oil RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 245 of 652

11A-128

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D7F – D4F, and 772

11A

aTighten to torque and in order the cylinder head

bolts (initial torque) (20 N.m).

aCheck that all the cylinder head bolts are pretight-

ened to 20 Nm.

aAngle tighten in order the cylinder head bolts (230˚

±± ± ±

6).

III - FINAL OPERATION

aRefit the exhaust bracket bolts.

aTighten the exhaust bracket bolts.

aConnect the water chamber hoses.

aFit the water chamber hose clips using the tool (Mot.

1448) or (Mot. 1202-01) or (Mot. 1202-02).

aConnect the coolant temperature sensor connector.

aRefit:

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the ignition coil.

aRefit:

-the inlet manifold (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aRefit:

-the air filter unit,

-the air filter box retaining belts,

-the intake distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) .

aRefit:

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment).

aRefit:

-a new oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aPerform the following operations:

-top up the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Re-

filling, page 10A-22) ,

18641

D4F

D7F

D4F

Page 247 of 652

11A-130

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D4F, and 780 or 782

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection).

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) ,-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the turbocharger oil pipes (see 12B, Turbocharg-

ing, Turbocharger oil pipe: Removal - Refitting,

page 12B-12) .

aUnclip the wiring from the turbocharger coolant rigid

pipe bracket.

aSeparate the clips (1) on the turbocharger cooling

hoses using the tool (Mot. 1448).

aDisconnect the turbocharger cooling hoses.

aRemove:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

cylinder head bolts (ini-

tial torque)20 N.m

cylinder head bolts230˚ ±± ± ±

6˚

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

121773

Page 249 of 652

11A-132

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D4F, and 780 or 782

11A

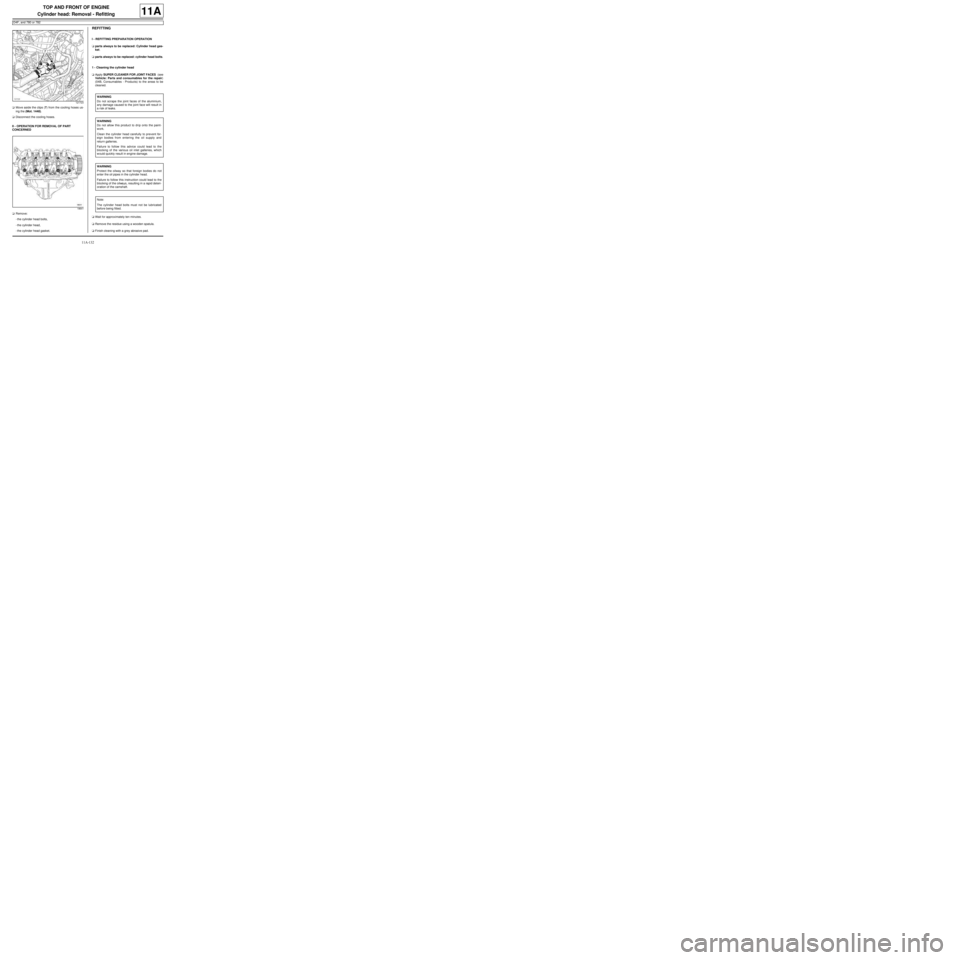

aMove aside the clips (7) from the cooling hoses us-

ing the (Mot. 1448).

