length RENAULT TWINGO RS 2009 2.G Chasiss Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 17 of 281

30A-13

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

This procedure applies to copper pipes diameter 4.7

mm.

REPAIR

I - PIPE PREPARATION OPERATION

a

aCut the pipe to the recommended length using a

tube cutter (see Garage equipment catalogue).

aPut the nuts or bolts on the pipe before forming the

rivets.

II - MAKING THE RIVETS

a Equipment required

compressed air nozzle

Tightening torquesm

brake pipe bolts8 N.m

underbody unions

(female/male)6 N.m

Note:

This procedure does not apply to:

-hybrid pipes (pipe + hose),

-pipes with diameters 6 mm and 8 mm.

WARNING

To avoid causing a breakdown in hydraulic brake

circuit , do not squash or bend the rigid pipe

when cutting.

128666

128643

128665

Note:

To make the r ivets, fit the rivet press in a vice.

Page 18 of 281

30A-14

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

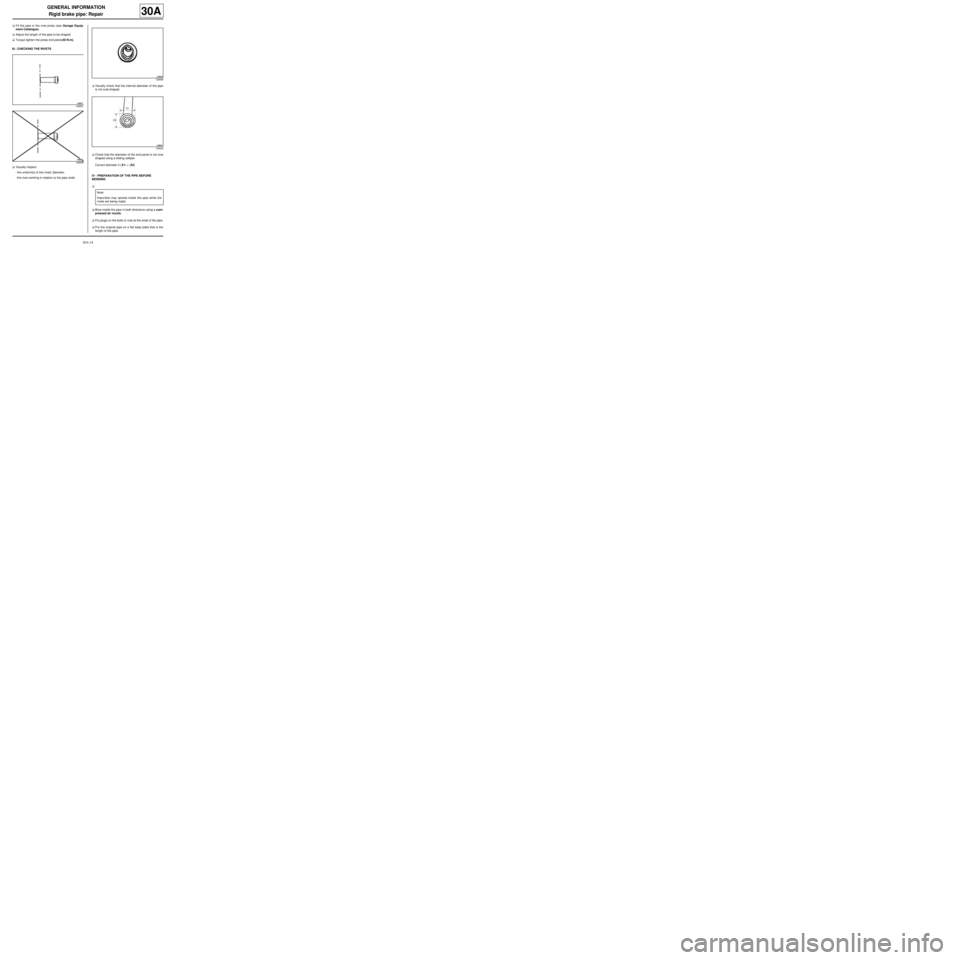

aFit the pipe in the rivet press (see Garage Equip-

ment Catalogue).

aAdjust the length of the pipe to be shaped.

aTorque tighten the press end piece(40 N.m).

III - CHECKING THE RIVETS

aVisually inspect:

-the uniformity of the rivets' diameter,

-the rivet centring in relation to the pipe shaft.aVisually check that the internal diameter of the pipe

is not oval-shaped.

aCheck that the diameter of the end panel is not oval

shaped using a sliding calliper.

