torque RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 6 of 652

Contents

Engine cooling fan assembly:

Removal - Refitting 19A-51

Coolant pump inlet pipe:

Removal - Refitting 19A-58

Expansion bottle: Removal -

Refitting 19A-64

Coolant temperature sensor:

Removal - Refitting 19A-66

19B EXHAUST

Exhaust: List and location of

components 19B-1

Exhaust: Precautions for the

repair 19B-8

Catalytic converter: Removal

- Refitting 19B-12

Expansion chamber :

Removal - Refitting 19B-23

Intermediate pipe: Removal -

Refitting 19B-28

Silencer : Removal - Refitting 19B-31

19C TANK

Fuel tank: Draining 19C-1

Fuel tank: Removal -

Refitting 19C-4

Filler neck: Removal -

Refitting 19C-11

Fuel level sensor module:

Removal - Refitting 19C-13 19A COOLING

19D ENGINE MOUNTING

Suspended engine

mounting: Tightening torque 19D-1

Left-hand suspended engine

mounting: Removal -

Refitting 19D-4

Right-hand suspended

engine mounting: Removal -

Refitting 19D-13

Lower engine tie-bar:

Removal - Refitting 19D-18

Page 12 of 652

10A-6

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

K9K

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection). Special tooling required

Tav. 476Ball joint extractor.

Tav. 1233-01Tooling for carrying out opera-

tions on the axle subframe.

Equipment required

flywheel immobiliser

safety strap(s)

Tightening torquesm

lowe r cylinder block

bolts14 Nm

multifunction support

bolt on the sump25 N.m

sump bolts on the gear-

box casing44 Nm

subframe front bolts62 N.m

subframe rear bolts105 Nm

subframe rear tie rod

inner bolts21 N.m

subframe rear tie rod

outer bolts90 N.m

lower ball joint bolts62 N.m

track rod end nuts37 N.m

subframe tie-rod upper

bolts21 N.m

subframe tie-rod lower

bolts62 N.m

bolts of the front right-

hand driveshaft relay

bearing44 N.m

bolt of the front right-

hand driveshaft relay

bearing bracket21 N.m

relay bearing bolts on

the front right-hand

driveshaft44 N.m

right-hand driveshaft

relay bearing closure

panel bolts21 Nm

catalytic converter

upstream stay bolt on

the cylinder block44 N.m

catalytic converter

downstream stay bolt on

the sump44 Nm

catalytic converter

downstream stay bolts

on the catalytic con-

verter26 Nm

universal joint bolt24 N.m Tightening torquesm

Page 17 of 652

10A-11

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

K9K

10A

aApply:

-four beads (17) of SILICONE ADHESIVE SEAL-

ANT (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) with a

diameter of 5 mm,

-two drops (18) of SILICONE ADHESIVE SEAL-

ANT (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) with a

diameter of 5 mm at the intersection between the

cylinder block and the crankshaft nose closure

panel.II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the oil sump fitted with a new seal.

aTighten to torque and in order the lower cylinder

block bolts (14 Nm).

aTighten the following until contact is made, and then

to torque:

-the multifunction support bolt on the sump (25

N.m).

-the sump bolts on the gearbox casing (44 Nm).

III - FINAL OPERATION

aRefit the subframe, gradually tightening the nuts of

the (Tav. 1233-01).

aRemove the threaded rods of the tool (Tav. 1233-

01) one by one, replacing them with new subframe

mounting bolts.

aTighten to torque:

-the subframe front bolts (62 N.m),

20167

20166

Note:

Ensure that the oil pump strainer fits well into the

correct location in the oil splash plate.

Note:

Take care not to damage the sump seal when fit-

ting the sump on the cylinder block.

