wheel RENAULT TWINGO 2009 2.G Electrical Equipment Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 241

Page 67 of 241

84A-12

CONTROL - SIGNALS

Lighting dimmer: Removal - Refitting

C44 or G44

84A

REMOVAL

I - REMOVAL PREPARATION OPERATION

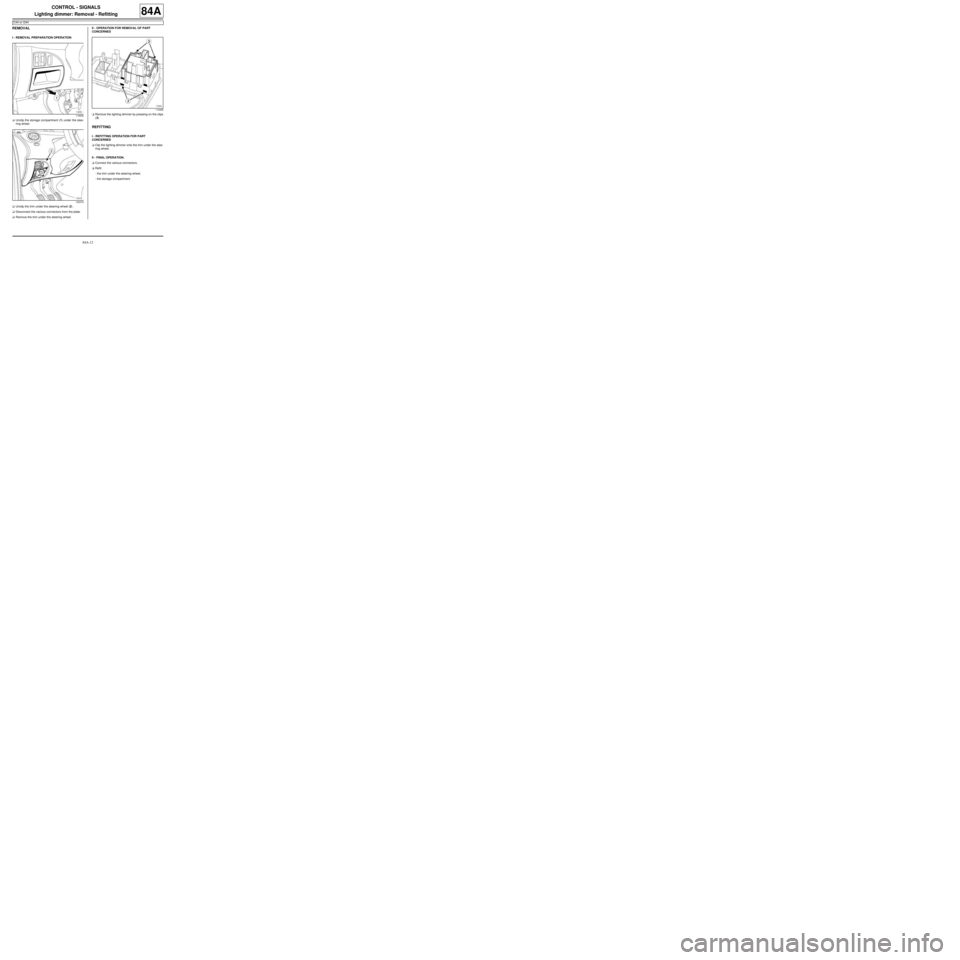

aUnclip the storage compartment (1) under the stee-

ring wheel.

aUnclip the trim under the steering wheel (2) .

aDisconnect the various connectors from the plate.

aRemove the trim under the steering wheel.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the lighting dimmer by pressing on the clips

(3) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aClip the lighting dimmer onto the trim under the stee-

ring wheel.

II - FINAL OPERATION.

aConnect the various connectors.

aRefit:

-the trim under the steering wheel,

-the storage compartment.

