wheel bolts RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 84 of 652

10A-78

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

aDrain the coolant circuit (see Refrigerant circuit:

Draining - Filling) .

aRemove:

-the air conditioning pipe bolts on the compressor,

-the air conditioning pipe bolt on the dehydrator res-

ervoir.

aDisconnect the air conditioning pressostat connec-

tor.

a

aDisconnect the fuel supply pipe union.

aInsert the blanking plugs.

aUnclip the fuel pipe on the upper timing cover.aSet the wheels straight ahead.

aPosition the flywheel immobiliser.

aRemove the cover from the universal joint (do not

keep).

aRemove the universal joint bolt (do not keep).

aRemove the universal joint from the steering box.

aDetach the electrical wiring on the cross member.

aLoosen the tie rod lower bolts.

aRemove:

-the tie rod upper bolts.

-the track rod end nuts,

-the track rod ends using the (Tav. 476),

-the lower guide pin bolts,

-the brake pads,

-the calliper mounting bolts,

-the brake callipers, and attach them to the suspen-

sion springs,

-the ABS sensor bolts (if fitted to the vehicle),

-the ABS sensors,

-the shock absorber base lower bolts, AIR CONDITIONING

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

119544

Page 89 of 652

10A-83

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

aTorque tighten:

-the front subframe bolts (62 N.m),

-the rear subframe bolts (105 N.m),

-the subframe rear tie rod inner bolts (21 N.m),

-the subframe rear tie rod outer bolts (90 N.m),

-the engine tie-bar bolts on the gearbox (105

N.m),

-the engine tie-bar bolt on the subframe (105

N.m).

aRefit the control cables onto the gearbox.

aRemove the blanking plugs from the openings.

aClip the clutch pipe onto the gearbox.

aConnect the clutch slave cylinder.

aRemove the hose clamp (Ms. 583).

aBleed the clutch circuit (see Clutch circuit: Bleed) .

aRefit the gear control linkage.

aAttach the gear control linkage to:

-the gear lever,

-the control lever on the gearbox.

aRefit:

-the heat shield,

-the heat shield bolts.

aRefit the clutch control cable on the manual gearbox.

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .aRefit the exhaust downpipe.

aFit the clip.

aTighten the intermediate pipe clip.

aRefit the exhaust downpipe bolts.

aTorque tighten the exhaust downpipe bolts (9

N.m).

aRefit:

-the shock absorber base lower bolts,

-the ABS sensors,

-the ABS sensor bolts (if fitted to the vehicle),

-the brake callipers,

-the calliper mounting bolts,

-the brake pads,

-the lower guide pin bolts,

-track rod ends,

-the track rod end nuts,

-the tie rod upper bolts.

aTorque tighten:

-the shock absorber base lower bolts (105 N.m ),

-the calliper mounting bolts (105 N.m),

-the lower guide pin bolts (34 N.m),

-the track rod end nuts (37 N.m),

-the tie rod upper bolts (21 N.m),

-the tie rod lower bolts (62 N.m).

aClip the electrical wiring on to the cross member.

aFit the steering box universal joint.

aRefit the universal joint bolt.

aTorque tighten the universal joint (24 N.m).

aRemove the flywheel immobiliser.

aClip the fuel pipe on to the upper timing cover.

aConnect the fuel supply pipe union.

aConnect the air conditioning pressostat connector. JH3

JB1 or JH1

D4F, and 772 – D7F

D4F, and 780 or 782

AIR CONDITIONING

Page 91 of 652

10A-85

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

aClip the fuse holder onto the engine compartment

connection unit.

aRefit:

-the engine compartment connection unit bolts,

-the engine compartment connection unit supply

nut.

aConnect:

-the fuses,

-the connector.

aRefit:

-the engine compartment connection unit cover,

-the engine compartment connection unit cover

bolts.

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion).

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the computer mounting,

-the computer mounting nuts,

-the computer mounting bolts,

-the injection computer (see 17B, Petrol injection,

Petrol injection computer: Removal - Refitting,

page 17B-20) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the battery (see ) (80A, Battery).

