engine oil RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 479 of 652

17B-4

PETROL INJECTION

Petrol injection: List and location of components

D7F, and 800

17B

(8) Coolant temper ature sensor

(9) Engine speed and position sen-

sor

120404

(10) Ignition coil

121732

(11) Upstream oxygen sensor

120415

(12) Downstream oxygen sensor

Page 480 of 652

17B-5

PETROL INJECTION

Petrol injection: List and location of components

D4F, and 780 or 782

17B

122387

(1) Fuel vapour recirculation sole-

noid valve

(2) Upstream oxygen sensor

(3) Petrol injection computer

(4) Motorised throttle valve

(5) Ignition coil

(6) Engine compar tment connec-

tion unit

(7) Intake distributor pressure sen-

sor

(8) Turbocharger

108254

(9) Fuel injection computer

Page 520 of 652

19A-10

COOLING

Cooling system: Draining - Refilling

D4F or D7F or K4M or K9K

19A

2 - Filling method without special tools

a

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the front engine cover.

aOpen the bleed screws (1) and (2) .

aFill the cooling system with engine coolant recom-

mended by the manufacturer (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) via the expansion bottle until it

overflows.

aClose all the bleed screws as soon as the coolant

starts to flow in a continuous stream.aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aRefit the engine cover.

aPressurise the system using the (Ms. 554-07) to

check that there are no leaks (see 19A, Cooling,

Engine cooling system: Check, page 19A-2) .

aRefit the expansion bottle cap.

aClean any surfaces soiled by the coolant.

IV - BLEEDING

a

aStart the engine.

aMaintain the engine speed at 2500 rpm using the

pedal press for 5 min.

aStabilise the engine speed at 2000 rpm until the fan

assembly has been activated twice.

aMaintain the engine speed at 2500 rpm, using the

pedal press for 5 minutes.

aStabilise the engine speed at 2000 rpm until the fan

assembly is activated.

aNote the coolant level in the expansion bottle after

this first activation.

aAccelerate at a minimum of 4000 rpm for several

seconds, until the level of coolant fluid in the expan-

sion bottle drops. WARNING

It is essential to open all of the bleed screws to

remove as much as air as possible in the cooling

system. Failure to perform this procedure may

prevent the cooling system from filling properly

and may damage the engine.

D4F, and 772 – K4M

K9K

120526

D4F, and 772 – K4M

K9K

WARNING

Do not open the bleed screw whilst the engine is

running; this would damage the engine.

D4F, and 772 – D7F, and 800

D4F, and 780 or 782

Page 555 of 652

19A-45

COOLING

Water chamber: Removal - Refitting

K9K

19A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the thermostat to the water chamber.

aRefit:

-a new water chamber seal,

-the water chamber.

aTorque tighten the water chamber bolts (10 N.m).

III - FINAL OPERATION

aConnect the cooling hoses on the water chamber.

aPosition the cooling hose clips on the water chamber

using the tool (Mot. 1448).

aClip on the cooling hose of the coolant-oil heat ex-

changer.

aConnect the intercooler air outlet pipe on the side of

the damper valve.

aTorque tighten the intercooler air outlet pipe clip

at the damper valve end (5.5 N.m).

aConnect the brake servo vacuum pipe.

aClip:

-the turbocharging pressure regulator vacuum pipe,

-the vacuum pipe from the brake servo.

aConnect the turbocharging pressure regulator vacu-

um pipe.

aRefit the nuts of the air hoses on the lifting eye.

aConnect the intercooler air inlet pipe at the turbo-

charger end.

aClip on the intercooler air inlet pipe clip at the turbo-

charger end.

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit the engine cover. K9K, and 718

Page 569 of 652

19A-59

COOLING

Coolant pump inlet pipe: Removal - Refitting

K9K

19A

aRemove:

-the front bolt (1) from the subframe,

-the rear bolt (2) from the subframe.

aPosition the (Mot. 1672).

aRemove:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the multifunction support (see 10A, Engine and

cylinder block assembly, Multifunction sup-

port: Removal - Refitting, page 10A-63) ,

-the oil cooler (see 10A, Engine and cylinder

block assembly, Oil-coolant heat exchanger:

Removal - Refitting, page 10A-33) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolt (3) from the coolant pump inlet pipe,

-the coolant pump inlet pipe,

-the coolant pump inlet pipe seal.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new water pump inlet pipe seal,

-the coolant pump inlet pipe,

-the coolant pump inlet pipe bolt.

aConnect the cooling hose using the tool (Mot. 1448).

