ESP RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Climate Control Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 99

Page 3 of 99

62B-3

MR-413-X44-62B000$046_eng.mif

V1

CLIMATE CONTROL

Fault finding - Introduction

Vdiag No.: 44

62B

Faults

Faults are declared as either present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but have not been diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

after the + after ignition feed (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors on these lines (corrosion, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check data that does not produce a fault on the diagnostic tool because the

data is inconsistent. Therefore, this stage is used to:

–carry out fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint.

–check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Special notes on the conformity check for the air conditioning function:

All variables (statuses and parameters) and commands required for the air conditioning function are divided into

three sub-functions:

●The COLD LOOP sub-function groups together all the information required for producing cold air.

●The HEATING sub-function groups together all the information required for producing warm air.

●The PASSENGER COMPARTMENT VENTILATION sub-function groups together all the information relating to

ventilation and the mixing and distribution of air within the passenger compartment.

Page 6 of 99

62B-6

MR-413-X44-62B000$046_eng.mif

V1

CLIMATE CONTROL

Fault finding - Introduction

Vdiag No.: 44

62B

4. FAULT FINDING PROCEDURE (CONTINUED)

Wiring check

Fault finding problems

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection of the connection:

●Check that the connector is connected correctly and that the male and female parts of the connection are

correctly coupled.

Visual inspection of the area around the connection:

●Check the condition of the mounting (pin, strap, adhesive tape, etc.) if the connectors are attached to the

vehicle.

●Check that there is no damage to the wiring trim (sheath, foam, adhesive tape, etc.) near the wiring.

●Check that there is no damage to the electrical wires at the connector outlets, in particular on the

insulating material (wear, cuts, burns, etc.).

Disconnect the connector to continue the checks.

Visual inspection of the plastic casing:

●Check that there is no mechanical damage (casing crushed, cracked, broken, etc.), in particular to the

fragile components (lever, lock, openings, etc.).

●Check that there is no heat damage (casing melted, darker, deformed, etc.).

●Check that there are no stains (grease, mud, liquid, etc.).

Visual inspection of the metal contacts:

(The female contact is called CLIP. The male contact is called TAB.)

●Check that there are no bent contacts (the contact is not inserted correctly and can come out of the back

of the connector). The spring contact of the connector when the wire is gently pulled.

●Check that there is no damage (folded tabs, clips open too wide, blackened or melted contact, etc.).

●Check that there is no oxidation on the metal contacts. Note:

Carry out each requested check visually. Do not remove a connector if it is not required.

Note:

Repeated connections and disconnections alter the functionality of the connectors and increase the risk of poor

electrical contact. Limit the number of connections/disconnections as much as possible.

Note:

The check is carried out on the 2 parts of the connection. There may be two types of connections:

–Connector / Connector

–Connector / Device

Page 21 of 99

62B-21

MR-413-X44-62B000$276_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Replacement of components

REPLACING THE CLIMATE CONTROL COMPUTER

–Note the computer configuration according to the optional equipment fitted on the vehicle (see climate control

computer configuration) or using the Shared World Information (ICM).

–Ensure that the ignition is switched off.

–After approval from the Techline, replace the computer.

–Switch on the ignition and carry out a check using the diagnostic tool.

–Configure the computer according to the vehicle specifications.

–Switch off the ignition and then back on for the configurations to register.

–Check in the Read configuration menu that the configurations have been recognised correctly.

–Check for faults and apply the corresponding fault finding procedure for any faults shown on the diagnostic tool.

–Clear any stored faults.

–Run command VP001 Enter VIN.

–Start the engine, switch on the air conditioning and ensure that it is operating correctly. WARNING

Before replacing the climate control computer, check that it is faulty (read faults, conformity of variables,

read customer complaints). Replacement of the computer must be authorised by the Techline after a fault

finding log has been completed and submitted.

Vdiag No.: 44

MR-413-X44-62B000$276_eng.mif

Page 22 of 99

62B-22

MR-413-X44-62B000$322_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Configuration and programming