aDisconnect the cooling hoses.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the cylinder head bolts,

-the cylinder head,

-the cylinder head gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Cylinder head gas-

ket.

aparts always to be replaced: cylinder head bolts.

1 - Cleaning the cylinder head

aApply SUPER CLEANER FOR JOINT FACES (see

Vehicle: Parts and consumables for the repair)

(04B, Consumables - Products) to the areas to be

cleaned.

aWait for approximately ten minutes.

aRemove the residue using a wooden spatula.

aFinish cleaning with a grey abrasive pad.

121723

18641

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

Do not allow this product to dr ip onto the paint-

work.

Clean the cylinder head carefully to prevent for-

eign bodies from entering the oil supply and

return galleries.

Failure to follow this advice could lead to the

blocking of the various oil inlet galleries, which

would quickly result in engine damage.

WARNING

Protect the oilway so that foreign bodies do not

enter the oil pipes in the cylinder head.

Failure to follow this instruction could lead to the

blocking of the oilways, resulting in a rapid deteri-

oration of the camshaft.

Note:

The cylinder head bolts must not be lubricated

before being fitted.

Page 250 of 652

11A-133

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D4F, and 780 or 782

11A

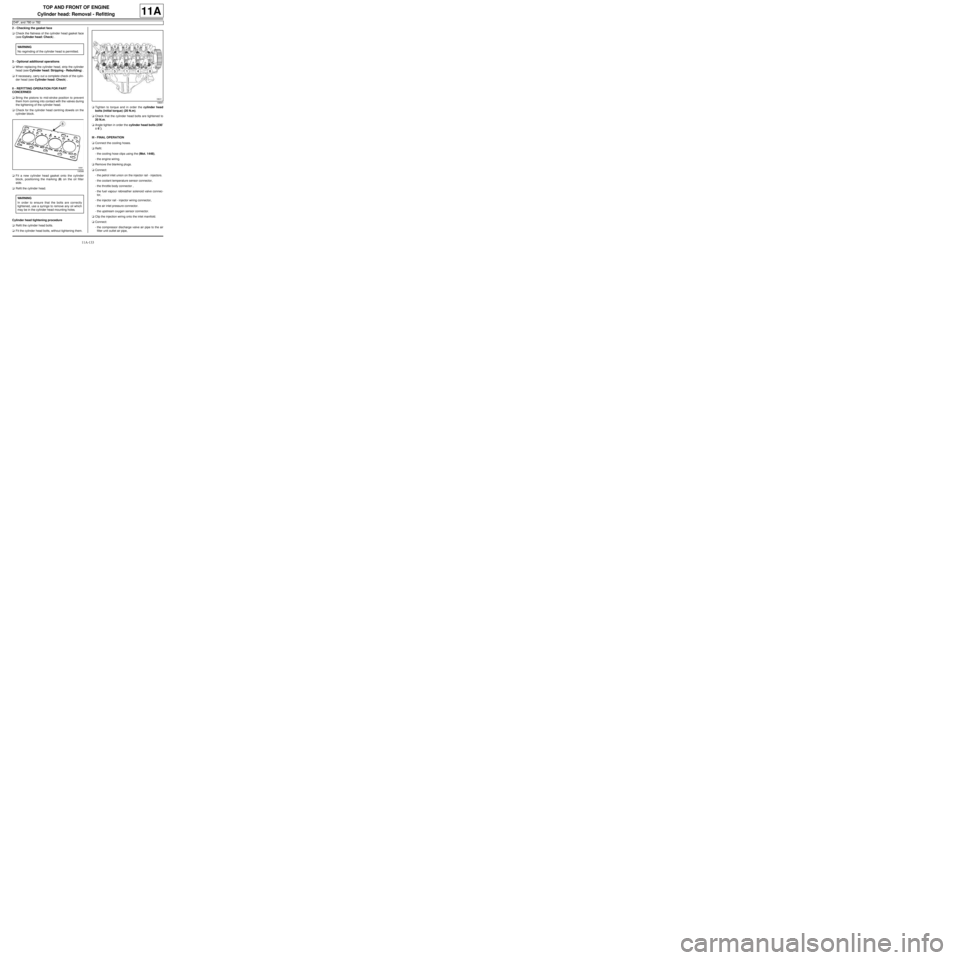

2 - Checking the gasket face

aCheck the flatness of the cylinder head gasket face

(see Cylinder head: Check) .

