lock RENAULT TWINGO 2009 2.G Transmission User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 135

Page 57 of 135

21A-42

MANUAL GEARBOX

Input shaft lip seal: Removal - Refitting

JB1

21A

aPlace the tightening clamp (3) onto the tube.

aLock the tightening clamp using the spanner (4) .

aTighten the nut firmly (5) .

aPosition the sleeve (6) and the split ring (7) .

aTurn the upper nut (8) .

aGently extract the guide tube.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aPosition the new guide tube on the clutch housing.

aGently remove the guide tube with a press and the

(Bvi. 1828).

II - FINAL OPERATION.

aRefit the gearbox (see 21A, Manual gearbox, Man-

ual gearbox: Removal - Refitting, page 21A-24)

(MR 411, 21A, Manual gearbox).

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

98937

98938

98939

98935-1

Page 73 of 135

21B-13

SEQUENTIAL GEARBOX

Electro-hydraulic unit: Removal - Refitting

D4F, and JH1

21B

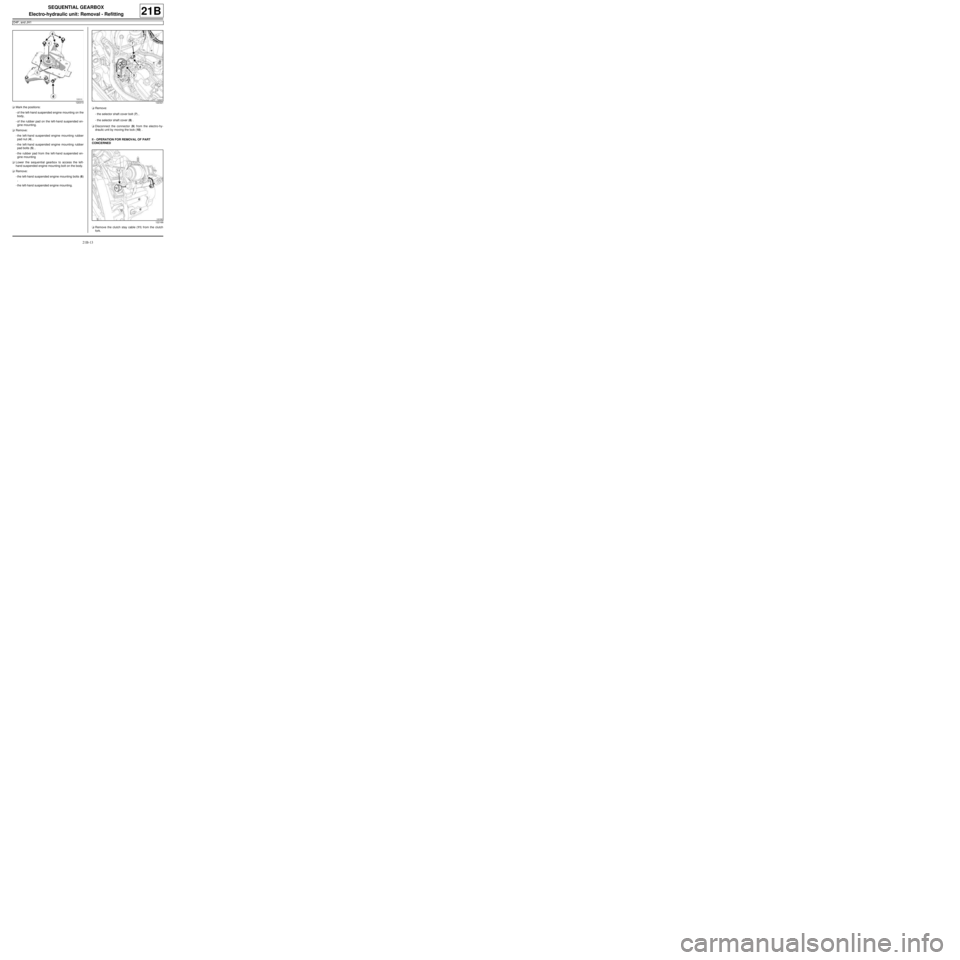

aMark the positions:

