Temperature sensor RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 306 of 652

12A-41

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

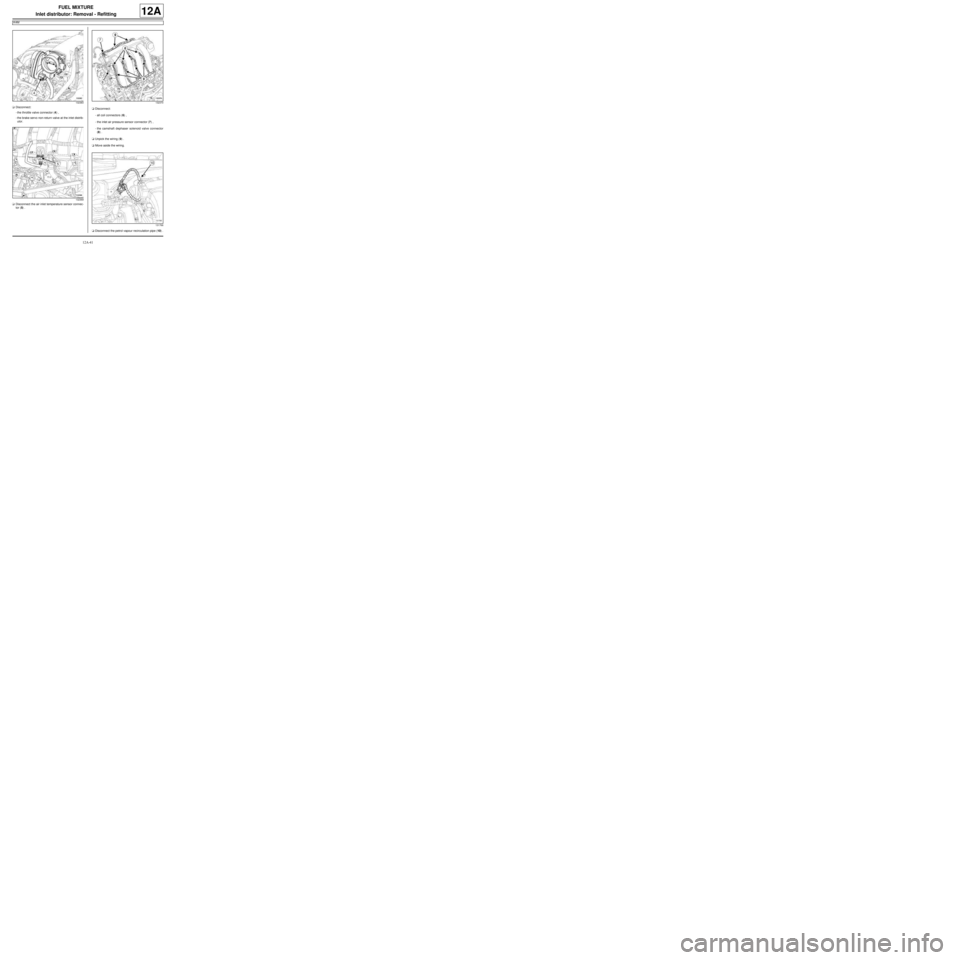

aDisconnect:

-the throttle valve connector (4) ,

-the brake servo non-return valve at the inlet distrib-

utor.

aDisconnect the air inlet temperature sensor connec-

tor (5) .aDisconnect:

-all coil connectors (6) ,

-the inlet air pressure sensor connector (7) ,

-the camshaft dephaser solenoid valve connector

(8) .

aUnpick the wiring (9) .

aMove aside the wiring.

aDisconnect the petrol vapour recirculation pipe (10) .