II - FINAL OPERATION.

aRefit:

-the coolant-oil heat exchanger (see 10A, Engine

and cylinder block assembly, Oil-coolant heat

exchanger: Removal - Refitting, page 10A-33) ,

-the multifunction support (see 10A, Engine and

cylinder block assembly, Multifunction sup-

port: Removal - Refitting, page 10A-63) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

120040

121417

Page 572 of 652

19A-62

COOLING

Coolant pump inlet pipe: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove:

-the dipstick,

-the bolts (1) from the dipstick guide,

-the dipstick guide.aDisconnect:

-the pinking sensor connector (2) ,

-the oil pressure sensor connector (3) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

coolant pump inlet pipe

bolts25 N.m

132368

132374

Page 573 of 652

19A-63

COOLING

Coolant pump inlet pipe: Removal - Refitting

K4M

19A

II - REMOVAL OPERATION

aRemove the clip (4) from each cooling hose using

the tool (Mot. 1448).

aDisconnect the cooling hoses from the coolant pump

inlet pipe.

aRemove:

-the bolts (5) from the coolant pump inlet pipe,

-the coolant pump inlet pipe.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: seal between cool-

ant pump inlet pipe and coolant pump.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the seal housing in the cylinder block,

-the coolant pump inlet pipe seal housing if it is be-

ing reused.

II - REFITTING OPERATION

aRefit the coolant pump inlet pipe fitted with a new

seal.aTorque tighten in order the coolant pump inlet pipe

bolts (25 N.m).

aConnect the cooling hoses to the coolant pump inlet

pipe.

aFit each cooling hose clip using the tool (Mot. 1448).

III - FINAL OPERATION

aConnect:

-the oil pressure sensor connector,

-the pinking sensor connector.

aRefit:

-dipstick guide ,

-the dipstick.

