battery RENAULT TWINGO 2009 2.G Heating And Air Conditioning - Heating Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 29

Page 4 of 29

61A-4

MR-413-X44-61A000$125_eng.mif

V1

HEATING

Fault finding - Introduction61A

Visual inspection of the sealing:

(Only for watertight connectors)

●Check for the seal on the connection (between the 2 parts of the connection).

●Check the seal at the back of the connectors:

–For unit joints (1 for each wire), check that the unit joints are present on each electrical wire and that they

are correctly positioned in the opening (level with the housing). Check that plugs are present on openings

which are not used.

–For a grommet seal (one seal which covers the entire internal surface of the connector), check that the

seal is present.

–For gel seals, check for gel in all of the openings without removing the excess or any protruding sections

(it does not matter if there is gel on the contacts).

–For hotmelt sealing (heat-shrink sheath with glue), check that the sheath has contracted correctly on the

rear of the connectors and electrical wires, and that the hardened glue comes out of the side of the wire.

●Check that there is no damage to any of the seals (cuts, burns, significant deformation, etc.).

If a fault is detected, repair or replace the wiring (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair).

5. FAULT FINDING LOG

You will always be asked for this log:

●when requesting technical assistance from Techline,

●for approval requests when replacing parts for which approval is mandatory,

●to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any damage or injury:

–check the battery voltage to avoid incorrect operation of computer functions,

–do not smoke,

–use the proper tools. IMPORTANTIMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the procedure, enables you to keep

track of the procedure which is carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE MANDATORY TO FILL OUT A FAULT FINDING LOG EACH TIME FAULT FINDING IS