20171

Page 18 of 652

10A-12

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

K9K

10A

-the subframe rear bolts (105 Nm),

-the subframe rear tie rod inner bolts (21 N.m),

-the subframe rear tie rod outer bolts (90 N.m).

aRefit the radiator mounting cross member (see Ra-

diator mounting cross member: Removal - Refit-

ting) (41A, Front lower structure).

aDetach the radiator and the intercooler from the up-

per cross member using a safety strap(s).

aDetach the radiator from the upper cross member

using a safety strap(s).

aRefit:

-the rear engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the lower ball joints,

-the track rod ends.

aTighten to torque:

-the lower ball joint bolts (62 N.m),

-the track rod end nuts (37 N.m).

aRefit the subframe tie rod upper bolts.

aTighten to torque:

-the subframe tie-rod upper bolts (21 N.m),

-the subframe tie-rod lower bolts (62 N.m).

aRefit the front right-hand driveshaft relay bearing

aTighten to torque:

-the bolts of the front right-hand driveshaft relay

bearing (44 N.m),

-the bolt of the front right-hand driveshaft relay

bearing bracket (21 N.m).aFit the relay bearing on its bearing on the front right-

hand driveshaft.

aTorque tighten the relay bearing bolts on the front

right-hand driveshaft (44 N.m).

aRefit the closure panel of the front right-hand drive-

shaft relay bearing

aTorque tighten the right-hand driveshaft relay

bearing closure panel bolts (21 Nm).

aRefit the catalytic converter upstream stay, by slid-

ing it in relation to the bolt remaining on the sump.

aTighten the following until contact is made and to tor-

que:

-the catalytic converter upstream stay bolt on

the cylinder block (44 N.m),

-the catalytic converter downstream stay bolt on

the sump (44 Nm),

-the catalytic converter downstream stay bolts

on the catalytic converter (26 Nm).

aFit the steering box universal joint equipped with a

new bolt.

aTorque tighten the universal joint bolt (24 N.m).

aRemove the flywheel immobiliser.

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aFill up the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) . K9K, and 718

K9K, and 740

K9K, and 718

K9K, and 740

Note:

Ensure that the right-hand dr iveshaft relay bear-

ing closure panel is refi tted the right way round.

Page 19 of 652

10A-13

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

D4F or D7F

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

aRemove the engine undertray.

aRemove the engine flywheel guard

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres), Special tooling required

Tav. 476Ball joint extractor.

Tav. 1233-01Tooling for carrying out opera-

tions on the axle subframe.

Mot. 1716Removes housing with sili-

cone seals.

Equipment required

flywheel immobiliser

Tightening torquesm

sump bolts10 N.m

front subframe bolts62 N.m

rear subframe bolts105 N.m

front end cross member

bolts21 N.m

subframe rear tie rod

inner bolts21 N.m

subframe rear tie rod

outer bolts90 N.m

lower ball joint bolts62 N.m

track rod end nuts37 N.m

subframe tie rod upper

bolts21 N.m

subframe tie rod lower

bolts62 N.m

universal joint24 N.m

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

Note:

The sump is sealed in the factory using silicone

adhesive sealant.

When removing the sump in a workshop, it is

essential to use the After-Sales seal available from

the Parts Department.

D4F, and 772 – D7F

120407

D4F, and 780 or 782

Page 22 of 652

10A-16

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

D4F or D7F

10A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the sump fitted with a new seal,

-the sump bolts.

aTighten to torque and in order the sump bolts (10

N.m).

III - FINAL OPERATION

aRefit the engine flywheel guard.aRefit the subframe, gradually tightening the nuts of

the (Tav. 1233-01).

aRemove the threaded rods of the (Tav. 1233-01)

one by one, replacing them with the subframe

mounting bolts.

aTorque tighten:

-the front subframe bolts (62 N.m),

-the rear subframe bolts (105 N.m),

-the front end cross member bolts (21 N.m)

-the subframe rear tie rod inner bolts (21 N.m),

-the subframe rear tie rod outer bolts (90 N.m).

aRefit:

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the lower arm ball joints,

-the lower ball joint bolts,

-track rod ends,

-the track rod end nuts,

aTorque tighten:

-the lower ball joint bolts (62 N.m),

-the track rod end nuts (37 N.m).

aRefit the subframe tie rod upper bolts.

aTorque tighten the subframe tie rod upper bolts

(21 N.m).

aTorque tighten the subframe tie rod lower bolts

(62 N.m).

aFit the steering box universal joint.

aRefit the universal joint bolt.

aTorque tighten the universal joint (24 N.m).

aRemove the flywheel immobiliser.

aRefit:

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

18643

D4F, and 772 – D7F

D4F, and 780 or 782

Page 24 of 652

10A-18

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the dipstick,

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the engine undertray.