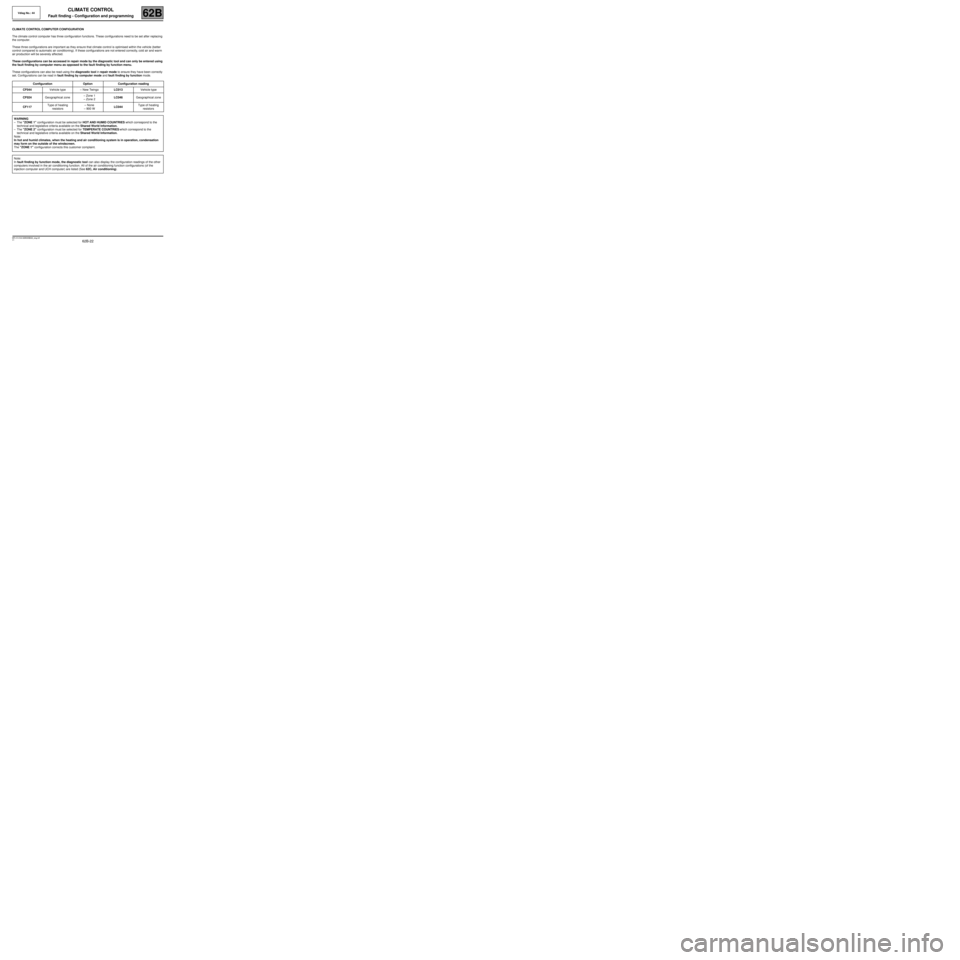

CLIMATE CONTROL COMPUTER CONFIGURATION

The climate control computer has three configuration functions. These configurations need to be set after replacing

the computer.

These three configurations are important as they ensure that climate control is optimised within the vehicle (better

control compared to automatic air conditioning). If these configurations are not entered correctly, cold air and warm

air production will be severely affected.

These configurations can be accessed in repair mode by the diagnostic tool and can only be entered using

the fault finding by computer menu as opposed to the fault finding by function menu.

These configurations can also be read using the diagnostic tool in repair mode to ensure they have been correctly

set. Configurations can be read in fault finding by computer mode and fault finding by function mode.

Configuration Option Configuration reading

CF044Vehicle type – New TwingoLC013Vehicle type

CF024Geographical zone– Zone 1

– Zone 2LC046Geographical zone

CF117Type of heating

resistors – None

– 900 WLC044Type of heating

resistors

WARNING

–The "ZONE 1" configuration must be selected for HOT AND HUMID COUNTRIES which correspond to the

technical and legislative criteria available on the Shared World Information.

–The "ZONE 2" configuration must be selected for TEMPERATE COUNTRIES which correspond to the

technical and legislative criteria available on the Shared World Information.

Note:

In hot and humid climates, when the heating and air conditioning system is in operation, condensation

may form on the outside of the windscreen.

The "ZONE 1" configuration corrects this customer complaint.

Note:

In fault finding by function mode, the diagnostic tool can also display the configuration readings of the other

computers involved in the air conditioning function. All of the air conditioning function configurations (of the

injection computer and UCH computer) are listed (See 62C, Air conditioning).

