light RENAULT TWINGO RS 2009 2.G Electrical Equipment - Petrol Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 348

Page 28 of 348

17B-28V7 MR-413-X44-17B000$070.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

1. OPERATING SAFETY

Activation of the warning lights

The SIM32 injection system manages the illumination of three warning lights according to the severity of the faults

detected, to inform the customer and to assist with fault finding.

The injection computer manages the activation of the warning lights on the instrument panel. These warning lights

illuminate during the starting phase and in the event of an injection fault or engine overheating.

The warning light activation commands are sent to the instrument panel.

Warning light illumination principle

When the ignition is switched on, the OBD (On Board Diagnostic) warning light is illuminated for approximately

3 seconds and is then extinguished.

If there is an injection fault (severity level 1), the SERVICE warning light is illuminated.

It indicates a reduced level of operation and a limited safety level.

The user must carry out repairs as soon as possible:

–motorised throttle valve,

–accelerator pedal potentiometer,

–inlet manifold pressure sensor,

–computer,

–actuator feed,

–the computer power supply,

–turbocharger pressure sensor (for D4FT 780).

For faults requiring the driver to stop the engine quickly, the severity level 2 warning light is illuminated.

If a fault causing excessive exhaust gas pollution is detected, the orange OBD warning light engine symbol is

illuminated:

–the light flashes if the fault could lead to a risk of destroying catalytic converter (destructive engine misfire). If this

happens, the vehicle must be stopped immediately.

–the light is permanently illuminated if the emission control standards are not met (pollutant engine misfire,

catalytic converter fault, oxygen sensor fault, inconsistency between the oxygen sensors and a fuel vapour

absorber fault).

Mileage travelled with fault

The parameter PR106 Mileage counter fault warning light illuminated displays the mileage covered and

illuminates one of the injection fault warning lights: fault severity level 1 (amber) and 2 (red). The parameter

PR105 Mileage counter OBD fault warning light illuminated displays the mileage covered and illuminates the

OBD warning light.

This counter is reset to 0 using the diagnostic tool via the command RZ001 Fault memory.

PETROL INJECTION

Fault finding – Role of components

Page 29 of 348

17B-29V7 MR-413-X44-17B000$070.mif

PETROL INJECTION

Fault finding – Role of components17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

3. INTERSYSTEM ENGINE FUNCTIONS

The intersystem connections relating to the particular requirements of the injection are as follows:

–The instrument panel computer requests illumination of the OBD warning light to warn of an emissions control fault.

–Requests illumination of the Severity level 1 warning light to warn of an operational safety fault related to the

injection system.

–Requests illumination of the Severity level 2 warning light to warn of an operational safety fault or engine

overheating.

–Requests activation of the fan assemblies (GMV) for engine cooling, but also for the air conditioning system and

sequential gearbox (BVR) functions.

–Request for air conditioning compressor switch-off for engine programming requirements such as starting,

performance, anti-stall, overspeed, etc.

–Passenger Compartment Heating Resistor cut-off or setting request for engine programming requirements such as

starting, performance, anti-stall, overspeed, etc.

–Request for gradual engagement of electrical consumers and to limit power: This last function is made possible by

the alternator being operated. This is used to improve the engine handling in critical operating phases, mainly when

idling and when starting. These requests are sent by the UCH via the CAN network where they are converted before

being sent to the alternator.

Page 35 of 348

17B-35V7 MR-413-X44-17B000$090.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

1. COMPUTER REPLACEMENT OR REPROGRAMMING OPERATIONS

Computer replacement or reprogramming for engines with the OCS (customised oil change interval)

function.

For Vdiag 44 and 4C, commands SC001 and SC003 are not accessible.

The system can be programmed via the diagnostic socket using the RENAULT CLIP diagnostic tool (refer to

Technical Note 3585A, COMPUTER PROGRAMMING AND REPROGRAMMING PROCEDURE or follow the

instructions given by the diagnostic tool). Only in Vdiag 54 and certain engines in Vdiag 50:

For Vdiag 50, the procedure below should be followed only if ET840 Customised Oil Change Interval is ACTIVE.

Certain variables linked to the O.C.S and the details of the last four oil services are saved by the computer.

