wiring RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Climate Control User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 99

Page 59 of 99

62B-59

MR-413-X44-62B000$644_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of parameters

Vdiag No.: 44

62B

PR092

BATTERY VOLTAGE

NOTESUse the Wiring Diagram Technical Note for the New Twingo.

This parameter specifies the supply voltage of the climate control computer.

This parameter must display a voltage equal to: 10.5 V < X < 14.4 V with the engine running.

Using a multimeter, check the consistency of the parameter by measuring the voltage across the battery

terminals.

If the parameter corresponds with the voltage measured on the battery terminals, run fault finding on the electric

charging circuit.

If the parameter does not correspond with the battery voltage, check the condition and position of fuse F29 (15A)

in the passenger compartment fuse unit.

Consult section 81C Fuses.

Disconnect the connectors of the following components of connection SP2:

●Component connector 615

●Component connector 419

●Component connector 645

●Component connector 319

●Component connector 261

●Component connector 653

●Component connector 1428

With connector A of component 419 disconnected, check the insulation and continuity of connection SP2

between components 419 and 1016.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check the vehicle earth connection NAM of the connector of component 419.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the wiring, otherwise replace the wiring.

If these checks do not reveal any faults, carry out a test on each of the components involved in connection

SP2 (short circuit).

AFTER REPAIRRepeat the conformity check from the start.

CLIM_V44_PR092

Page 68 of 99

62B-68

MR-413-X44-62B000$828_eng.mif

V1

62B

CLIMATE CONTROL

Diagnostic - Fault finding chart

ALP 1 No dialogue with the computer

NOTESSpecial notes: To run fault finding on the vehicle computers, use the key to switch on

the ignition.

Use the W iring Diagram Technical Note for the New Twingo.

Check that the vehicle is equipped with climate control.

Try to establish dialogue with a computer on another vehicle to make sure that the diagnostic tool is not faulty.

If the tool is not at fault, and dialogue cannot be established with any other computer on the same vehicle, the

cause could be a faulty computer interfering on the multiplex network.

Check the battery voltage and perform the necessary operations to obtain a correct voltage (9.5 V < Battery

voltage < 17.5 V, see section 16A Starting-charging).

Check:

–the connection between the diagnostic tool and the diagnostic probe (lead in good condition),

–the connection between the diagnostic sensor and the diagnostic socket (lead in good condition).

Carry out fault finding on the multiplex network using the diagnostic tool (see 88B, Multiplex).

Check the condition and position of fuse F29 (15 A) in the passenger compartment fuse box.

Consult section 81C Fuses.

Disconnect the connectors of the following components of connection SP2:

●Component connector 615

●Component connector 419

●Component connector 645

●Component connector 319

●Component connector 261

●Component connector 653

●Component connector 1428

Check the insulation and continuity of connection SP2 between components 419 and 1016.

Check the vehicle earth connection NAM of the connector of component 419.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the wiring, otherwise replace the wiring.

If these checks do not reveal any faults, carry out a test on each of the components involved in connection

SP2 (short circuit).

Check the condition and position of fuse F18 (10 A) in the passenger compartment fuse box.

Consult section 81C Fuses.

Disconnect the connectors of the following components of connection BP6:

●Component connector 995

●Component connector 419

AFTER REPAIRCarry out a complete check with the diagnostic tool.

CLIM_V44_ALP1

Vdiag No.: 44

MR-413-X44-62B000$828_eng.mif

Page 69 of 99

62B-69

MR-413-X44-62B000$828_eng.mif

V1

CLIMATE CONTROL

Diagnostic - Fault finding chart

Vdiag No.: 44

62B

ALP 1

CONTINUED

●Component connector 645

Check the insulation and continuity of connection BP6 between components 419 and 1016.

Check the vehicle earth connection NAM of the connector of component 419.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the wiring, otherwise replace the wiring.

If these checks do not reveal any faults, carry out a test on each of the components involved in connection

BP6 (short circuit).

Ensure that the supply to the diagnostic socket is correct:

Check the condition and position of fuse F12 (5 A) in the passenger compartment fuse box.

Consult section 81C Fuses.

Connector of component 645 of connection BP19 disconnected:

–Check for + after ignition feed on connection BP19 of component 225.

If the + after ignition feed on connection BP 19 is not guaranteed, check component 1016.

–Check connections NAM and MAM of component 225.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for the

repair), repair the wiring, otherwise replace the wiring.

