fuel pressure RENAULT TWINGO 2009 2.G Engine And Peripherals Manual PDF

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 436 of 652

14A-18

ANTIPOLLUTION

Exhaust gas recirculation assembly: Removal - Refitting

K9K

14A

aRefit:

-new seals on the coolant circulation cover,

-the coolant circulation cover on the exhaust gas

cooler.

aTorque tighten the coolant circulation cover bolts

on the exhaust gas cooler (12 N.m).

aRemove the tool (Ms. 583) from the coolant inlet and

outlet hoses of the exhaust gas cooler.

III - FINAL OPERATION

aFit the intercooler air outlet pipe at the damper valve

end.

aConnect the intercooler air outlet pipe on the side of

the damper valve.

aTorque tighten the intercooler air outlet pipe clip

at the damper valve end (5.5 N.m).

aRefit the intercooler air outlet pipe nut on the lifting

eye.

aConnect the turbocharging pressure regulator vacu-

um pipe.

aClip:

-the turbocharging pressure regulator vacuum pipe,

-the vacuum pipe from the brake servo.

aConnect the brake servo vacuum pipe.

aFit the intercooler air inlet pipe at the turbocharger

end.

aRefit the intercooler air inlet pipe nut at the turbo-

charger end on the lifting eye.

aConnect the intercooler air inlet pipe at the turbo-

charger end.

aClip on the intercooler air inlet pipe clip at the turbo-

charger end.

aRefit the air outlet pipe onto the air filter unit.

aTighten the air filter unit air outlet pipe clip on the tur-

bocharger.

aConnect the oil vapour rebreathing pipe.

aRefit:

-the exhaust gas recirculation rigid pipe (see 14A,

Antipollution, Exhaust gas recirculation rigid

pipe: Removal - Refitting, page 14A-19) ,-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

aConnect the battery (see ) (80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine cover. K9K, and 718