-of the left-hand suspended engine mounting on the

body,

-of the rubber pad on the left-hand suspended en-

gine mounting.

aRemove:

-the left-hand suspended engine mounting rubber

pad nut (4) ,

-the left-hand suspended engine mounting rubber

pad bolts (5) ,

-the rubber pad from the left-hand suspended en-

gine mounting

aLower the sequential gearbox to access the left-

hand suspended engine mounting bolt on the body.

aRemove:

-the left-hand suspended engine mounting bolts (6)

,

-the left-hand suspended engine mounting.aRemove:

-the selector shaft cover bolt (7) ,

-the selector shaft cover (8) .

aDisconnect the connector (9) from the electro-hy-

draulic unit by moving the lock (10) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the clutch stay cable (11) from the clutch

fork.

120310122321

122168

Page 74 of 135

21B-14

SEQUENTIAL GEARBOX

Electro-hydraulic unit: Removal - Refitting

D4F, and JH1

21B

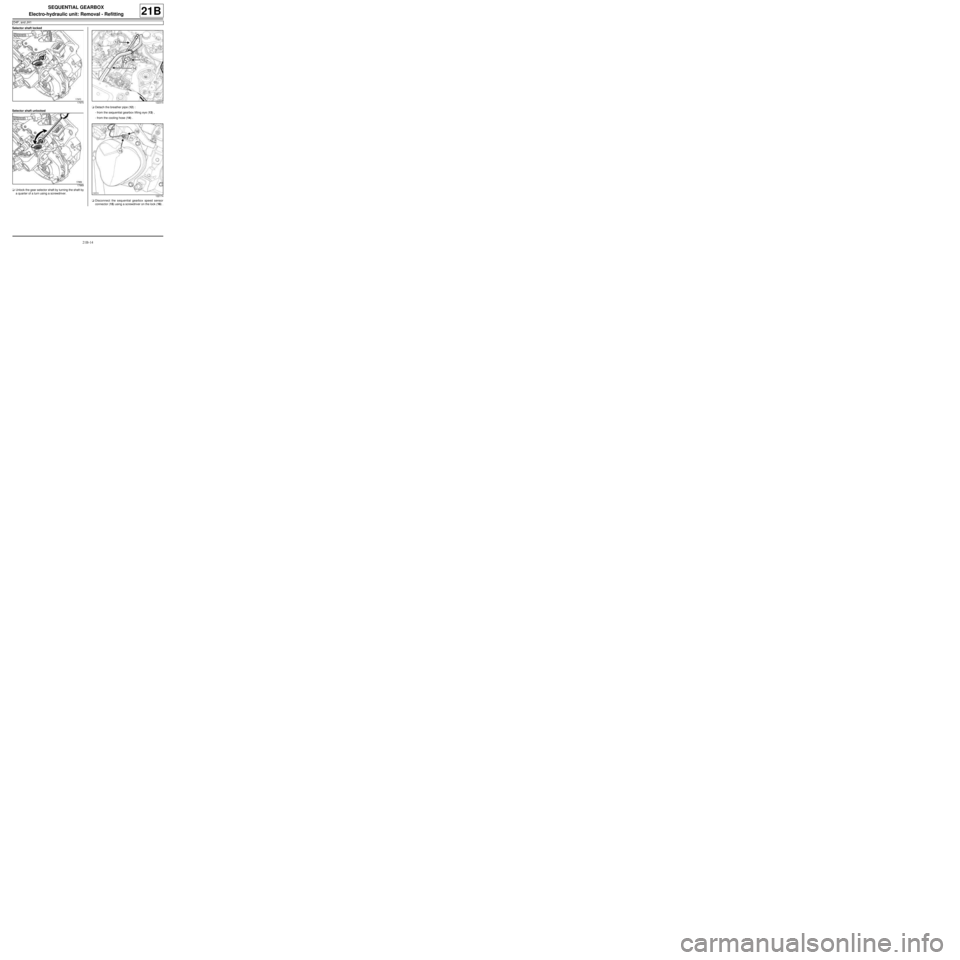

Selector shaft locked

Selector shaft unlocked

aUnlock the gear selector shaft by turning the shaft by

a quarter of a turn using a screwdriver.aDetach the breather pipe (12) :

-from the sequential gearbox lifting eye (13) ,

-from the cooling hose (14) .

aDisconnect the sequential gearbox speed sensor

connector (15) using a screwdriver on the lock (16) .