Vdiag No.: 44

MR-413-X44-62B000$322_eng.mif

Page 24 of 99

62B-24

MR-413-X44-62B000$368_eng.mif

V1

62B

CLIMATE CONTROL

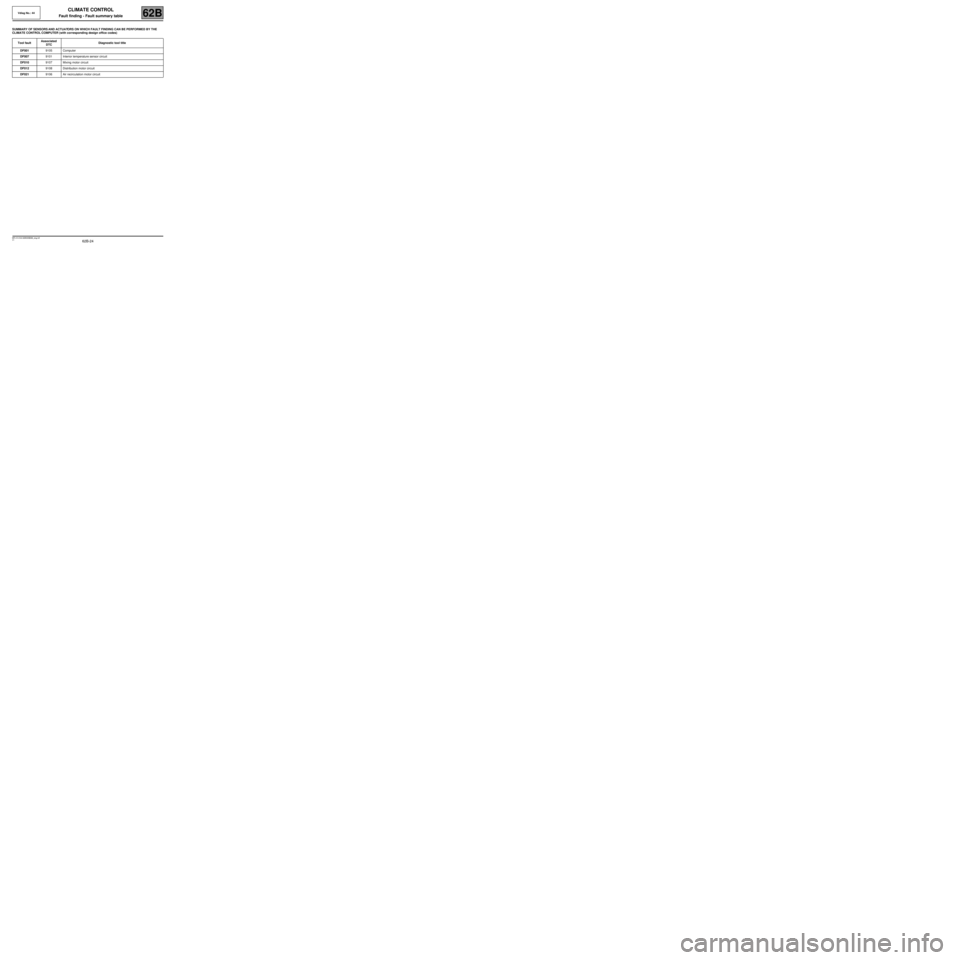

Fault finding - Fault summary table

SUMMARY OF SENSORS AND ACTUATORS ON WHICH FAULT FINDING CAN BE PERFORMED BY THE

CLIMATE CONTROL COMPUTER (with corresponding design office codes)

