ignition RENAULT TWINGO 2009 2.G Transmission Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 135

Page 61 of 135

21B-1

SEQUENTIAL GEARBOX

Sequential gearbox: Precautions for the repair

D4F, and JH1

21B

I - SEQUENTIAL GEARBOX

II - SEQUENTIAL GEARBOX COMPUTER

To disconnect the computer, switch off the ignition and

wait for 1 minute.

III - ELECTRO-HYDRAULIC UNIT

Discharge the pressure accumulator using the Diag-

nostic tool before any operation on the electro-hy-

draulic unit.

Be careful not to twist the high pressure pipes when re-

moving the electro-hydraulic unit.

IV - GEAR SELECTION SENSOREquipment required

Diagnostic tool

IMPORTANT

Before any operation on the sequential system, dis-

charge the accumulator using the Diagnostic tool.

WARNING

If any operation is carried out on the electro-hydrau-

lic unit, it is essential to clean the unit using a clean-

ing product and compressed air.

Never leave the circuit open and never use a high

pressure cleaner.

WARNING

After the accumulator has been fully filled (15 sec-

onds after the ignition has been switched on): the

oil level is at the MINIMUM mark.

WARNING

To remove the gear selection sensor it is essential

that you shift to first gear before removal.

Page 67 of 135

21B-7

SEQUENTIAL GEARBOX

Pressure accumulator: Removal - Refitting

D4F, and JH1

21B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aRemove the pressure accumulator (8) from the actu-

ator module using the (Mot. 445) (9) .

REFITTING

I - REFITTING PREPARATION OPERATION

aIf replacing the pressure accumulator, affix a safety

label to the accumulator.

aIt is essential to replace the pressure accumulator

seal.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the pressure accumulator onto the actuator

module using the (Mot. 445).

III - FINAL OPERATION

aClip the pump assembly supply connector onto the

electro-hydraulic unit connector mounting.

aConnect the pump assembly supply connector.aRefit:

-the sequential gearbox lifting eye on the sequential

gearbox,

-the sequential gearbox lifting eye nut,

-the breather pipe on the sequential gearbox.

aAttach the breather pipe:

-to the cooling hose,

-to the sequential gearbox lifting eye.

aFit:

-the petrol injection computer support,

-the engine wiring harness on the petrol injection

computer mounting.

aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip onto the petrol injection computer mounting:

-the battery wiring harness,

-the petrol injection computer wiring harness,

-the sequential gearbox computer wiring harness,

-the cooling hose.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

122315

Note:

Prepare for oil to flow out of the electro-hydraulic

unit.

WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 70 of 135

21B-10

SEQUENTIAL GEARBOX

Pump assembly reservoir: Removal - Refitting

D4F, and JH1

21B

REFITTING

I - REFITTING PREPARATION OPERATION

aIn the event of replacement, refit:

-the low pressure hose,

-the low pressure hose clip.

aIt is essential to replace the pump assembly reser-

voir seal on the pump inlet.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the pump assembly reservoir,

-the pump assembly reservoir bolts.

III - FINAL OPERATION

aAssemble:

-the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Re-

fitting, page 21B-11) ,

aRemove

-the pump assembly on the electro-hydraulic unit

(see 21B, Sequential gearbox, Pump assembly:

Removal - Refitting, page 21B-18) ,

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox). WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 77 of 135

21B-17

SEQUENTIAL GEARBOX

Electro-hydraulic unit: Removal - Refitting

D4F, and JH1

21B

aRefit:

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting).

Refit.

aFit:

-the petrol injection computer support,

-the engine wiring harness on the petrol injection

computer mounting.

aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip onto the petrol injection computer mounting:

-the battery wiring harness,

-the petrol injection computer wiring harness,

-the sequential gearbox computer wiring harness,

-the cooling hose.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.aIf replacing the electro-hydraulic unit, carry out the

necessary operations using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 21B, Sequential gearbox).

WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 79 of 135

21B-19

SEQUENTIAL GEARBOX

Pump assembly: Removal - Refitting

D4F, and JH1

21B

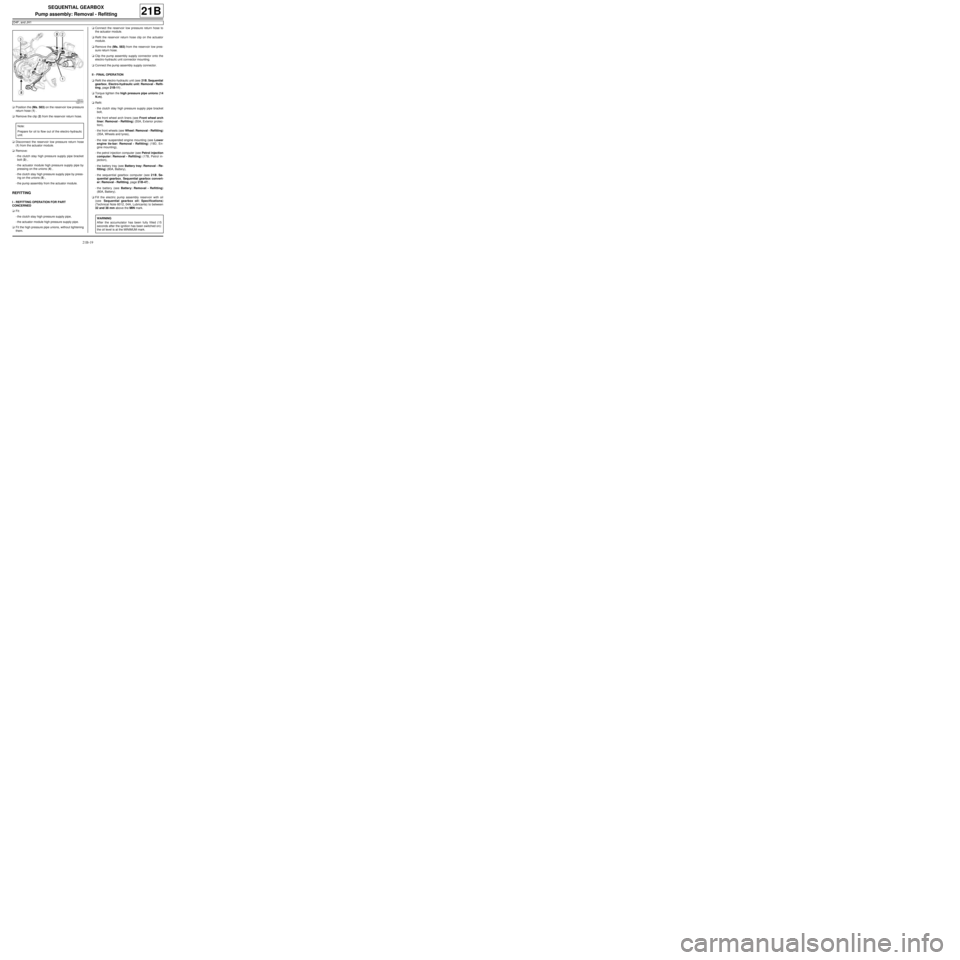

aPosition the (Ms. 583) on the reservoir low pressure

return hose (1) .

aRemove the clip (2) from the reservoir return hose.

aDisconnect the reservoir low pressure return hose

(1) from the actuator module.

aRemove:

-the clutch stay high pressure supply pipe bracket

bolt (3) ,

-the actuator module high pressure supply pipe by

pressing on the unions (4) ,

-the clutch stay high pressure supply pipe by press-

ing on the unions (5) ,

-the pump assembly from the actuator module.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aFit:

-the clutch stay high pressure supply pipe,

-the actuator module high pressure supply pipe.

aFit the high pressure pipe unions, without tightening

them.aConnect the reservoir low pressure return hose to

the actuator module.

aRefit the reservoir return hose clip on the actuator

module.

aRemove the (Ms. 583) from the reservoir low pres-

sure return hose.

aClip the pump assembly supply connector onto the

electro-hydraulic unit connector mounting.

aConnect the pump assembly supply connector.

II - FINAL OPERATION

aRefit the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Refit-

ting, page 21B-11) .

aTorque tighten the high pressure pipe unions (14

N.m).

aRefit:

-the clutch stay high pressure supply pipe bracket

bolt,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (17B, Petrol in-

jection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(80A, Battery).

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

122171

Note:

Prepare for oil to flow out of the electro-hydraulic

unit.

WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 86 of 135

21B-26

SEQUENTIAL GEARBOX

Solenoid valves: Removal - Refitting

D4F, and JH1

21B

aFit the left-hand suspended engine mounting rubber

pad nut without tightening it.

aTorque tighten the left-hand suspended engine

mounting rubber pad nut (105 N.m ).

aRefit:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres).

3 - Refitting all solenoid valves

aFit:

-the petrol injection computer support,

-the engine wiring harness on the petrol injection

computer mounting.

aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip onto the petrol injection computer mounting:

-the battery wiring harness,

-the petrol injection computer wiring harness,

-the sequential gearbox computer wiring harness,

-the cooling hose.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox). WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 90 of 135

21B-30

SEQUENTIAL GEARBOX

Actuator module: Removal - Refitting

D4F, and JH1

21B

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox). WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 97 of 135

21B-37

SEQUENTIAL GEARBOX

Solenoid valve assembly pressure sensor: Removal - Refitting

D4F, and JH1

21B

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the connector (4) from the solenoid

valve unit pressure sensor.

aRemove the solenoid valve unit pressure sensor (5)

.

REFITTING

I - REFITTING PREPARATION OPERATION

aIt is essential to replace the solenoid valve unit pres-

sure sensor seal.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the solenoid valve unit pressure sensor.

aConnect the solenoid valve unit pressure sensor

connector.

III - FINAL OPERATION

aFit:

-the petrol injection computer support,

-the engine wiring harness on the petrol injection

computer mounting.aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip:

-the battery wiring harness to the petrol injection

computer mounting,

-the petrol injection computer wiring harness to the

petrol injection computer mounting,

-the sequential gearbox computer wiring harness to

the petrol injection computer mounting,

-the cooling hose to the petrol injection computer

mounting.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox).

122317

Note:

Prepare for oil to flow out of the electro-hydraulic

unit.

WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.