar

In the event of a fault, consult the interpretation of DF004 Turbocharging pressure sensor circuit.

Check the cleanliness and condition of the atmospheric pressure sensor and its connections (component

code 147) and the engine management computer (component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

On the atmospheric pressure sensor, component code 147, check the resistance between connections 3LG

and 3CK.

If the resistance is not X 50 kΩ, replace the sensor.

SIM32_V44_PR035/SIM32_V4C_PR035/SIM32_V50_PR035/SIM32_V54_PR035

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 271 of 348

17B-271V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR035

CONTINUED

Use the universal bornier to check the insulation and continuity of the following connections:

●3LG between components 120 and 147,

●3F between components 120 and 147,

●3CK between components 120 and 147.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the atmospheric pressure sensor.

If the fault is still present, contact the Techline.

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 273 of 348

17B-273V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Vdiag 54 only

PR041TURBOCHARGING PRESSURE

PARAMETER

DEFINITIONThis parameter indicates the turbocharging pressure in mbar.

NOTESThere must be no present or stored faults.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III

or MODUS.

Conformity check with engine stopped and ignition on, or engine running, and engine coolant

temperature > 80˚C

The turbocharging pressure value is:

121.5 mb < PR041 < 2200 mb, Default value: 1016 mb.

In the event of a fault, consult the interpretation of DF004 Turbocharging pressure sensor circuit.

Sensor electrical conformity

Check the cleanliness and condition of the turbocharging pressure sensor and its connections (component

code 1071) and of the engine management computer (component code 120).

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Use the universal bornier to check the insulation and continuity of the following connections:

●3LQ between components 120 and 1071,

●3LP between components 120 and 1071,

●3LN between components 120 and 1071.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, replace the sensor.

If the fault is still present, carry out the following checks:

SIM32_V54_PR041

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 274 of 348

17B-274V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR041

CONTINUED

–Check the cleanliness of the air filter.

–Replace the filter if necessary.

–Check that the air inlet circuit is not blocked.

The turbocharging system must be perfectly sealed, from the exhaust manifold to the turbocharger, from the

turbocharger to the heat exchanger and from the heat exchanger to the throttle valve.

Check that there are no air leaks:

–around the turbocharger pressure sensor,

–around the air temperature sensor.

Check absence of leaks in the wastegate capsule pressure circuit connected to the turbocharger system.

Check that the air-air heat exchanger is not clogged (presence of oil).

If there is oil in the heat exchanger, the turbocharger is certainly damaged.

Using a pressure/vacuum pump, check that the turbocharger protection and turbocharging valve capsule

diaphragms do not leak.

Check the condition the motorised throttle valve in terms of clogging.

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 276 of 348

17B-276V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR059INLET AIR TEMPERATURE

PARAMETER

DEFINITIONThis parameter indicates the air inlet temperature in ˚C.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system operation

programming.

There must be no present or stored faults.

Perform this fault finding procedure:

–after finding an inconsistency in the parameter,

–after a customer complaint (e.g. lack of power).

Conformity check with engine stopped and ignition on.

With the ignition on the inlet air temperature varies according to the exterior temperature.

Parameter PR059 ≈ PR064 Coolant temperature engine cold.

In the event of a fault, apply the interpretation of DF089 Inlet manifold pressure sensor circuit.

Conformity check with the engine running and engine coolant temperature > 80˚C

With the engine running at idle speed the inlet air temperature varies according to the engine coolant temperature.

In the event of a fault, apply the interpretation of DF089.

SIM32_V44_PR059/SIM32_V4C_PR059/SIM32_V50_PR059/SIM32_V54_PR059

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.

Page 277 of 348

17B-277V7 MR-413-X44-17B000$171.mif

PETROL INJECTION

Fault finding – Interpretation of parameters17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PR064COOLANT TEMPERATURE

PARAMETER

DEFINITIONThis parameter indicates the engine coolant temperature in ˚C.

NOTESSpecial notes:

Only perform these tests if the parameters do not correspond with the system operation

programming.

There must be no present or stored faults.

Perform this fault finding procedure:

–after finding an inconsistency in the parameter,

–after a customer complaint (e.g. lack of power).

Conformity check with engine stopped and ignition on.

With the ignition on the coolant temperature varies according to the exterior temperature.

In the event of a fault, refer to the interpretation of DF001 Coolant temperature sensor circuit.

Parameter PR059: Inlet air temperature ≈ PR064 engine cold.

Conformity check with the engine running and engine coolant temperature > 80˚C

With the engine running at idle speed the coolant temperature varies according to the engine temperature.

If there is a fault, refer to the interpretation of fault DF001.

SIM32_V44_PR064/SIM32_V4C_PR064/SIM32_V50_PR064/SIM32_V54_PR064

AFTER REPAIRCarry out a road test followed by a check with the diagnostic tool.