Tool faultAssociated

DTCDiagnostic tool title

DF0019105 Computer

DF0079101 Interior temperature sensor circuit

DF0109107 Mixing motor circuit

DF0129108 Distribution motor circuit

DF0219106 Air recirculation motor circuit

Vdiag No.: 44

MR-413-X44-62B000$368_eng.mif

Page 32 of 99

62B-32

MR-413-X44-62B000$460_eng.mif

V1

62B

CLIMATE CONTROL

Fault finding - Conformity check

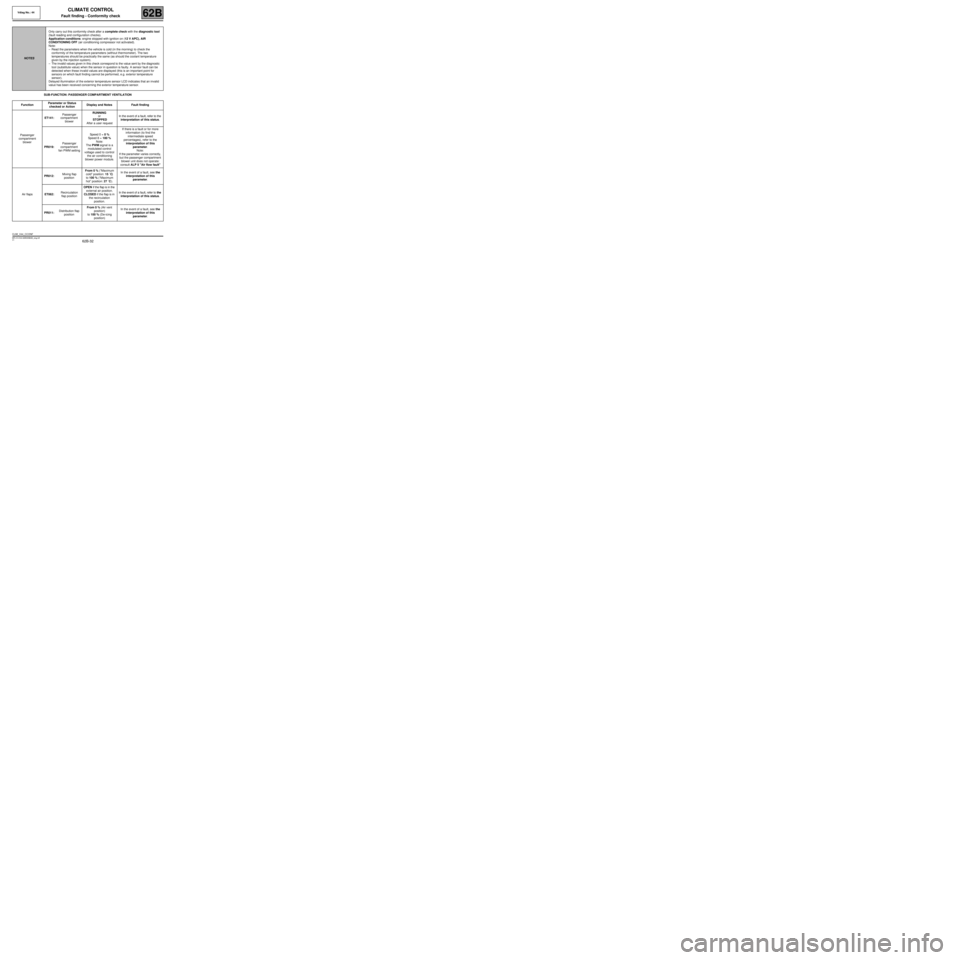

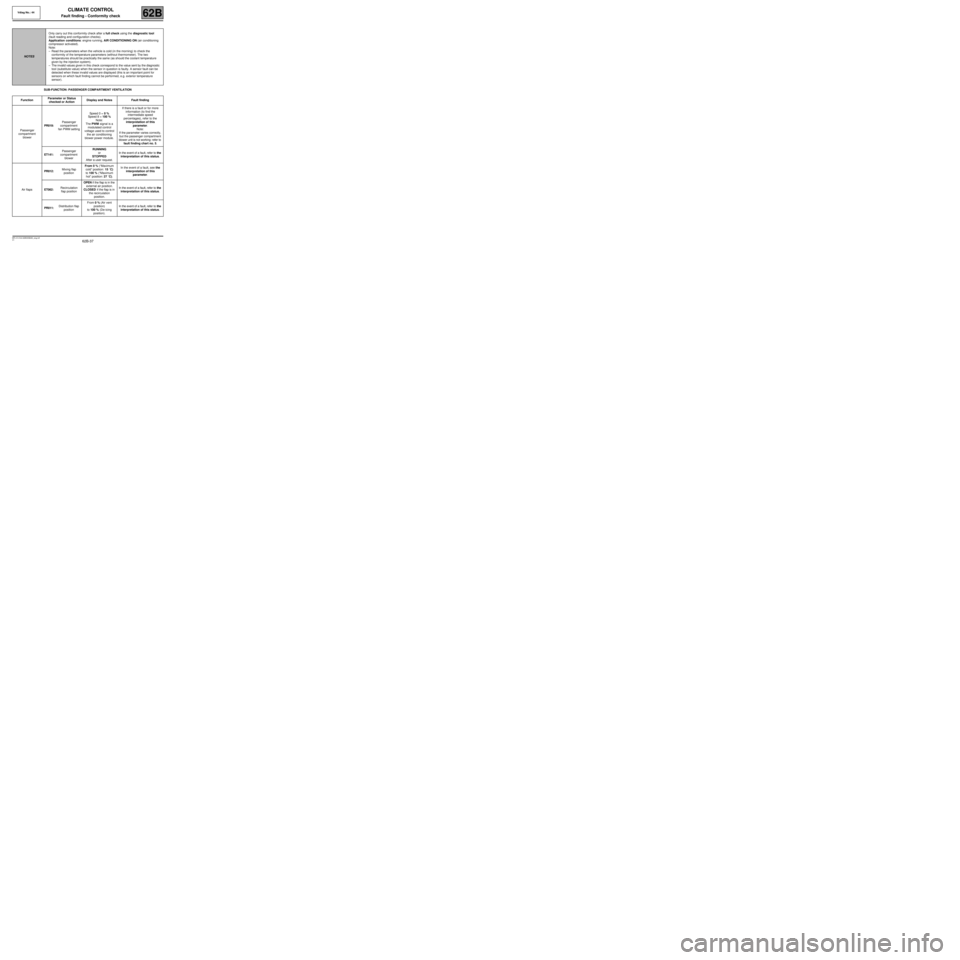

SUB-FUNCTION: PASSENGER COMPARTMENT VENTILATION

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped with ignition on (12 V APC), AIR

CONDITIONING OFF (air conditioning compressor not activated).