132383

132369132370

131766

Page 307 of 652

12A-42

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

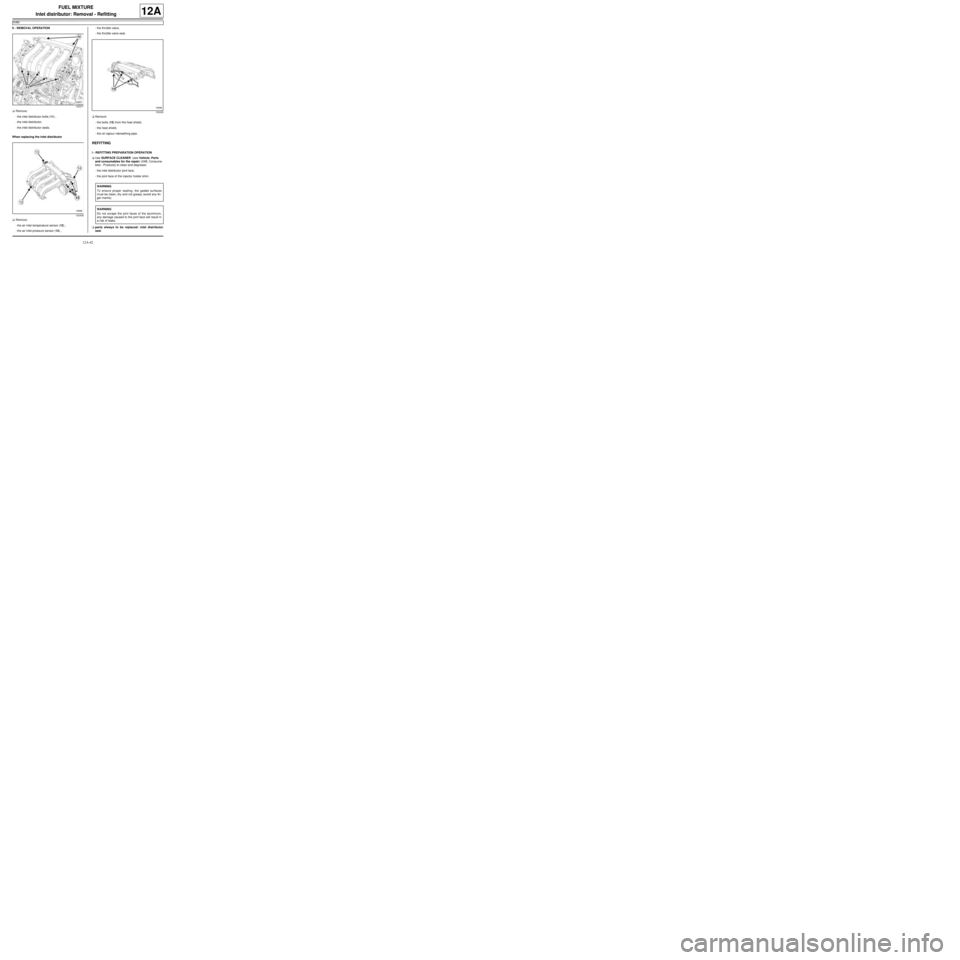

II - REMOVAL OPERATION

aRemove:

-the inlet distributor bolts (11) ,

-the inlet distributor,

-the inlet distributor seals.

When replacing the inlet distributor

aRemove:

-the air inlet temperature sensor (12) ,

-the air inlet pressure sensor (13) ,-the throttle valve,

-the throttle valve seal.

aRemove:

-the bolts (15) from the heat shield,

-the heat shield,

-the oil vapour rebreathing pipe.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the inlet distributor joint face,

-the joint face of the injector holder shim.

aparts always to be replaced: inlet distributor

seal.

132371

132438

132439

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger mar ks).