119506

120279

119495

Page 93 of 241

85A-23

WIPING - WASHING

Screen washer pump: Removal - Refitting

85A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

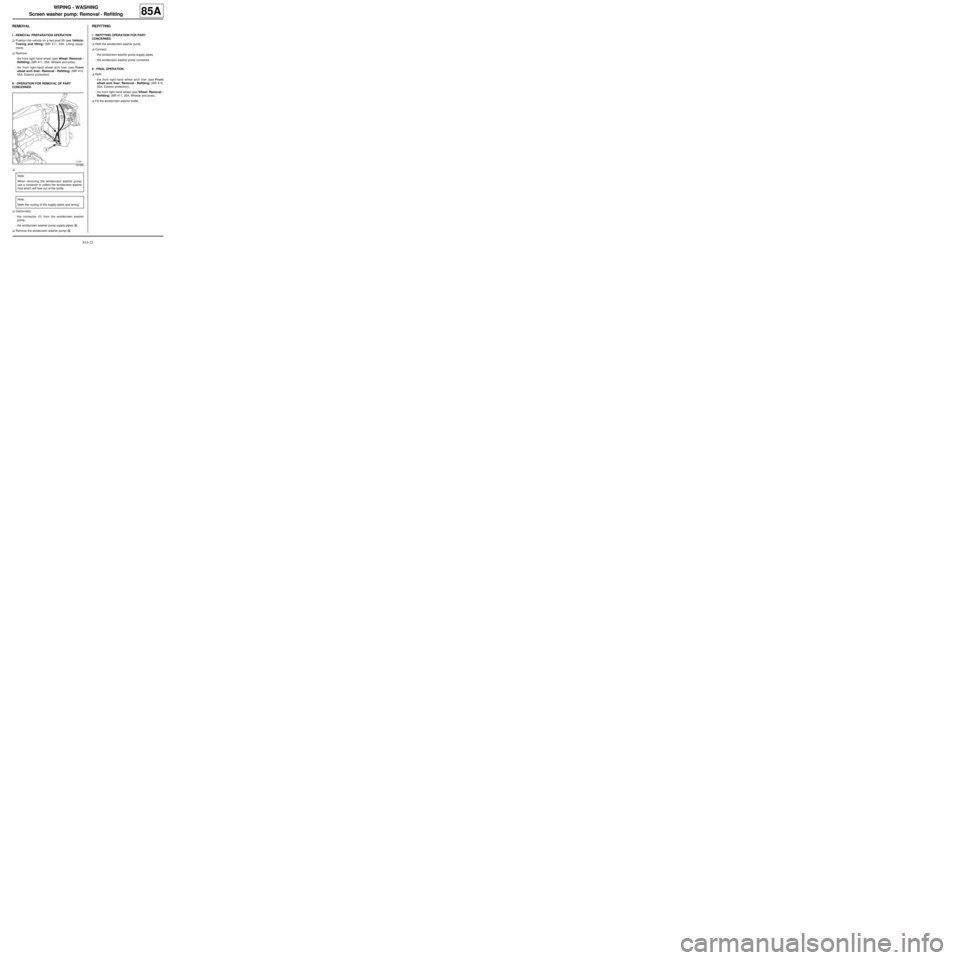

aDisconnect:

-the connector (1) from the windscreen washer

pump,

-the windscreen washer pump supply pipes (2) .

aRemove the windscreen washer pump (3) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the windscreen washer pump.

aConnect:

-the windscreen washer pump supply pipes,

-the windscreen washer pump connector.

II - FINAL OPERATION.

aRefit:

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres).

aFill the windscreen washer bottle.

121089

Note:

When removing the windscreen washer pump,

use a container to collect the windscreen washer

fluid which will flow out of the bottle.

Note:

Mark the routing of the supply pipes and wiring.