17970

17969122314

122174

Page 76 of 135

21B-16

SEQUENTIAL GEARBOX

Electro-hydraulic unit: Removal - Refitting

D4F, and JH1

21B

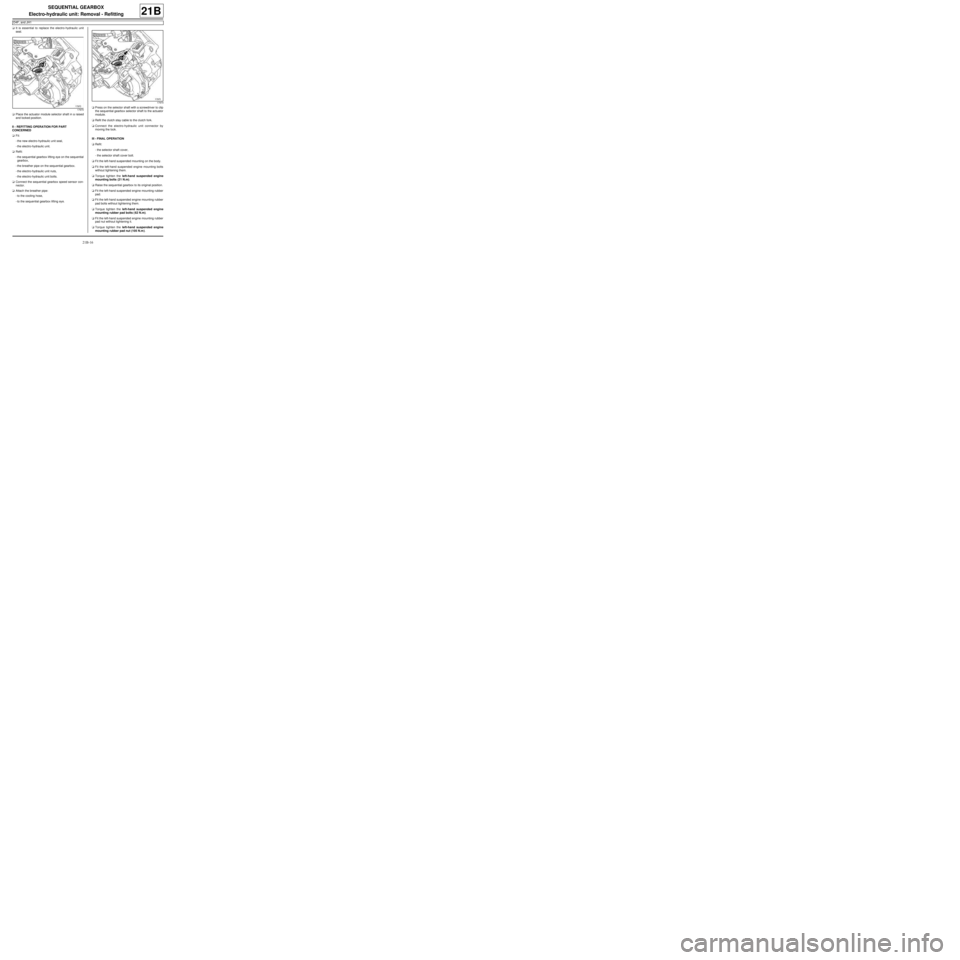

aIt is essential to replace the electro-hydraulic unit

seal.

aPlace the actuator module selector shaft in a raised

and locked position.

II - REFITTING OPERATION FOR PART

CONCERNED

aFit:

-the new electro-hydraulic unit seal,

-the electro-hydraulic unit.

aRefit:

-the sequential gearbox lifting eye on the sequential

gearbox,

-the breather pipe on the sequential gearbox.