aConnect the battery (see ) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

131781

131781

Page 574 of 652

19A-64

COOLING

Expansion bottle: Removal - Refitting

D4F or D7F or K4M or K9K

19A

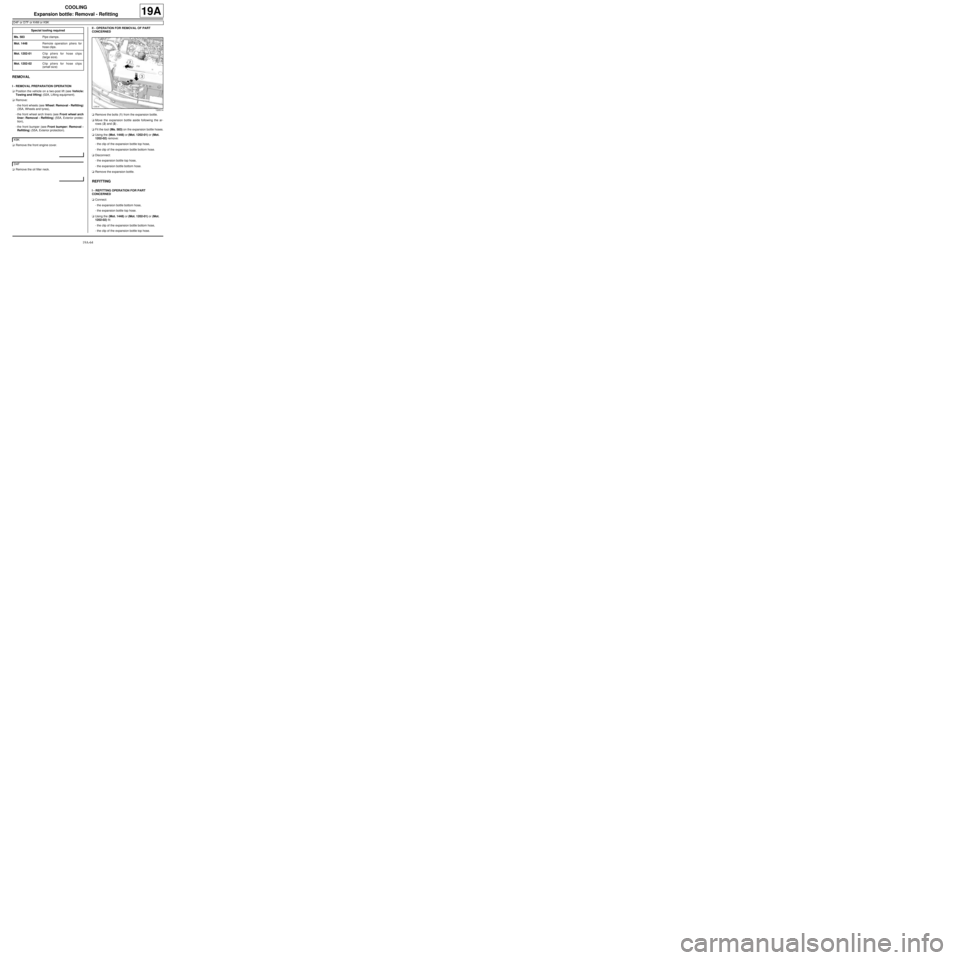

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aRemove the front engine cover.

aRemove the oil filler neck.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the bolts (1) from the expansion bottle.

aMove the expansion bottle aside following the ar-

rows (2) and (3) .

aFit the tool (Ms. 583) on the expansion bottle hoses.

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) remove:

-the clip of the expansion bottle top hose,

-the clip of the expansion bottle bottom hose.

aDisconnect:

-the expansion bottle top hose,

-the expansion bottle bottom hose.

aRemove the expansion bottle.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aConnect:

-the expansion bottle bottom hose,

-the expansion bottle top hose.

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) fit:

-the clip of the expansion bottle bottom hose,

-the clip of the expansion bottle top hose. Special tooling required

Ms. 583Pipe clamps .

Mot. 1448Remote operation pliers for

hose clips .

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

K9K

D4F

120514

Page 575 of 652

19A-65

COOLING

Expansion bottle: Removal - Refitting

D4F or D7F or K4M or K9K

19A

aRemove the tool (Ms. 583) from the expansion bottle

hoses.

aRefit the expansion bottle.

II - FINAL OPERATION

aTop up the coolant level in the expansion bottle.

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aRefit the engine cover.

aRefit the oil filler neck. K9K

D4F

Page 596 of 652

19B-14

EXHAUST

Catalytic converter: Removal - Refitting

K9K

19B

aIf they are replaced, torque tighten the catalytic

converter studs on the turbocharger (9 Nm ).

II - REFITTING OPERATION FOR PART

CONCERNED

aFrom underneath the vehicle, fit:

-the catalytic converter on the turbocharger fitted

with a new seal between the catalytic converter

and the turbocharger,

-one of the catalytic converter nuts on the turbo-

charger.

aIn order, fit (without tightening):

-the catalytic converter upstream strut bolts on the

engine,

-the catalytic converter downstream strut bolt and

nut on the gearbox,

-the catalytic converter upstream strut bolts on the

catalytic converter,

-the catalytic converter downstream strut bolt on the

catalytic converter,

-the catalytic converter nuts on the turbocharger,

aTorque tighten and in order:

-the catalytic converter nuts on the turbocharger

(26 Nm),

-the catalytic converter upstream strut bolts on

the engine (44 Nm),

-the catalytic converter downstream strut bolts

on the gearbox (21 Nm),

-the catalytic converter downstream strut nut on

the gearbox (21 Nm),

-the catalytic converter upstream strut bolts on

the catalytic converter (26 Nm),

-the catalytic converter downstream strut bolt

on the catalytic converter (21 Nm).

aFit in order:

-a new exhaust system sealing ring on the catalytic

converter,

-the exhaust pipe on the catalytic converter,

-the exhaust pipe springs and bolts on the catalytic

converter.aTorque tighten the exhaust pipe bolts on the cata-

lytic converter (21 Nm).

aCheck the following and deal with if necessary:

-that there is no contact with the underbody,

-the presence and correct positioning of all the ex-

haust pipe heat shields.

III - FINAL OPERATION.

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille ( (see

Scoop under the scuttle panel grille: Removal -

Refitting) ),

-the scuttle panel grille ( (see Scuttle panel grille:

Removal - Refitting) ),

-the windscreen wiper arms ( (see Windscreen

wiper arm: Removal - Refitting) ).

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

aStart the engine.

aCheck that there are no leaks and deal with them if

necessary. Note:

Check that there is no contact between the cata-

lytic conver ter and the turbocharger oil return

pipe during the entire catalytic converter tighten-

ing operation.