If these checks do not reveal any faults, carry out a test on each of the components involved in connection

BP19 (short circuit).

If dialogue has still not been established after these checks, contact the Techline.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

CLIM_V44_ALP1

Page 77 of 99

62B-77

MR-413-X44-62B000$828_eng.mif

V1

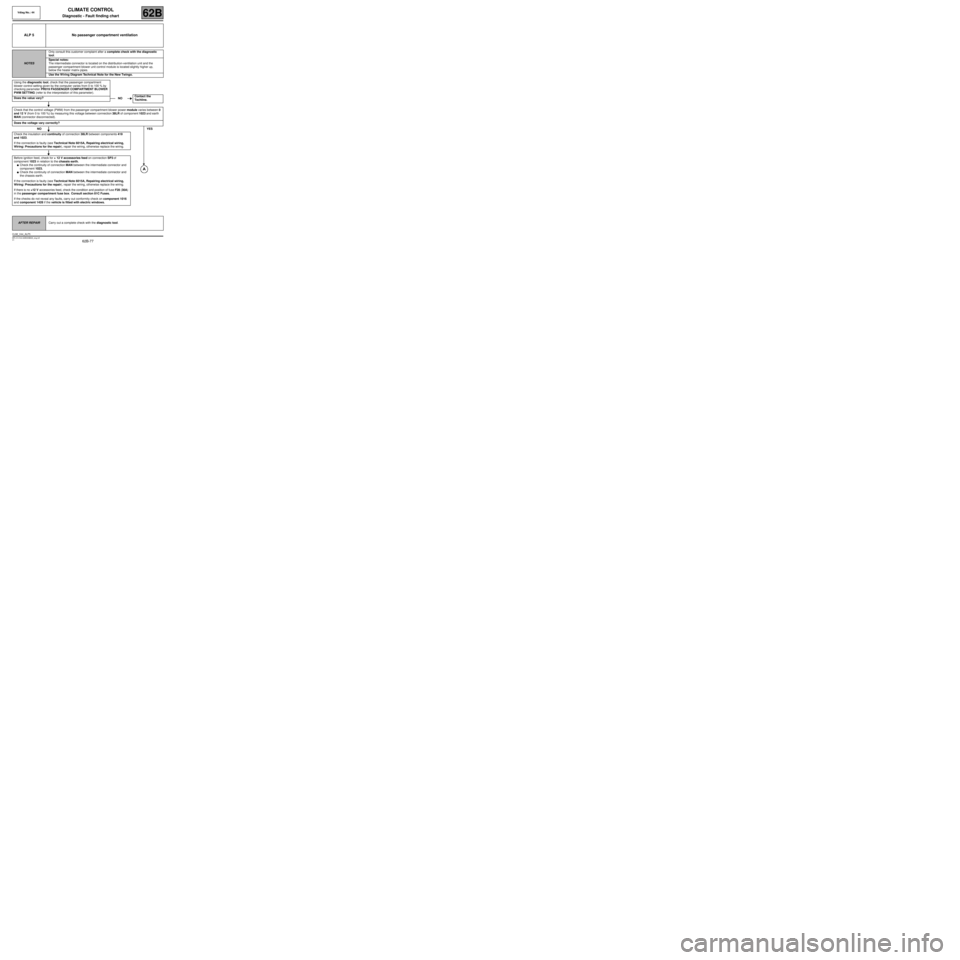

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 5 No passenger compartment ventilation

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Special notes:

The intermediate connector is located on the distribution-ventilation unit and the

passenger compartment blower unit control module is located slightly higher up,

below the heater matrix pipes.

Use the W iring Diagram Technical Note for the New Twingo.

Using the diagnostic tool, check that the passenger compartment

blower control setting given by the computer varies from 0 to 100 % by

checking parameter PR019 PASSENGER COMPARTMENT BLOWER

PWM SETTING (refer to the interpretation of this parameter).

Does the value vary?

Check that the control voltage (PWM) from the passenger compartment blower power module varies between 0

and 12 V (from 0 to 100 %) by measuring this voltage between connection 38LR of component 1023 and earth

MAN (connector disconnected).

Does the voltage vary correctly?

NOYES

Check the insulation and continuity of connection 38LR between components 419

and 1023.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for the repair), repair the wiring, otherwise replace the wiring.

Before ignition feed, check for + 12 V accessories feed on connection SP3 of

component 1023 in relation to the chassis earth.