-the electro-hydraulic unit nuts,

-the electro-hydraulic unit bolts.

aConnect the sequential gearbox speed sensor con-

nector.

aAttach the breather pipe:

-to the cooling hose,

-to the sequential gearbox lifting eye.aPress on the selector shaft with a screwdriver to clip

the sequential gearbox selector shaft to the actuator

module.

aRefit the clutch stay cable to the clutch fork.

aConnect the electro-hydraulic unit connector by

moving the lock.

III - FINAL OPERATION

aRefit:

-the selector shaft cover,

-the selector shaft cover bolt.

aFit the left-hand suspended mounting on the body.

aFit the left-hand suspended engine mounting bolts

without tightening them.

aTorque tighten the left-hand suspended engine

mounting bolts (21 N.m).

aRaise the sequential gearbox to its original position.

aFit the left-hand suspended engine mounting rubber

pad.

aFit the left-hand suspended engine mounting rubber

pad bolts without tightening them.

aTorque tighten the left-hand suspended engine

mounting rubber pad bolts ( 62 N.m).

aFit the left-hand suspended engine mounting rubber

pad nut without tightening it.

aTorque tighten the left-hand suspended engine

mounting rubber pad nut (105 N.m ).

17970

17970

Page 94 of 135

21B-34

SEQUENTIAL GEARBOX

Clutch position sensor: Removal - Refitting

D4F, and JH1

21B

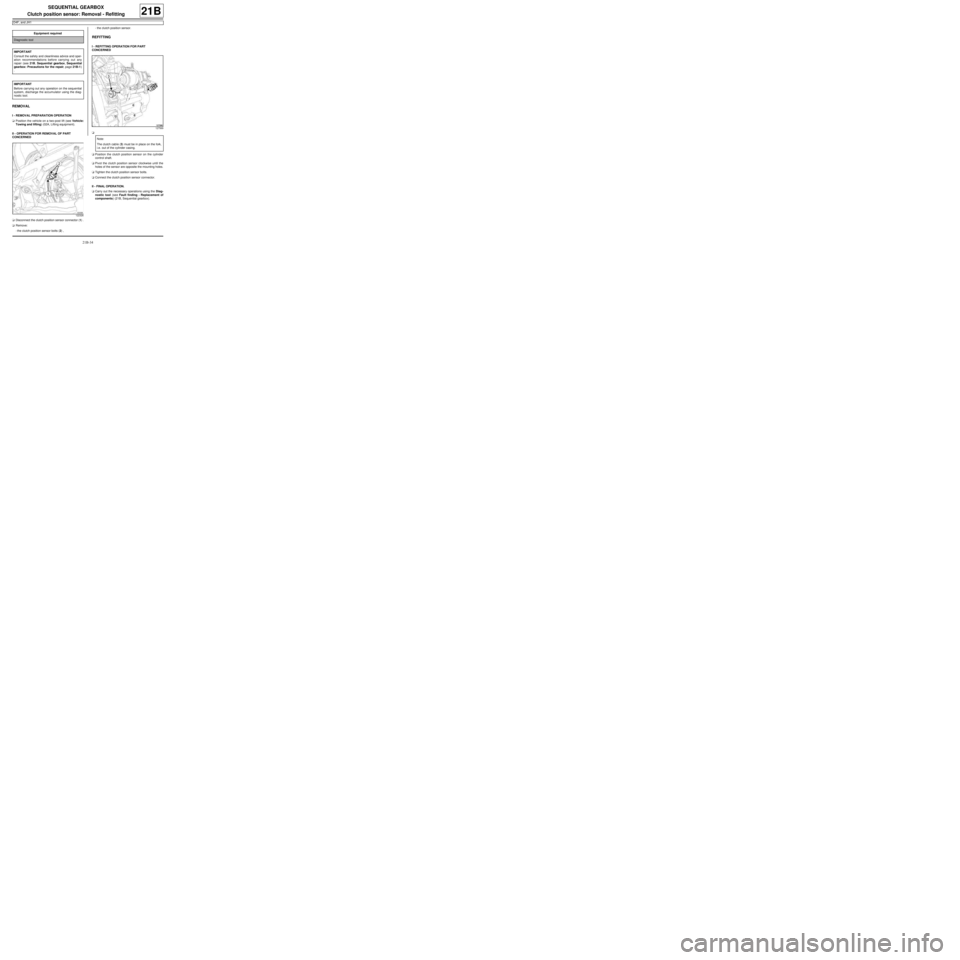

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the clutch position sensor connector (1) .

