ignition RENAULT TWINGO 2009 2.G Engine Diesel Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 269

Page 202 of 269

13B-202

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 54

PR879MAXIMUM AUTHORISED SPEED

PARAMETER

DEFINITIONThis parameter indicates the maximum authorised speed in mph (km/h) requested by

the customer using command SC040 Speed limiter.

NOTESSpecial notes:

It is possible to modify the value of PR879 using command SC040 Speed limiter.

This parameter is valid only on Kangoo 2.

Conformity check: Engine stopped and ignition on, or engine running and engine coolant

temperature > 80

°C

If ET741 "Optional vehicle speed restriction" is ACTIVE, the value of PR879 is between 18 mph (30 km/h) and

150 mph (250 km/h).

In the event of a fault or modification of this speed, use command SC040 Speed limiter.

DCM1.2_V54_PR879

Page 203 of 269

13B-203

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault

memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 54, 5C

PR932DEGREE OF ENGINE OIL DILUTION

PARAMETER

DEFINITIONThis parameter gives the value for the degree of oil wear in %.

NOTESThis parameter is not to be interpreted:

–on the K9K812 engine,

–if PR932 = 0 (Vdiag 58 only).

Conformity check: Engine stopped, ignition on or engine running.

PR932 = 0% for the first 900 miles (1500 km), beyond this value the PR932 changes regularly until it

reaches 100%.

If PR932 = 100% it means that the oil should be changed.

DCM1.2_V54_PR932/DCM1.2_V5C_PR932

Page 204 of 269

13B-204

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault

memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$170.mif

DIESEL INJECTION

Fault finding – Interpretation of parameters13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 54, 5C

PR1015OIL SERVICE INTERVAL

PARAMETER

DEFINITIONThis parameter indicates the vehicle distance before the next oil change in miles (km).

NOTES–This parameter is not to be interpreted:

–on the K9K812 engine,

–if PR1015 = 50000 (Vdiag 58 only).

Conformity check: Engine stopped, ignition on or engine running.

20000 km < PR1015 < 0 km.

This parameter decreases to 0 according to the vehicle distance and the degree of oil wear.

DCM1.2_V54_PR1015/DCM1.2_V5C_PR1015

Page 205 of 269

13B-205V6 MR-413-X44-13B000$180.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

