lock RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 258 of 652

11A-141

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) .

II - REMOVAL OPERATION

a

aCompletely unscrew the nut (1) and the bolt (Mot.

1577) of the (2) . Special tooling required

Mot. 1577Lip seal e xtractor (shaft diam-

eter 28 mm to 42 mm).

Mot. 1632Tool for fitting camshaft PTFE

seal

105257

Note:

The camshaft seal is removed using the (Mot.

1577).

Page 259 of 652

11A-142

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K4M

11A

Removing the seal on the exhaust side and inlet

side

aPosition the claws of the (Mot. 1577) on the cam-

shaft.

aPush the (Mot. 1577) until contact is made between

the ends of the claws and the camshaft seal.aSeparate the claws by turning the nut (3) clockwise

using an open-jawed spanner.

aRemove the camshaft seal by turning the bolt clock-

wise using a spanner (4) .

126608

126608

126609

126605

Page 262 of 652

11A-145

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K4M

11A

aFit the cover (13) and the collar nut (14) of the (Mot.

1632).

aScrew on the collar nut until the cover touches the

cylinder head.

aRemove:

-the collar nut from the (Mot. 1632),

-the cover from the (Mot. 1632),

-the stud from the (Mot. 1632).

III - FINAL OPERATION

aRefit:

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

126222

Page 314 of 652

12A-49

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

D4F, and 772 – D7F

12A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (3) from the exhaust manifold,

-the exhaust manifold,

-the exhaust manifold gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces.

aparts always to be replaced: exhaust manifold

seal.

aparts always to be replaced: ring between ex-

haust manifold and catalytic converter.

aTorque tighten the exhaust manifold studs on the

cylinder head (10 N.m).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the exhaust manifold nuts.aTighten to torque and in order the exhaust manifold

nuts (25 N.m).

III - FINAL OPERATION

aRefit:

-the heat shield on the exhaust manifold,

-the heat shield bolts on the exhaust manifold.

aRefit the exhaust flange nuts.

aCheck:

-that there is no exhaust gas leak,

-that there is no contact between the underbody and

the exhaust pipe,

120312

Note:

If any of the studs become loose during these

operations, coat them with HIGH STRENGTH

THREAD LOCK (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

120312

D4F

Page 320 of 652

12A-55

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aDrain the gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).aRemove:

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the upstream expansion chamber (see 19B, Ex-

haust, Expansion chamber: Removal - Refit-

ting, page 19B-23) .

aRemove:

-the bolts (1) from the driveshaft relay bearing,

-the driveshaft relay bearing. Tightening torquesm

exhaust manifold studs9 N.m

heat shield bolts12 N.m

upstream and down-

stream oxygen sensors44 N.m

strut mounting bolt on

the cylinder block75 N.m

upstream strut bolt (ini-

tial torque)14 N.m

exhaust manifold nuts26 N.m

upstream and down-

streamstrut bolts44

N.m

upstream strut bolts44 N.m

driveshaft relay bearing

bolts21 N.m

IMPORTANT

Wear cut-resistant gloves during the operation.

131770

Page 323 of 652

12A-58

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

If replacing the « exhaust manifold - catalytic

converter » assembly

aRemove:

-the upstream and downstream oxygen sensors (6)

,

-the heat shield (7) .

REFITTING

I - REMOVAL PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the exhaust manifold joint face if it is to be re-used,

-the cylinder head joint face.

aparts always to be replaced: exhaust manifold

seal.

aTorque tighten the exhaust manifold studs (9

N.m).If replacing the « exhaust manifold - catalytic

converter » assembly

aClean the threading of the upstream and down-

stream oxygen sensors using a wire brush.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the thread holes of the upstream and downstream

oxygen sensors on the exhaust manifold,

-the threading of the upstream and downstream ox-

ygen sensors.

aRefit the heat shield.

aTighten:

-to torque and in order the heat shield bolts (12

N.m),

-to torque the upstream and downstream oxygen

sensors ( 44 N.m).

aIf the strut mounting bolt on the cylinder block be-

comes loose, torque tighten the strut mounting

bolt on the cylinder block ( 75 N.m).

II - REFITTING OPERATION

aRefit:

-a new seal on the « exhaust manifold - catalytic

converter » assembly,

-the « exhaust manifold - catalytic converter » as-

sembly.

132441

Note:

If a stud loosens during removal, coat it with

HIGH RESISTANCE THREADLOCK (see Vehi-

cle: Parts and consumables for the repair)

(04B, Consumables - Products).

132441

Page 326 of 652

12B-1

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

I - TURBOCHARGER: GENERAL INSTRUCTIONS

For the turbocharging pressure regulator check (see

Fault finding - Tests) (Technical Note 3419A, 12B,

Turbocharging).