Note:

–Read the parameters when the vehicle is cold (in the morning) to check the

conformity of the temperature parameters (without thermometer). The two

temperatures should be practically the same (as should the coolant temperature

given by the injection system).

–The invalid values given in this check correspond to the value sent by the diagnostic

tool (substitute value) when the sensor in question is faulty. A sensor fault can be

detected when these invalid values are displayed (this is an important point for

sensors on which fault finding cannot be performed, e.g. exterior temperature

sensor).

Delayed illumination of the exterior temperature sensor LCD indicates that an invalid

value has been received concerning the exterior temperature sensor.

FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

Passenger

compartment

blowerET141:Passenger

compartment

blowerRUNNING

or

STOPPED

After a user requestIn the event of a fault, refer to the

interpretation of this status.

PR019:Passenger

compartment

fan PWM settingSpeed 0 = 0 %

Speed 8 = 100 %

Note:

The PWM signal is a

modulated control

voltage used to control

the air conditioning

blower power module.If there is a fault or for more

information (to find the

intermediate speed

percentages), refer to the

interpretation of this

parameter.

Note:

If the parameter varies correctly,

but the passenger compartment

blower unit does not operate:

consult ALP 5 "Air flow fault"

Air flapsPR012:Mixing flap

positionFrom 0 % (“Maximum

cold” position: 15 ˚C)

to 100 % (“Maximum

hot” position: 27 ˚C).In the event of a fault, see the

interpretation of this

parameter.

ET062:Recirculation

flap positionOPEN if the flap is in the

external air position.

CLOSED if the flap is in

the recirculation

position.In the event of a fault, refer to the

interpretation of this status.

PR011:Distribution flap

positionFrom 0 % (Air vent

position)

to 100 % (De-icing

position)In the event of a fault, see the

interpretation of this

parameter.

CLIM_V44_CCONF

Vdiag No.: 44

MR-413-X44-62B000$460_eng.mif

Page 33 of 99

62B-33

MR-413-X44-62B000$460_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Fault finding - Conformity check62B