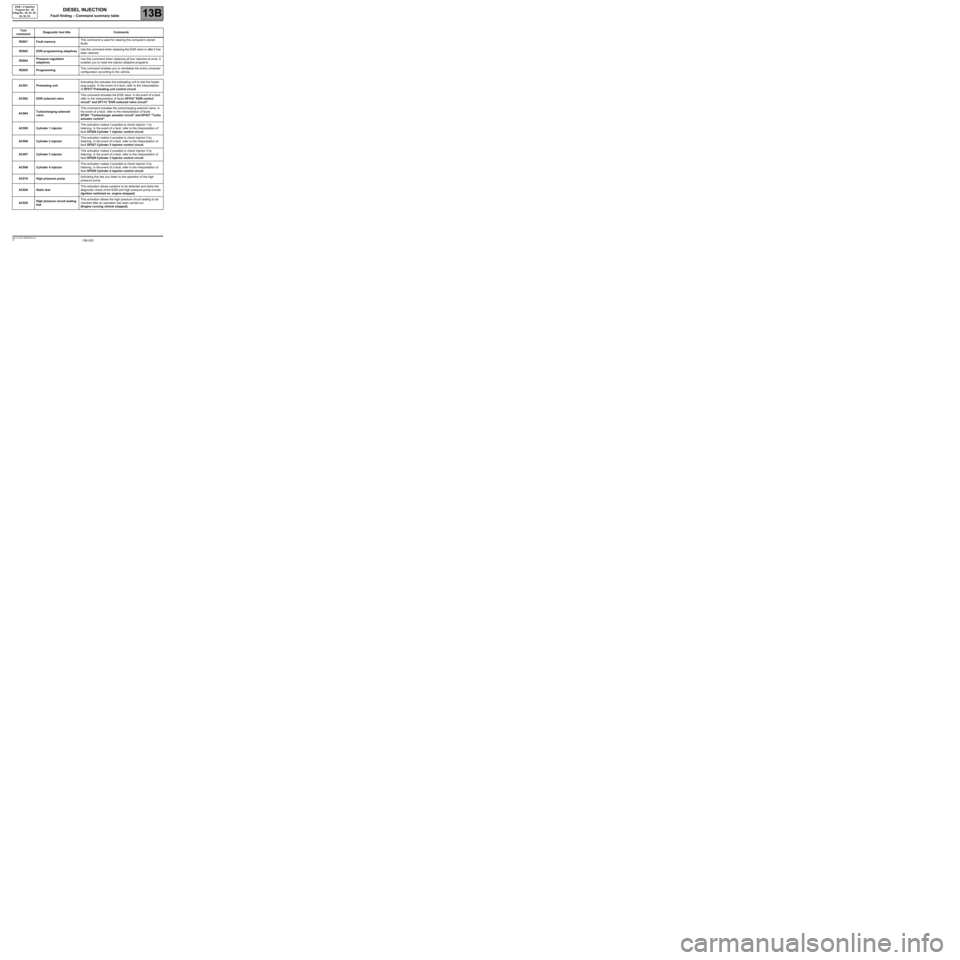

Tool

commandDiagnostic tool titleComments

RZ001 Fault memoryThis command is used for clearing the computer's stored

faults.

RZ002 EGR programming adaptivesUse this command when replacing the EGR valve or after it has

been cleaned.

RZ004Pressure regulation

adaptivesUse this command when replacing all four injectors at once. It

enables you to reset the injector adaptive programs.

RZ005 ProgrammingThis command enables you to reinitialise the entire computer

configuration according to the vehicle.

AC001 Preheating unitActivating this actuates the preheating unit to test the heater

plug supply. In the event of a fault, refer to the interpretation

of DF017 Preheating unit control circuit.

AC002 EGR solenoid valveThis command actuates the EGR valve. In the event of a fault,

refer to the interpretation of faults DF016 "EGR control

circuit" and DF114 "EGR solenoid valve circuit".

AC004Turbocharging solenoid

valveThis command actuates the turbocharging solenoid valve. In

the event of a fault, refer to the interpretation of faults

DF261 "Turbocharger actuator circuit" and DF427 "Turbo

actuator control".

AC005 Cylinder 1 injectorThis activation makes it possible to check injector 1 by

listening. In the event of a fault, refer to the interpretation of

fault DF026 Cylinder 1 injector control circuit.

AC006 Cylinder 2 injectorThis activation makes it possible to check injector 2 by

listening. In the event of a fault, refer to the interpretation of

fault DF027 Cylinder 2 injector control circuit.

AC007 Cylinder 3 injectorThis activation makes it possible to check injector 3 by

listening. In the event of a fault, refer to the interpretation of

fault DF028 Cylinder 3 injector control circuit.

AC008 Cylinder 4 injectorThis activation makes it possible to check injector 4 by

listening. In the event of a fault, refer to the interpretation of

fault DF029 Cylinder 4 injector control circuit.

AC010 High pressure pumpActivating this lets you listen to the operation of the high

pressure pump.

AC028 Static testThis activation allows systems to be detected and starts the

diagnostic check of the EGR and high pressure pump circuits

(Ignition switched on, engine stopped).

AC029High pressure circuit sealing

testThis activation allows the high pressure circuit sealing to be

checked after an operation has been carried out

(Engine running vehicle stopped).

DIESEL INJECTION

Fault finding – Command summary table

Page 212 of 269

13B-212V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

TEST 6 High pressure system check

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

WARNING

Running the starter motor for more than 5 seconds is dangerous and serves no

useful purpose.

Preliminary checks:

–Check for the presence of fuel

–Check that there is no air in the low pressure circuit. Run TEST 1 Low pressure circuit check.

–Ensure that the correct fuel is being used. Run test 13 Diesel fuel conformity check.

The pump's capacity to produce high pressure can be checked by the following procedure:

–With the ignition off, disconnect the low pressure actuator from the pump (IMV brown connector)

and connect a test IMV or the adapter of MOT. 1711.

–Electrically disconnect the four injectors.

–Switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system.

–Go to the Main computer statuses and parameters screen.

–Run the test cold, PR064 "Coolant temperature" < 30

°C or equal to ambient temperature.

–Engage the starter for 5 seconds.