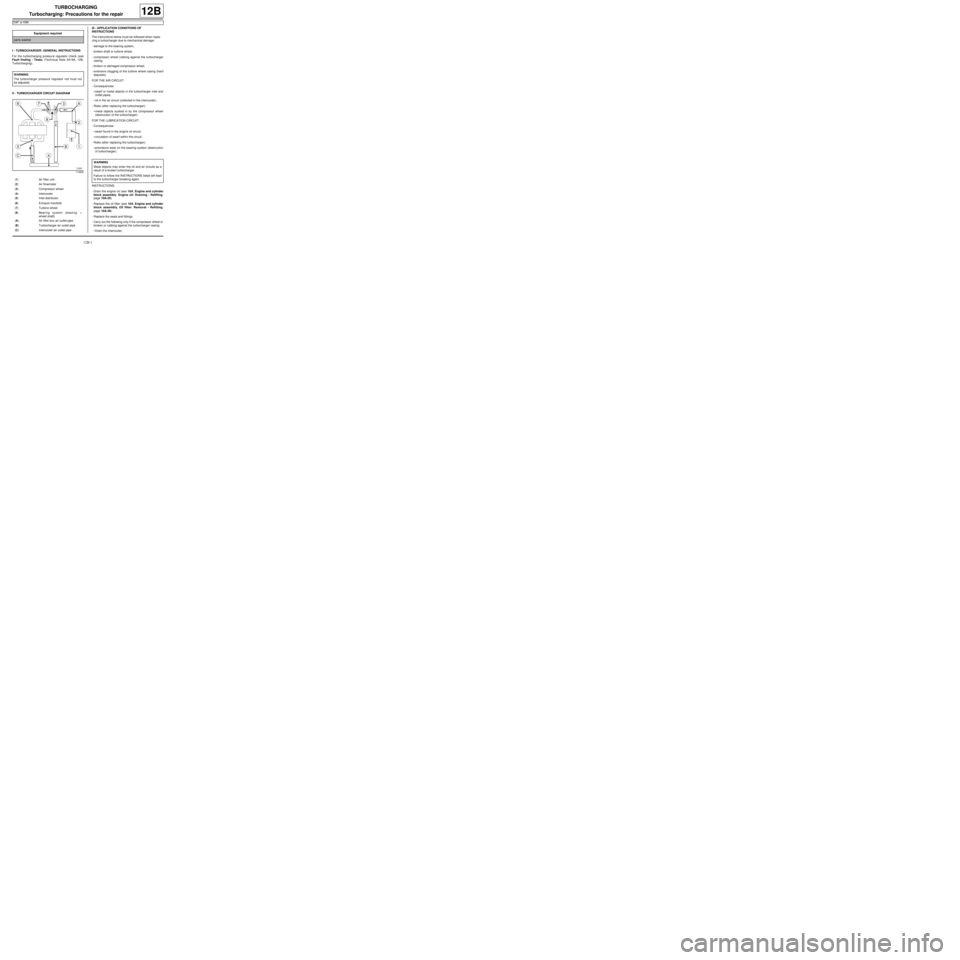

II - TURBOCHARGER CIRCUIT DIAGRAMIII - APPLICATION CONDITIONS OF

INSTRUCTIONS

The instructions below must be followed when repla-

cing a turbocharger due to mechanical damage:

-damage to the bearing system,

-broken shaft or turbine wheel,

-compressor wheel rubbing against the turbocharger

casing,

-broken or damaged compressor wheel,

-extensive clogging of the turbine wheel casing (hard

deposits).

FOR THE AIR CIRCUIT:

-Consequences:

•swarf or metal objects in the turbocharger inlet and

outlet pipes,

•oil in the air circuit (collected in the intercooler).

-Risks (after replacing the turbocharger):

•metal objects sucked in by the compressor wheel

(destruction of the turbocharger).

FOR THE LUBRICATION CIRCUIT:

-Consequences:

•swarf found in the engine oil circuit,

•circulation of swarf within the circuit.

-Risks (after replacing the turbocharger):

•premature wear on the bearing system (destruction

of turbocharger).

INSTRUCTIONS:

-Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22)

-Replace the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting,

page 10A-29) .

-Replace the seals and fittings,

-Carry out the following only if the compressor wheel is

broken or rubbing against the turbocharger casing:

•Drain the intercooler, Equipment required

par ts washer

WARNING

The turbocharger pressure regulator rod must not

be adjusted.