aRemove:

-the clutch position sensor bolts (2) ,-the clutch position sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

a

aPosition the clutch position sensor on the cylinder

control shaft.

aPivot the clutch position sensor clockwise until the

holes of the sensor are opposite the mounting holes.

aTighten the clutch position sensor bolts.

aConnect the clutch position sensor connector.

II - FINAL OPERATION.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (21B, Sequential gearbox). Equipment required

Diagnostic tool

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

IMPORTANT

Before carrying out any operation on the sequential

system, discharge the accumulator using the diag-

nostic tool.

122326

127569

Note:

The clutch cab le (3) must be in place on the fork,

i.e. out of the cylinder casing.

Page 107 of 135

21B-47

SEQUENTIAL GEARBOX

Sequential gearbox converter: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip (1) the sequential gearbox computer from its

mounting (2) .aDisconnect the sequential gearbox computer con-

nectors (3) by pressing the locks.

aRemove the sequential gearbox computer.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aConnect the sequential gearbox computer connec-

tors by pressing the locks.

aClip the sequential gearbox computer onto its

mounting.

II - FINAL OPERATION

aRefit the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

aIf replacing the sequential gearbox computer, carry

out the necessary operations using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents) (MR 413, 21B, Sequential gearbox). Equipment required

Diagnostic tool

122324

122325

Page 109 of 135

29A-1

DRIVESHAFTS

Driveshaft: Precautions for the repair

JB1 or JH1 or JH3 or JR5

29A

WARNING

A gearbox oil leak at the driveshaft may destroy it.

WARNING

Lubricate the base of the bearing with MOLYKOTE

to prevent the bear ing sticking.

Make sure that the O-ring is correctly positioned in

the base of the relay bearing, if the bearing has

one.

WARNING

Always replace seals whenever the driveshaft is

removed.

WARNING

Always replace the left-hand driveshaft lock ring, if

the driveshaft has one.

WARNING

In order to prevent irreversible damage to the front

hub bear ing:

-Do not loosen or tighten the driveshaft nut when

the wheels are on the ground.

-Do not place the vehicle with its wheels on the

ground when the driveshaft has been loosened or

removed.

