RENAULT TWINGO 2009 2.G General Vehicle Information Service Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 46

Page 41 of 46

04B-6

CONSUMABLES - PRODUCTS

Vehicle: Parts and consumables for the repair

04B

GREASE

WHITE GREASE 400 ml aerosol77 11 236 174

OPENING ELEMENT MECHA-

NISM GREASE20 g sachets77 11 419 865

SILICONE LUBRICANT 500 ml aerosol77 11 236 168

SILICONE-FREE LUBRICANT 500 ml aerosol77 11 236 167

SOUNDPROOFING

SPR GREY EVOLUTION 1 l cartridge77 11 419 114

SPR GREY EVOLUTION SPRAY 400 ml aerosol77 11 419 116

SPR BLACK EVOLUTION II 1 l cartridge77 11 419 115

SOUNDPROOFING PAD (3.5 Kg/

m²)Pack of 10 77 01 423 546

SOUNDPROOFING PAD (6.5 Kg/

m²)Pack of 5 77 01 423 269

POLISHING

POLISHING LIQUID 1 L container77 11 420 288

FINISHING LIQUID 1 L container77 11 420 289

MASTIC

Universal mastic

GALAXI 2.5 kg pack77 11 172 238

OPTIMAX 1.23 l cartridge77 11 172 239

EXCELLENCE +

For finishing plastic repair960 g car tridge77 11 423 539

1 kg pack77 11 423 540

Plugging mastic

XFIBRE FIBREGLASS MASTIC 975 kg pack77 11 172 235

STANDARD BASIX POLYESTER

MASTIC1.975 kg pack77 11 172 234

ALUX ALUMINIUM MASTIC 975 kg pack77 11 172 236

Sprayable mastic

PIXTO SPRAYABLE POLYESTER

MASTIC1.5 kg tin77 11 172 237

Finishing mastic

IXTRA POLYESTER MASTIC 1.625 kg pack77 11 172 233

Anti-grit mastic

Page 42 of 46

04B-7

CONSUMABLES - PRODUCTS

Vehicle: Parts and consumables for the repair

04B

MAG PRO 1 310 ml cartridge77 11 172 679

MAG PRO 3 (Dual component)1.5 kg tin77 11 218 364

SURFACE CLEANER

HEPTANE 500 ml container77 11 170 064

SOLVENT SURFACE CLEANER 5 L container77 01 404 178

WATER-BASED SURFACE

CLEANER5 L container77 11 421 337

ANTISTATIC THINNER (for plastic

materials)400 ml aerosol77 01 408 493

COMPOSITE MATERIAL REPAIR BY BONDING

PLASTIC REPAIR KIT 77 11 170 064

NOZZLE FOR PLASTIC REPAIR

KIT77 11 423 523

PLASTIC REPAIR CLEANER 1 L container77 11 423 517

PLASTIC REPAIR PRIMER 150 ml bottle77 11 423 518

PLASTIC REPAIR ADHESIVE 2 x 25 ml bicomponent cartridge77 11 423 519

PLASTIC REPAIR CLOTH 90 m roller77 11 423 520

PLASTIC REPAIR NOZZLES 12 nozzles 77 11 423 522

COMPOSITE MATERIAL REPAIR BY WELDING

PLASTIC WELD REPAIR SET 77 11 425 742

PROTECTIVE STRIPSBag of 10 protective strips77 11 425 744

STAINLESS STEEL MESHBag of 2 meshes77 11 425 743

COOLER 400 ml aerosol77 11 425 745

BRUSHBox of 10 brushes77 11 237 793

WINDOW MASKING TAPE

10 MM WINDSCREEN TAPE 77 11 171 708

20 MM WINDSCREEN TAPE 77 11 171 709

PROTECTIVE WELDING

ANTI-SPLASH SPRAY 400 ml aerosol77 11 218 270

SPECIFIED UNDERCOAT

PRE-TREATMENT PRIMER WITH-

OUT ZINC CHROMATE (I-Alpha) +

THINNER1 L container77 11 420 027 (Primer)

77 11 420 028 (Thinner)

Page 43 of 46

04B-8

CONSUMABLES - PRODUCTS

Vehicle: Parts and consumables for the repair

04B

I-PREMIA REACTIVE PRIMER (do

not use on aluminium)3.5 l container77 11 239 243 (Primer)

77 11 228 654 (Thinner)

I-PREMIA REACTIVE PRIMER (do

not use on aluminium)400 ml aerosol77 11 419 416

ADHÉRA SPRAY (adhesion pro-

moter for thermoplastics)400 ml aerosol77 11 423 734

PRIMARA BLACK (adhesion pro-

moter/pr imer for thermoplastics)1 L container77 11 423 735

77 11 171 514 (Activator)

PRIMARA (adhesion promoter/

primer for thermoplastics)1 L container77 11 171 513

77 11 171 514 (Activator)