Page 96 of 241

85A-26

WIPING - WASHING

Windscreen washer reservoir: Removal - Refitting

85A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

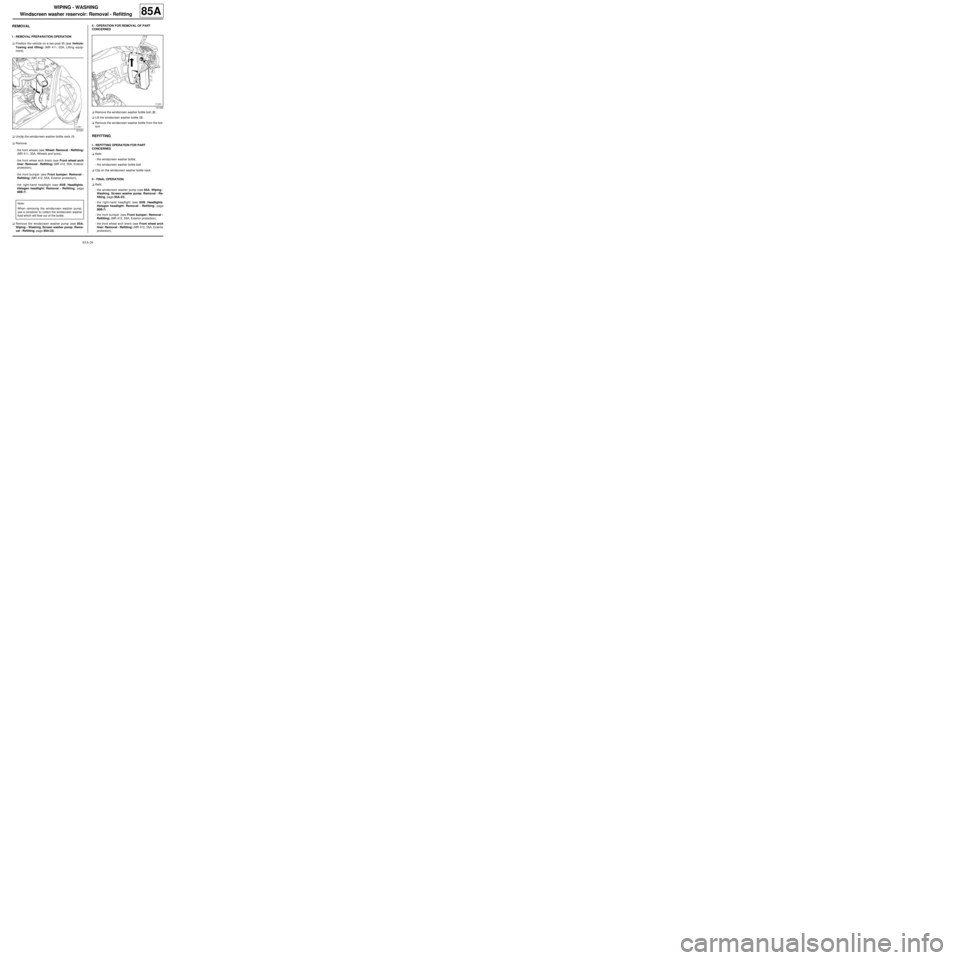

aUnclip the windscreen washer bottle neck (1) .

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the right-hand headlight (see 80B, Headlights,

Halogen headlight: Removal - Refitting, page

80B-7) .

aRemove the windscreen washer pump (see 85A,

Wiping - Washing, Screen washer pump: Remo-

val - Refitting, page 85A-23) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the windscreen washer bottle bolt (2) .

aLift the windscreen washer bottle (3) .

aRemove the windscreen washer bottle from the bot-

tom.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the windscreen washer bottle,

-the windscreen washer bottle bolt.

aClip on the windscreen washer bottle neck.

II - FINAL OPERATION.

aRefit:

-the windscreen washer pump (see 85A, Wiping -

Washing, Screen washer pump: Removal - Re-

fitting, page 85A-23) ,

-the right-hand headlight (see 80B, Headlights,

Halogen headlight: Removal - Refitting, page

80B-7) ,

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

121091

Note:

When removing the windscreen washer pump,

use a container to collect the windscreen washer

fluid which will flow out of the bottle.

121090

Page 97 of 241

85A-27

WIPING - WASHING

Windscreen washer reservoir: Removal - Refitting

85A

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres).

aFill the windscreen washer bottle.

aAdjust the headlight beam (see 80B, Headlights,

Halogen headlight: Adjustment, page 80B-9) .