CARRIED OUT

Page 11 of 29

61A-11

MR-413-X44-61A000$625_eng.mif

V1

61A

HEATING

Fault finding - Conformity check

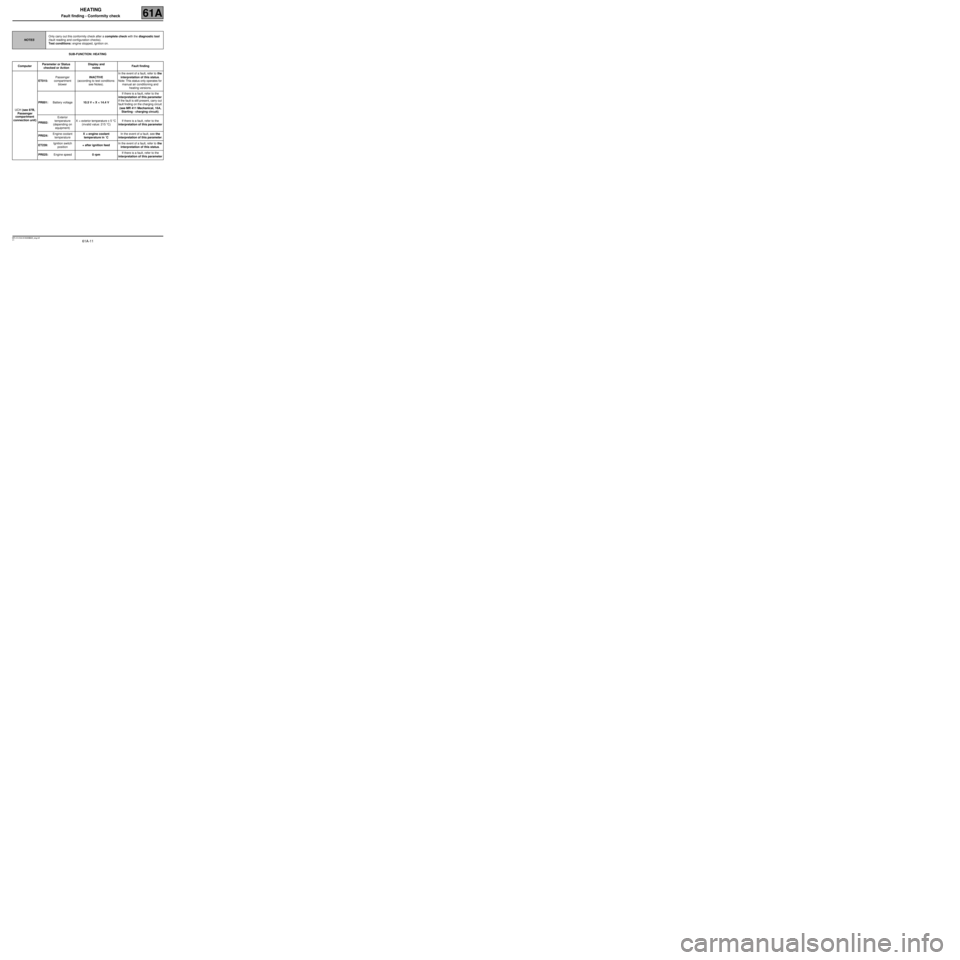

SUB-FUNCTION: HEATING

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Test conditions: engine stopped, ignition on.

ComputerParameter or Status

checked or ActionDisplay and

notesFault finding

UCH (see 87B,

Passenger

compartment

connection unit)ET015:Passenger

compartment

blowerINACTIVE

(according to test conditions:

see Notes).In the event of a fault, refer to the

interpretation of this status.

Note: This status only operates for

manual air conditioning and

heating versions.

PR001: Battery voltage10.5 V < X < 14.4 VIf there is a fault, refer to the

interpretation of this parameter

If the fault is still present, carry out

fault finding on the charging circuit

(see MR 411 Mechanical, 16A,

Starting - charging circuit).

PR002: Exterior

temperature

(depending on

equipment)X = exterior temperature ± 5 °C

(invalid value: 215 °C)If there is a fault, refer to the

interpretation of this parameter

PR024: Engine coolant

temperatureX = engine coolant

temperature in ˚CIn the event of a fault, see the

interpretation of this parameter.

ET239: Ignition switch

position+ after ignition feedIn the event of a fault, refer to the

interpretation of this status.

