ECU RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Climate Control Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 99

Page 3 of 99

62B-3

MR-413-X44-62B000$046_eng.mif

V1

CLIMATE CONTROL

Fault finding - Introduction

Vdiag No.: 44

62B

Faults

Faults are declared as either present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

after the + after ignition feed (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors on these lines (corrosion, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Special notes on the conformity check for the air conditioning function:

All variables (statuses and parameters) and commands required for the air conditioning function are divided into

three sub-functions:

●The COLD LOOP sub-function groups together all the information required for producing cold air.

●The HEATING sub-function groups together all the information required for producing warm air.

●The PASSENGER COMPARTMENT VENTILATION sub-function groups together all the information relating to

ventilation and the mixing and distribution of air within the passenger compartment.

Page 25 of 99

62B-25

MR-413-X44-62B000$414_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Interpretation of faults

DF001

PRESENT

OR

STOREDCOMPUTER

1. DEF: Internal electronic fault

NOTESConditions for running fault finding on a present or stored fault:

Apply this fault finding procedure if the fault reappears as present or stored after the

ignition is switched of f and on again.

Switch off the ignition and wait for the immobiliser warning light (Power-latch) to come one,

–Switch on the ignition again.

–Start the engine and switch on the air conditioning.

If the fault recurs, contact the Techline.

If the fault does not reappear: leave the climate control switched on and select various ventilation and air

distribution settings to check that the system is operating correctly.

–Check that no fault is displayed.

If the fault is still present, contact the Techline.

AFTER REPAIRFollow the instructions to confirm repair.

If the computer was replaced (at the request of the Techline), reconfigure the

computer (see Configurations and programming).

Deal with any other faults.

CLIM_V44_DF001

Vdiag No.: 44

MR-413-X44-62B000$414_eng.mif

Page 30 of 99

62B-30

MR-413-X44-62B000$414_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of faults

Vdiag No.: 44

62B

DF012

CONTINUED

With the connector disconnected, measure the resistance value of component 1115 between the following

connections:

●connections S and 38KY,

●connections S and 38LA,

●connections S and 38LB,

●connections S and 38KZ.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

The results of the four checks should be 100 ΩΩ Ω Ω

± 5

ΩΩ Ω Ω

at 20 ˚C, replace the distribution motor if this is not the case.

If the fault is still present, remove the distribution motor but leave it electrically connected, send a motor command

from the distribution buttons on the control panel: switch the distribution setting to demisting (a value of 100 %),

then switch the distribution setting to air vent (a value of 0 %), the motor must change from one direction to the

other. If the connections tested earlier match but the motor does not switch during the commands, replace the

distribution motor.

If the commands have been executed correctly, check that the distribution motor flap is not blocked by trying to

move the gears. Repair if necessary.

If the fault is still present, contact the Techline.

AFTER REPAIRClear the stored faults.

Follow the instructions to confirm repair.

If the motor has been replaced (see Configuration and programming).

Deal with any other faults.

Page 71 of 99

62B-71

MR-413-X44-62B000$828_eng.mif

V1

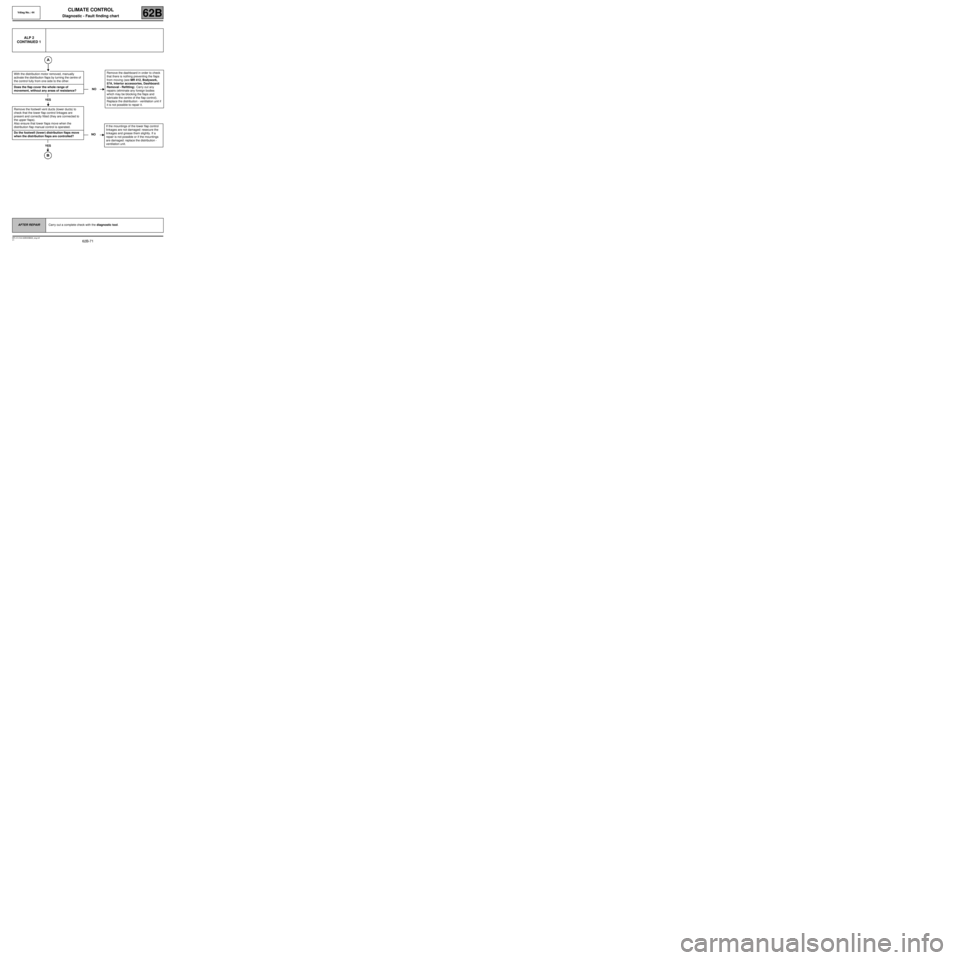

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 2

CONTINUED 1

With the distribution motor removed, manually

activate the distribution flaps by turning the centre of

the control fully from one side to the other.

Does the flap cover the whole range of

movement, without any areas of resistance?

YES

Remove the footwell vent ducts (lower ducts) to

check that the lower flap control linkages are

present and correctly fitted (they are connected to

the upper flaps).

Also ensure that lower flaps move when the

distribution flap manual control is operated.

Do the footwell (lower) distribution flaps move

when the distribution flaps are controlled?

YES

NORemove the dashboard in order to check

that there is nothing preventing the flaps

from moving (see MR 412, Bodywork,

57A, Interior accessories, Dashboard:

Removal - Refitting). Carry out any

repairs (eliminate any foreign bodies

which may be blocking the flaps and

lubricate the centre of the flap control).

Replace the distribution - ventilation unit if

it is not possible to repair it.

NOIf the mountings of the lower flap control

linkages are not damaged: resecure the

linkages and grease them slightly. If a

repair is not possible or if the mountings

are damaged: replace the distribution -

ventilation unit.

AFTER REPAIRCarry out a complete check with the diagnostic tool.