Page 110 of 135

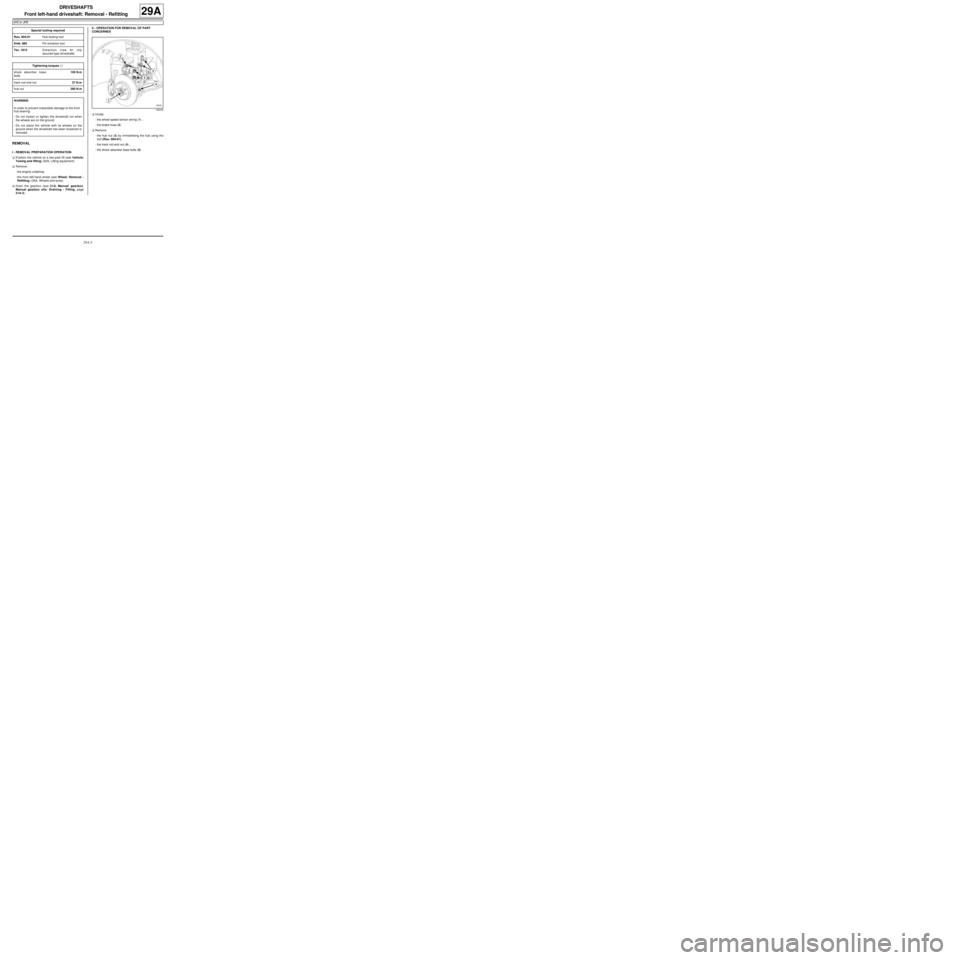

29A-2

DRIVESHAFTS

Front left-hand driveshaft: Removal - Refitting

JB1 or JH1

29A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray bolts,

-the engine undertray.

aDrain the manual gearbox (see 21A, Manual gear-

box, Manual gearbox oils: Draining - Filling, page

21A-2) .

aRemove the front left-hand wheel (see Wheel: Re-

moval - Refitting) (35A, Wheels and tyres).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach the wiring from the wheel speed sensor (1) .

aRemove:

-the hub nut (2) by immobilising the hub using the

tool (Rou. 604-01),

-the track rod end nut (3) ,

-the track rod end from the stub axle carrier using

the (Tav. 476),

-the shock absorber base bolts (4) . Special tooling required

Rou. 604-01Hub locking tool.

Tav. 476Ball joint extractor.

Tightening torquesm

the flange mounting

bolts21 Nm

shock absorber base

bolts105 N.m

track rod end nut37 Nm

hub nut280 N.m

WARNING

In order to prevent irreversible damage to the front

hub bear ing:

-Do not loosen or tighten the driveshaft nut when

the wheels are on the ground.

-Do not place the vehicle with its wheels on the

ground when the driveshaft has been loosened or

removed.

130488

Page 113 of 135

29A-5

DRIVESHAFTS

Front left-hand driveshaft: Removal - Refitting

JH3 or JR5

29A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray.

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aDrain the gearbox (see 21A, Manual gearbox,

Manual gearbox oils: Draining - Filling, page

21A-2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip:

-the wheel speed sensor wiring (1) ,

-the brake hose (2) .

aRemove:

-the hub nut (3) by immobilising the hub using the

tool (Rou. 604-01),

-the track rod end nut (4) ,

-the shock absorber base bolts (5) . Special tooling required

Rou. 604-01Hub locking tool.

Emb. 880Pin extractor tool.

Tav. 1813Extraction claw for clip

secured type driveshafts

Tightening torquesm

shock absorber base

bolts105 N.m

track rod end nut37 N.m

hub nut280 N.m

WARNING

In order to prevent irreversible damage to the front

hub bear ing:

-Do not loosen or tighten the driveshaft nut when

the wheels are on the ground.

-Do not place the vehicle with its wheels on the

ground when the driveshaft has been loosened or

removed.