PR025: Engine speed0 rpmIf there is a fault, refer to the

interpretation of this parameter

MR-413-X44-61A000$625_eng.mif

Page 14 of 29

61A-14

MR-413-X44-61A000$625_eng.mif

V1

HEATING

Fault finding - Conformity check61A

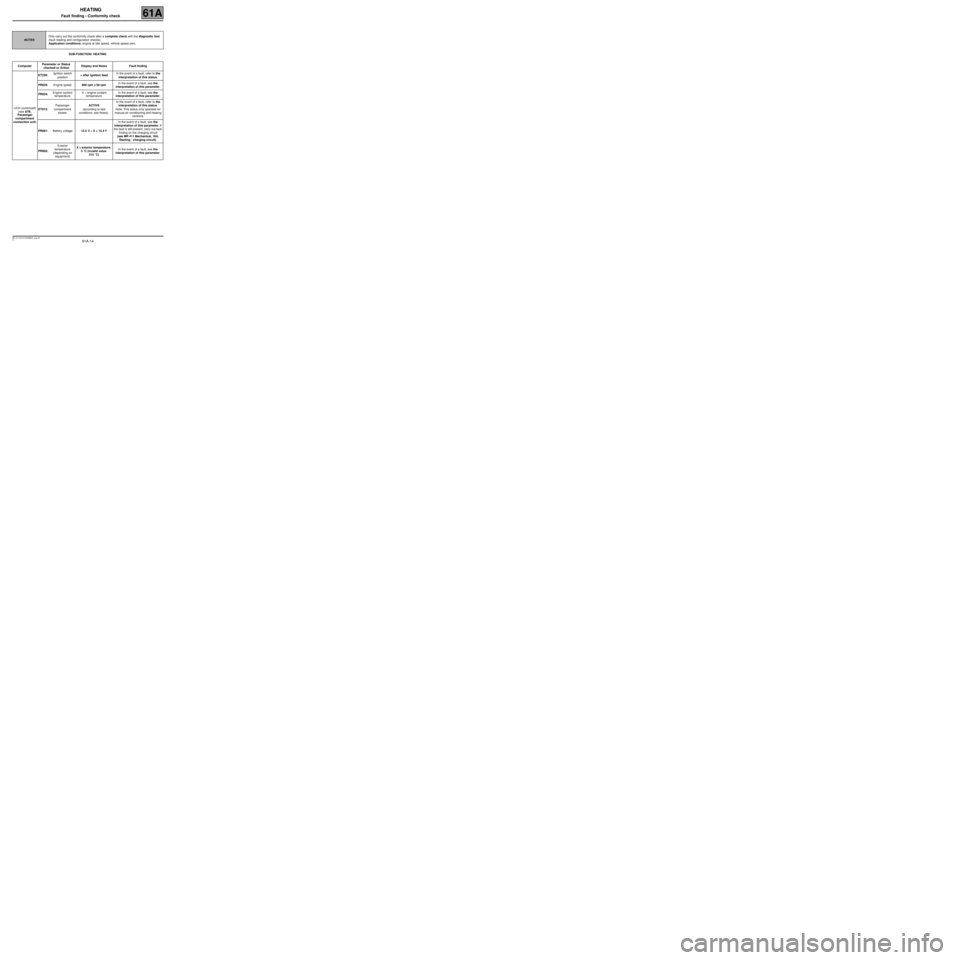

SUB-FUNCTION: HEATING

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine at idle speed, vehicle speed zero.

ComputerParameter or Status

checked or ActionDisplay and Notes Fault finding

UCH (continued)

(see 87B,

Passenger

compartment

connection unit)ET239: Ignition switch

position+ after ignition feedIn the event of a fault, refer to the

interpretation of this status.

PR025: Engine speed800 rpm ± 50 rpmIn the event of a fault, see the

interpretation of this parameter.

PR024: Engine coolant

temperatureX = engine coolant

temperatureIn the event of a fault, see the

interpretation of this parameter.

ET015: Passenger

compartment

blowerACTIVE

(according to test

conditions: see Notes).In the event of a fault, refer to the

interpretation of this status.

Note: This status only operates for

manual air conditioning and heating

versions.

PR001: Battery voltage12.5 V < X < 14.4 VIn the event of a fault, see the

interpretation of this parameter. If

the fault is still present, carry out fault

finding on the charging circuit

(see MR 411 Mechanical, 16A,

Starting - charging circuit).

PR002: Exterior

temperature

(depending on

equipment)X = exterior temperature:

5 ˚C (invalid value:

215 ˚C)In the event of a fault, see the

interpretation of this parameter.

