diagram RENAULT TWINGO RS 2009 2.G Chasiss ABS Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 76

Page 1 of 76

Chassis

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V1

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s.

V1 MR-413-X44-38C000$000_engTOC.mif

ANTI-LOCK BRAKING SYSTEM

MK70 ABS

Vdiag No: 04

Fault finding - Introduction 38C - 2

Fault finding - List and location of components 38C - 7

Fault finding - Operating diagram 38C - 8

Fault finding - Function 38C - 9

Fault finding - Role of components 38C - 10

Fault finding - Defect and safe modes 38C - 11

Diagnostics - Replacing parts 38C - 12

Diagnostics - Configuration and Programming 38C - 13

Fault finding - Fault summary table 38C - 14

Fault finding - Interpretation of faults 38C - 15

Fault finding - Conformity check 38C - 51

Diagnostic - Summary table of statuses and parameters 38C - 52

Fault finding - Interpretation of statuses 38C - 53

Fault finding - Dealing with command modes 38C - 57

Fault finding - Command summary table 38C - 58

Fault finding - Dealing with command modes 38C - 59

Fault finding - Customer complaints 38C - 64

Fault finding - Fault Finding Chart 38C - 65

38C

MR-413-X44-38C000$000_engTOC.mif

Page 2 of 76

38C-2

MR-413-X44-38C000$047_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP

Special tooling required

Vehicle: New Twingo

Function concerned: MK70 ABSComputer name: TEVES ABS

Vdiag No.: 04

Special tooling required

Multimeter

Elé. 1681 Universal bornier

ABS_V04_PRELI

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$047_eng.mif

Page 8 of 76

38C-8

MR-413-X44-38C000$141_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

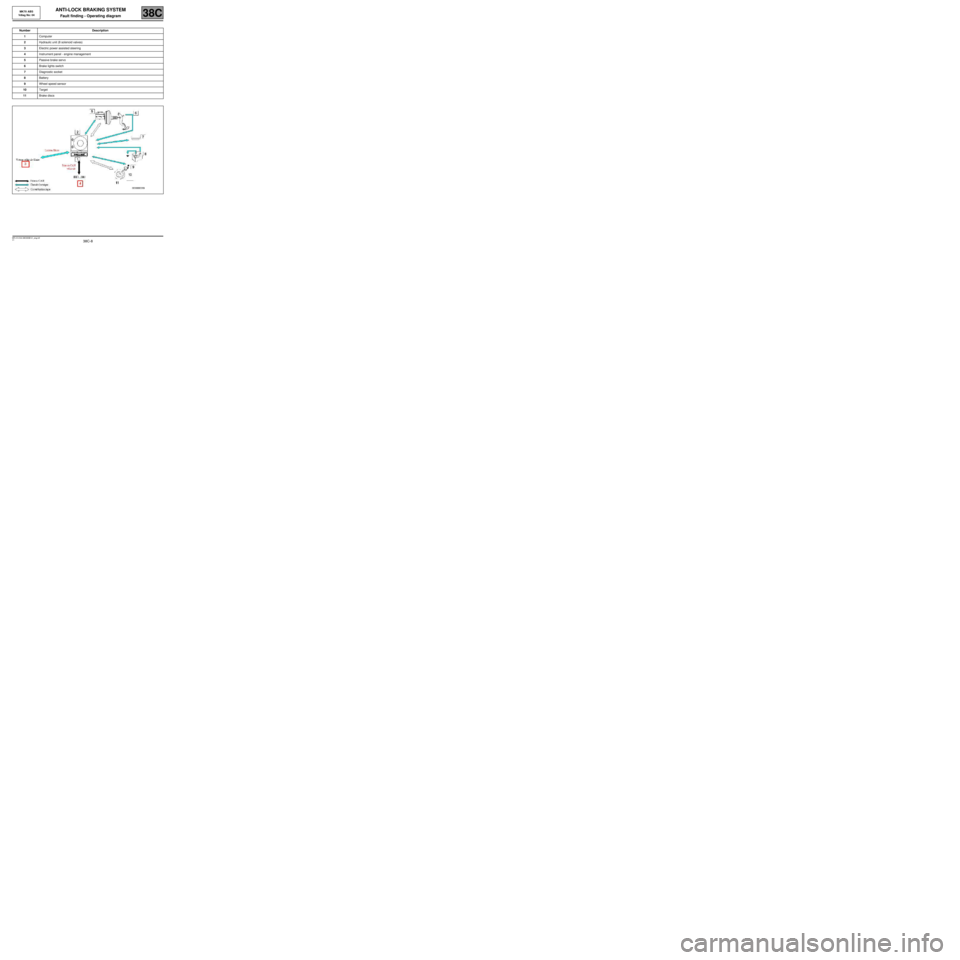

Fault finding - Operating diagram

Number Description

1Computer

2Hydraulic unit (8 solenoid valves)

3Electric power assisted steering

4Instrument panel - engine management

5Passive brake servo

6Brake lights switch

7Diagnostic socket

8Battery

9Wheel speed sensor

10Target

11Brake discs

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$141_eng.mif

Page 15 of 76

38C-15

MR-413-X44-38C000$470_eng.mif

V1

38C

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults

DF001

PRESENT

OR

STOREDCOMPUTER SUPPLY VOLTAGE

1.DEF: Feed voltage too low

2.DEF: Feed voltage too high

NOTESConditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure whether the fault is present or stored.

