torque RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 431 of 652

14A-13

ANTIPOLLUTION

Exhaust gas cooler: Removal - Refitting

K9K

14A

II - REFITTING OPERATION FOR PART

CONCERNED

aOn the workbench, refit the following to the intercoo-

ler:

-a new mounting seal on the gearbox side,

-the mounting on the gearbox side,

-the mounting bolts (gearbox side) onto the inter-

cooler without tightening them,

-a new exhaust gas recirculation rigid pipe,

-the bolts of the exhaust gas recirculation rigid pipe

bracket on the cooler without tightening them.

aFit the exhaust gas recirculation assembly onto the

cylinder head.

aAdjust the mounting (gearbox side) and the exhaust

gas recirculation rigid pipe until they are flat against

the cylinder head.

aFit the exhaust gas recirculation unit assembly bolts,

without tightening them.

aTighten the bolts of the mounting (gearbox side) and

of the exhaust gas recirculation rigid pipe on the ex-

haust gas cooler to secure them on the exhaust gas

cooler.

aRemove the exhaust gas recirculation assembly.

aOn the workbench, torque tighten:

-the mounting bolts (gearbox side) on the cooler

(12 N.m),

-the bolts of the exhaust gas recirculation rigid

pipe on the exhaust gas cooler (12 N.m),

-the bolts of the exhaust gas recirculation rigid

pipe bracket (25 N.m).aOn the workbench, refit the following to the intercoo-

ler:

-a new mounting seal on the gearbox side,

-the mounting on the gearbox side,

-the mounting bolts (gearbox side) onto the inter-

cooler without tightening them,

-a new mounting seal on the timing end,

-the mounting on the timing end,

-the mounting bolts (timing end) onto the intercooler

without tightening them.

aFit the exhaust gas recirculation assembly onto the

cylinder head.

aAdjust the two mountings until they are flat against

the cylinder head.

aFit the exhaust gas recirculation unit assembly bolts,

without tightening them.

aTighten the bolts of the two mountings on the ex-

haust gas cooler to immobilise them on the exhaust

gas cooler.

aRemove the exhaust gas recirculation assembly.

aOn the workbench, torque tighten the mounting

bolts on the cooler (12 N.m).

III - FINAL OPERATION

aRefit the exhaust gas recirculation assembly (see

14A, Antipollution, Exhaust gas recirculation as-

sembly: Removal - Refitting, page 14A-15) . K9K, and 718

Note:

The cooler must absolutely be able to move in

relation to the mounting (gearbox side) and to the

exhaust gas recirculation rigid pipe so that it can

be properly adjusted afterwards on the cylinder

head.

K9K, and 740

Note:

The cooler must absolutely be able to move in

relation to its tw o mountings so that it can be

properly adjusted afterwards on the cylinder

head.

Page 432 of 652

14A-14

ANTIPOLLUTION

Exhaust gas cooler: Removal - Refitting

K9K

14A

aRefit the bolts (4) of the exhaust gas recirculation

rigid pipe on the exhaust manifold.

aTorque tighten the exhaust gas recirculation rigid

pipe bolts (36 N.m).

aRefit the rigid exhaust gas recirculation pipe (see

14A, Antipollution, Exhaust gas recirculation rig-

id pipe: Removal - Refitting, page 14A-19) .

aRefit:

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

aTop up the coolant level.

aConnect the battery (see ) (80A, Battery).

aBleed the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRefit the engine cover. K9K, and 718

141224

K9K, and 740

Page 433 of 652

14A-15

ANTIPOLLUTION

Exhaust gas recirculation assembly: Removal - Refitting

K9K

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing)

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the rigid exhaust gas recirculation pipe (see 14A,