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

Page 308 of 652

12A-43

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

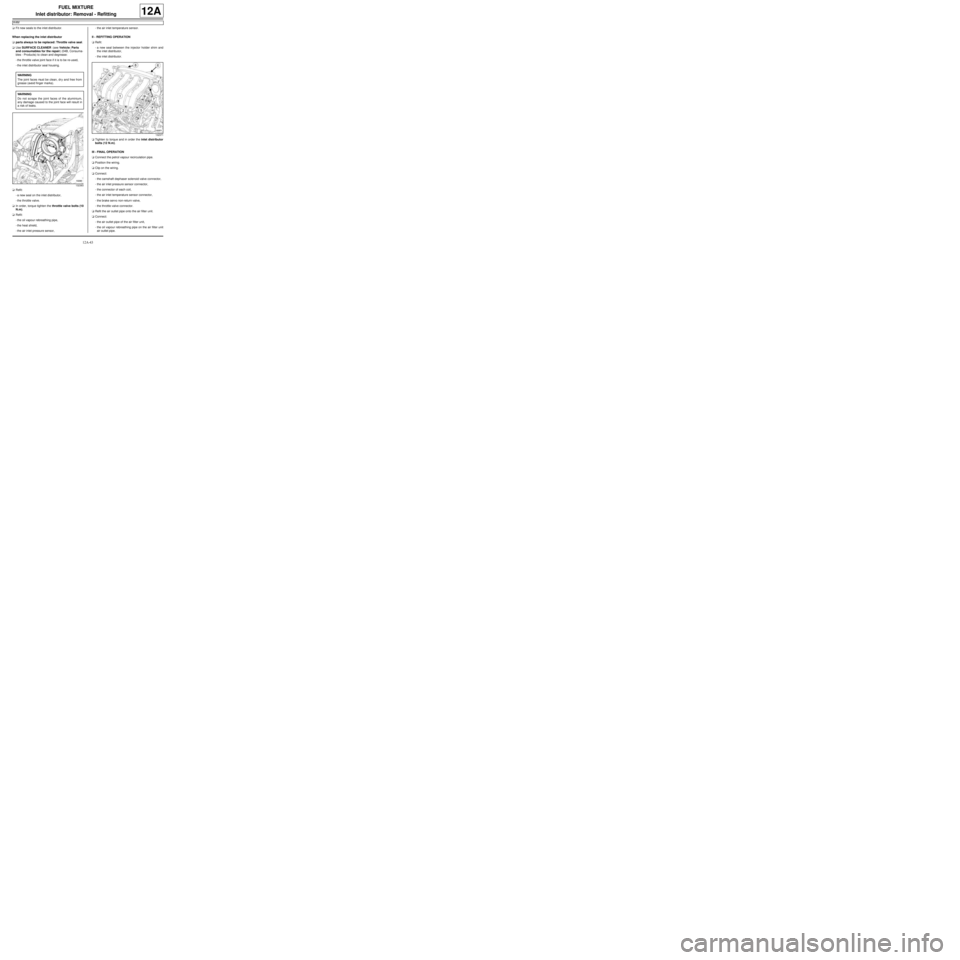

aFit new seals to the inlet distributor.

When replacing the inlet distributor

aparts always to be replaced: Throttle valve seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the throttle valve joint face if it is to be re-used,

-the inlet distributor seal housing.

aRefit:

-a new seal on the inlet distributor,

-the throttle valve.

aIn order, torque tighten the throttle valve bolts (10

N.m).

aRefit:

-the oil vapour rebreathing pipe,

-the heat shield,

-the air inlet pressure sensor,-the air inlet temperature sensor.

II - REFITTING OPERATION

aRefit:

-a new seal between the injector holder shim and

the inlet distributor,

-the inlet distributor.

aTighten to torque and in order the inlet distributor

bolts (12 N.m).

III - FINAL OPERATION

aConnect the petrol vapour recirculation pipe.

aPosition the wiring.

aClip on the wiring.

aConnect:

-the camshaft dephaser solenoid valve connector,

-the air inlet pressure sensor connector,

-the connector of each coil,

-the air inlet temperature sensor connector,

-the brake servo non-return valve,

-the throttle valve connector.

aRefit the air outlet pipe onto the air filter unit.

aConnect:

-the air outlet pipe of the air filter unit,

-the oil vapour rebreathing pipe on the air filter unit

air outlet pipe. WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

132383

132371

Page 369 of 652

13B-8

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 740

13B

121418

(1) High pressure pump

(2) Venturi

(3) Injectors

(4) Heater plugs

102315

(5) Fuel fl ow actuator

(6) Diesel fuel temperature sensor

(7) Accelerometer

121420

(8) Injector rail

(9) Injector rail pressure sensor

121422

(10) Diesel injection computer

Page 370 of 652

13B-9

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 740

13B

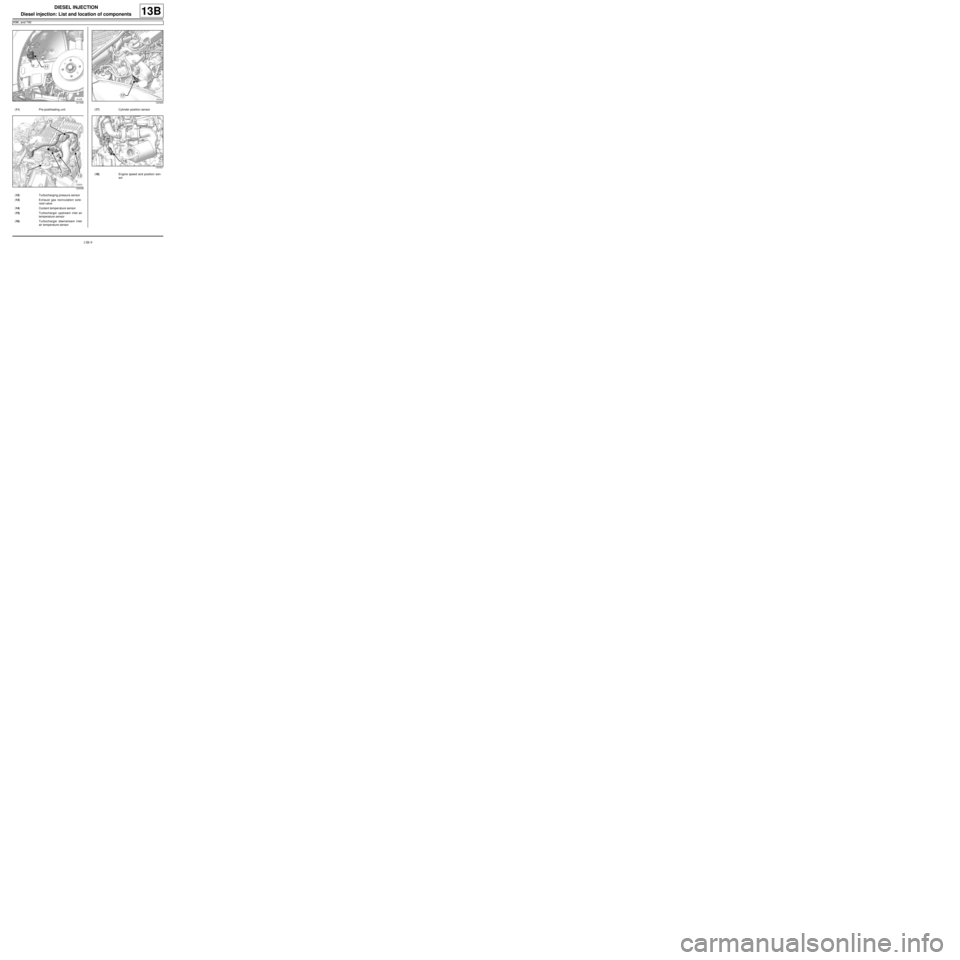

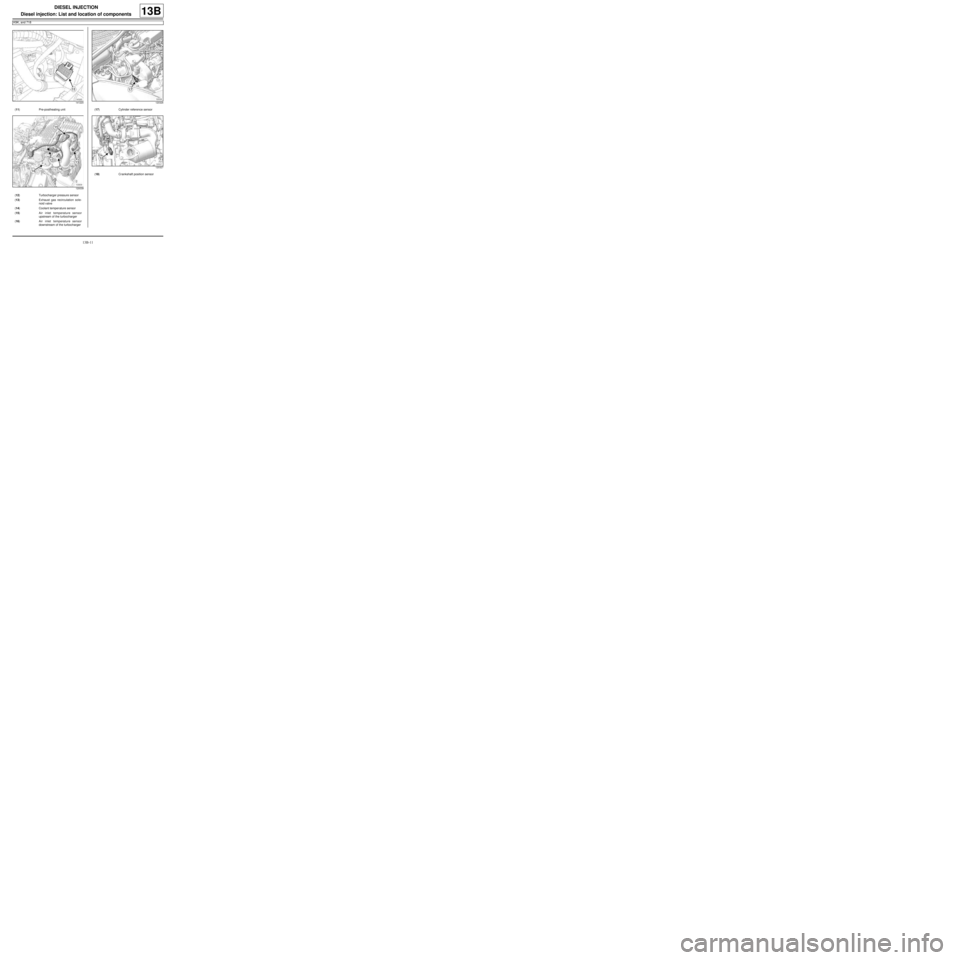

121436

(11) Pre-postheating unit

120039

(12) Turbocharging pressure sensor

(13) Exhaust gas recirculation sole-

noid valve

(14) Coolant temper ature sensor