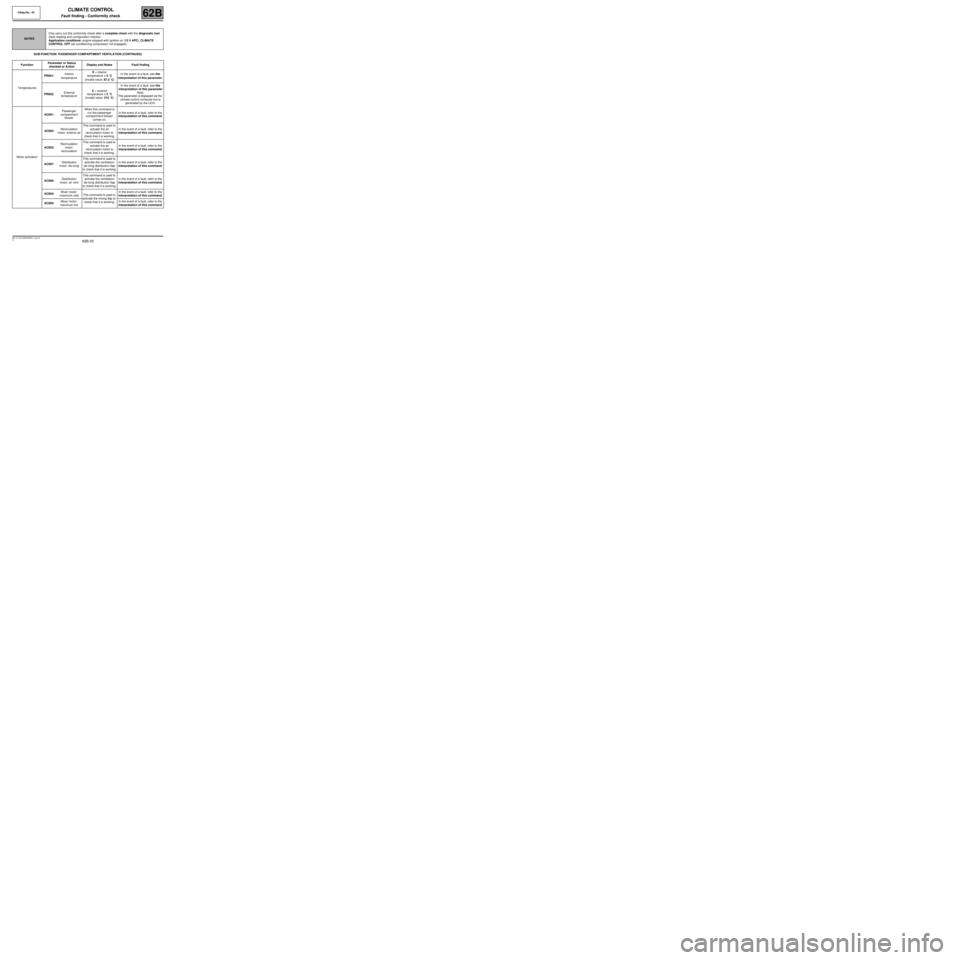

SUB-FUNCTION: PASSENGER COMPARTMENT VENTILATION (CONTINUED)

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped with ignition on (12 V APC), CLIMATE

CONTROL OFF (air conditioning compressor not engaged).

FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

TemperaturesPR001: Interior

temperatureX = interior

temperature ± 5 ˚C

(invalid value: 87.5 ˚C)In the event of a fault, see the

interpretation of this parameter.

PR002: External

temperatureX = exterior

temperature ± 5 ˚C

(invalid value: 215 ˚C)In the event of a fault, see the

interpretation of this parameter

Note:

This parameter is displayed via the

climate control computer but is

generated by the UCH.

Motor activationAC001:Passenger

compartment

blowerWhen this command is

run the passenger

compartment blower

comes on.In the event of a fault, refer to the

interpretation of this command.

AC002:Recirculation

motor: exterior airThis command is used to

actuate the air

recirculation motor to

check that it is working.In the event of a fault, refer to the

interpretation of this command.

AC003:Recirculation

motor:

recirculationThis command is used to

actuate the air

recirculation motor to

check that it is working.In the event of a fault, refer to the

interpretation of this command.

AC007:Distribution

motor: de-icingThis command is used to

activate the ventilation/

de-icing distribution flap

to check that it is working.In the event of a fault, refer to the

interpretation of this command.

AC006:Distribution

motor: air ventThis command is used to

activate the ventilation/

de-icing distribution flap

to check that it is working.In the event of a fault, refer to the

interpretation of this command.

AC004:Mixer motor:

maximum coldThis command is used to

activate the mixing flap to

check that it is working.In the event of a fault, refer to the

interpretation of this command.

AC005:Mixer motor:

maximum hotIn the event of a fault, refer to the

interpretation of this command.

Page 34 of 99

62B-34

MR-413-X44-62B000$460_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Fault finding - Conformity check62B