However, all data saved is cleared during a reprogramming operation. When replacing or reprogramming the

computer, it is necessary to save the data from the old computer so it can be written to the new computer

(or reprogrammed). To do this before changing (or reprogramming) the computer, it is necessary to run the request

SC003 Save computer data, and after it has been changed (or reprogrammed), it is necessary to run the request

SC001 Write saved data.

For Vdiag 50, if ET840 Customised Oil Change Interval is INACTIVE, commands SC001 and SC003 should

not be used.

Operations to check before reprogramming the injection computer:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Ignition switched on and main switch in rest position (the computer detects rest position at that moment).

Switch in Cruise control position to activate the Cruise control function.

Switch in Speed limiter position to activate the Speed limiter function.

IMPORTANT:

–Switch on the diagnostic tool (mains or cigarette lighter supply).

–Connect a battery charger.

–Switch off all electrical consumers (lights, interior lighting, air conditioning, radio, etc.).

–Wait for the engine to cool (engine coolant temperature below 60˚C and air temperature below 50˚C).

PETROL INJECTION

Fault finding – Replacement of components

Page 37 of 348

17B-37V7 MR-413-X44-17B000$100.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

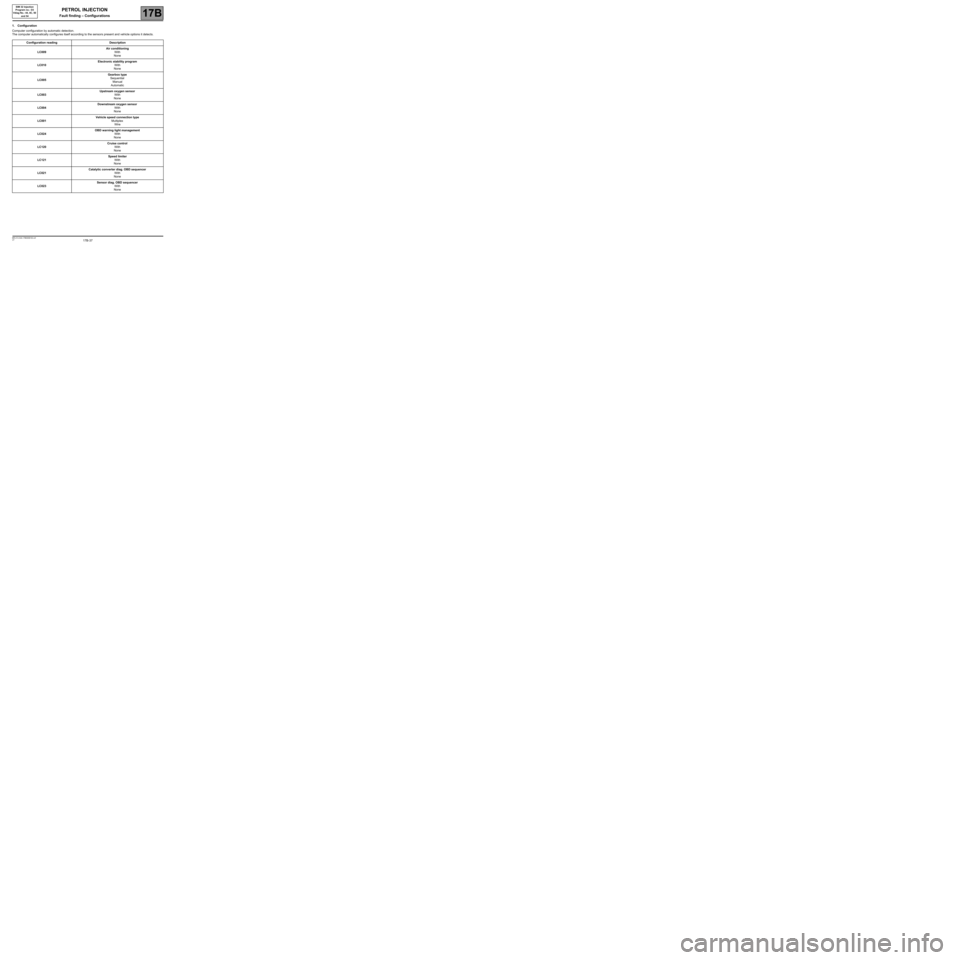

1. Configuration

Computer configuration by automatic detection.