Use the Technical Note wiring diagram for New Twingo.

1.DEF

NOTESSpecial notes: This fault will appear in a road test

(speed greater than 12 mph (20 km/h)) if the computer

supply voltage is below the minimum operating voltage

(9.4 V < min battery voltage < 10 V).

Check the tightness and the condition of the battery terminals.

Check the battery voltage and carry out any work required to obtain the correct voltage (10 V < battery voltage

< 17 V).

Check the charging circuit (see 80A, battery).

Check the condition and position of the 15A and 20A fuses in the engine fuse and relay box.

Check the condition and position of the F10 5 A fuse in the Passenger compartment fuse box.

Consult section 81C, Fuses.

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

●Connector of component 1094 disconnected, check the insulation and continuity of connection MAH of

component 1094 (tightness, oxidisation etc.).

●Connectors of component 1094 and R107 disconnected, check the insulation and continuity of

connection AP5 between component 1094 and intermediate connector R107.

●Check the insulation and continuity of connection AP5 between intermediate connector R107 and

component 1016.

●Connectors of component 1094 and R67 disconnected, check the insulation and continuity of

connections BP8 and BP14 between component 1094 and intermediate connector R67.

●Check the insulation and continuity of connections BP8 and BP14 between intermediate connector R67

and component 597.

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the connectors or wiring, otherwise replace the wiring.

If the checks reveal no faults, perform a conformity check of component 597.

If all the checks are in order, reconnect the computer and clear the computer fault memory.

Exit the fault finding procedure and carry out a road test.

If the fault is still present, contact the Techline.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF001

MK70 ABS

Vdiag No: 04

MR-413-X44-38C000$470_eng.mif

Page 17 of 76

38C-17

MR-413-X44-38C000$470_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults38C

DF006

PRESENT

OR

STOREDFRONT LEFT-HAND WHEEL SPEED SENSOR CIRCUIT

1.DEF: Fault on the wheel speed sensor circuit

NOTESConditions for applying the fault finding procedure to stored faults:

Follow the fault finding procedure described below for DF006 stored.

Use the Technical Note wiring diagram for New Twingo.

DF006 PRESENT

NOTESNone

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

Check the connection and condition (possible damage to the wiring) of the connector of component 153.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check for a voltage of approximately 12 V between the two connections of component 153 near component 1094.

Is the voltage measured correct?

YES

Swap the 2 front wheel speed sensors over. Clear the computer fault memory.

Switch off the ignition. Switch on the ignition again.

If the fault initially declared as DF006 Front left wheel speed sensor circuit has

become a present DF026 Front right wheel speed sensor circuit, replace the wheel

speed sensor.

If the fault remains on the same side, the wiring between the computer and the sensor is

faulty.

Check insulation and continuity of connections 4C and 4E between

components 153 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

Check insulation and continuity of connections 4C and 4E between

components 153 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

If the fault is still present, contact the Techline.

NO

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF006

Page 19 of 76

38C-19

MR-413-X44-38C000$470_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults38C

DF007

PRESENT

OR

STOREDREAR LEFT-HAND WHEEL SPEED SENSOR CIRCUIT

1.DEF: Fault on the wheel speed sensor circuit

NOTESConditions for applying the fault finding procedure to stored faults:

Follow the fault finding procedure described below for DF007 stored.

Use the Technical Note wiring diagram for New Twingo.

DF007 PRESENT

NOTESNone

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

Check the connection and condition (possible damage to the wiring) of the connector of component 151.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check for a voltage of approximately 12 V between the two connections of component 151 near

component 1094.

Is the voltage measured correct?

YES

Check insulation and continuity of connections 4G and 4H between

components 151 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

If the checks reveal no faults, replace the speed sensor (see MR411 Mechanical

systems, 38C Wheel speed sensor, Removal - Refitting).

Check insulation and continuity of connections 4G and 4H between

components 151 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

If all the checks are in order, contact Techline.

NO

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF007

Page 23 of 76

38C-23

MR-413-X44-38C000$470_eng.mif

V1

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults

MK70 ABS

Vdiag No: 04

38C

DF010

PRESENT

OR

STOREDPUMP MOTOR CIRCUIT

NOTESSpecial notes:

If this fault appears after the computer is replaced, the pump motor connection

has been twisted. Separate the hydraulic unit from the computer and restore the

connection to working order.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after: Brake pedal held down and AC016 Test pump

motor actuator command.