–Read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

A

DCM1.2_V48_TEST6/DCM1.2_V4C_TEST6/DCM1.2_V50_TEST6/DCM1.2_V54_TEST6/DCM1.2_V58_TEST6/DCM1.2_V5C_TEST6

Page 213 of 269

13B-213V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

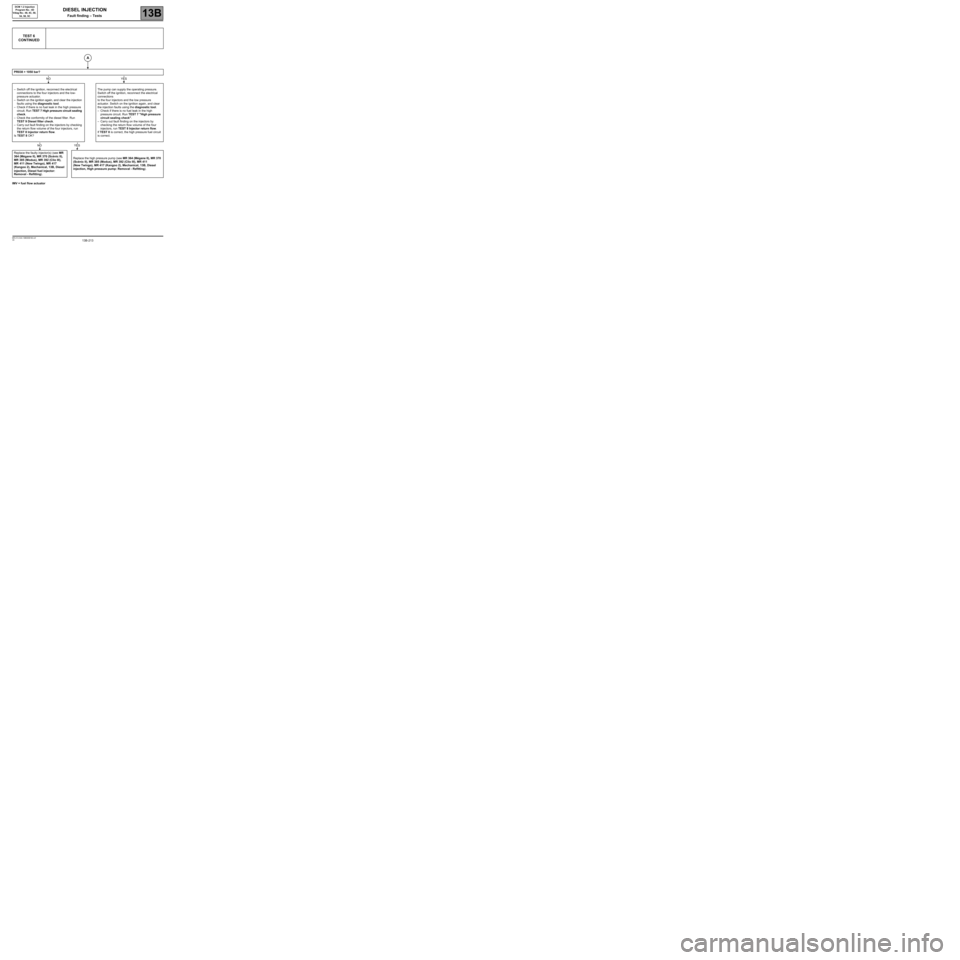

IMV = fuel flow actuator

TEST 6

CONTINUED

PR038 > 1050 bar?

–Switch off the ignition, reconnect the electrical

connections to the four injectors and the low-

pressure actuator.

–Switch on the ignition again, and clear the injection

faults using the diagnostic tool.

–Check if there is no fuel leak in the high pressure

circuit. Run TEST 7 High pressure circuit sealing

check.

–Check the conformity of the diesel filter. Run

TEST 9 Diesel filter check.

–Carry out fault finding on the injectors by checking

the return flow volume of the four injectors, run

TEST 8 Injector return flow.

Is TEST 8 OK?The pump can supply the operating pressure.

Switch off the ignition, reconnect the electrical

connections

to the four injectors and the low pressure

actuator. Switch on the ignition again, and clear

the injection faults using the diagnostic tool.

–Check if there is no fuel leak in the high

pressure circuit. Run TEST 7 "High pressure

circuit sealing check".

–Carry out fault finding on the injectors by

checking the return flow volume of the four

injectors, run TEST 8 Injector return flow.

If TEST 8 is correct, the high pressure fuel circuit

is correct.

Replace the faulty injector(s) (see MR

364 (Mégane II), MR 370 (Scénic II),

MR 385 (Modus), MR 392 (Clio III),

MR 411 (New Twingo), MR 417

(Kangoo 2), Mechanical, 13B, Diesel

injection, Diesel fuel injector:

Removal - Refitting).Replace the high pressure pump (see MR 364 (Mégane II), MR 370

(Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411

(New Twingo), MR 417 (Kangoo 2), Mechanical, 13B, Diesel

injection, High pressure pump: Removal - Refitting).