Page 480 of 652

17B-5

PETROL INJECTION

Petrol injection: List and location of components

D4F, and 780 or 782

17B

122387

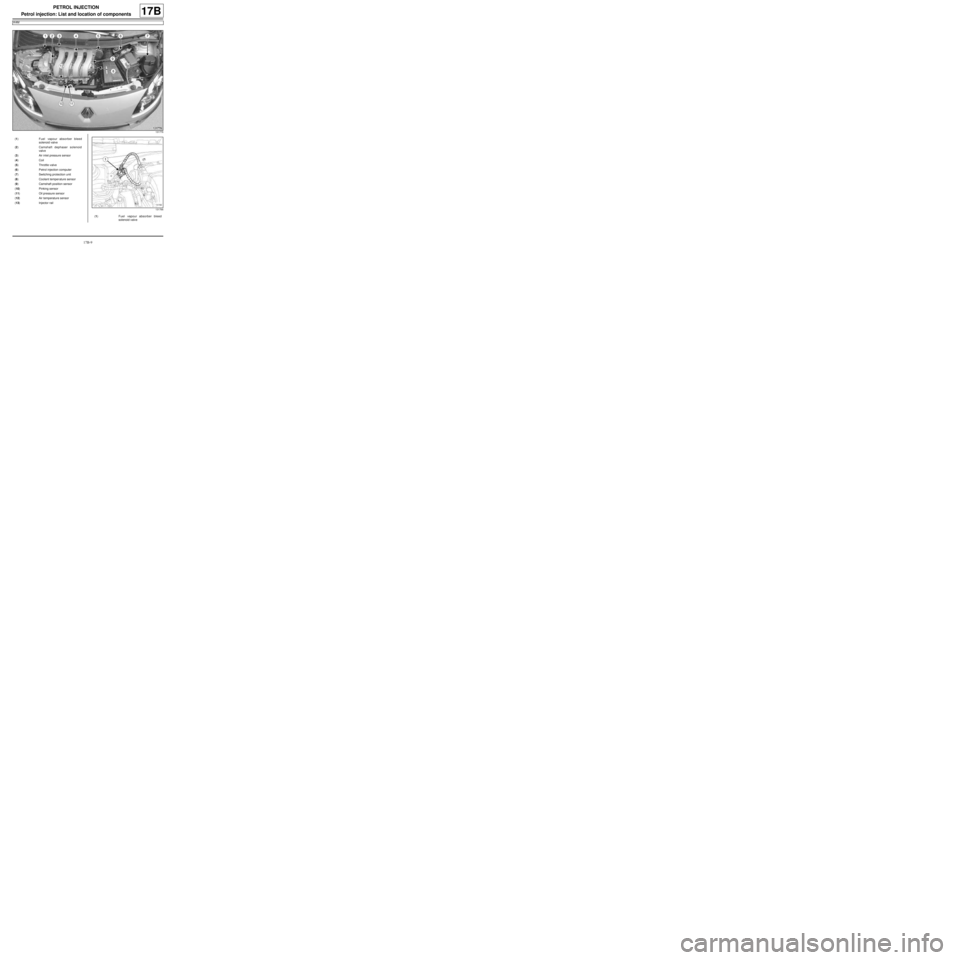

(1) Fuel vapour recirculation sole-

noid valve

(2) Upstream oxygen sensor

(3) Petrol injection computer

(4) Motorised throttle valve

(5) Ignition coil

(6) Engine compar tment connec-

tion unit

(7) Intake distributor pressure sen-

sor

(8) Turbocharger

108254

(9) Fuel injection computer

Page 484 of 652

17B-9

PETROL INJECTION

Petrol injection: List and location of components

K4M

17B

131776

(1) Fuel vapour absorber bleed

solenoid valve

(2) Camshaft dephaser solenoid

valve

(3) Air inlet pressure sensor

(4) Coil

(5) Throttle valve

(6) Petrol injection computer

(7) Switching protection unit

(8) Coolant temper ature sensor

(9) Camshaft position sensor

(10) Pinking sensor

(11) Oil pressure sensor

(12) Air temperature sensor

(13) Injector rail

131766

(1) Fuel vapour absorber bleed

solenoid valve

Page 553 of 652

19A-43

COOLING

Water chamber: Removal - Refitting

K9K

19A

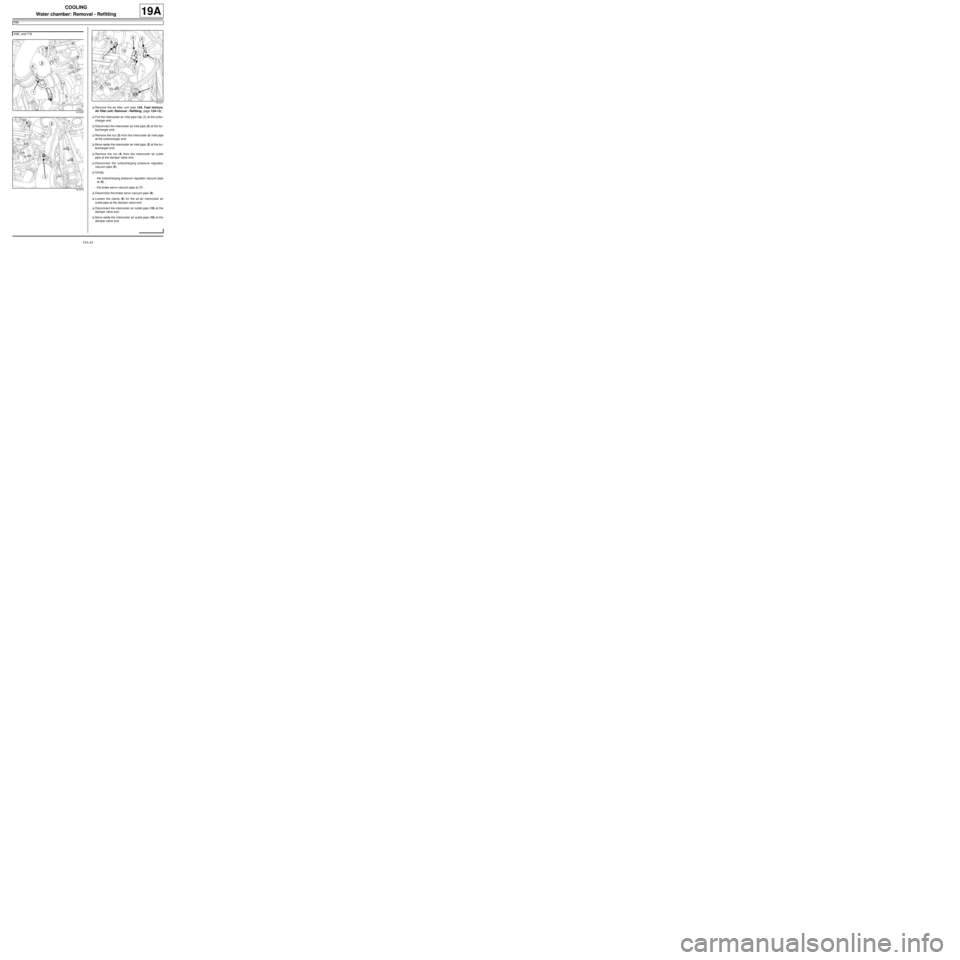

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aPull the intercooler air inlet pipe clip (1) at the turbo-

charger end.

aDisconnect the intercooler air inlet pipe (2) at the tur-

bocharger end.

aRemove the nut (3) from the intercooler air inlet pipe

at the turbocharger end.

aMove aside the intercooler air inlet pipe (2) at the tur-

bocharger end.

aRemove the nut (4) from the intercooler air outlet

pipe at the damper valve end.

aDisconnect the turbocharging pressure regulator

vacuum pipe (5) .

aUnclip:

-the turbocharging pressure regulator vacuum pipe

at (6) ,

-the brake servo vacuum pipe at (7) .

aDisconnect the brake servo vacuum pipe (8) .

aLoosen the clamp (9) for the air-air intercooler air

outlet pipe at the damper valve end.

aDisconnect the intercooler air outlet pipe (10) at the

damper valve end.

aMove aside the intercooler air outlet pipe (10) at the

damper valve end. K9K, and 718

141222

141213

141217

Page 644 of 652

19D-14

ENGINE MOUNTING

Right-hand suspended engine mounting: Removal - Refitting

C44, and K9K

19D

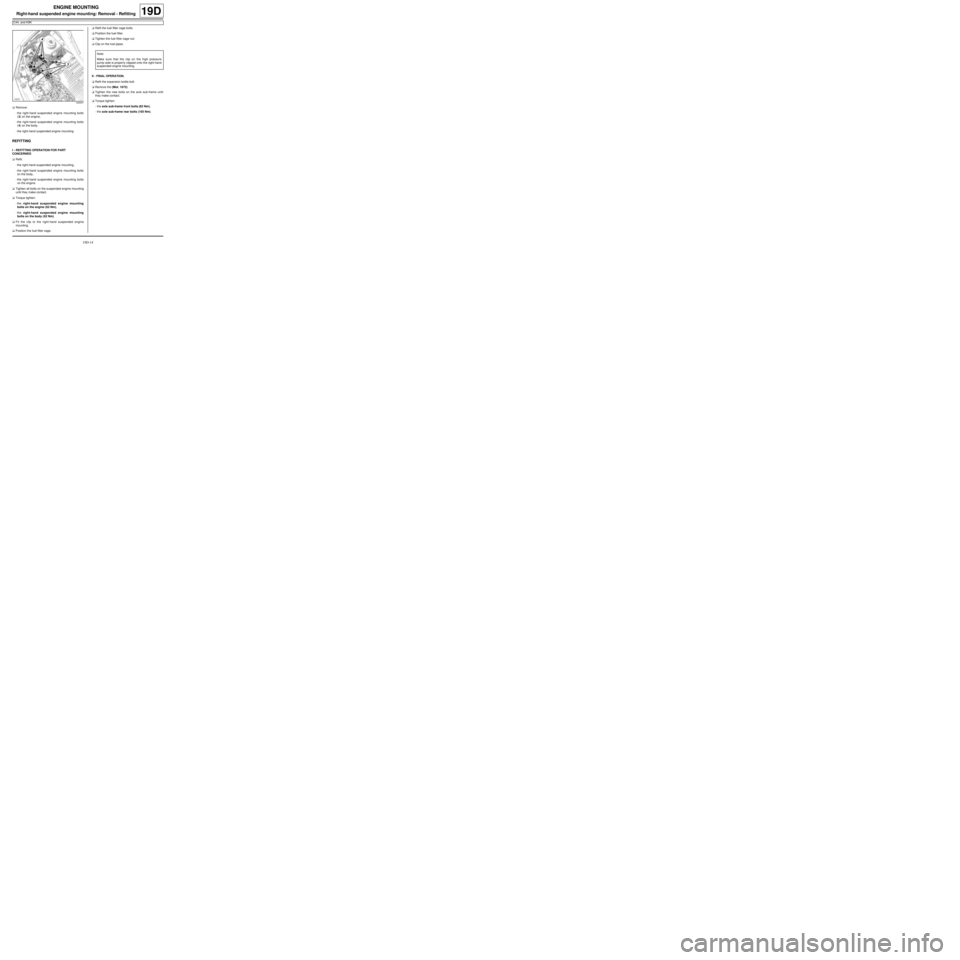

aRemove:

-the right-hand suspended engine mounting bolts

(3) on the engine,

-the right-hand suspended engine mounting bolts

(4) on the body,

-the right-hand suspended engine mounting.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the right-hand suspended engine mounting,

-the right-hand suspended engine mounting bolts

on the body,

-the right-hand suspended engine mounting bolts

on the engine.

aTighten all bolts on the suspended engine mounting

until they make contact.

aTorque tighten:

-the right-hand suspended engine mounting

bolts on the engine (62 Nm),

-the right-hand suspended engine mounting

bolts on the body ( 62 Nm).

aFit the clip to the right-hand suspended engine

mounting.

aPosition the fuel filter cage.aRefit the fuel filter cage bolts.

aPosition the fuel filter.

aTighten the fuel filter cage nut.

aClip on the fuel pipes.

II - FINAL OPERATION.

aRefit the expansion bottle bolt.

aRemove the (Mot. 1672).

aTighten the new bolts on the axle sub-frame until

they make contact.

aTorque tighten:

-the axle sub-frame front bolts (62 Nm),

-the axle sub-frame rear bolts (105 Nm).

120047

Note:

Make sure that the clip on the high pressure

pump side is proper ly clipped onto the right-hand

suspended engine mounting.