112666

(1) Air filter unit

(2) Air flowmeter

(3) Compressor wheel

(4) Intercooler

(5) Inlet distributor

(6) Exhaust manifold

(7) Turbine wheel

(8) Bearing system (bearing +

wheel shaft)

(A) Air filter box air outlet pipe

(B) Turbocharger air outlet pipe

(C) Intercooler air outlet pipe

WARNING

Metal objects may enter the oil and air circuits as a

result of a broken turbocharger.

Failure to follow the INSTRUCTIONS listed will lead

to the turbocharger breaking again.

Page 328 of 652

12B-3

TURBOCHARGING

Turbocharging: Precautions for the repair

D4F or K9K

12B

One by one, clean the pipes removed with the parts

washer :

-brush as much of the inside of the pipe as possible

(only use brushes with plastic bristles),

-wash plenty of cleaning product from the cleaning sta-

tion through the pipe,

-allow the cleaned pipe to drain by standing it upright,

-ensure the cleaning product has drained out com-

pletely (check areas where liquid may be retained,

e.g. gaiters, resonators etc.).

Dry the pipes one by one using a compressed air spray

gun.

For pipes comprising several components:

-assemble the components, taking note of their correct

fitting position (10) .

Refit:

-the air pipe(between the air filter unit and the turbo-

charger) (A) ,

-the air pipe (B) (between the turbocharger and the in-

tercooler).

Refit the intercooler, if fitted to the vehicle (see 12B,

Turbocharging, Intercooler: Removal - Refitting,

page 12B-18) .V - LUBRICATION CIRCUIT**: INSTRUCTIONS

FOLLOWING MECHANICAL DAMAGE TO THE

TURBOCHARGER

Drain the engine oil (see 10A, Engine and cylinder

block assembly, Engine oil: Draining - Refilling,

page 10A-22) .

Replace the oil filter (see 10A, Engine and cylinder

block assembly, Oil filter: Removal - Refitting, page

10A-29) .

Only fill the engine with a suitable oil type (see Engine

oil: Specifications) (Technical Note 6013A, 04A, Lu-

bricants).

VI - GENERAL INSTRUCTIONS TO BE FOLLOWED

WHEN REMOVING A TURBOCHARGER

Always replace:

-the oil supply pipe:

•if the pipe is blocked, even partially (due to scale,

carbonised oil etc.),

•if the pipe is fitted with self-retaining seals.

-the oil return pipe:

•if the pipe is blocked, even partially (due to scale,

carbonised oil etc.),

•if the pipe is fitted with self-retaining seals.

-all seals that have been removed,

-all fittings that have been removed.

When starting the engine:

-do not accelerate,

-allow the engine to run for 1 minute,the time taken for

the oil circuit pressure to increase (until the oil pres-

sure warning light on the instrument panel goes out),

-accelerate several times at no load,

-check the air circuit and the oil circuit for leaks.

112771

Note:

(**) These instructions relating to the lubrication cir-

cuit must always be followed in all cases of

mechanical damage as listed above.

WARNING

Failure to observe the following procedure may lead

to destr uction of the turbocharger.

Page 335 of 652

12B-10

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

aLoosen the clip of the air filter unit air outlet pipe.

aRemove:

-the air outlet pipe of the air filter unit,

-the turbocharger cooling pipe bracket bolt,

-the turbocharger cooling hollow pipe bolts,

-the turbocharger cooling pipes.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Turbocharger nut.

aparts always to be replaced: seal between ex-

haust manifold and turbocharger.

aparts always to be replaced: Turbocharger cool-

ant pipe if replacing the turbocharger.

aUse a SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease the sealing

surfaces:

-of the turbocharger (if being reused),

-of the exhaust manifold.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new turbocharger seal,

-the turbocharger,

-new turbocharger nuts.

aTorque tighten the turbocharger nuts (21 N.m).

1 - If replacing the turbocharger

aRefit:

-the turbocharger cooling pipes,

-the turbocharger cooling hollow pipe bolts,

-the turbocharger cooling pipe bracket bolts,-the air outlet pipe of the air filter unit.

aTighten the clip of the air outlet pipe on the air filter

unit.

aTorque tighten:

-the turbocharger cooling pipe hollow bolts (30

N.m),

-the turbocharger cooling pipe bracket bolts (10

N.m).

a

aConnect the turbocharging pressure regulation

pipes.

aClip on the clips of the turbocharging pressure regu-

lation pipes.