132032

Page 116 of 135

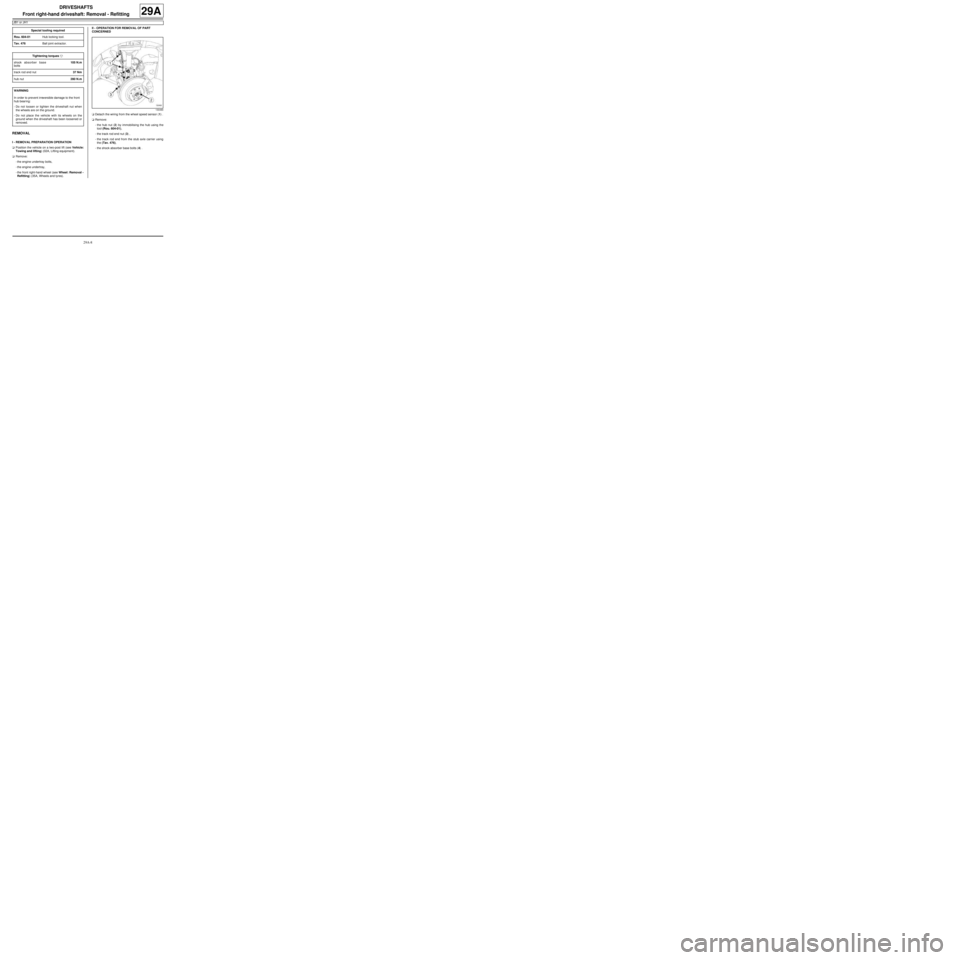

29A-8

DRIVESHAFTS

Front right-hand driveshaft: Removal - Refitting

JB1 or JH1

29A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray bolts,

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach the wiring from the wheel speed sensor (1) .

aRemove:

-the hub nut (2) by immobilising the hub using the

tool (Rou. 604-01),

-the track rod end nut (3) ,

-the track rod end from the stub axle carrier using

the (Tav. 476),

-the shock absorber base bolts (4) . Special tooling required

Rou. 604-01Hub locking tool.

Tav. 476Ball joint extractor.

Tightening torquesm

shock absorber base

bolts105 N.m

track rod end nut37 Nm

hub nut280 N.m

WARNING

In order to prevent irreversible damage to the front

hub bear ing:

-Do not loosen or tighten the driveshaft nut when

the wheels are on the ground.

-Do not place the vehicle with its wheels on the

ground when the driveshaft has been loosened or

removed.

130490