RENAULT TWINGO RS 2009 2.G Electrical Equipment - Airbags And Pretensioners Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 67, PDF Size: 0.3 MB

Page 1 of 67

8Electrical equipment

V3 MR-413-X44-88C000$TOC.mif

V3

88C

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V3

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s. 2009

AIRBAGS AND PRETENSIONERS

MRSZ AIRBAG

Vdiag: 04

Fault finding - Introduction 88C - 2

Fault finding - List and location of components 88C - 7

Fault finding - Operating diagram 88C - 14

Fault finding - Function 88C - 16

Fault finding - Replacement of components 88C - 18

Fault finding - Configurations and programming 88C - 19

Fault finding - Fault summary table 88C - 21

Fault finding - Interpretation of faults 88C - 22

Fault finding - Conformity check 88C - 61

Fault finding - List of Statuses and parameters 88C - 64

Fault finding - Customer complaints 88C - 65

Fault finding - Fault Finding Chart 88C - 66

Page 2 of 67

88C-2

MR-413-X44-88C000$077.mif

V3

88C

AIRBAGS AND PRETENSIONERS

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this manual):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu-Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP

Special tooling required

3. REMINDERS

To run fault finding on the vehicle computers, switch on the ignition. Proceed as follows:

–turn the ignition key to APC,

–connect the diagnostic tool and perform the required operations.

To cut off the + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–turn the ignition key to OFF,

–verify that the forced + after ignition feed has been switched off by checking that the computer warning lights on

the control panel have gone out. Vehicle (s): New TWINGO

Function concerned: AIRBAGName of computer: TEMIC MRSZ

Vdiag No.: 04

Special tooling required

Multimeter

–Dummy module (Part no. Elé. 1835 yellow)

–Dummy module (Part no. Elé. 1837 - 2)

–Dummy module (Part no. Elé. 1837 - 5)

–Dummy module (Part no. Elé. 1837 - 6)

ABGMRSZ_V04_PRELI

MR-413-X44-88C000$077.mif

MRSZ AIRBAG

Vdiag: 04

Page 3 of 67

88C-3

MR-413-X44-88C000$077.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - Introduction88C

Faults

Consider the fault status, present or stored when the diagnostic tool is used after the + after ignition feed

(without operating the system components).

Present faults must be dealt with according to the procedure specified in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the Notes section.

If the fault is confirmed when the notes are applied, the fault is present. Deal with the fault

If the fault is not confirmed, check:

–the electrical lines which correspond to the fault,

–the connectors on these lines (corrosion, bent pins, etc.),

–the resistance of the component detected as faulty,

–the condition of the wires (melted or split insulation, wear).

Or use the fault finding to check the circuit of the faulty component.

Conformity check

The aim of the conformity check is to check statuses and parameters that do not produce a fault display on the

diagnostic tool when they are inconsistent. Therefore, this stage is used to:

–Run fault finding on faults that do not have a fault display, and which may correspond to a customer

complaint,

–To check that the system is operating correctly, and that there is no risk of a fault recurring after repairs.

–This section gives the fault finding procedures for statuses and parameters and the conditions for

checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the diagnostic tool check is in order, but the customer complaint is still present, the fault should be dealt with as a

customer complaint.

A summary of the overall procedure to follow is provided on the following page in the

form of a flow chart.

Page 4 of 67

88C-4

MR-413-X44-88C000$077.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - Introduction88C