aDrain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

aRemove:

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),-the rear engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents).

aRemove:

-the front right-hand driveshaft flange bolt (1) on the

relay bearing,

-the bolts (2) from the front right-hand driveshaft re-

lay bearing,

-the front right-hand driveshaft relay bearing. Tightening torquesm

sump bolts (initial

torque)14 N.m

sump bolts14 N.m

sump bolts on the gear-

box44 N.m

bolt mounting the multi-

function support on the

sump25 N.m

catalytic pre-converter

upstream bracket bolt44 N.m

driveshaft relay bearing

bolts44 N.m.

right-hand driveshaft

bracket bolt on the relay

bearing21 N.m

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

128800

Page 27 of 652

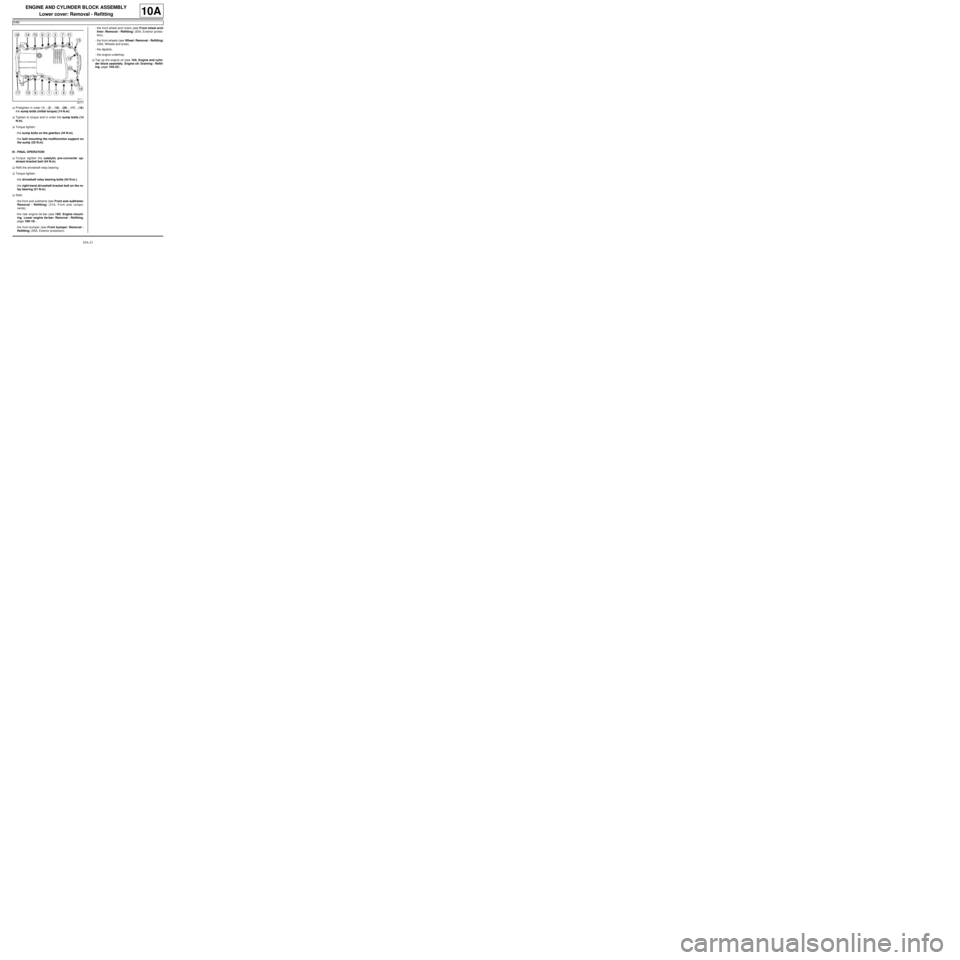

10A-21

ENGINE AND CYLINDER BLOCK ASSEMBLY

Lower cover: Removal - Refitting

K4M

10A

aPretighten in order (1) , (2) , (19) , (20) , (17) , (18)

the sump bolts (initial torque) (14 N.m).

aTighten to torque and in order the sump bolts (14

N.m).

aTorque tighten:

-the sump bolts on the gearbox (44 N.m),

-the bolt mounting the multifunction support on

the sump (25 N.m).