Page 99 of 652

10A-93

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K9K

10A

II - FINAL OPERATION

aRemove the.

aLubricate the seals using recommended air condi-

tioning oil to make fitting easier.

aRefit:

-the connecting pipes to the compressor,

-the connecting pipe union bolts on the compressor,

-the bolt for the connecting pipe mounting on the

compressor.

aConnect:

-the pressostat connector,

-the hose to the coolant pump inlet pipe using the

tool (Mot. 1448).

aFit:

-the hose clip on the coolant pump inlet pipe using

the tool (Mot. 1448),

-the earth on the front left-hand wing.

aRefit the earth nut on the front left-hand wing.

aClip:

-the engine compartment connection unit relay

plates,

-the fuse holders.

aRefit the fuses.

aConnect the preheating unit connector.

aRefit the earth nut on the front left-hand side mem-

ber.

aFit the engine compartment connection unit.

aRefit the engine compartment connection unit

mountings on the body.

aConnect the black connector.

aClip on the black connector.

aRefit:

-the engine compartment connection unit cover,

-a new clip on the battery mounting to hold the elec-

trical wiring.

aConnect the wiring connectors to the fan assembly.aClip the fan assembly wiring.

aRemove the blanking plugs.

aConnect the high pressure pump inlet pipe.

aClip on the fuel supply pipe.

aConnect the high pressure pump return pipe.

aClip on the fuel return pipe.

aRemove the blanking plugs on the clutch hydraulic

control and on the control pipe.

aConnect the clutch hydraulic control to the gearbox.

aClip:

-the clutch control hydraulic pipe on the gearbox,

-the gearbox controls on the cable sleeve stops,

-the gearbox controls on the gear selectors.

aConnect:

-the hoses to the heater radiator,

-the top hose to the water chamber.

aFit:

-the hose clips on the heater radiator using the tool

(Mot. 1448),

-the clip for the top hose on the water chamber us-

ing the tool (Mot. 1448).

aRefit:

-the front section of the intermediate pipe (see 19B,

Exhaust, Intermediate pipe: Removal - Refit-

ting, page 19B-28) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) . WARNING

To prevent any leaks, check that the seal and the

surface of the pipe are in good condition. The

seal and the surface must be clean and scratch

free.

Page 102 of 652

10A-96

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRemove:

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the engine undertray,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain:

-the gearbox (see Manual gearbox oils: Draining -

Filling) (21A, Manual gearbox),-the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) ,

-the engine, if necessary (see 10A, Engine and

cylinder block assembly, Engine oil: Draining -

Refilling, page 10A-22) ,

-the refrigerant circuit using a refrigerant charging

station (see Refrigerant circuit: Draining - Fill-

ing) (62A, Air conditioning).

aAttach the « engine cooling radiator - condenser »

assembly to the front upper cross member.

aRemove:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the differential output seal (see Differential output

seal: Removal - Refitting) (21A, Manual gear-

box).

aRemove the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

Tightening torquesm

rubber pad mounting

bolts for the suspended

engine mounting on the

gearbox21 N.m

bolts of the suspended

mounting r ubber pad62 N.m

suspended engine

mounting shaft nut62 N.m

Page 113 of 652

10A-107

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

D4F – D7F – K9K

10A

REMOVAL

I - REFITTING PREPARATIONS OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the gearbox (see Manual gearbox: Removal - Re-

fitting) ,

-the clutch plate and pressure plate (see Pressure

plate - Disc: Removal - Refitting) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

