fuel RENAULT TWINGO RS 2009 2.G Air Conditioning User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 122

Page 112 of 122

62A-31

AIR CONDITIONING

Dehydrator reservoir - expansion valve connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

aClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs.II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the assembly of the « dehydrator reservoir - ex-

pansion valve » and « expansion valve - intermedi-

ate pipe » connecting pipes.

aFit:

-the « dehydrator reservoir - expansion valve » con-

necting pipe on the dehydrator reservoir,

-the connecting pipes on the expansion valve.

aCouple the « expansion valve - intermediate pipe »

connecting pipe to the « compressor - intermediate

pipe » connecting pipe.

aRefit:

-the bolts of the connecting pipes on the expansion

valve,

-the bolt of the « dehydrator reservoir - expansion

valve » connecting pipe on the dehydrator reser-

voir.

aFit the connecting pipes on the body.

aRefit the connecting pipe bracket nuts on the body.

III - FINAL OPERATION

aRefit the bulkhead heat-resistant protectors.

aRefit:

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) (17B, Petrol injection),

-the air filter box (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture).

aConnect the air temperature sensor.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

143880

143882

D4F, and 780 – K4M

D4F, and 780

K4M

Page 114 of 122

62A-33

AIR CONDITIONING

Compressor - condenser connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the pressure sensor connector (1) . Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part no.

77 01 208 229 or 77 01 476 857 to plug any open-

ings exposed to the open air. They must be clean.

Do not use any which have already been used to

plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

121174

Page 118 of 122

62A-37

AIR CONDITIONING

Compressor - intermediate pipe connecting pipe: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

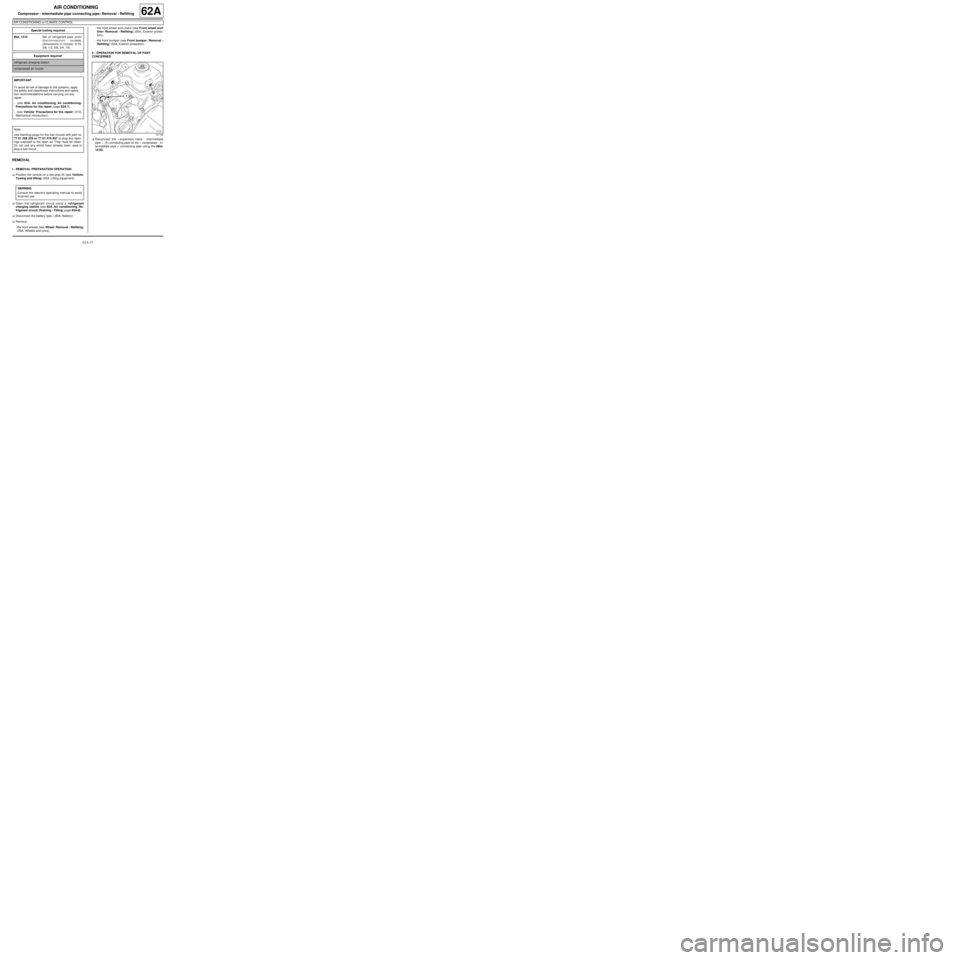

aDisconnect the « expansion valve - intermediate

pipe » (1) connecting pipe on the « compressor - in-

termediate pipe » connecting pipe using the (Mot.

1410). Special tooling required

Mot. 1410Set of refrigerant pipe union

disconnection sockets.

(dimensions in inches): 5/16,

3/8, 1/2, 5/8, 3/4, 7/8.

Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part no.

77 01 208 229 or 77 01 476 857 to plug any open-

ings exposed to the open air. They must be clean.

Do not use any which have already been used to

plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

121180