A

NOYES

NOYES

Page 215 of 269

13B-215V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

TEST 8 Injector return flow

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

Does the engine start?

Command AC029 High pressure circuit sealing also checks the return volume of each injector to detect

any leaks inside the injectors.

Be careful with any objects (tool or other) on the engine housing during the four cycles of the operation

(possible vibrations).

Tooling required

–Mot. 1711 Injector flow measuring kit.

Or: Use four tubes of internal diameter 4 mm and approximately 50 cm long, and four graduated measuring

cylinders.

Procedure

–Check that the engine coolant temperature is above 60

°C,

–switch off the ignition,

–disconnect the return pipes from the four injectors,

–cap the pump venturi tube to prevent the low-pressure circuit from depriming,

–connect the four transparent tubes in place of the return pipes,

–put the other ends of the four pipes into four graduated measuring cylinders.

When all the preparations are complete, start the engine and leave it running:

30 secondsfor Euro 4 engines: K9K 766 - 768 (Clio III and Modus); K9K 724 (Mégane II

and Scénic II); K9K 740 -718 (New Twingo); K9K 800 - 802 - 812 (Kangoo 2).

Let it idle for 2 minutesfor Euro 3 type engines: K9K 750 - 752 (Clio III and Modus).

Note:

These time periods must be respected for the test results to be interpreted correctly.

–Run command AC029 High pressure circuit sealing check.

The engine will carry out automatically a cycle of four accelerations to increase the rail pressure and measure

internal injector leaks under these conditions.

–When the cycle has finished, run command AC029 High pressure circuit sealing test a second time to

obtain the correct return volume reading for each injector.

–Switch off the engine at the end of the cycle.