3 - Optional additional operations

aWhen replacing the cylinder head, strip the cylinder

head (see Cylinder head: Stripping - Rebuilding) .

aIf necessary, carry out a complete check of the cylin-

der head (see Cylinder head: Check) .

II - REFITTING OPERATION FOR PART

CONCERNED

aBring the pistons to mid-stroke position to prevent

them from coming into contact with the valves during

the tightening of the cylinder head.

aCheck for the cylinder head centring dowels on the

cylinder block.

aFit a new cylinder head gasket onto the cylinder

block, positioning the marking (8) on the oil filter

side.

aRefit the cylinder head.

Cylinder head tightening procedure

aRefit the cylinder head bolts.

aFit the cylinder head bolts, without tightening them.aTighten to torque and in order the cylinder head

bolts (initial torque) (20 N.m).

aCheck that the cylinder head bolts are tightened to

20 N.m.

aAngle tighten in order the cylinder head bolts (230˚

±± ± ±

6˚).

III - FINAL OPERATION

aConnect the cooling hoses.

aRefit:

-the cooling hose clips using the (Mot. 1448),

-the engine wiring.

aRemove the blanking plugs.

aConnect:

-the petrol inlet union on the injector rail - injectors.

-the coolant temperature sensor connector,

-the throttle body connector ,

-the fuel vapour rebreather solenoid valve connec-

tor,

-the injector rail - injector wiring connector,

-the air inlet pressure connector.

-the upstream oxygen sensor connector.

aClip the injection wiring onto the inlet manifold.

aConnect:

-the compressor discharge valve air pipe to the air

filter unit outlet air pipe, WARNING

No regrinding of the cylinder head is permitted.

19598

WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

18641

Page 251 of 652

11A-134

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

D4F, and 780 or 782

11A

-the turbocharging solenoid valve connector to the

turbocharger.

aTighten the compressor discharge valve air pipe

clip.

aPosition the intercooler outlet air pipe on the throttle

valve.

aRefit:

-the intercooler air outlet pipe bolts,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aConnect the turbocharger cooling hoses.

aFit the turbocharger cooling hose clips using the tool

(Mot. 1448).

aClip the wiring onto the turbocharger coolant rigid

pipe bracket.

aRefit:

-the turbocharger oil pipes (see 12B, Turbocharg-

ing, Turbocharger oil pipe: Removal - Refitting,

page 12B-12) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the ignition coil (see 17A, Ignition, Coils: Remov-

al - Refitting, page 17A-1) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).aRefit:

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

Page 260 of 652

11A-143

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K4M

11A

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the seal mating face of each camshaft,

-the cylinder head seal housings.

aparts always to be replaced: Camshaft seal on

timing end.

II - REFITTING OPERATION

a1 - Refitting the exhaust side seal

aPosition the protector fitted with a new seal (7) on

the camshaft (taking care not to touch the seal).

aScrew the stud (8) of the (Mot. 1632) onto the cam-

shaft. WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

18687

Note:

Always hold the camshaft seal with the protector

(5) when handling, as this type of camshaft seal

is very FRAGILE. Touching the camshaft seal (6)

is strictly forbidden in order to avoid any oil leaks

once the camshaft seal is fitted on the engine.

105531

126219

Page 264 of 652

11A-147

TOP AND FRONT OF ENGINE

Oil decanter: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) .