Page 111 of 241

86B-1

CAR PHONE

Car phone: List and location of components

HANDS-FREE TELEPHONE KIT

86B

I - LIST OF COMPONENTS

The « car phone » consists of:

-a telephone aerial

-a computer

-a "hands-free" microphone

-a telephone control on the steering wheel

II - LOCATION OF COMPONENTS

Telephone aerial

To remove the telephone aerial (see 86A, Radio, Ra-

dio aerial: Removal - Refitting, page 86A-5) .

Computer

The computer is secured under the glovebox by a self-

fastening strip."Hands-free" microphone

Telephone control on the steering wheel

To remove the car phone control on the steering wheel

(see 86A, Radio, Radio control satellite: Removal -

Refitting, page 86A-11) .

121087

132408

132406

109918

Page 131 of 241

87F-1

PARKING DISTANCE CONTROL

Parking distance control: List and location of components

REAR PROXIMITY RADAR

87F

I - LIST OF COMPONENTS

II - LOCATION OF COMPONENTS

1 - Parking distance control switch

The parking distance control switch (1) is located on

the dashboard lower trim under the steering wheel.2 - Parking distance control buzzer

The parking distance control buzzer (2) is located un-

der the left-hand rear quarter panel trim (see Quarter

panel trim: Removal - Refitting) (MR 412, 71A, Body

internal trim).

3 - Distance control radar No. Description

(1) Parking distance control switch

(2) Parking distance control buzzer

(3) Distance control radar

(4) Parking distance control computer

121372

121367

121374

Page 138 of 241

88A-2

WIRING HARNESS

Wiring: Precautions for the repair

88A

I - SAFETY

1 - Potentially dangerous components

Do not leave any unused +12V connectors exposed to

the air without any protection (see Connector: Sea-

ling and locking) (Technical Note 6015A, 88A, Wi-

ring).

Check that there is no contact between the wiring and

the fuel and brake pipes.

Avoid mounting the wiring in areas with a temperature

above 100˚C.

2 - Advice to be followed before any operation

Before carrying out any work on the wiring, disconnect

the battery.

3 - Instructions to be followed during the operation

To prevent the wiring from being damaged, check that

the surrounding area is not mechanically harmful (e.g.:

door windows, sharp corners, burrs, studs, etc.).

The wiring should be at least 30 mm away from any

moving components (belt, pulley, steering column,

etc.).

Depending on the surrounding area, check that the

unused connectors respect the necessary sealing

constraints (see Connector: Sealing and locking)

(Technical Note 6015A, 88A, Wiring).

All of the connections (connectors) used in the engine

compartment are sealed; do not remove the seal from

around the connectors.II - GENERAL RECOMMENDATIONS

Do not connect an earth to a stud with insulating pro-

tection (paint,etc.).

Do not use more than two earth terminals on the same

point.

Do not use power earths on the same point as electro-

nic earths.

To prevent water flowing into the connectors, make a

low point just on the wiring routing (just before the con-

nector).

For connections between fixed and mobile compo-

nents, secure the wiring on the fixed part.

Overlapping of the battery feed wires (positive and ne-

gative) causes disruption; they must be secured sepa-

rately.

Wiring mountings:

- use plastic clips, ensuring that the colour coding is

respected,

-do not use steel clips that are not protected with rub-

ber,

- keep the clips integrated into the wiring during a re-

placement operation,

- do not leave steering wheel wires without protection.

Check that:

- the shunts are correctly secured,

- the connectors are correctly housed and locked.

Wiring routing:

- when it is visible it must be aesthetically pleasing, and

resemble the routing marked during removal,

- prohibit wiring routing in grooves and overlaps (risk of

wear through friction),

- prohibit mounting several wires on the same clip,

- do not lock the connectors or wiring in areas that are

sensitive to drilling (number plate etc.). WARNING

To prevent damaging the connectors, consult the

disconnection procedure (see Connector: Discon-

nection and reconnection) (Technical Note

6015A, 88A, Wiring).