NOA

YES

DCM1.2_V48_TEST8/DCM1.2_V4C_TEST8/DCM1.2_V50_TEST8/DCM1.2_V54_TEST8/DCM1.2_V58_TEST8/DCM1.2_V5C_TEST8

Page 216 of 269

13B-216V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

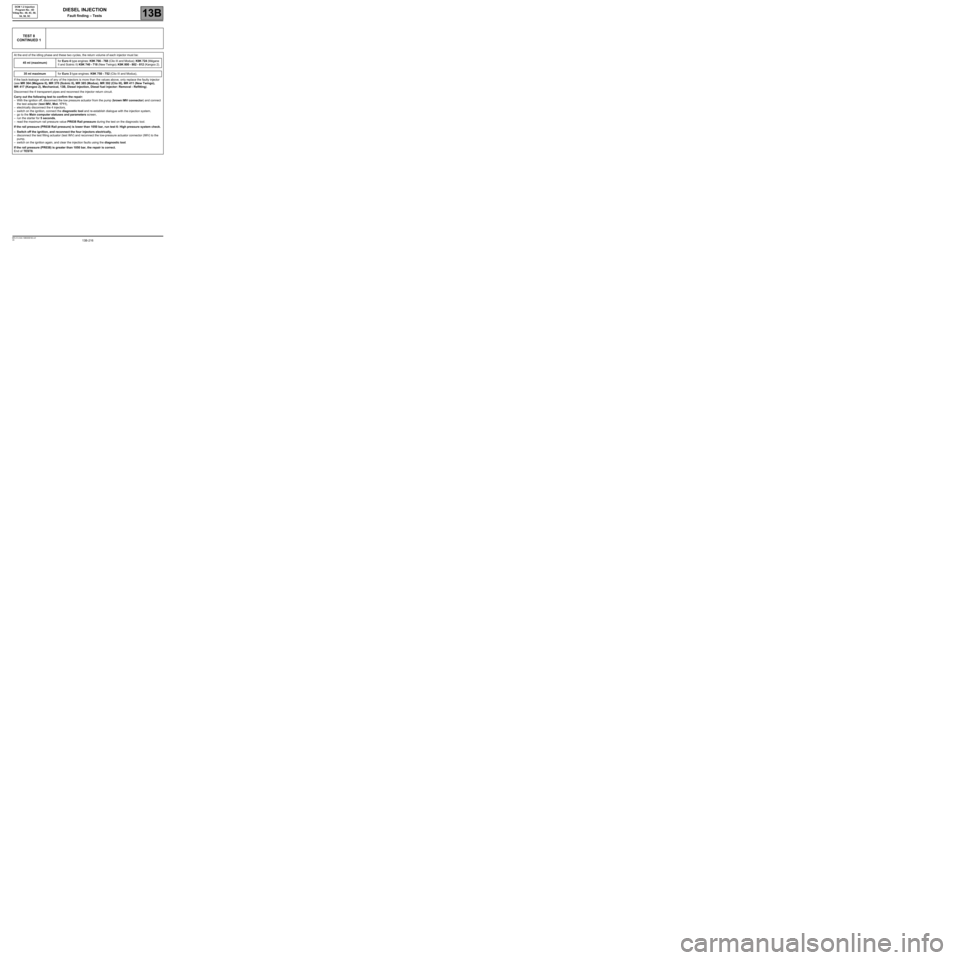

TEST 8

CONTINUED 1

At the end of the idling phase and these two cycles, the return volume of each injector must be:

45 ml (maximum)for Euro 4 type engines: K9K 766 - 768 (Clio III and Modus); K9K 724 (Mégane

II and Scénic II) K9K 740 - 718 (New Twingo); K9K 800 - 802 - 812 (Kangoo 2).

35 ml maximumfor Euro 3 type engines: K9K 750 - 752 (Clio III and Modus),

If the back-leakage volume of any of the injectors is more than the values above, only replace the faulty injector

(see MR 364 (Mégane II), MR 370 (Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo),

MR 417 (Kangoo 2), Mechanical, 13B, Diesel injection, Diesel fuel injector: Removal - Refitting).

Disconnect the 4 transparent pipes and reconnect the injector return circuit.

Carry out the following test to confirm the repair:

–With the ignition off, disconnect the low pressure actuator from the pump (brown IMV connector) and connect

the test adapter (test IMV, Mot. 1711),

–electrically disconnect the 4 injectors,

–switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system,

–go to the Main computer statuses and parameters screen,

–run the starter for 5 seconds,

–read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

If the rail pressure (PR038 Rail pressure) is lower than 1050 bar, run test 6: High pressure system check.

–Switch off the ignition, and reconnect the four injectors electrically,

–disconnect the test filling actuator (test IMV) and reconnect the low-pressure actuator connector (IMV) to the

pump,

–switch on the ignition again, and clear the injection faults using the diagnostic tool.

If the rail pressure (PR038) is greater than 1050 bar, the repair is correct.

End of TEST8.

Page 217 of 269

13B-217V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

TEST 8

CONTINUED 2

If the engine does not start, only the static leakage can be measured, i.e. the leakage with the injector closed, not

actuated and under high pressure.

Make sure that the ignition circuit is working correctly (minimum engine speed 200 rpm).

Tooling required

–Mot. 1711 Injector flow measuring kit.

Or: Use four tubes of internal diameter 4 mm and approximately 50 cm long and a test adapter (TEST IMV).

Procedure

–Switch off the ignition,

–disconnect the return pipes from the four injectors,

–cap the pump venturi tube to prevent the low-pressure circuit from depriming,

–connect the four transparent pipes in place of the return pipes (Mot. 1711),

–disconnect the low pressure actuator from the pump (brown IMV connector) and connect a test IMV or

the Mot. 1711 adapter,

–disconnect the four injectors electrically,

–switch on the ignition and engage the starter for 5 seconds,

–measure the amount of diesel fuel in each pipe.

If the return leakage is greater than 10 cm, replace the injector(s) (see MR 364 (Mégane II), MR 370

(Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo), MR 417 (Kangoo 2), Mechanical, 13B,

Diesel injection, Diesel fuel injector: Removal - Refitting).

Switch off the ignition, and reconnect the four injectors electrically.

Disconnect the test low pressure actuator and reconnect the low pressure actuator connector to the pump.

Disconnect the four transparent tubes and reconnect the injectors return circuit. Switch on the ignition again,

and clear the injection faults using the diagnostic tool.

Carry out the following test to confirm the repair:

–With the ignition off, disconnect the low pressure actuator from the pump (brown IMV connector)

and connect the test adapter (test IMV, Mot. 1711),

–disconnect the four injectors electrically,

–switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system,

–go to the Main computer statuses and parameters screen,

–run the starter for 5 seconds,

–read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

If the rail pressure (PR038 Rail pressure) is lower than 1050 bar, run test 6: High pressure system check.

–Switch off the ignition, and reconnect the four injectors electrically,

–disconnect the test IMV and reconnect the low-pressure actuator connector to the pump,

–switch on the ignition again, and clear the injection faults using the diagnostic tool.

End of TEST 8.