Page 21 of 29

61A-21

MR-413-X44-61A000$875_eng.mif

V1

HEATING

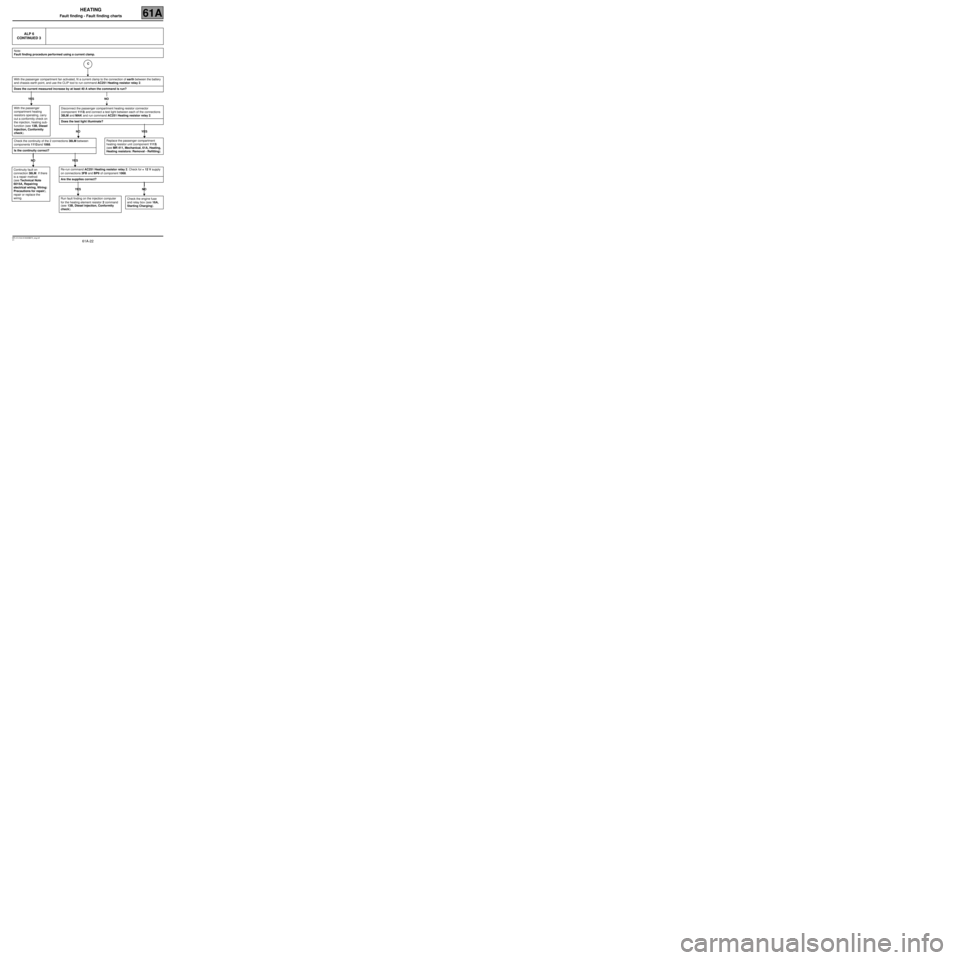

Fault finding - Fault finding charts61A

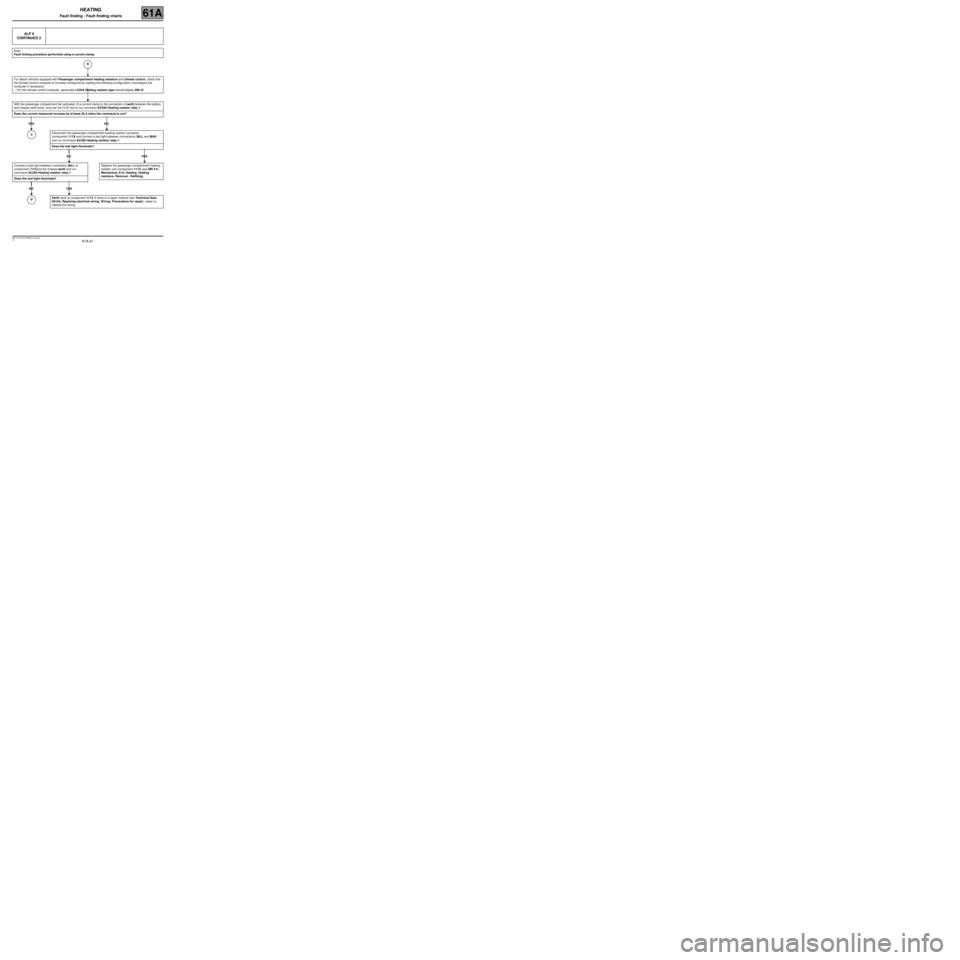

ALP 6

CONTINUED 2

Note:

Fault finding procedure performed using a current clamp.

For diesel vehicles equipped with Passenger compartment heating resistors and climate control, check that

the climate control computer is correctly configured by reading the following configuration (reconfigure the

computer if necessary):

–For the climate control computer, parameter LC044 Heating resistor type should display 900 W.

With the passenger compartment fan activated, fit a current clamp to the connection of earth between the battery

and chassis earth point, and use the CLIP tool to run command AC250 Heating resistor relay 1.

Does the current measured increase by at least 20 A when the command is run?

YES NO

Connect a test light between connection 38LL of

component 1113 and the chassis earth and run

command AC250 Heating resistor relay 1.

Does the test light illuminate?

NO YES

Disconnect the passenger compartment heating resistor connector

(component 1113) and connect a test light between connections 38LL and MAK

and run command AC250 Heating resistor relay 1.

Does the test light illuminate?

NO YES

Replace the passenger compartment heating

resistor unit (component 1113) (see MR 411,

Mechanical, 61A, Heating, Heating

resistors: Removal - Refitting).

Earth fault on component 1113. If there is a repair method (see Technical Note

6015A, Repairing electrical wiring, W iring: Precautions for repair), repair or

replace the wiring.

B

C

D

Page 22 of 29

61A-22