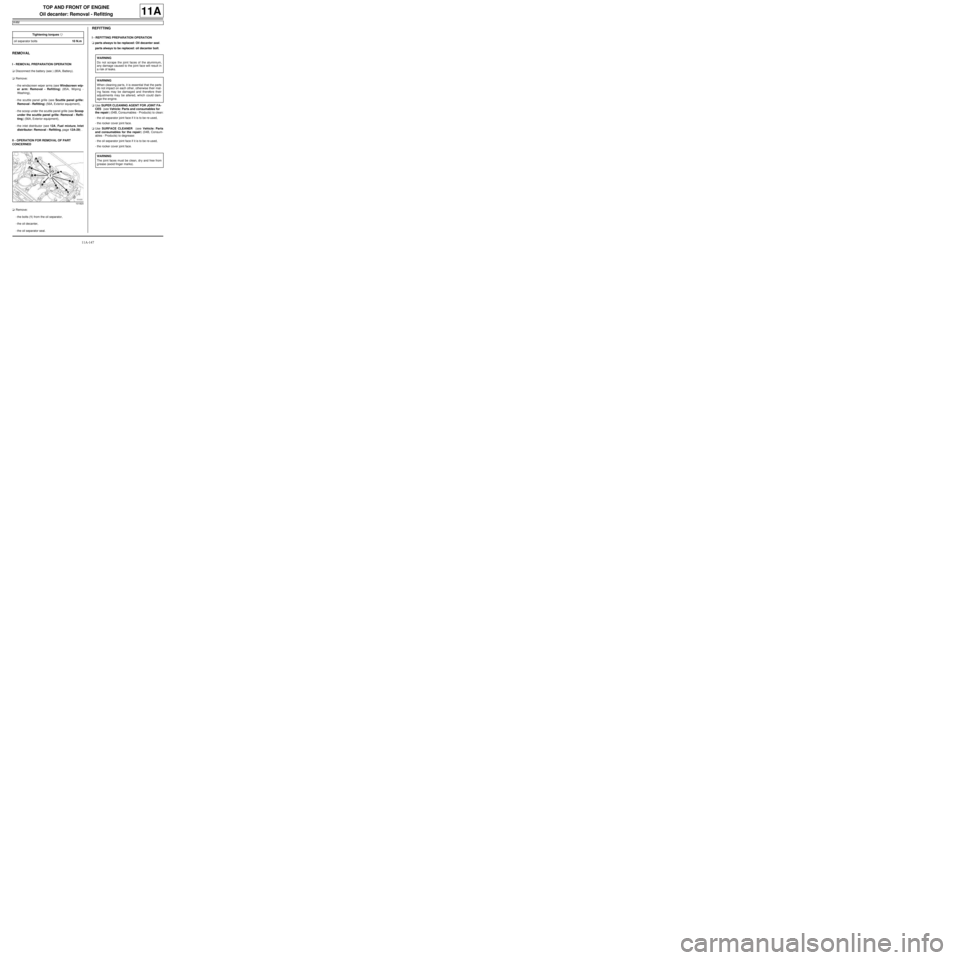

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (1) from the oil separator,

-the oil decanter,

-the oil separator seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Oil decanter seal.

parts always to be replaced: oil decanter bolt.

aUse SUPER CLEANING AGENT FOR JOINT FA-

CES (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) to clean:

-the oil separator joint face if it is to be re-used,

-the rocker cover joint face.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to degrease:

-the oil separator joint face if it is to be re-used,

-the rocker cover joint face. Tightening torquesm

oil separator bolts10 N.m

101820

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

When cleaning par ts, it is essential that the parts

do not impact on each other, otherwise their mat-

ing faces may be damaged and therefore their

adjustments may be altered, which could dam-

age the engine.

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

Page 265 of 652

11A-148

TOP AND FRONT OF ENGINE

Oil decanter: Removal - Refitting

K4M

11A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the oil separator,

-the oil decanter.

aTighten to torque and in order the oil separator

bolts (10 N.m).

III - FINAL OPERATION

aRefit:

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see ) (80A, Battery).