●Check the continuity of connection MAN between the intermediate connector and

component 1023.

●Check the continuity of connection MAN between the intermediate connector and

the chassis earth.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for the repair), repair the wiring, otherwise replace the wiring.

If there is no +12 V accessories feed, check the condition and position of fuse F28 (30A)

in the passenger compartment fuse box. Consult section 81C Fuses.

If the checks do not reveal any faults, carry out conformity check on component 1016

and component 1428 if the vehicle is fitted with electric windows.

NOContact the

Techline.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

CLIM_V44_ALP5

Page 78 of 99

62B-78

MR-413-X44-62B000$828_eng.mif

V1

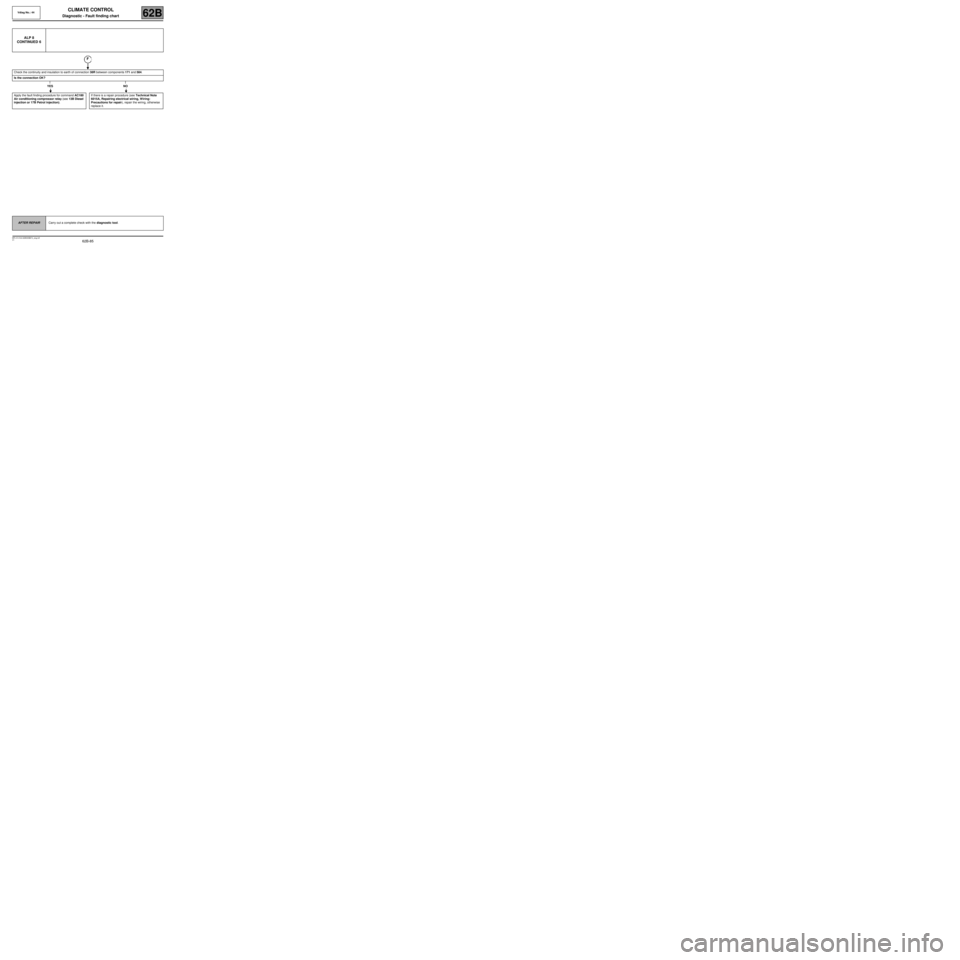

CLIMATE CONTROL

Diagnostic - Fault finding chart

Vdiag No.: 44

62B

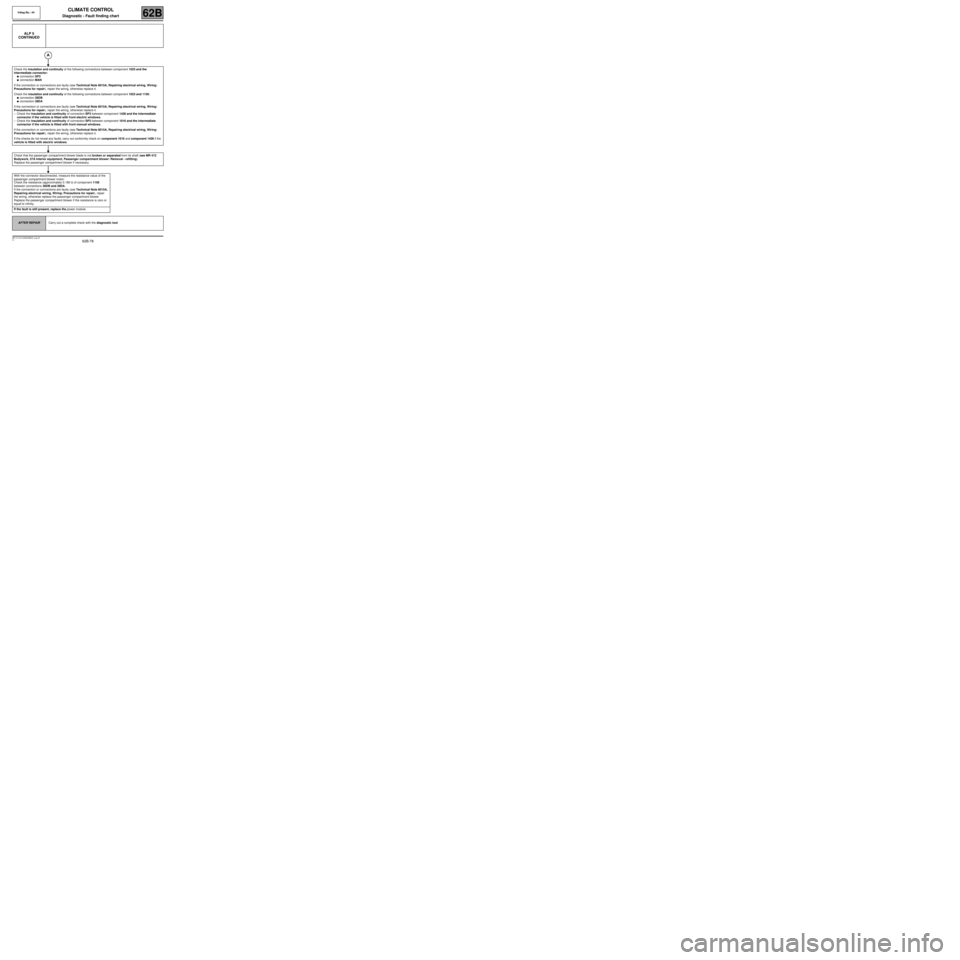

ALP 5

CONTINUED

Check the insulation and continuity of the following connections between component 1023 and the

intermediate connector:

●connection SP3

●connection MAN

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation and continuity of the following connections between component 1023 and 1156:

●connection 38DB

●connection 38DA

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

–Check the insulation and continuity of connection SP3 between component 1428 and the intermediate

connector if the vehicle is fitted with front electric windows.

–Check the insulation and continuity of connection SP3 between component 1016 and the intermediate

connector if the vehicle is fitted with front manual windows.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

If the checks do not reveal any faults, carry out conformity check on component 1016 and component 1428 if the

vehicle is fitted with electric windows.

Check that the passenger compartment blower blade is not broken or separated from its shaft (see MR 412

Bodywork, 57A Interior equipment, Passenger compartment blower: Removal - refitting).

Replace the passenger compartment blower if necessary.

With the connector disconnected, measure the resistance value of the

passenger compartment blower motor:

Check the resistance (approximately 0.180 Ω of component 1156

between connections 38DB and 38DA.

If the connection or connections are faulty (see Technical Note 6015A,

Repairing electrical wiring, Wiring: Precautions for repair), repair

the wiring, otherwise replace the passenger compartment blower.

Replace the passenger compartment blower if the resistance is zero or

equal to infinity.