(15) Turbocharger upstream inlet air

temperature sensor

(16) Turbocharger downstream inlet

air temperature sensor

120326

(17) Cylinder position sensor

120327

(18) Engine speed and position sen-

sor

Page 371 of 652

13B-10

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 718

13B

121418

(1) High pressure pump

(2) Venturi

(3) Injectors

(4) Heater plugs

102315

(5) Fuel fl ow actuator

(6) Diesel temperature sensor

(7) Accelerometer

121420

(8) Injector rail

(9) Injector rail pressure sensor

121422

(10) Diesel injection computer

Page 372 of 652

13B-11

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 718

13B

141220

(11) Pre-postheating unit

120039

(12) Turbocharger pressure sensor

(13) Exhaust gas recirculation sole-

noid valve

(14) Coolant temper ature sensor

(15) Air inlet temperature sensor

upstream of the turbocharger

(16) Air inlet temperature sensor

downstream of the turbocharger

120326

(17) Cylinder reference sensor

120327

(18) Crankshaft position sensor

Page 377 of 652

13B-16

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

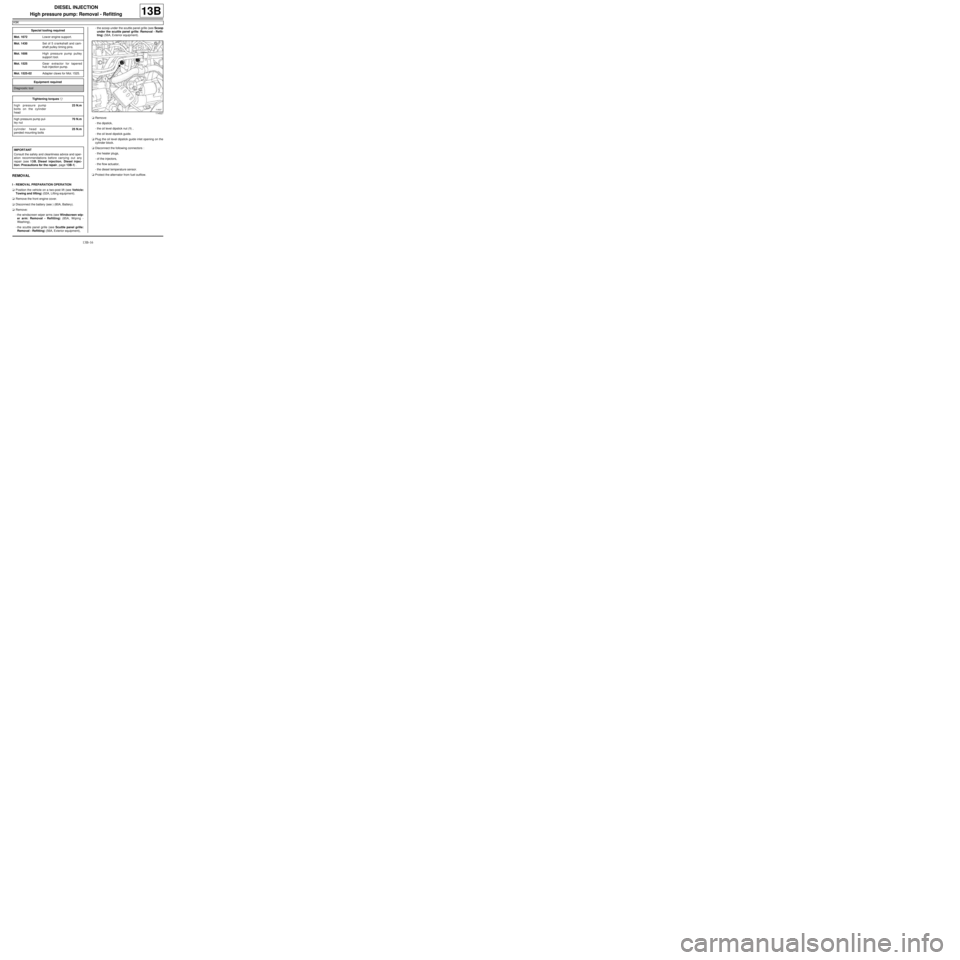

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the dipstick,

-the oil level dipstick nut (1) ,

-the oil level dipstick guide.

aPlug the oil level dipstick guide inlet opening on the

cylinder block.

aDisconnect the following connectors :

-the heater plugs,

-of the injectors,

-the flow actuator,

-the diesel temperature sensor.

aProtect the alternator from fuel outflow. Special tooling required

Mot. 1672Low er engine support.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Mot. 1606High pressure pump pulley

support tool.

Mot. 1525Gear extractor for tapered

hub injection pump.

Mot. 1525-02Adapter claws for Mot. 1525.