Antipollution, Exhaust gas recirculation rigid

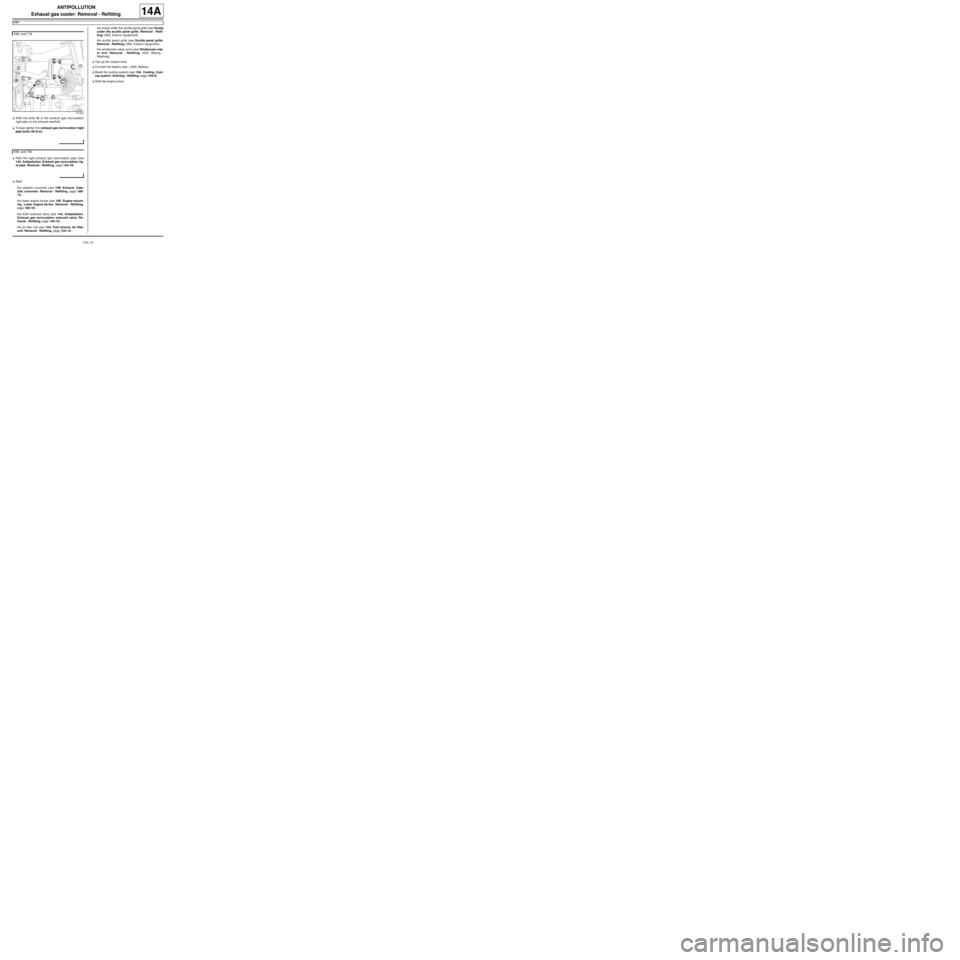

pipe: Removal - Refitting, page 14A-19) .aUndo the clip (1) of the air filter unit air outlet pipe on

the turbocharger.

aDisconnect the oil vapour rebreathing pipe (2) by

carefully separating the brackets (3) .