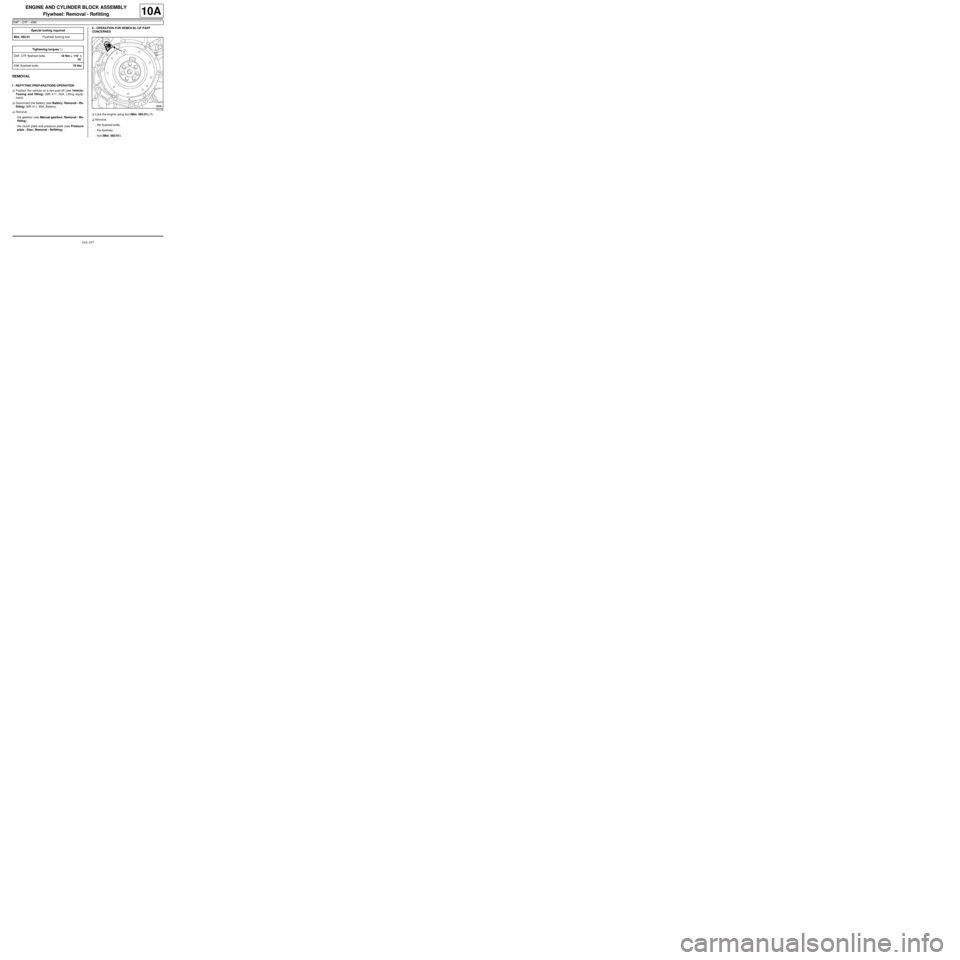

aLock the engine using tool (Mot. 582-01) (1) .

aRemove:

-the flywheel bolts,

-the flywheel,

-tool (Mot. 582-01). Special tooling required

Mot. 582-01Flywheel locking tool.