If the fault is still present, replace the power module.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 79 of 99

62B-79

MR-413-X44-62B000$874_eng.mif

V1

62B

CLIMATE CONTROL

Diagnostic - Fault finding chart

Preliminary cold loop efficiency test

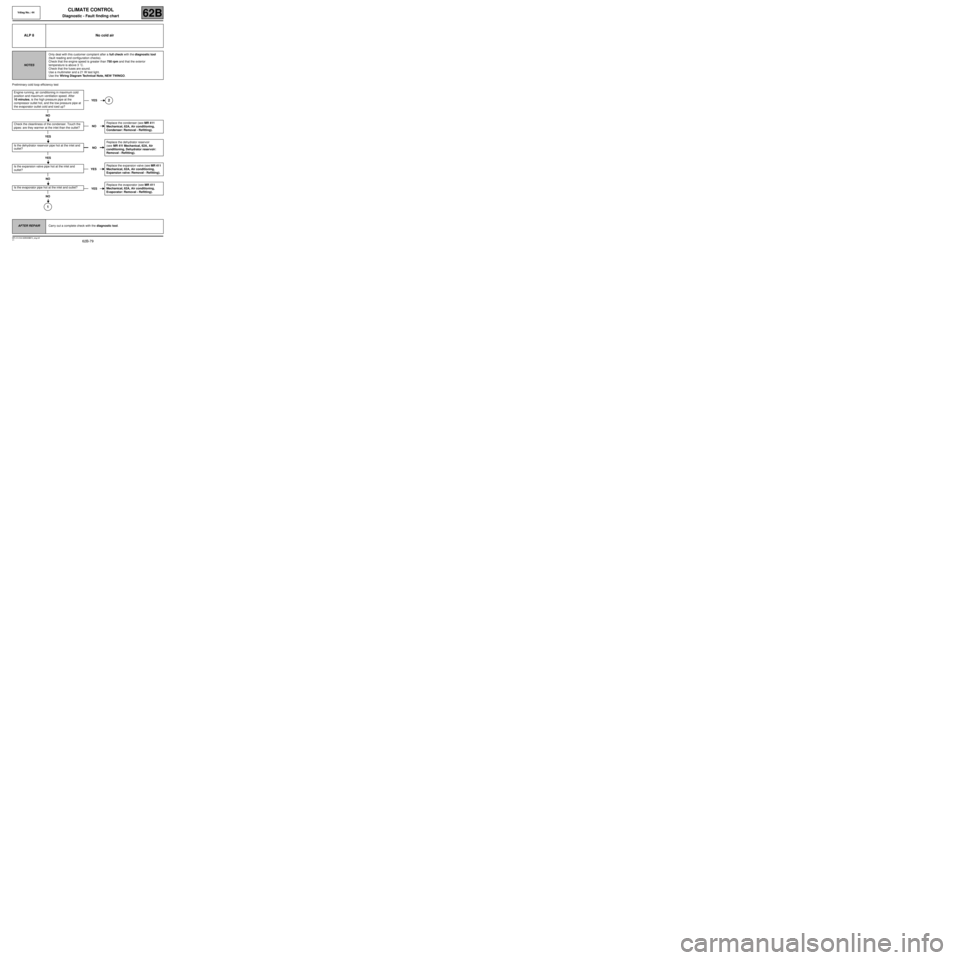

ALP 8 No cold air

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the engine speed is greater than 750 rpm and that the exterior

temperature is above 3 ˚C.

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, NEW TWINGO.

Engine running, air conditioning in maximum cold

position and maximum ventilation speed. After

10 minutes, is the high pressure pipe at the

compressor outlet hot, and the low pressure pipe at

the evaporator outlet cold and iced up?

NO

Check the cleanliness of the condenser. Touch the

pipes: are they warmer at the inlet than the outlet?

YES

Is the dehydrator reservoir pipe hot at the inlet and

outlet?

YES

Is the expansion valve pipe hot at the inlet and

outlet?

NO

Is the evaporator pipe hot at the inlet and outlet?

NO

1

YES2

NOReplace the condenser (see MR 411

Mechanical, 62A, Air conditioning,

Condenser: Removal - Refitting).

NOReplace the dehydrator reservoir

(see MR 411 Mechanical, 62A, Air

conditioning, Dehydrator reservoir:

Removal - Refitting).

YESReplace the expansion valve (see MR 411

Mechanical, 62A, Air conditioning,

Expansion valve: Removal - Refitting).