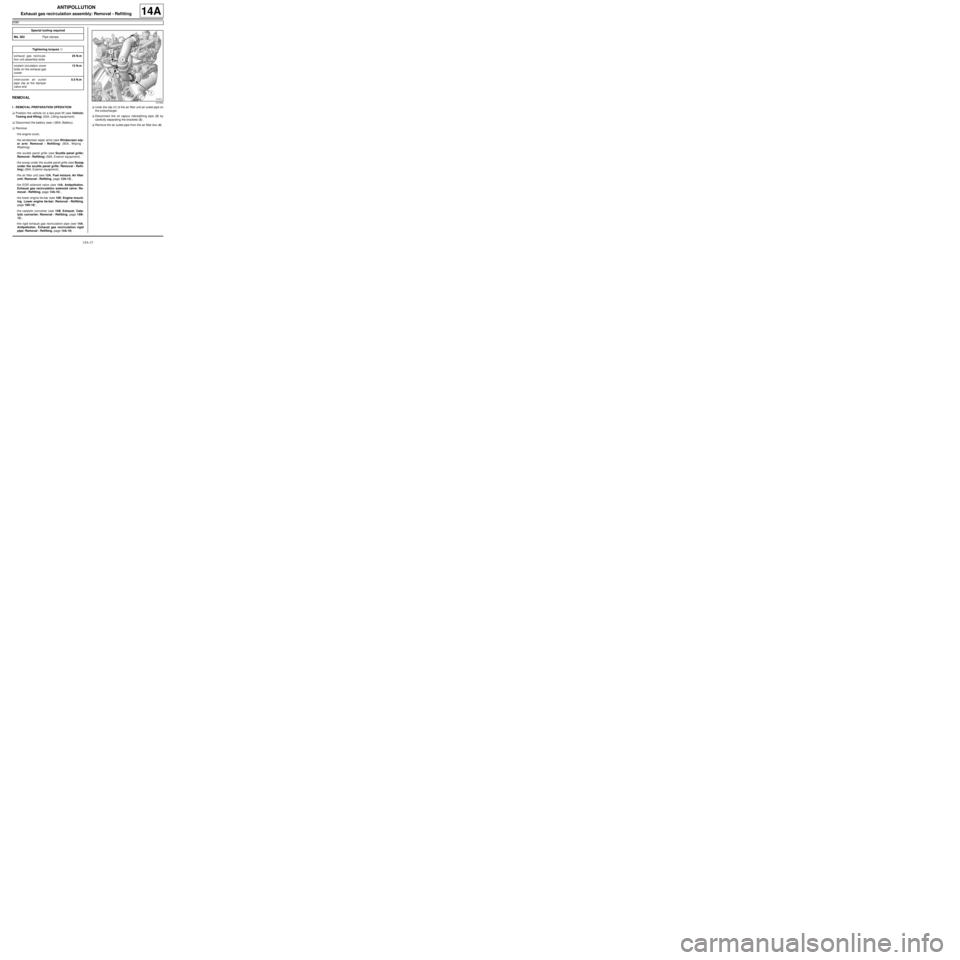

aRemove the air outlet pipe from the air filter box (4) . Special tooling required

Ms. 583Pipe clamps .