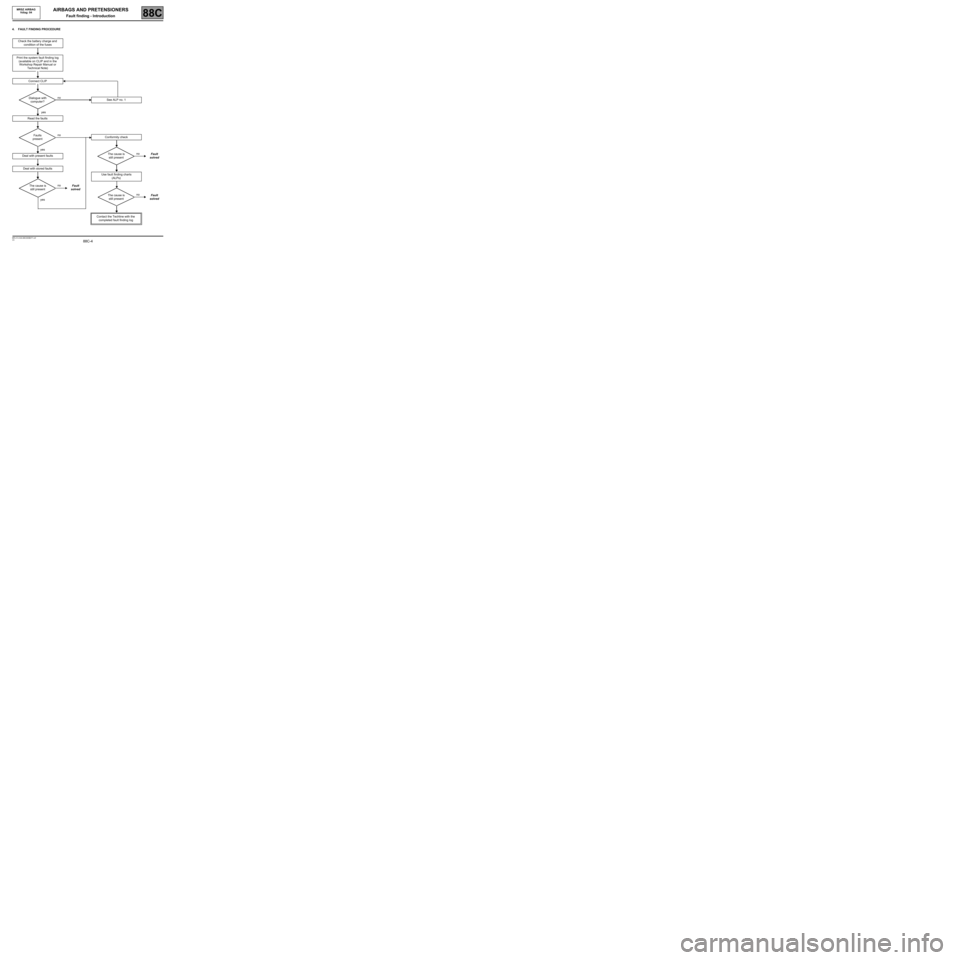

4. FAULT FINDING PROCEDURE

Check the battery charge and

condition of the fuses

Print the system fault finding log

(available on CLIP and in the

Workshop Repair Manual or

Technical Note)

Connect CLIP

no

Dialogue with

computer?

yes

Read the faults

no

Faults

present

yes

Deal with present faults

Deal with stored faults

no

The cause is

still presentFault

solved

yes

See ALP no. 1

Conformity check

no

The cause is

still presentFault

solved

Use fault finding charts

(ALPs)

no

The cause is

still presentFault

solved

Contact the Techline with the

completed fault finding log

Page 5 of 67

88C-5

MR-413-X44-88C000$077.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - Introduction88C

4. FAULT FINDING PROCEDURE (CONTINUED)

Wiring check

Fault finding problems:

Disconnecting the connectors and/or manipulating the wiring harness may temporarily remove the cause of a fault.

Electrical measurements of voltage, resistance and insulation are generally correct, especially if the fault is not

present when the analysis is made (stored fault).

Visual inspection:

Look for damage under the bonnet and in the passenger compartment.

Carefully check the fuses, insulators and wiring harness routing.

Look for signs of oxidation.

Tactile inspection:

While manipulating the wiring harness, use the diagnostic tool to note any change in fault status from stored to

present.

Make sure that the connectors are properly locked.

Apply light pressure to the connectors.

Twist the wiring harness.

If there is a change in status, try to locate the source of the fault.

Inspection of each component:

Disconnect the connectors and check the appearance of the clips and tabs, as well as their crimping (no crimping on

the insulating section).

Make sure that the clips and tabs are properly locked in the sockets.

Make sure that no clips or tabs have been dislodged during connection.

Check the clip contact pressure using an appropriate model of tab.

Resistance check:

Check the continuity of entire lines, then section by section.

Look for a short circuit to earth, to + 12 V or to another wire.

If a fault is detected, repair or replace the wiring harness.

Page 6 of 67

88C-6

MR-413-X44-88C000$077.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - Introduction88C

5. FAULT FINDING LOG

You will always be asked for this log:

●when requesting technical assistance from Techline,

●for approval requests when replacing parts for which approval is mandatory,

●to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed

.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any damage or injury:

Check the battery voltage to avoid incorrect operation of computer functions.

During work on the airbag/seat belt pretensioner systems, it is vital that you lock the computer using the

diagnostic tool to prevent any risk of accidental triggering (all the trigger lines will be disabled).

The locked mode is indicated when the instrument panel warning light comes on.

If it is impossible to connect the diagnostic tool, switch off the ignition, remove the system power supply

fuse and wait at least 2 seconds for the discharge of the reserve power capacity.

Never measure the airbag or pretensioner trigger lines with any device other than XRBAG or CLIP's "Airbag

and pretensioner wiring harness check".

Before using a dummy ignition module, ensure that its resistance is between 1.8 and 2.5 Ω.

During the procedure, check that the computer feed voltage does not drop below 10 V.

Disconnect the battery before removing and refitting any pyrotechnic component (airbag module,

pretensioner or seat belt retractor).IMPORTANTIMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the procedure, enables you to keep

track of the procedure which is carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE ESSENTIAL THAT THE FAULT FINDING LOG

IS FILLED OUT EVERY TIME IT IS REQUESTED BY TECHLINE OR THE WARRANT RETURNS

DEPARTMENT.

IMPORTANT

Airbag and pretensioner destruction and scrapping is subject to national legislation.