The computer automatically configures itself according to the sensors present and vehicle options it detects.

Configuration readingDescription

LC009

Air conditioning

With

None

LC010

Electronic stability program

With

None

LC005

Gearbox type

Sequential

Manual

Automatic

LC003

Upstream oxygen sensor

With

None

LC004

Downstream oxygen sensor

With

None

LC001

Vehicle speed connection type

Multiplex

Wire

LC024

OBD warning light management

With

None

LC120

Cruise control

With

None

LC121

Speed limiter

With

None

LC021

Catalytic converter diag. OBD sequencer

With

None

LC023

Sensor diag. OBD sequencer

With

None

PETROL INJECTION

Fault finding – Configurations

Page 43 of 348

17B-43V7 MR-413-X44-17B000$131.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

* EOBD: European On Board Diagnostics

DF001

PRESENT

OR

STOREDCOOLANT TEMPERATURE SENSOR CIRCUIT

1.DEF: signal incoherence

2.DEF: abnormal voltage

3.DEF: EOBD*

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present when the ignition is switched on.

Special notes:

If the fault is present, the EOBD* warning light is illuminated and the low speed engine

cooling fan is permanently activated.

1.DEF: Consult the parameter PR064 Coolant temperature:

If the tool displays 120˚C, this indicates a short circuit to 12V or an open circuit.

If the tool displays - 40˚C, this indicates a short circuit to earth.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the condition of the connector of the coolant temperature sensor (component code 244) and of the engine

management computer (component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of the coolant temperature sensor, component code 244 between the connections 3C and

3JK:

●at 10˚C: 12030 Ω < X < 12890 Ω,

●at 25˚C: 2195 Ω < X < 2309 Ω,

●at 50˚C: 795.5 Ω < X < 826.5 Ω,

●at 80˚C: 279.3 Ω < X < 286.7 Ω.

If the coolant temperature sensor resistances are not correct, replace the coolant temperature sensor.

Check the insulation and continuity of the following connections:

●3C between components 120 and 244,

●3JK between the components 120 and 244.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact Techline.

SIM32_V44_DF001/SIM32_V4C_DF001/SIM32_V50_DF001/SIM32_V54_DF001

PETROL INJECTION

Fault finding – Interpretation of faults

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.

Page 44 of 348

17B-44V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF002

PRESENT

OR

STOREDAIR TEMPERATURE SENSOR CIRCUIT

1.DEF: Abnormal voltage

2.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present, with the ignition on.

Special notes:

The OBD warning light is lit.

Consult the parameters PR059 Air inlet temperature:

If the tool displays 120˚C, this indicates a short circuit to 12V or an open circuit.

If the tool displays - 40˚C, this indicates a short circuit to earth.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the condition of the connector of the air temperature sensor (component code 272) and of the engine

management computer (component code 120).

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the connector, otherwise change the wiring.

Measure the resistance of the air temperature sensor, component code 272 between connections 3B and 3JQ:

●at 25˚C: 1928 Ω < X < 2174 Ω,

●at 50˚C: 763 Ω < X < 857 Ω.

If the air temperature sensor resistances are not correct, replace the air temperature sensor.

Check the insulation and continuity of the following connections:

●3B between components 120 and 272,

●3JQ between the components 120 and 272.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, contact Techline.

SIM32_V44_DF002/SIM32_V4C_DF002/SIM32_V50_DF002/SIM32_V54_DF002

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.

Page 45 of 348

17B-45V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Only Vdiag 54.

DF004

PRESENT

OR

STOREDTURBOCHARGING PRESSURE SENSOR CIRCUIT

1.DEF: Voltage outside permitted range of values

2.DEF: Data inconsistency

3.DEF: EOBD

NOTESPriority when dealing with a number of faults:

Deal with fault DF012 Sensor supply voltage no. 2 as a priority if it is present

or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present after the ignition is switched on or after the engine has

been running at an engine speed above 600 rpm.

Special notes:

–illumination of the OBD warning light,

–Throttle valve defect mode types 5 and 6.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the cleanliness, condition, and fitting of the turbocharging pressure sensor (component code 1071).