YESReplace the evaporator (see MR 411

Mechanical, 62A, Air conditioning,

Evaporator: Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Vdiag No.: 44

MR-413-X44-62B000$874_eng.mif

Page 83 of 99

62B-83

MR-413-X44-62B000$874_eng.mif

V1

CLIMATE CONTROL

Diagnostic - Fault finding chart

Vdiag No.: 44

62B

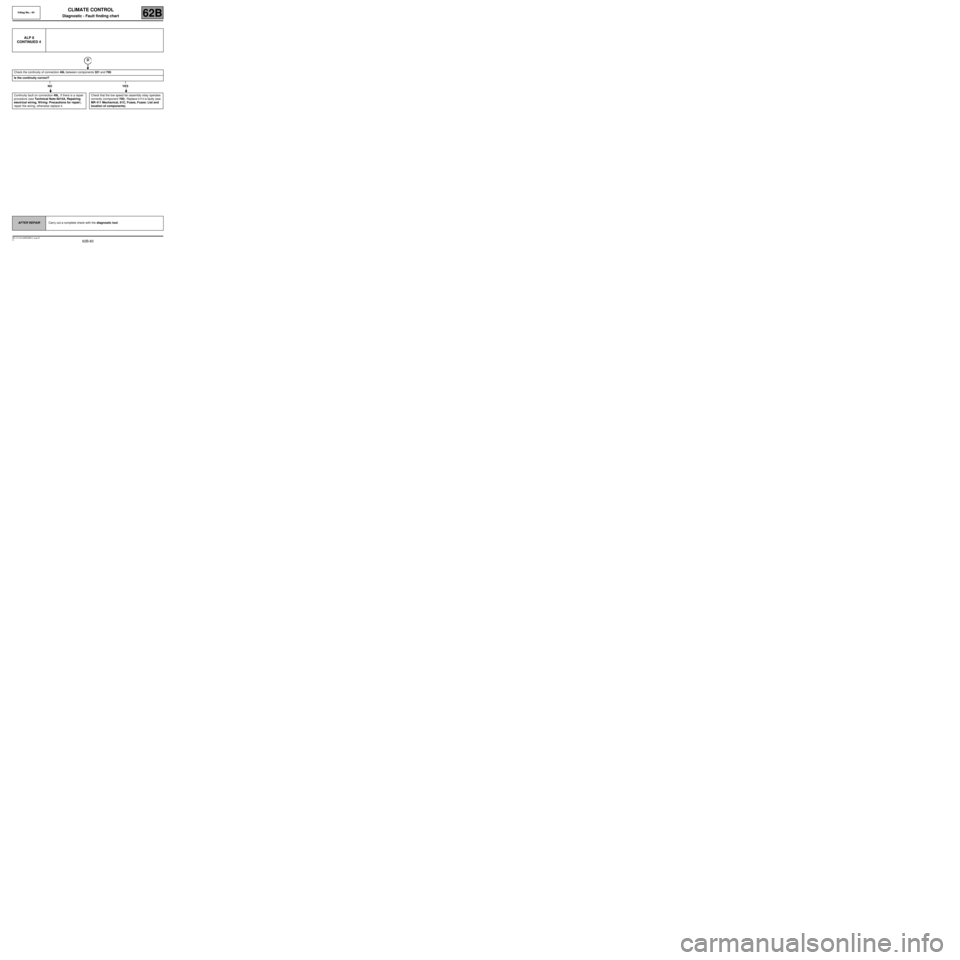

ALP 8

CONTINUED 4

Check the continuity of connection 49L between components 321 and 700.

Is the continuity correct?

NO YES

Continuity fault on connection 49L. If there is a repair

procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair),

repair the wiring, otherwise replace it.Check that the low speed fan assembly relay operates

correctly (component 700). Replace it if it is faulty (see

MR 411 Mechanical, 81C, Fuses, Fuses: List and

location of components).