UNDERCOAT

LEVIA 3.5 l container77 11 228 651

FORTIA 3.5 l container77 11 228 650

Page 44 of 46

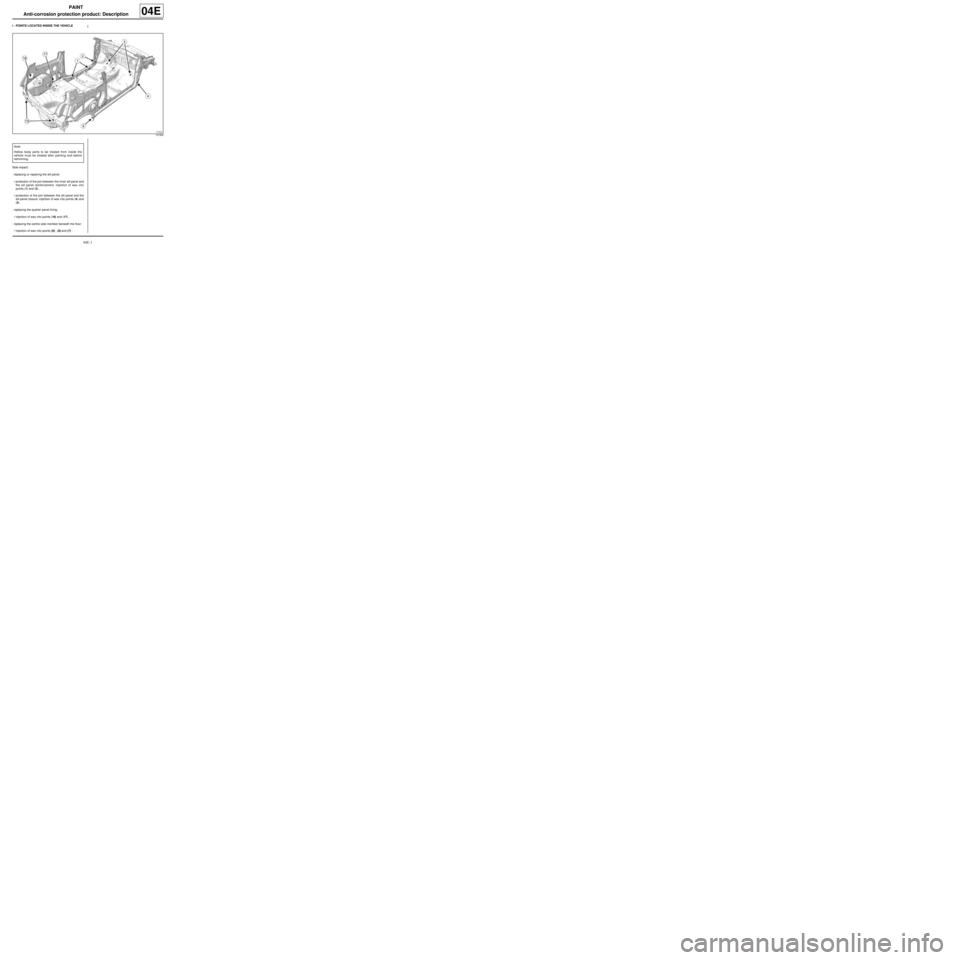

04E-1

PAINT

Anti-corrosion protection product: Description

04E

I - POINTS LOCATED INSIDE THE VEHICLE

Side impact:

-replacing or repairing the sill panel:

•protection of the join between the inner sill panel and

the sill panel reinforcement: injection of wax into

points (1) and (2) ,

•protection of the join between the sill panel and the

sill panel closure: injection of wax into points (4) and

(5) .

-replacing the quarter panel lining:

•injection of wax into points (16) and (17) .

-replacing the centre side member beneath the floor:

•injection of wax into points (6) , (8) and (7) .

121909

Note:

Hollow body parts to be treated from inside the

vehicle must be treated after painting and before

retrimming.

Page 45 of 46

04E-2

PAINT

Anti-corrosion protection product: Description

04E

II - POINTS BENEATH THE VEHICLE

Frontal impact:

-replacing or repairing the front side member, the front

side member closure panel and the front sub-frame

mounting unit:

•injection of wax into points (3) and (9) .

-replacing the front side cross member or the front half

unit:

•injection of wax into points (10) and (11) .

Rear impact:

-replacing the complete rear side member:

•injection of wax into points (12) and (13) .

-Replacement of the rear end panel:

•injection of wax into point (15) .-replacing the rear floor centre cross member:

•injection of wax into points (13) and (14) .

III - PRODUCTS AND EQUIPMENT FOR TREATING

HOLLOW SECTIONS

The products and equipment required for carrying out

this work are available from the Parts Department.

121910

Note:

Blanking pieces are fitted to the injection points

located beneath the vehicle. When any work is car-

ried out on the vehicle, plug all the points used for

injection. Replace any damaged or deformed blank-

ing pieces with new ones.

Page 46 of 46

04E-3

PAINT

Anti-corrosion protection product: Description

04E

« PAC1, PAC2 » kit

The hollow body parts of the structure of the vehicle

are protected in the factory by injecting hot wax. To

guarantee equivalent protection after repair, inject one

after the other the two complementary products which

make up a « PAC1, PAC2 » kit.

After injection, all the orifices must be covered using

blanking covers moulded to fit each one.

The necessary information concerning blanking covers

can be found in the Parts Catalogue for the vehicle.

Injector assemblyProtective wax

The subframe under the floor is protected with a spe-

cial wax.

IV - OPERATING PROCEDURE FOR TREATING

HOLLOW SECTIONS

Insert the nozzle tip until it reaches the end of the hol-

low section (21) .

Inject the wax whilst retracting the nozzle tip (22) .

272-2

272-1

(18) Wax flow control

(19) Quick-release union end piece

(20) Interchangeable injection hose

272

109692