WARNING

To prevent any risk of noise, premature wear, short

circuits, etc. after the refitting operation, mark the

wiring routing and how to connect the connectors.

WARNING

To prevent any damage during the removal opera-

tion, check that the wiring is free from its mountings

(retaining clip, plastic clip, adhesive tape, connec-

tor, etc.).

Page 139 of 241

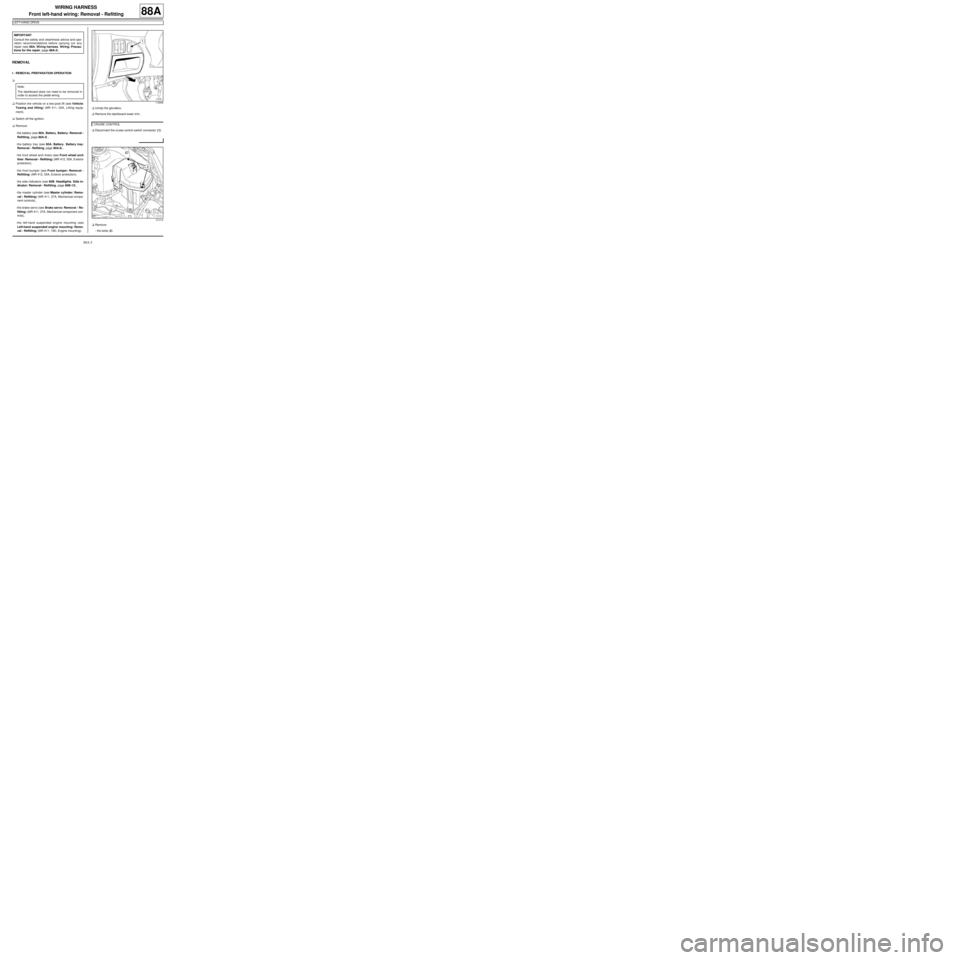

88A-3

WIRING HARNESS

Front left-hand wiring: Removal - Refitting

LEFT-HAND DRIVE

88A

REMOVAL

I - REMOVAL PREPARATION OPERATION

a

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aSwitch off the ignition.

aRemove:

-the battery (see 80A, Battery, Battery: Removal -

Refitting, page 80A-2) ,

-the battery tray (see 80A, Battery, Battery tray:

Removal - Refitting, page 80A-6) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the side indicators (see 80B, Headlights, Side in-

dicator: Removal - Refitting, page 80B-13) ,

-the master cylinder (see Master cylinder: Remo-

val - Refitting) (MR 411, 37A, Mechanical compo-

nent controls),

-the brake servo (see Brake servo: Removal - Re-

fitting) (MR 411, 37A, Mechanical component con-

trols),

-the left-hand suspended engine mounting (see

Left-hand suspended engine mounting: Remo-

val - Refitting) (MR 411, 19D, Engine mounting).aUnclip the glovebox.

aRemove the dashboard lower trim.

aDisconnect the cruise control switch connector (1) .

aRemove:

-the bolts (2) IMPORTANT

Consult the safety and cleanliness advice and ope-

ration recommendations before carrying out any

repair (see 88A, Wiring harness, Wiring: Precau-

tions for the repair, page 88A-2) .

Note:

The dashboard does not need to be removed in

order to access the pedal wiring.

119506

CRUISE CONTROL

121212

Page 143 of 241

88A-7

WIRING HARNESS

Front left-hand wiring: Removal - Refitting

LEFT-HAND DRIVE

88A

-the horn connector (13) ,

-the windscreen washer pump connector (14) ,

-the front left-hand side light connector (15) ,

-the front left-hand headlight connector (16) ,

-the front left-hand indicator connector (17) ,

-the headlight beam adjustment motor connectors

(18) ,

-the front right-hand wheel speed sensor connector

(19) ,

-the hydraulic brake unit connector (20) ,

-the injection computer connector (21) ,

-the front left-hand wheel speed sensor connector

(22) ,

-the front left-hand wiring/passenger compartment

wiring connectors (23) ,

-the clutch pedal position sensor connector (24) ,

-the STOP warning light switch connector (25) ,

-the acceleration pedal potentiometer connector

(26) .

aDisconnect the regulated additional heater connec-

tor (27) .

aRemove the additional heater earth wiring nut (28) .

aDisconnect the gearbox pump assembly relay con-

nector (29) .

aRemove:

-the earth wiring nut on the front right-hand side

member (30) ,

-the earth wiring nut on the front left-hand side

member (31) ,

-the earth wiring nut on the body (32) ,

-the hydraulic brake unit earth wiring nut (33) ,

-the earth wiring nut on the negative battery terminal

(34) ,

-the earth wiring nut on the bodywork (35) ,-the front windscreen wiper mechanism (see 85A,

Wiping - Washing, Windscreen wiper mecha-

nism: Removal - Refitting, page 85A-10) .

aUnclip:

-the section of wiring from the bulkhead,

-the section of wiring on the front bumper cross

member,

-the section of wiring from the windscreen washer

reservoir

-the section of wiring from the dashboard cross

member.

aUnclip the front left-hand wiring from the bulkhead.

aRemove the front left-hand wiring through the engi-

ne compartment.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aIf replacing with a complete wiring harness, lock the

unused connectors (see Connectors: Sealing and

locking) (Technical Note 6015A, 88A, Wiring).

II - REFITTING OPERATION FOR PART

CONCERNED

aPosition the front left-hand wiring across the bulk-

head.

aClip the front left-hand wiring onto the bulkhead.

aConnect:

-the acceleration pedal potentiometer connector,

-the STOP warning light switch connector,

-the clutch pedal position sensor connector ,

-the front left-hand wiring/passenger compartment

wiring connectors,

-the injection computer connector,

-the front left-hand wheel speed sensor connector,

-the hydraulic brake unit connector,

-the front right-hand wheel speed sensor connector,

-the headlight beam adjustment motor connectors, CLIMATE CONTROL

JH1

WARNING

To prevent any damage during the removal ope-

ration, check that the wiring is free from its moun-

tings (retaining clip, plastic clip, adhesive tape,

connector, etc.).

Page 145 of 241

88A-9

WIRING HARNESS

Front left-hand wiring: Removal - Refitting

LEFT-HAND DRIVE

88A

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the battery tray (see 80A, Battery, Battery tray:

Removal - Refitting, page 80A-6) ,

-the battery (see 80A, Battery, Battery: Removal -

Refitting, page 80A-2) .