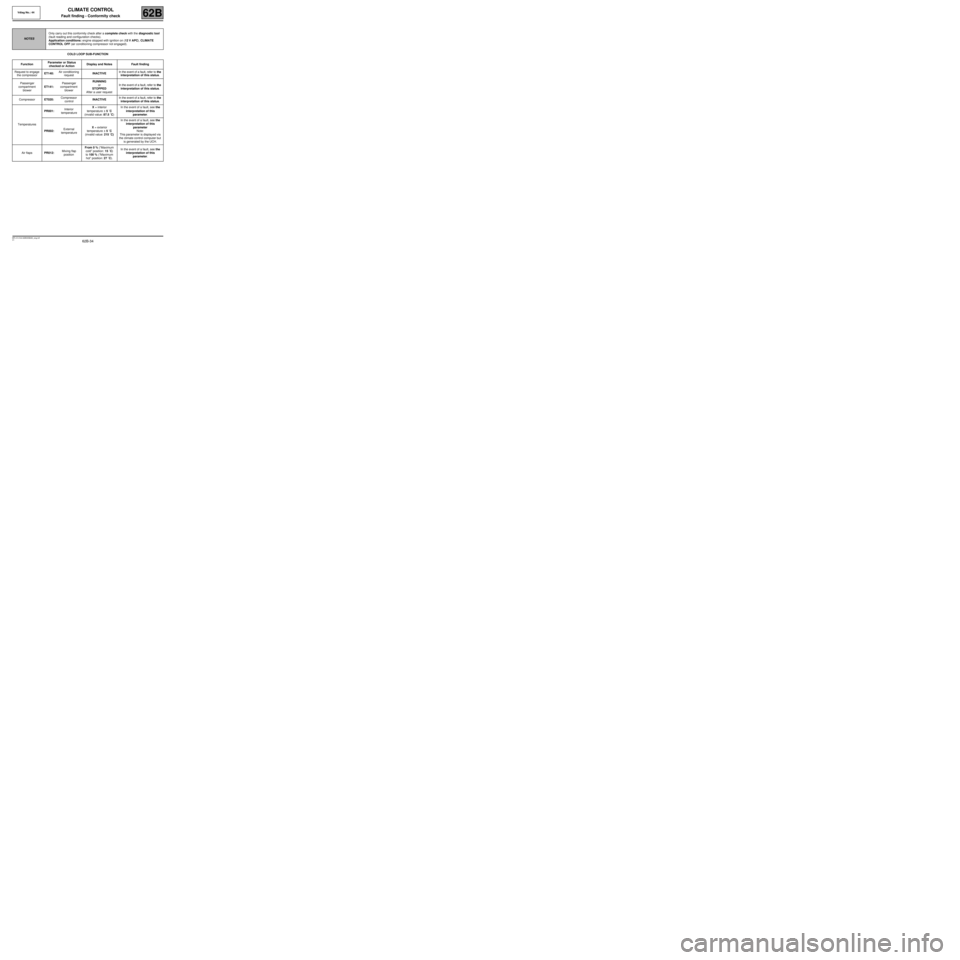

COLD LOOP SUB-FUNCTION

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped with ignition on (12 V APC), CLIMATE

CONTROL OFF (air conditioning compressor not engaged).

FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

Request to engage

the compressorET140:Air conditioning

requestINACTIVEIn the event of a fault, refer to the

interpretation of this status.

Passenger

compartment

blowerET141:Passenger

compartment

blowerRUNNING

or

STOPPED

After a user requestIn the event of a fault, refer to the

interpretation of this status.

CompressorET020:Compressor

controlINACTIVEIn the event of a fault, refer to the

interpretation of this status.

TemperaturesPR001:Interior

temperatureX = interior

temperature ± 5 ˚C

(invalid value: 87.5 ˚C)In the event of a fault, see the

interpretation of this

parameter.

PR002:External

temperatureX = exterior

temperature ± 5 ˚C

(invalid value: 215 ˚C)In the event of a fault, see the

interpretation of this

parameter

Note:

This parameter is displayed via

the climate control computer but

is generated by the UCH.

Air flapsPR012:Mixing flap

positionFrom 0 % (“Maximum

cold” position: 15 ˚C)

to 100 % (“Maximum

hot” position: 27 ˚C).In the event of a fault, see the

interpretation of this

parameter.

Page 36 of 99

62B-36

MR-413-X44-62B000$460_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Fault finding - Conformity check62B