Use the Technical Note wiring diagram for New Twingo.

Check the tightness and the condition of the battery terminals.

Check the condition and position of the 15A and 20A fuses in the engine fuse and relay box.

Check the condition and position of the F10 5A fuse in the Passenger compartment fuse box.

Consult section 81C, Fuses.

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

●Connector of component 1094 disconnected, check the insulation and continuity of connection MAH of

component 1094 (tightness, oxidisation etc.).

●Connectors of component 1094 and R107 disconnected, check the insulation and continuity of

connection AP5 between component 1094 and intermediate connector R107.

●Check the insulation and continuity of connection AP5 between intermediate connector R107 and

component 1016.

●Connectors of component 1094 and R67 disconnected, check the insulation and continuity of

connections BP8 and BP14 between component 1094 and intermediate connector R67.

●Check the insulation and continuity of connections BP8 and BP14 between intermediate connector R67

and component 597.

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the connectors or wiring, otherwise replace the wiring.

Use command AC016 Pump motor test. If the fault is still present (no sound of the pump turning or loss of

communication with the computer), replace the entire unit (pump mechanically seized, pump short circuited, etc.).

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF010

Page 26 of 76

38C-26

MR-413-X44-38C000$470_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults38C

DF026

PRESENT

OR

STOREDFRONT RIGHT-HAND WHEEL SPEED SENSOR CIRCUIT

1.DEF: Fault on the wheel speed sensor circuit

NOTESConditions for applying the fault finding procedure to stored faults:

Follow the fault finding procedure described below for DF026 stored.

Use the Technical Note wiring diagram for New Twingo.

DF026 PRESENT

NOTESNone

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

Check the connection and condition (possible damage to the wiring) of the connector of component 152.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check for a voltage of approximately 12 V between the two connections of component 152 near component 1094.

Is the voltage measured correct?

YES

Swap the 2 front wheel speed sensors over. Clear the computer fault memory.

Switch off the ignition. Switch on the ignition again.

If a fault, which was initially registered as DF026 Front right-hand wheel speed

sensor circuit becomes present DF006 Front left-hand wheel speed sensor circuit,

replace the wheel speed sensor (see MR411 Mechanical, 38C, ABS, Wheel speed

sensor: Removal - Refitting).

If the fault remains on the same side, the wiring between the computer and the sensor is

faulty.

Check the insulation and continuity of connections 4M and 4N between

components 152 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

Check the insulation and continuity of connections 4M and 4N between

components 152 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

If all the checks are in order, contact Techline.

NO

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF026

Page 28 of 76

38C-28

MR-413-X44-38C000$470_eng.mif

V1

MK70 ABS

Vdiag No: 04ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults38C

DF027

PRESENT

OR

STOREDREAR RIGHT-HAND WHEEL SPEED SENSOR CIRCUIT

1.DEF: Fault on the wheel speed sensor circuit

NOTESConditions for applying the fault finding procedure to stored faults:

Follow the fault finding procedure described below for DF027 stored.

Use the Technical Note wiring diagram for New Twingo.

DF027 PRESENT

NOTESNone

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

Check the connection and condition (possible damage to the wiring) of the connector of component 150.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check for a voltage of approximately 12 V between the two connections of component 150 near

component 1094.

Is the voltage measured correct?

YES

Check the insulation and continuity of connections 4S and 4T between

components 150 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

If the checks reveal no faults, replace the speed sensor (see MR411 Mechanical

systems, 38C Wheel speed sensor, Removal - Refitting).

Check the insulation and continuity of connections 4S and 4T between

components 150 and 1094.

Also check the insulation between these 2 connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connectors or wiring,

otherwise replace the wiring.

If all the checks are in order, contact Techline.

NO

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF027

Page 42 of 76

38C-42

MR-413-X44-38C000$517_eng.mif

V1

ANTI-LOCK BRAKING SYSTEM

Fault finding - Interpretation of faults

MK70 ABS

Vdiag No: 04

38C

DF152

PRESENT

OR

STOREDMULTIPLEX NETWORK

1.DEF: Multiplex line connection fault

NOTESSpecial notes:

If several computers are affected by a similar multiplex network fault, contact the

Techline to check the cases previously noted first.

Conditions for applying the fault finding procedure to stored faults:

Apply the fault finding procedure as below.

Use the Technical Note wiring diagram for New Twingo.

If no other computer has detected the failure of the multiplex network but only the absence of ABS frames, carry

out the following checks:

Check the connection and condition (possible damage to the wiring) of the connector of component 1094.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check the Insulation and continuity of connections 133B, 133C and HK of component 1094.

Also check the insulation between these connections.

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the connectors or wiring, otherwise replace the wiring.

Run a multiplex network test (see 88B, Multiplex).

If the fault is still present, contact the Techline.

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

ABS_V04_DF152