III - FINAL OPERATION

aTorque tighten the catalytic pre-converter up-

stream bracket bolt (44 N.m).

aRefit the driveshaft relay bearing.

aTorque tighten:

-the driveshaft relay bearing bolts (44 N.m.),

-the right-hand driveshaft bracket bolt on the re-

lay bearing (21 N.m).

aRefit:

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the rear engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the dipstick,

-the engine undertray.

aTop up the engine oil (see 10A, Engine and cylin-

der block assembly, Engine oil: Draining - Refill-

ing, page 10A-22) .

20171

Page 28 of 652

10A-22

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

D4F or D7F

10A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced :

-copper seal.aConsumable (see Vehicle: Parts and consuma-

bles for the repair) (04B, Consumables - Products).

-Engine oil (see Engine oil: Specifications) (Tech-

nical Note 6013A, 04A, Lubricants).

I - OIL SERVICE

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment). Special tooling required

Mot. 10188 mm square engine drain

plug spanner.

Equipment required

oil change wrench

oil recovery tray

torque wrench

oil change end piece with an 8 mm square drive

Tightening torquesm

drain plug20 N.m

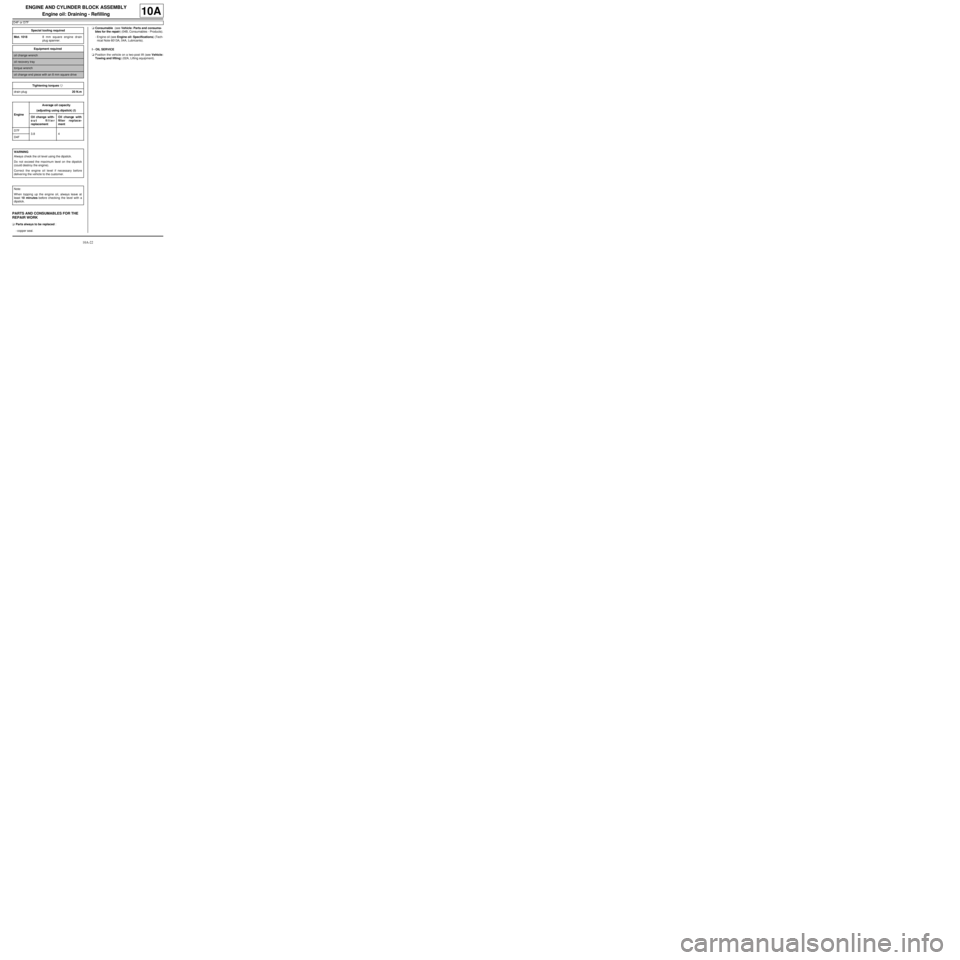

EngineAverage oil capacity

(adjusting using dipstick) (l)

Oil change with-

out filter

replacementOil change with

filter replace-

ment

D7F

3.8 4

D4F

WARNING

Always check the oil level using the dipstick.