MR-413-X44-61A000$875_eng.mif

V1

HEATING

Fault finding - Fault finding charts61A

ALP 6

CONTINUED 3

Note:

Fault finding procedure performed using a current clamp.

With the passenger compartment fan activated, fit a current clamp to the connection of earth between the battery

and chassis earth point, and use the CLIP tool to run command AC251 Heating resistor relay 2.

Does the current measured increase by at least 40 A when the command is run?

YES NO

With the passenger

compartment heating

resistors operating, carry

out a conformity check on

the injection, heating sub-

function (see 13B, Diesel

injection, Conformity

check).

Disconnect the passenger compartment heating resistor connector

(component 1113) and connect a test light between each of the connections

38LM and MAK and run command AC251 Heating resistor relay 2.

Does the test light illuminate?

NO YES

Replace the passenger compartment

heating resistor unit (component 1113)

(see MR 411, Mechanical, 61A, Heating,

Heating resistors: Removal - Refitting).Check the continuity of the 2 connections 38LM between

components 1113 and 1068.

Is the continuity correct?

NO YES

Continuity fault on

connection 38LM. If there

is a repair method

(see Technical Note

6015A, Repairing

electrical wiring, Wiring:

Precautions for repair),

repair or replace the

wiring.Re-run command AC251 Heating resistor relay 2. Check for + 12 V supply

on connections 3FB and BP9 of component 1068.

Are the supplies correct?

YES NO

Check the engine fuse

and relay box (see 16A,

Starting Charging).Run fault finding on the injection computer

for the heating element resistor 2 command

(see 13B, Diesel injection, Conformity

check).

C