Tightening torquesm

D4F, D7F flywheel bolts18 Nm + 110˚ ±± ± ±

10˚

K9K flywheel bolts70 Nm

109158

Page 114 of 652

10A-108

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

D4F – D7F – K9K

10A

REFITTING

I - REFITTING PREPARATIONS OPERATION

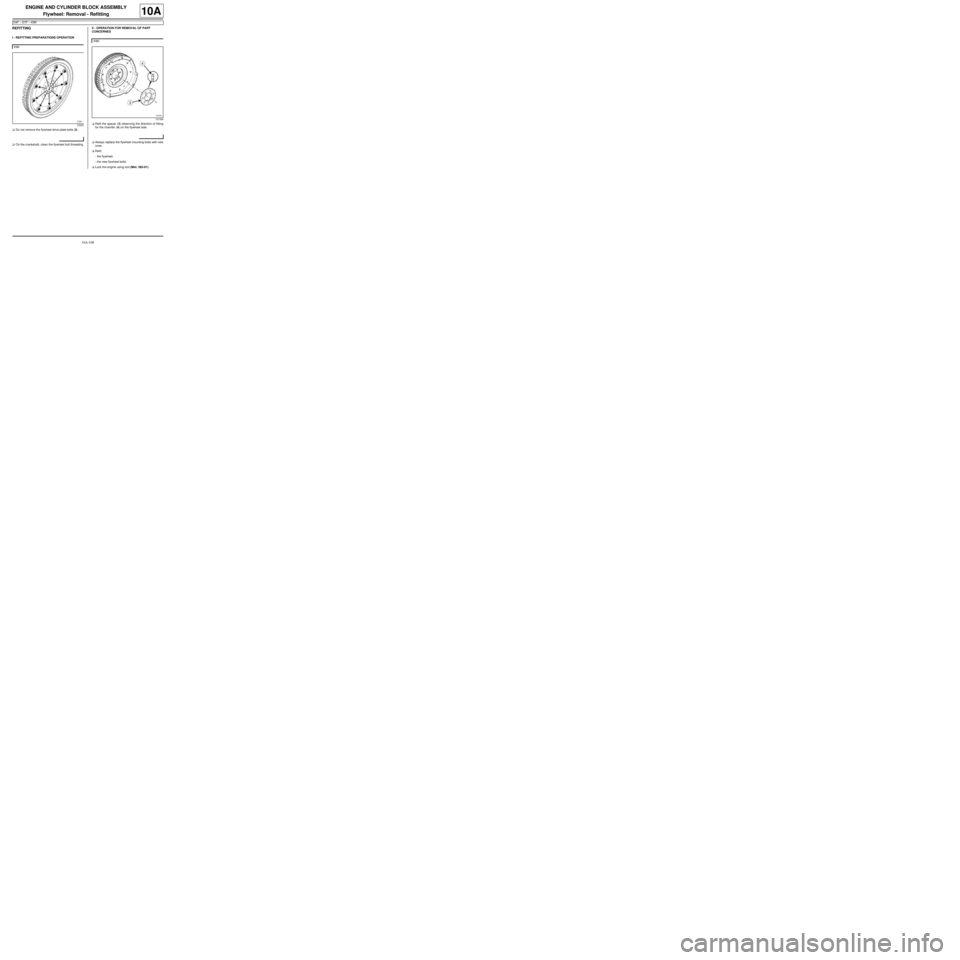

aDo not remove the flywheel drive plate bolts (2) .

aOn the crankshaft, clean the flywheel bolt threading.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRefit the spacer (3) observing the direction of fitting

for the chamfer (4) on the flywheel side.

aAlways replace the flywheel mounting bolts with new

ones.

aRefit:

-the flywheel,

-the new flywheel bolts.