Do not exceed the maximum level on the dipstick

(could destroy the engine).

Correct the engine oil level if necessary before

deliver ing the vehicle to the customer.

Note:

When topping up the engine oil, always leave at

least 10 minutes before checking the level with a

dipstick.

Page 30 of 652

10A-24

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine oil: Draining - Refilling

D4F or D7F

10A

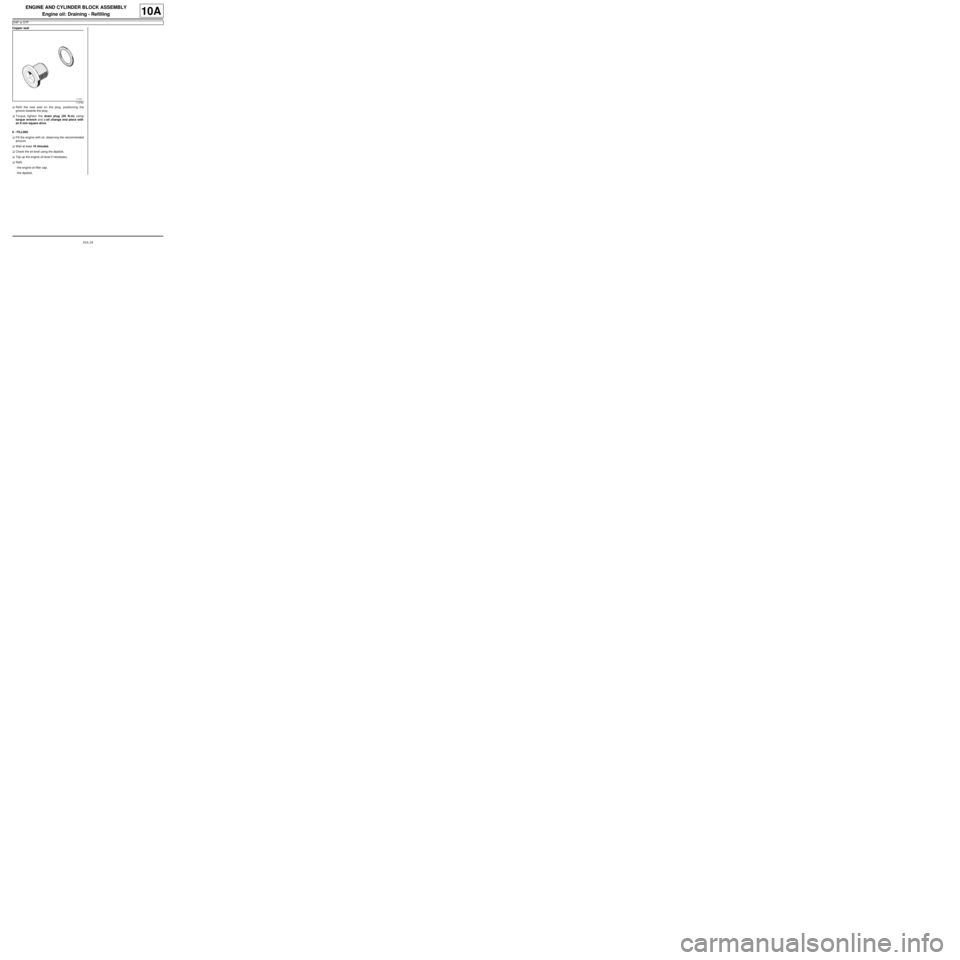

Copper seal

aRefit the new seal on the plug, positioning the

groove towards the plug.

aTorque tighten the drain plug (20 N.m) using

torque wrench and a oil change end piece with

an 8 mm square drive.

II - FILLING

aFill the engine with oil, observing the recommended

amount.

aWait at least 10 minutes.

aCheck the oil level using the dipstick.

aTop up the engine oil level if necessary.

aRefit:

-the engine oil filler cap,

-the dipstick.

113764