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

If the fault is still present, manipulate the wiring harness in order to note a change in fault status (present

→

stored).

Look for possible damage to the wiring harness.

Check the condition of the engine management computer connector (component code 120).

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check for + 5V on connection 3LQ and for an earth on connection 3LN of the turbocharger pressure sensor,

component code 1071.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Contact the Techline if it is not correct.

SIM32_V54_DF004

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.

Page 47 of 348

17B-47V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF011

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE NO. 1

1.DEF: Abnormal voltage

2.DEF: Fault on potentiometer supply 1

3.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Deal with the fault DF084 Actuator relay control circuit or DF046 Battery voltage as

a priority if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is declared present when the ignition is switched on.

Special notes:

In the event of a short circuit to earth or to + 12V, the severity level 1 warning light is

illuminated.

The injection changes over to defect modes 4 and 5, which causes:

–the speed to be limited to 66 mph (110 km/h),

–a loss of power when accelerating (impression that the accelerator pedal is spongy),

–loss of signals from other computers and switch to safe mode on automatic and

sequential gearboxes, if required.

The OBD warning light may illuminate, depending on the sensors affected.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the cleanliness and condition of the sensor connections for supply voltage assembly No.1:

–manifold pressure sensor, component code 147,

–pedal potentiometer (gang 2), component code 921,

–rotary switch, component code 689,

–refrigerant fluid pressure sensor, component code 1202.

Check the condition of the engine management computer connector, component code 120.

If the connector or connectors are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

SIM32_V44_DF011/SIM32_V4C_DF011/SIM32_V50_DF011/SIM32_V54_DF011

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.

Page 49 of 348

17B-49V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF012

PRESENT

OR

STOREDSENSOR SUPPLY VOLTAGE No. 2

1.DEF: Abnormal voltage

2.DEF: Fault on potentiometer supply 2

3.DEF: EOBD

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present, with the ignition on.

Special notes:

In the event of a short circuit to earth or to + 12V, the severity level 1 warning light

illuminates. The injection enters defect mode 1 and 2, causing the vehicle and engine

speed to be limited. The ESP and the cruise control/speed limiter are deactivated.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III,

or MODUS.

Check the cleanliness and condition of the sensor connections for supply voltage assembly No. 2:

–pedal potentiometer (gang 1), component code 921.

Check the condition of the engine management computer connector, component code 120.

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

●3LR between the components 120 and 921,

●3MN between the components 120 and 1076.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

SIM32_V44_DF012/SIM32_V4C_DF012/SIM32_V50_DF012/SIM32_V54_DF012

AFTER REPAIRFollow the instructions to confirm repair:

If the fault is present, continue to deal with the fault.

If the fault is stored, ignore it.

Deal with any other faults.

Clear the stored faults.

Page 51 of 348

17B-51V7 MR-413-X44-17B000$131.mif

PETROL INJECTION

Fault finding – Interpretation of faults17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

DF026

PRESENT

OR

STOREDCYLINDER No. 1 INJECTOR CONTROL CIRCUITCO: Open circuit

CC.0: Short circuit to earth

CC.1: Short circuit to + 12 V

1.DEF: EOBD

NOTESPriorities when dealing with a number of faults:

Deal with the fault DF084 Actuator relay control circuit or DF046 Battery voltage as

a priority if they are present or stored.

Conditions for applying the fault finding procedure to stored faults:

The fault is considered present when the engine is running.

Special notes:

CO/CC.1: No injection on cylinder 1. Greatly reduced performance.

OBD warning light illuminated.

CC.0: The injector is still open: there is a risk of the engine stalling or being damaged

when starting. Greatly reduced performance. OBD warning light illuminated.

Use the Wiring Diagrams Technical Note for NEW TWINGO, E33, CLIO III, or

MODUS.

Check the condition of the injector no. 1 connector (component code 193).

If the connector is faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector, otherwise change the wiring.

SIM32_V44_DF026/SIM32_V4C_DF026/SIM32_V50_DF026/SIM32_V54_DF026

AFTER REPAIRDeal with any other faults. Clear the fault memory.

Switch off the ignition, wait 1 minute and carry out a road test followed by a check with

the diagnostic tool.