A

Page 218 of 269

13B-218V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

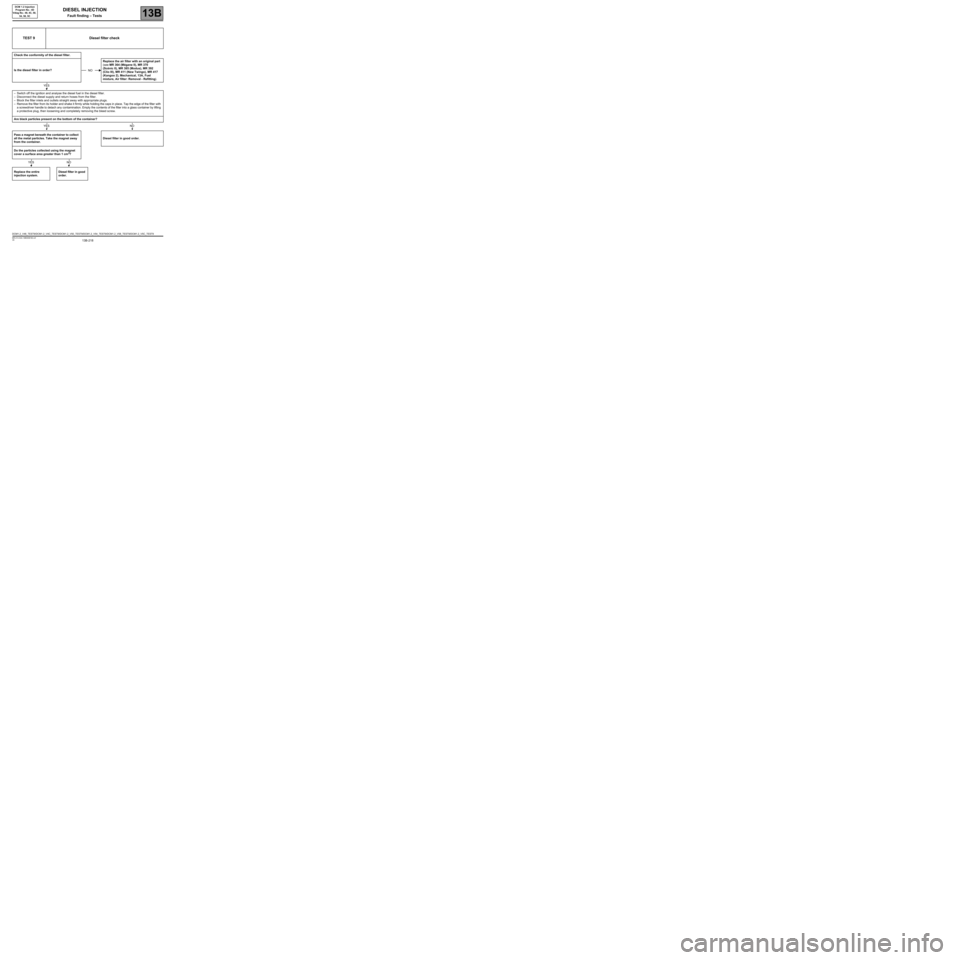

TEST 9 Diesel filter check

Check the conformity of the diesel filter.

Is the diesel filter in order?Replace the air filter with an original part

(see MR 364 (Mégane II), MR 370

(Scénic II), MR 385 (Modus), MR 392

(Clio III), MR 411 (New Twingo), MR 417

(Kangoo 2), Mechanical, 13A, Fuel

mixture, Air filter: Removal - Refitting).

–Switch off the ignition and analyse the diesel fuel in the diesel filter.

–Disconnect the diesel supply and return hoses from the filter.

–Block the filter inlets and outlets straight away with appropriate plugs.

–Remove the filter from its holder and shake it firmly while holding the caps in place. Tap the edge of the filter with

a screwdriver handle to detach any contamination. Empty the contents of the filter into a glass container by lifting

a protective plug, then loosening and completely removing the bleed screw.

Are black particles present on the bottom of the container?

Pass a magnet beneath the container to collect

all the metal particles. Take the magnet away

from the container.Diesel filter in good order.

Do the particles collected using the magnet

cover a surface area greater than 1 cm

2?

Replace the entire

injection system.Diesel filter in good

order.

NO

YES

YESNO

YESNO

DCM1.2_V48_TEST9/DCM1.2_V4C_TEST9/DCM1.2_V50_TEST9/DCM1.2_V54_TEST9/DCM1.2_V58_TEST9/DCM1.2_V5C_TEST9