2 - If the turbocharger is not being replaced

aClip the wiring onto the turbocharger coolant rigid

pipe strut.

aConnect:

-the turbocharger discharge air pipe,

-the oil vapour recirculation pipe on the air filter unit

air outlet pipe,

-the petrol vapour recirculation pipe on the air filter

unit air outlet pipe,

-the turbocharging regulation solenoid valve con-

nector from the turbocharger,

-the ignition coil connector.

aTighten the turbocharger discharge air pipe clip.

aRefit the turbocharger oil supply pipe (see 12B, Tur-

bocharging, Turbocharger oil pipe: Removal -

Refitting, page 12B-12) .

aRefit the turbocharger cooling pipe strut bolt.

aConnect the turbocharger cooling hoses.

aFit the turbocharger cooling hose clips using the tool

(Mot. 1448).

aRemove the tools (Ms. 583).

aRefit the turbocharger oil return pipe (see 12B, Tur-

bocharging, Turbocharger oil pipe: Removal -

Refitting, page 12B-12) . WARNING

Ensure that no foreign bodies enter the turbine or

compressor during the refitting operation.

Check that the turbocharger oil return pipe is not

partially or completely blocked by scale. Check

that there are no leaks. If there are, replace the

part.Note:

Dur ing this operation, use a set of feeler gauges

to ensure that there is a minimum clearance of 3

mm between the turbocharger water outlet pipe

and the turbocharger heat shield.

Page 337 of 652

12B-12

TURBOCHARGING

Turbocharger oil pipe: Removal - Refitting

D4F, and 780 or 782

12B

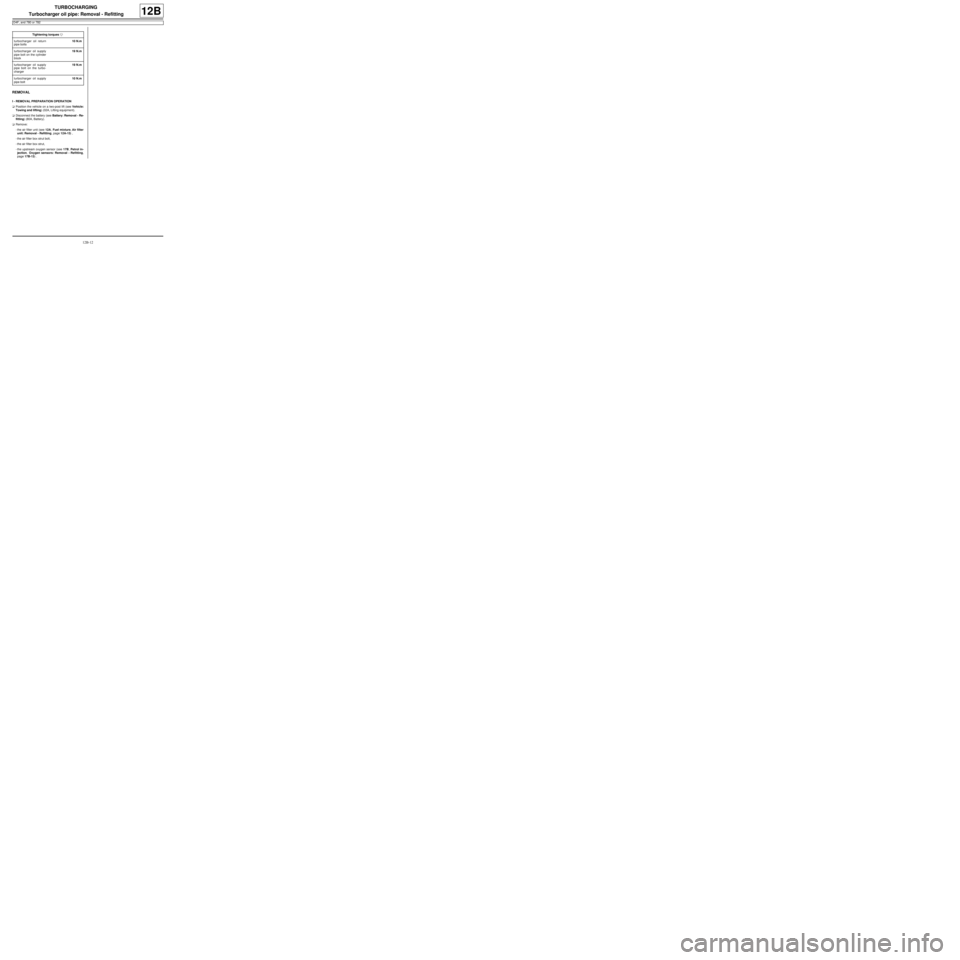

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the air filter box strut bolt,

-the air filter box strut,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) . Tightening torquesm

turbocharger oil return

pipe bolts10 N.m

turbocharger oil supply

pipe bolt on the cylinder

block19 N.m

turbocharger oil supply

pipe bolt on the turbo-

charger19 N.m

turbocharger oil supply

pipe bolt10 N.m