Equipment required

Diagnostic tool

Tightening torquesm

high pressure pump

bolts on the cylinder

head23 N.m

high pressure pump pul-

ley nut70 N.m

cylinder head sus-

pended mounting bolts25 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

114527

Page 385 of 652

13B-24

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

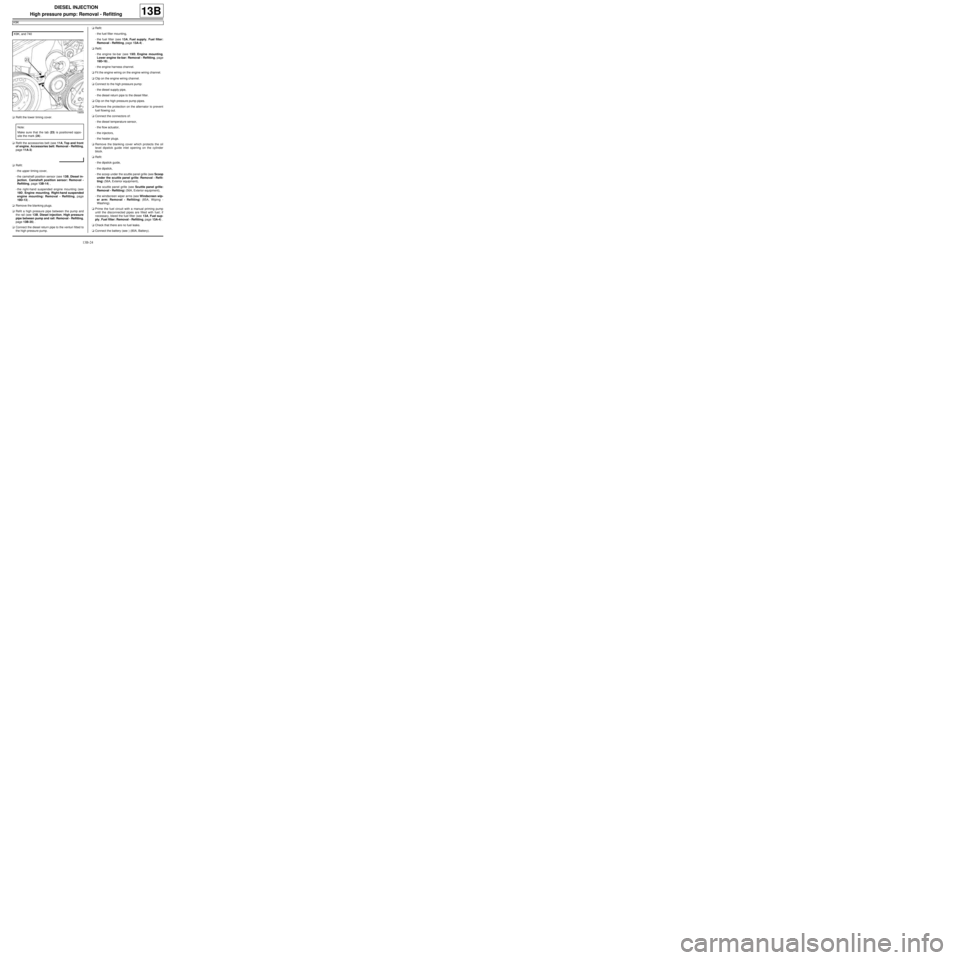

aRefit the lower timing cover.

aRefit the accessories belt (see 11A, Top and front

of engine, Accessories belt: Removal - Refitting,

page 11A-3)

aRefit:

-the upper timing cover,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

aRemove the blanking plugs.

aRefit a high pressure pipe between the pump and

the rail (see 13B, Diesel injection, High pressure

pipe between pump and rail: Removal - Refitting,

page 13B-35) .

aConnect the diesel return pipe to the venturi fitted to

the high pressure pump.aRefit:

-the fuel filter mounting,

-the fuel filter (see 13A, Fuel supply, Fuel filter:

Removal - Refitting, page 13A-4) .

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the engine harness channel.

aFit the engine wiring on the engine wiring channel.

aClip on the engine wiring channel.

aConnect to the high pressure pump:

-the diesel supply pipe,

-the diesel return pipe to the diesel filter.

aClip on the high pressure pump pipes.

aRemove the protection on the alternator to prevent

fuel flowing out.

aConnect the connectors of:

-the diesel temperature sensor,

-the flow actuator,

-the injectors,

-the heater plugs.

aRemove the blanking cover which protects the oil

level dipstick guide inlet opening on the cylinder

block.

aRefit:

-the dipstick guide,

-the dipstick,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aPrime the fuel circuit with a manual priming pump

until the disconnected pipes are filled with fuel; if

necessary, bleed the fuel filter (see 13A, Fuel sup-

ply, Fuel filter: Removal - Refitting, page 13A-4) .

aCheck that there are no fuel leaks.

aConnect the battery (see ) (80A, Battery). K9K, and 740

19659

Note:

Make sure that the tab (23) is positioned oppo-

site the mark (24) .