Correct diameter if (X1) = (X2)

IV - PREPARATION OF THE PIPE BEFORE

BENDING

a

aBlow inside the pipe in both directions using a com-

pressed air nozzle.

aPut plugs on the bolts or nuts at the ends of the pipe.

aPut the original pipe on a flat base plate that is the

length of the pipe.

128667

128669

128668

128645

Note:

Impurities may spread inside the pipe while the

rivets are being made.

Page 236 of 281

37A-57

MECHANICAL COMPONENT CONTROLS

Clutch circuit: Bleed

JH3 or JR5

37A

2 - Bleed using a new syringe.

aKeep the clutch pedal in the upper position using a

strap attached to the steering wheel to ensure conti-

nuity of the hydraulic circuit during the bleed opera-

tion.

aRemove the bleed plug from the clutch slave cylin-

der.

aConnect a transparent pipe of sufficient length to the

bleed hole (at least thirty centimetres) in order to

place it at the same height as the reservoir.

aOpen the bleed screw.

aFill the brake fluid master cylinder reservoir until

brake fluid flows out of the bleed screw.

aConnect a new hydraulic circuit bleed syringe

filled with a useful volume of 60 ml of approved

brake fluid to the end of the transparent pipe.

aSlowly inject the entire contents of the syringe into

the hydraulic clutch circuit without injecting any of

the air from the top section of the syringe.

aClose the bleed screw.

aRemove the transparent pipe from the bleed hole.

aRefit the bleed plug.

aTop up the brake fluid level in the master cylinder

reservoir.

aDisengage and engage the clutch quickly around

twenty times.

aCheck that the clutch system is operating correctly.

aRepeat the bleed operation if necessary.

aCheck the adjustment of the switch. (see 37A, Me-

chanical component controls, Clutch pedal

switch: Removal - Refitting, page 37A-52) (37A,

mechanical control elements).IV - BLEED PROCEDURE IF PARTS OF THE

HYDRAULIC CIRCUIT ARE REMOVED.

a

Note:

Take care not to disrupt the adjustment of the

clutch start of travel switch.

Note:

The transparent pipe must remain at the same

height as the master cylinder reservoir to prevent

air from entering inside the clutch circuit.

WARNING

The master cylinder pipe must be disconnected

from its take-off point on the br ake fluid reservoir,

to avoid any foreign matter penetrating inside the

hydraulic brake circuit.

WARNING

Prepare for the fl ow of fluid and protect the sur-

rounding components.

Note:

Prefill the hydraulic circuit pipe equipped with a

filter.

Position the filter head facing downwards to

ensure that it fills.

Page 238 of 281

37A-59

MECHANICAL COMPONENT CONTROLS

Clutch circuit: Bleed

JH3 or JR5

37A

aPrefill the hydraulic tappet using the new syringe (by

gravity).

aRefit the part(s) concerned.V - BLEED PROCEDURE AFTER A REMOVING A

COMPONENT OF THE HYDRAULIC CIRCUIT.

aKeep the clutch pedal in the upper position using a

strap attached to the steering wheel to ensure conti-

nuity of the hydraulic circuit during the bleed opera-

tion.

aRemove the bleed plug from the clutch slave cylin-

der.

aConnect a transparent pipe of sufficient length to the

bleed hole (at least thirty centimetres) in order to

place it at the same height as the reservoir.

aOpen the bleed screw.

aFill the brake fluid master cylinder reservoir until

brake fluid flows out of the bleed screw.

aConnect a new syringe containing 60 ml of ap-

proved brake fluid to the end of the transparent pipe.

aSlowly inject the entire contents of the syringe into

the hydraulic clutch circuit without injecting any of

the air from the top section of the syringe.

aClose the bleed screw.

aRemove the transparent pipe from the bleed hole.

aRefit the bleed plug.

aTop up the brake fluid level in the master cylinder

reservoir.

aDisengage and engage the clutch quickly around

twenty times.

aCheck that the clutch system is operating correctly.

aRepeat the bleed operation if necessary.

aCheck the adjustment of the switch. (see 37A, Me-

chanical component controls, Clutch pedal

switch: Removal - Refitting, page 37A-52) (37A,

mechanical control elements).

141809

Note:

Take care not to disrupt the adjustment of the

clutch start of travel switch.

Note:

The transparent pipe must remain at the same

height as the master cylinder reser voir to prevent

air from enter ing inside the clutch circuit.