Page 7 of 67

88C-7

MR-413-X44-88C000$154.mif

V3

88C

AIRBAGS AND PRETENSIONERS

Fault finding - List and location of components

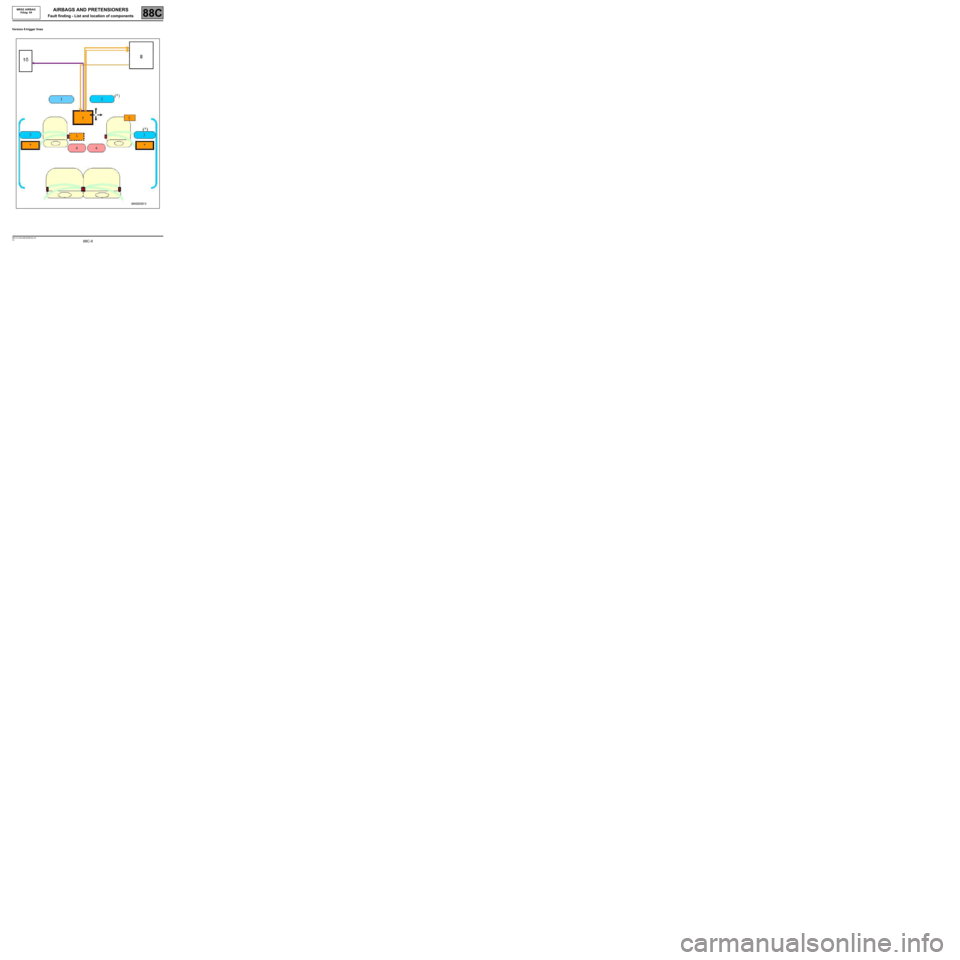

There are 3 types of computers depending on the vehicle equipment level:

➡ Version 10 trigger lines (only computer available from the spare parts department).

➡ Version 6 trigger lines.

➡ Version 4 trigger lines.

Version 10 trigger lines

MR-413-X44-88C000$154.mif

MRSZ AIRBAG

Vdiag: 04

Page 8 of 67

88C-8

MR-413-X44-88C000$154.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - List and location of components88C

Version 10 trigger lines (continued)

Number Description

1Driver's frontal airbag

2Passenger frontal airbag

3Side chest-level airbag (passenger or driver)

4Rear curtain airbag (passenger or driver)

5Rear seat belt pyrotechnic retractor

6Lap belt pyrotechnic pretensioner (passenger and driver)

7Airbag computer

8Driver's seat belt buckle sensor

9Side impact sensor (passenger or driver)

10 Sensor for front passenger airbag inhibition by key

11 Instrument panel

12 Information to other systems (transmission via CAN)

(*) Component which can be deactivated by key

Page 9 of 67

88C-9

MR-413-X44-88C000$154.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - List and location of components88C

Version 6 trigger lines

Page 10 of 67

88C-10

MR-413-X44-88C000$154.mif

V3

MRSZ AIRBAG

Vdiag: 04AIRBAGS AND PRETENSIONERS

Fault finding - List and location of components88C

Version: 6 trigger lines (continued)

Number Description

1Driver's frontal airbag

2Passenger frontal airbag

3Side chest-level airbag (passenger or driver)

4Lap belt pyrotechnic pretensioner (passenger or driver)

5Airbag computer

6Driver's seat belt buckle sensor

7Side impact sensor (passenger or driver)

8Instrument panel

9Sensor for front passenger airbag inhibition by key

10 Information to other systems (transmission via CAN)

(*) Component which can be deactivated by key