aLock the engine using tool (Mot. 582-01). K9K

23325

K9K

101356

Page 115 of 652

10A-109

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

D4F – D7F – K9K

10A

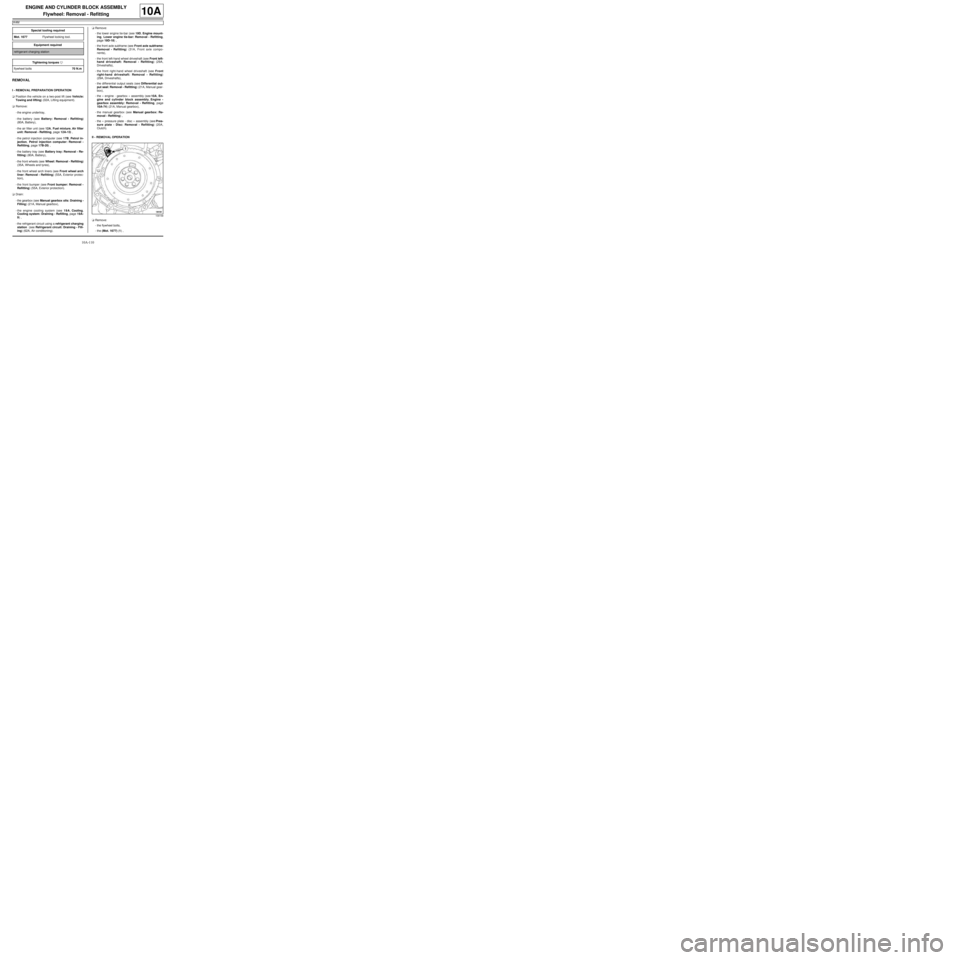

Tightening order

aObserve the tightening order.

aTorque and angle tighten, in order, the D4F, D7F fly-

wheel bolts (18 Nm + 110˚ ±± ± ±

10˚).

aTighten to torque and in order the K9K flywheel

bolts (70 Nm).

aRemove tool (Mot. 582-01).

III - FINAL OPERATION.

aRefit:

-the clutch plate and pressure plate (see Pressure

plate - Disc: Removal - Refitting) ,

-the gearbox (see Manual gearbox: Removal - Re-

fitting) .

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

23326

D4F – D7F

K9K

Page 116 of 652

10A-110

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray,

-the battery (see Battery: Removal - Refitting)

(80A, Battery),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain:

-the gearbox (see Manual gearbox oils: Draining -

Filling) (21A, Manual gearbox),

-the engine cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) ,

-the refrigerant circuit using a refrigerant charging

station (see Refrigerant circuit: Draining - Fill-

ing) (62A, Air conditioning).aRemove:

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the differential output seals (see Differential out-

put seal: Removal - Refitting) (21A, Manual gear-

box),

-the « engine - gearbox » assembly (see 10A, En-

gine and cylinder block assembly, Engine -

gearbox assembly: Removal - Refitting, page

10A-74) (21A, Manual gearbox),

-the manual gearbox (see Manual gearbox: Re-

moval - Refitting) ,

-the « pressure plate - disc » assembly (see Pres-

sure plate - Disc: Removal - Refitting) (20A,

Clutch).

II - REMOVAL OPERATION

aRemove:

-the flywheel bolts,

-the (Mot. 1677) (1) , Special tooling required

Mot. 1677Flywheel locking tool.

Equipment required

refrigerant charging station

Tightening torquesm

flywheel bolts70 N.m

109158

Page 117 of 652

10A-111

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

K4M

10A

-the flywheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the flywheel bearing face if reusing,

-the crankshaft bearing face.

aAlways replace the flywheel bolts.

II - REFITTING OPERATION

aFit the flywheel.

aFit the new flywheel bolts without tightening them.

aPosition the (Mot. 1677).

aTighten to torque and in order the flywheel bolts

(70 N.m).

III - FINAL OPERATION

aRefit:

-the « pressure plate - disc » assembly (see Pres-

sure plate - Disc: Removal - Refitting) (20A,

Clutch),

-the manual gearbox (see Manual gearbox: Re-

moval - Refitting) (21A, Manual gearbox).-the « engine and gearbox » assembly (see 10A,

Engine and cylinder block assembly, Engine -

gearbox assembly: Removal - Refitting, page

10A-74) ,

-the differential output seals (see Differential out-

put seal: Removal - Refitting) (21A, Manual gear-

box),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the battery (see Battery: Removal - Refitting)

(80A, Battery).

aPerform the following operations:

-fill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) ,

-fill the gearbox (see Manual gearbox oils: Drain-

ing - Filling) (21A, Manual gearbox).

-fill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aRefit the engine undertray.

109158