Tightening torquesm

exhaust gas recircula-

tion unit assembly bolts25 N.m

coolant circulation cover

bolts on the exhaust gas

cooler12 N.m

intercooler air outlet

pipe clip at the damper

valve end5.5 N.m

121633

Page 435 of 652

14A-17

ANTIPOLLUTION

Exhaust gas recirculation assembly: Removal - Refitting

K9K

14A

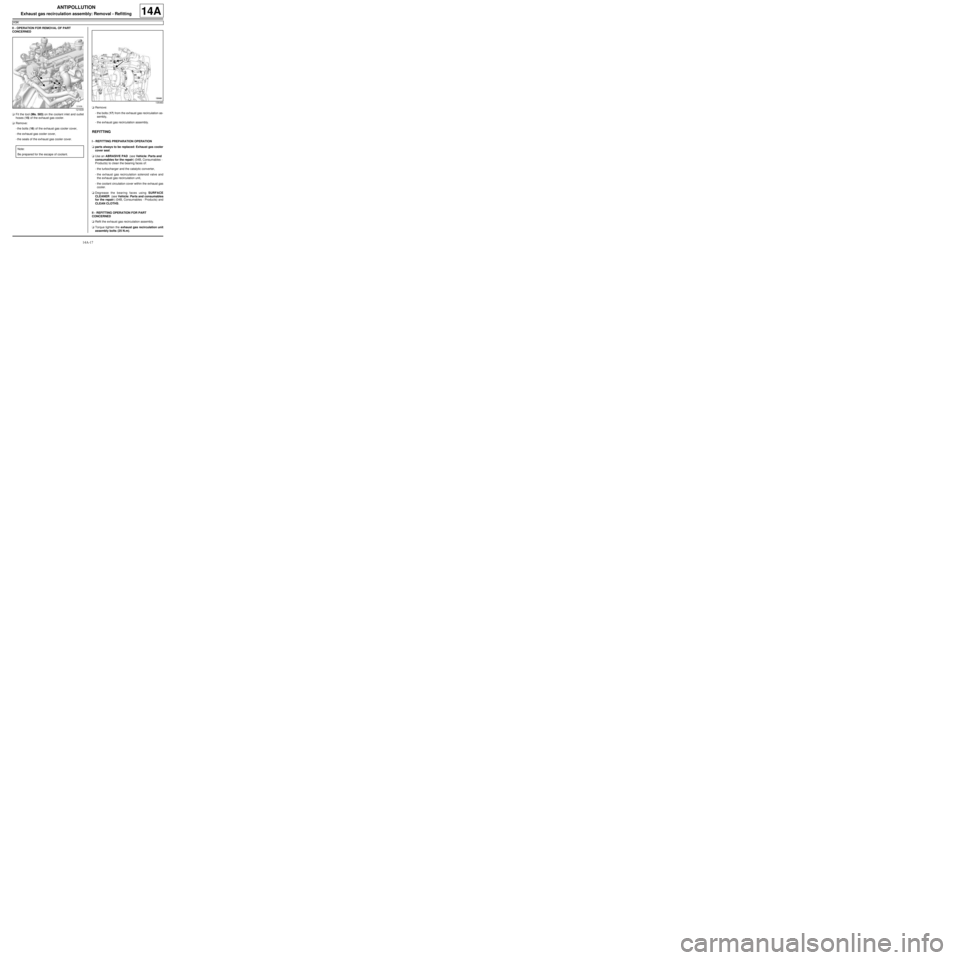

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aFit the tool (Ms. 583) on the coolant inlet and outlet

hoses (15) of the exhaust gas cooler.

aRemove:

-the bolts (16) of the exhaust gas cooler cover,

-the exhaust gas cooler cover,

-the seals of the exhaust gas cooler cover.aRemove:

-the bolts (17) from the exhaust gas recirculation as-

sembly,

-the exhaust gas recirculation assembly.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Exhaust gas cooler

cover seal.

aUse an ABRASIVE PAD (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products) to clean the bearing faces of:

-the turbocharger and the catalytic converter,

-the exhaust gas recirculation solenoid valve and

the exhaust gas recirculation unit,

-the coolant circulation cover within the exhaust gas

cooler.

aDegrease the bearing faces using SURFACE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products) and

CLEAN CLOTHS.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the exhaust gas recirculation assembly.

aTorque tighten the exhaust gas recirculation unit

assembly bolts (25 N.m).

121639

Note:

Be prepared for the escape of coolant.

135460

Page 436 of 652

14A-18

ANTIPOLLUTION

Exhaust gas recirculation assembly: Removal - Refitting

K9K

14A

aRefit:

-new seals on the coolant circulation cover,

-the coolant circulation cover on the exhaust gas

cooler.

aTorque tighten the coolant circulation cover bolts

on the exhaust gas cooler (12 N.m).

aRemove the tool (Ms. 583) from the coolant inlet and

outlet hoses of the exhaust gas cooler.

III - FINAL OPERATION

aFit the intercooler air outlet pipe at the damper valve

end.

aConnect the intercooler air outlet pipe on the side of

the damper valve.

aTorque tighten the intercooler air outlet pipe clip

at the damper valve end (5.5 N.m).

aRefit the intercooler air outlet pipe nut on the lifting

eye.

aConnect the turbocharging pressure regulator vacu-

um pipe.

aClip:

-the turbocharging pressure regulator vacuum pipe,

-the vacuum pipe from the brake servo.

aConnect the brake servo vacuum pipe.

aFit the intercooler air inlet pipe at the turbocharger

end.

aRefit the intercooler air inlet pipe nut at the turbo-

charger end on the lifting eye.

aConnect the intercooler air inlet pipe at the turbo-

charger end.

aClip on the intercooler air inlet pipe clip at the turbo-

charger end.

aRefit the air outlet pipe onto the air filter unit.

aTighten the air filter unit air outlet pipe clip on the tur-

bocharger.

aConnect the oil vapour rebreathing pipe.

aRefit:

-the exhaust gas recirculation rigid pipe (see 14A,

Antipollution, Exhaust gas recirculation rigid

pipe: Removal - Refitting, page 14A-19) ,-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

aConnect the battery (see ) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine cover. K9K, and 718

Page 437 of 652

14A-19

ANTIPOLLUTION

Exhaust gas recirculation rigid pipe: Removal - Refitting

K9K

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (1) from the exhaust gas recirculation rigid

pipe on the exhaust manifold,

-the bolts (2) of the exhaust gas recirculation rigid

pipe on the exhaust gas cooler,

-the bolts (3) of the exhaust gas recirculation rigid

pipe bracket,

-the EGR rigid pipe. Tightening torquesm

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust manifold36 N.m

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust gas

cooler12 N.m

bolts of the exhaust gas

recirculation rigid pipe

bracket25 N.m

rigid exhaust gas recir-

culation pipe clip5 N.m

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust manifold36 N.m

K9K, and 718

141224

Page 438 of 652

14A-20

ANTIPOLLUTION

Exhaust gas recirculation rigid pipe: Removal - Refitting

K9K

14A

aRemove:

-the clip (4) of the exhaust gas recirculation rigid

pipe,

-the bolts (5) from the EGR rigid pipe,

-the EGR rigid pipe.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Exhaust gas recir-

culation rigid pipe

aparts always to be replaced: exhaust gas recir-

culation pipe bolt

aparts always to be replaced: Exhaust gas recir-

culation pipe seal

aparts always to be replaced: exhaust gas cooler

sealaparts always to be replaced: Exhaust gas recir-

culation pipe clip

aUsing an ABRASIVE PAD (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products), clean the bearing face of the exhaust gas

recirculation rigid pipe on the cylinder head.

aUse SURFACE CLEANER and CLEAN CLOTHS to

degrease the bearing face of the exhaust gas recir-

culation rigid pipe on the cylinder head (see Vehi-

cle: Parts and consumables for the repair) (04B,

Consumables - Products).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the rigid exhaust gas recirculation pipe.

aCheck that the rigid exhaust gas recirculation pipe is

not constrained.

aTighten to torque:

-the bolts of the exhaust gas recirculation rigid

pipe on the exhaust manifold (36 N.m),

-the bolts of the exhaust gas recirculation rigid

pipe on the exhaust gas cooler (12 N.m),

-the bolts of the exhaust gas recirculation rigid

pipe bracket (25 N.m). K9K, and 740

114531

K9K, and 718

K9K, and 740

K9K, and 718

Page 439 of 652

14A-21

ANTIPOLLUTION

Exhaust gas recirculation rigid pipe: Removal - Refitting

K9K

14A

aRefit the exhaust gas recirculation rigid pipe with a

new clip.

aFit the rigid exhaust gas recirculation pipe bolts,

without tightening them.

aAdjust the rigid exhaust gas recirculation pipe in re-

lation to the exhaust gas recirculation assembly.

aTorque tighten the rigid exhaust gas recirculation

pipe clip (5 N.m).

aCheck that the rigid exhaust gas recirculation pipe is

not constrained.

aTorque tighten the bolts of the exhaust gas recir-

culation rigid pipe on the exhaust manifold (36

N.m).

III - FINAL OPERATION

aRefit:

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the engine cover.

aConnect the battery (see ) (80A, Battery). K9K, and 740

Page 440 of 652

16A-1

STARTING - CHARGING

Alternator: Removal - Refitting

D4F or D7F, and STANDARD HEATING

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection).

aUndo the lower bolt on the sub-frame tie-rod.

aRemove the upper bolt from the sub-frame tie-rod.

aRemove the sub-frame tie-rod.

aRemove the accessories belt (see 11A, Top and

front of engine, Accessories belt: Removal - Re-

fitting, page 11A-3) . Tightening torquesm

alter nator bolts25 Nm

sub-frame tie-rod lower

bolt62 Nm

sub-frame tie-rod upper

bolt21 Nm

Page 442 of 652

16A-3

STARTING - CHARGING

Alternator: Removal - Refitting

D4F or D7F, and STANDARD HEATING

16A

aPress in the rings (6) using pliers or a vice to make

the fitting operation easier.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the alternator,

-the alternator bolts.

aTorque tighten the alternator bolts (25 Nm).

aRefit:

-the power lead on the alternator,

-the power lead nut on the alternator.

aConnect the alternator excitation lead connector.

III - FINAL OPERATION

aConnect the fuel pipe to the injector rail.

aRefit:

-the dipstick,

-the filler neck,

-the filler neck bolt.

aAlways replace the accessories belt.aRefit the new accessories belt (see 11A, Top and

front of engine, Accessories belt: Removal - Re-

fitting, page 11A-3) .

aFit the sub-frame tie-rod.

aRefit the upper bolt on the sub-frame tie-rod.

aTorque tighten:

-the sub-frame tie-rod lower bolt (62 Nm),

-the sub-frame tie-rod upper bolt (21 Nm).

aRefit:

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres).

aConnect the battery (see ) (MR 411, 80A, Battery).

18987

D4F, and 780