Page 387 of 652

13B-26

DIESEL INJECTION

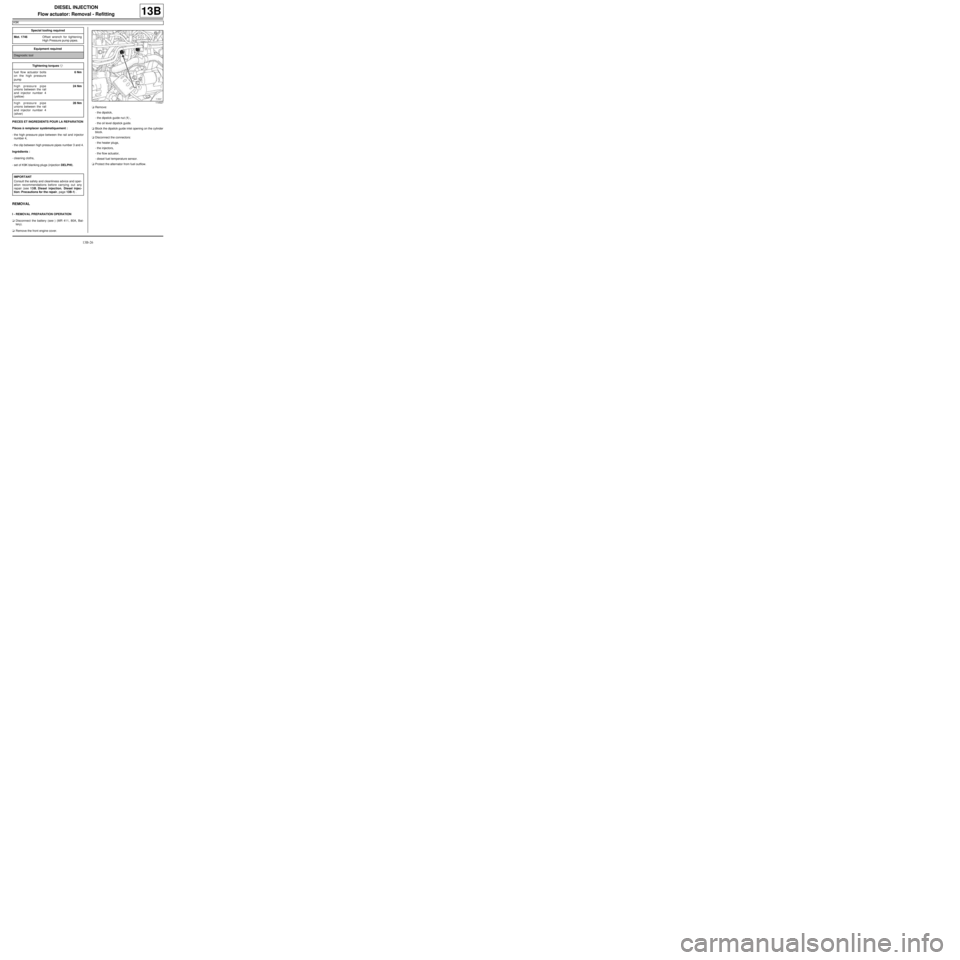

Flow actuator: Removal - Refitting

K9K

13B

PIECES ET INGREDIENTS POUR LA REPARATION

Pièces à remplacer systématiquement :

-the high pressure pipe between the rail and injector

number 4,

-the clip between high pressure pipes number 3 and 4.

Ingrédients :

-cleaning cloths,

-set of K9K blanking plugs (injection DELPHI).

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove the front engine cover.aRemove:

-the dipstick,

-the dipstick guide nut (1) ,

-the oil level dipstick guide.

aBlock the dipstick guide inlet opening on the cylinder

block.

aDisconnect the connectors:

-the heater plugs,

-the injectors,

-the flow actuator,

-diesel fuel temperature sensor.

aProtect the alternator from fuel outflow. Special tooling required

Mot. 1746Offset wrench for tightening

High Pressure pump pipes.

Equipment required

Diagnostic tool

Tightening torquesm

fuel flow actuator bolts

on the high pressure

pump6 Nm

high pressure pipe

unions between the rail

and injector number 4

(yellow)24 Nm

high pressure pipe

unions between the rail

and injector number 4

(silver)28 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

114527