101820

Page 278 of 652

12A-13

FUEL MIXTURE

Air filter unit: Removal - Refitting

D4F, and 772

12A

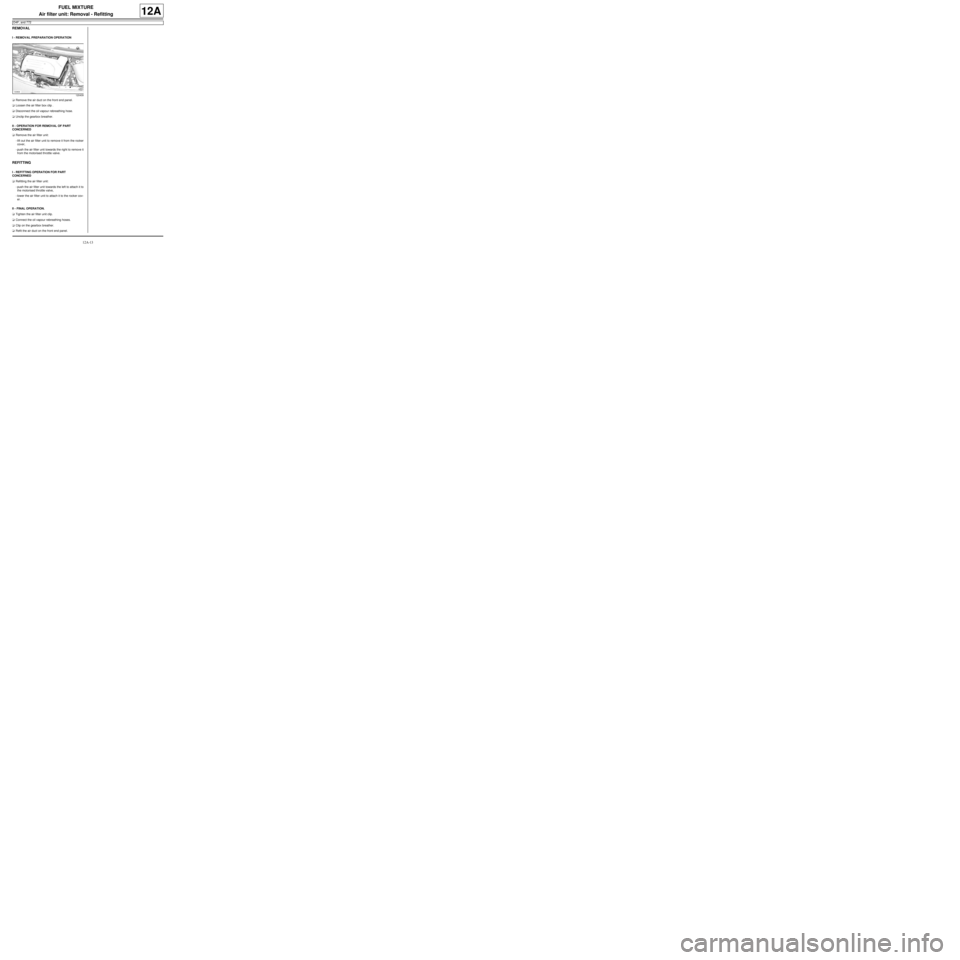

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air duct on the front end panel.

aLoosen the air filter box clip .

aDisconnect the oil vapour rebreathing hose.

aUnclip the gearbox breather.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the air filter unit:

-lift out the air filter unit to remove it from the rocker

cover,

-push the air filter unit towards the right to remove it

from the motorised throttle valve.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefitting the air filter unit:

-push the air filter unit towards the left to attach it to

the motorised throttle valve,

-lower the air filter unit to attach it to the rocker cov-

er.

II - FINAL OPERATION.

aTighten the air filter unit clip.

aConnect the oil vapour rebreathing hoses.

aClip on the gearbox breather.

aRefit the air duct on the front end panel.

120409

Page 281 of 652

12A-16

FUEL MIXTURE

Air filter unit: Removal - Refitting

D7F

12A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced :

-the air filter.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the anti-interference wire bolt.

aDisconnect the ignition coil connector (1) .

aRemove the ignition coil bolts (2) .

aMove aside the ignition coil.

aRemove the air filter box cover (3) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect:

-the non-return valve pipe on the brake servo,

-the petrol vapour rebreather pipe union from the in-

take distributor.

aMove aside the air filter box air inlet duct.

aUndo the air filter box air outlet duct clip.

aRemove the air filter box air outlet duct.

aUnclip the air filter box elastic straps.

aRemove:

-the air filter box,

-the air filter from the air filter unit.

REFITTING

I - REFITTING PREPARATIONS OPERATION

If reusing the air filter box

aUse a compressed air nozzle to clean the air filter

housing to get rid of any foreign bodies.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the air filter box fitted with a new seal.

aClip on the air filter box elastic straps.

aRefit the air filter box air outlet duct.

aTighten the air filter box air outlet duct clip.

aRefit the air filter box air inlet duct.

aConnect:

-the non-return valve pipe on the brake servo,

-the petrol vapour rebreather pipe union from the in-

take distributor.

III - FINAL OPERATION.

aFit the ignition coil.

aRefit the ignition coil bolts.

aConnect the connector of the ignition coil.

aRefit the anti-interference wire bolt. Equipment required

compressed air nozzle

120404