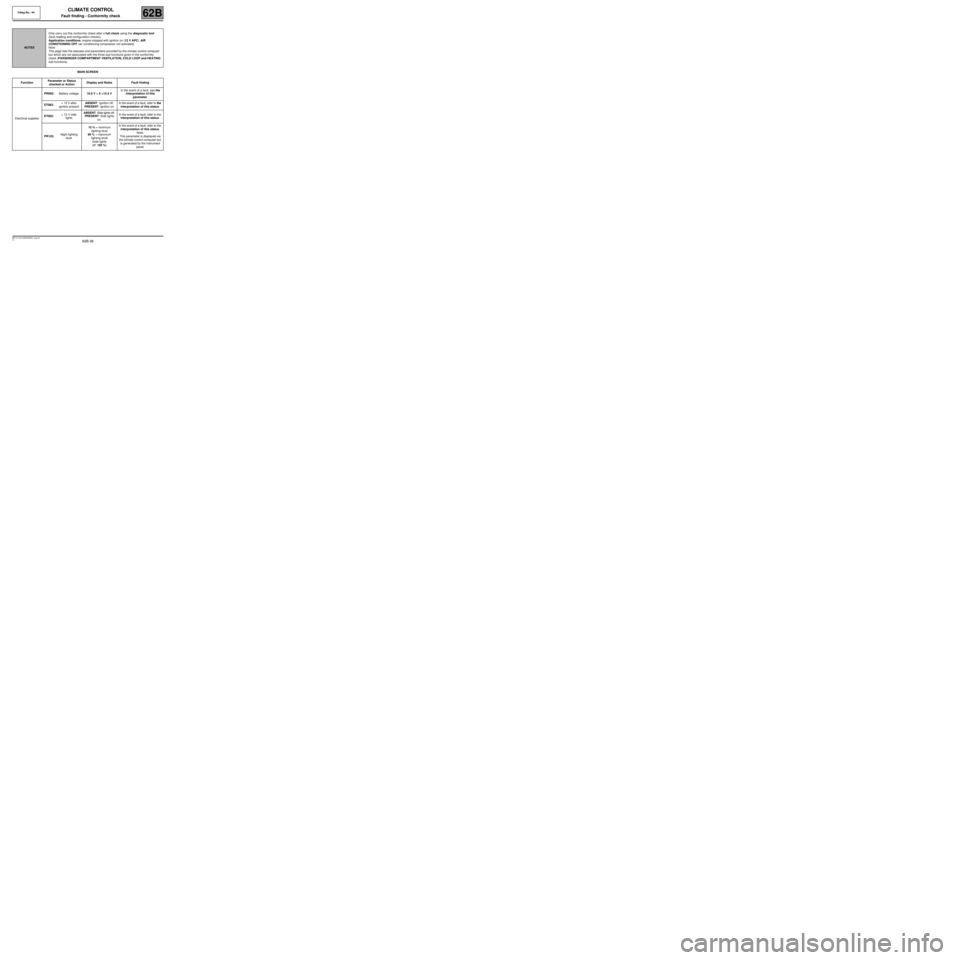

MAIN SCREEN

NOTESOnly carry out this conformity check after a full check using the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine stopped with ignition on (12 V APC), AIR

CONDITIONING OFF (air conditioning compressor not activated).

Note:

This page lists the statuses and parameters provided by the climate control computer

but which are not associated with the three sub-functions given in the conformity

check (PASSENGER COMPARTMENT VENTILATION, COLD LOOP and HEATING

sub-functions).

FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

Electrical suppliesPR092:Battery voltage10.5 V < X <14.4 VIn the event of a fault, see the

interpretation of this

parameter.

ET083:+ 12 V after

ignition present ABSENT: Ignition off.

PRESENT: Ignition on.In the event of a fault, refer to the

interpretation of this status.

ET002:+ 12 V side

lightsABSENT: Side lights off.

PRESENT: Side lights

on.In the event of a fault, refer to the

interpretation of this status.

PR122:Night lighting

level15 % = minimum

lighting level

99 % = maximum

lighting level

(side lights

off: 102 %)In the event of a fault, refer to the

interpretation of this status.

Note:

This parameter is displayed via

the climate control computer but

is generated by the instrument

panel.

Page 37 of 99

62B-37

MR-413-X44-62B000$460_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Fault finding - Conformity check62B

SUB-FUNCTION: PASSENGER COMPARTMENT VENTILATION

NOTESOnly carry out this conformity check after a full check using the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine running, AIR CONDITIONING ON (air conditioning

compressor activated).

Note:

–Read the parameters when the vehicle is cold (in the morning) to check the

conformity of the temperature parameters (without thermometer). The two

temperatures should be practically the same (as should the coolant temperature

given by the injection system).

–The invalid values given in this check correspond to the value sent by the diagnostic

tool (substitute value) when the sensor in question is faulty. A sensor fault can be

detected when these invalid values are displayed (this is an important point for

sensors on which fault finding cannot be performed, e.g. exterior temperature

sensor).

FunctionParameter or Status

checked or ActionDisplay and Notes Fault finding

Passenger

compartment

blowerPR019: Passenger

compartment

fan PWM settingSpeed 0 = 0 %

Speed 8 = 100 %

Note:

The PWM signal is a

modulated control

voltage used to control

the air conditioning

blower power module.If there is a fault or for more

information (to find the

intermediate speed

percentages), refer to the

interpretation of this

parameter.

Note:

If the parameter varies correctly,

but the passenger compartment

blower unit is not working: refer to

fault finding chart no. 5.

ET141: Passenger

compartment

blowerRUNNING

or

STOPPED

After a user request.In the event of a fault, refer to the

interpretation of this status.

Air flapsPR012: Mixing flap

positionFrom 0 % (“Maximum

cold” position: 15 ˚C)

to 100 % (“Maximum

hot” position: 27 ˚C).In the event of a fault, see the

interpretation of this

parameter.

ET062: Recirculation

flap positionOPEN if the flap is in the

external air position.

CLOSED if the flap is in

the recirculation

position.In the event of a fault, refer to the

interpretation of this status.

PR011: Distribution flap

positionFrom 0 % (Air vent

position)

to 100 % (De-icing

position).In the event of a fault, refer to the

interpretation of this status.