D

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 84 of 99

62B-84

MR-413-X44-62B000$874_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

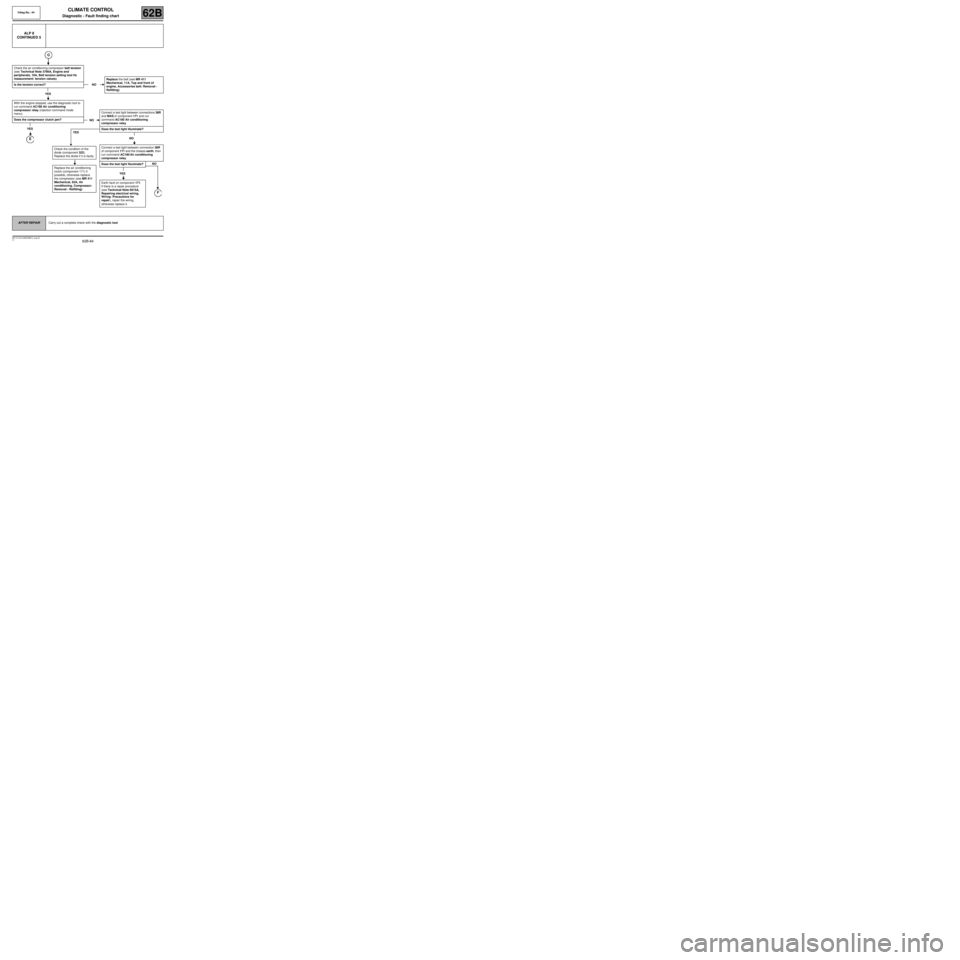

ALP 8

CONTINUED 5

Check the air conditioning compressor belt tension

(see Technical Note 3786A, Engine and

peripherals, 10A, Belt tension setting tool Hz

measurement: tension values).

Is the tension correct?

YES

With the engine stopped, use the diagnostic tool to

run command AC180 Air conditioning

compressor relay (injection command mode

menu).

Does the compressor clutch jam?

YES

E

NOReplace the belt (see MR 411

Mechanical, 11A, Top and front of

engine, Accessories belt: Removal -

Refitting).

NOConnect a test light between connections 38R

and MAS of component 171 and run

command AC180 Air conditioning

compressor relay.

Does the test light illuminate?

NO

Connect a test light between connection 38R

of component 171 and the chassis earth, then

run command AC180 Air conditioning

compressor relay.

Does the test light illuminate?

YES

Earth fault on component 171.

If there is a repair procedure

(see Technical Note 6015A,

Repairing electrical wiring,

Wiring: Precautions for

repair), repair the wiring,

otherwise replace it.

NO

F

YES

Check the condition of the

diode (component 322).

Replace the diode if it is faulty.

Replace the air conditioning

clutch (component 171) if

possible, otherwise replace

the compressor (see MR 411

Mechanical, 62A, Air

conditioning, Compressor:

Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 85 of 99

62B-85

MR-413-X44-62B000$874_eng.mif

V1

CLIMATE CONTROL

Diagnostic - Fault finding chart

Vdiag No.: 44

62B

ALP 8

CONTINUED 6

Check the continuity and insulation to earth of connection 38R between components 171 and 584.

Is the connection OK?

YES NO

Apply the fault finding procedure for command AC180

Air conditioning compressor relay (see 13B Diesel

injection or 17B Petrol injection).If there is a repair procedure (see Technical Note

6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise

replace it.

F

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 87 of 99

62B-87

MR-413-X44-62B000$874_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

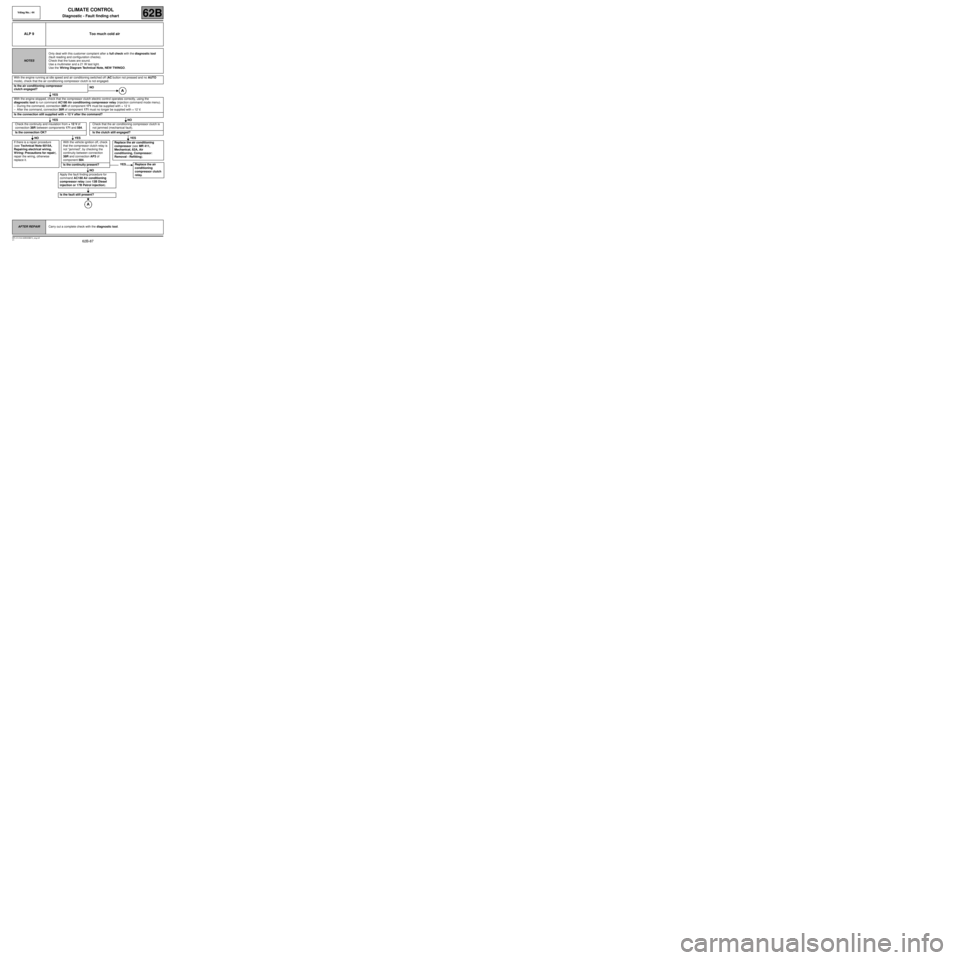

ALP 9 Too much cold air

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, NEW TWINGO.

With the engine running at idle speed and air conditioning switched off (AC button not pressed and no AUTO

mode), check that the air conditioning compressor clutch is not engaged.

Is the air conditioning compressor

clutch engaged?NO

YES

With the engine stopped, check that the compressor clutch electric control operates correctly, using the

diagnostic tool to run command AC180 Air conditioning compressor relay (injection command mode menu).

–During the command, connection 38R of component 171 must be supplied with + 12 V.

–After the command, connection 38R of component 171 must no longer be supplied with + 12 V.

Is the connection still supplied with + 12 V after the command?

YES NO

Check the continuity and insulation from + 12 V of

connection 38R between components 171 and 584.Check that the air conditioning compressor clutch is

not jammed (mechanical fault).

Is the connection OK? Is the clutch still engaged?

NO YES YES

If there is a repair procedure

(see Technical Note 6015A,

Repairing electrical wiring,

Wiring: Precautions for repair),

repair the wiring, otherwise

replace it.With the vehicle ignition off, check

that the compressor clutch relay is

not “jammed”, by checking the

continuity between connection

38R and connection AP3 of

component 584.

Is the continuity present?

NO

Apply the fault finding procedure for

command AC180 Air conditioning

compressor relay (see 13B Diesel

injection or 17B Petrol injection).

Is the fault still present?

Replace the air conditioning

compressor (see MR 411,

Mechanical, 62A, Air

conditioning, Compressor:

Removal - Refitting).

YES Replace the air

conditioning

compressor clutch

relay.

AFTER REPAIRCarry out a complete check with the diagnostic tool.