engine RENAULT TWINGO RS 2009 2.G Electrical Equipment Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 241

Page 164 of 241

88A-28

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

-the fuel vapour absorber connector (3) ,

-the ignition coil connector (4) ,

-the upstream oxygen sensor connector (5) ,

-the downstream oxygen sensor connector (6) ,

-the reversing lights switch connector (7) ,

-the radio interference suppressor connector (8) ,

-the alternator connector (11) ,

-the engine harness/injection wiring connector (12) ,

-the air inlet temperature sensor connector (13) ,

-the pinking sensor connector (14) ,

-the air inlet pressure sensor connector (15) ,

-the motorised throttle valve connector (16) ,

-the coolant temperature sensor connector (17) ,

-the crankshaft position sensor connector (18)

-the petrol injection computer connectors (19) ,

-the engine harness/front of engine wiring connec-

tor (20) .

aDisconnect the cooling fan assembly connector (21)

.aDisconnect:

-the engine cooling fan assembly connector (22) ,

-the engine cooling fan assembly resistor connector

(23) ,

-the refrigerant fluid pressure sensor connector (9) ,

-the air conditioning compressor connector (10) .

aRemove:

-the alternator earth wiring nut (24) ,

-the nuts from the starter supply and earth terminals

(25) ,

-the engine earth wiring nuts (26) ,

-the earth wiring nut on the front left-hand side

member (27) ,

-the positive battery terminal wiring nut (28) ,

-the negative battery terminal wiring nuts (29) ,

-the wiring mounting nut on the battery protection

fuse board (30) ,

-the engine compartment connection unit supply

terminal nut (31) .

aUnclip:

-the section of wiring on the cylinder head, STANDARD HEATING

122359

AIR CONDITIONING

125249

Page 165 of 241

88A-29

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

-the section of wiring on the cylinder block and sub-

frame,

-the section of wiring on the engine cooling fan as-

sembly.

aRemove the engine harness.

WARNING

To prevent any damage during the removal ope-

ration, check that the wiring is free from its moun-

tings (retaining clip, plastic clip, adhesive tape,

connector, etc.).

Page 166 of 241

88A-30

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

aDisconnect:

-the air inlet pressure sensor connector (32) , D4F

122361

122362122368

Page 167 of 241

88A-31

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

-the fuel vapour absorber connector (33) ,

-the ignition coil connector (34) ,

-the radio interference suppressor connector (35) ,

-the oil pressure sensor connector (36) ,

-the downstream oxygen sensor connector (37) ,

-the upstream oxygen sensor connector (38) ,

-the reverse gear switch connector (39) ,

-the motorised throttle valve connector (40) ,

-the alternator connector (43) ,

-the pinking sensor connector (44) ,

-the engine harness/injection wiring connector (45) ,

-the crankshaft position sensor connector (46) ,

-the coolant temperature sensor connector (47) ,

-the petrol injection computer connectors (48) ,

-the engine harness/front of engine wiring connec-

tor (49) .

aDisconnect the cooling fan assembly connector (50)

.aDisconnect:

-the engine cooling fan assembly connector (51) ,

-the engine cooling fan assembly resistor connector

(52) ,

-the refrigerant fluid pressure sensor connector (41)

,

-the air conditioning compressor connector (42) . STANDARD HEATING

122359

AIR CONDITIONING

125249

Page 168 of 241

88A-32

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

aDisconnect:

-the sequential gearbox computer connectors (53) ,-the engine harness/sequential gearbox wiring con-

nector (54) .

aRemove:

-the alternator earth wiring nut (55) ,

-the nuts from the starter supply and earth terminals

(56) ,

-the engine earth wiring nuts (57) ,

-the earth wiring nut on the front left-hand side

member (58) ,

-the positive battery terminal wiring nut (59) ,

-the negative battery terminal wiring nuts (60) ,

-the wiring mounting nut on the battery protection

fuse board (61) ,

-the engine compartment connection unit supply wi-

ring nut (62) .

aUnclip:

-the section of wiring on the cylinder head, JH1

125270

125271

Page 169 of 241

88A-33

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

-the section of wiring on the cylinder block and sub-

frame,

-the section of wiring on the engine cooling fan as-

sembly.

aRemove the engine harness.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aIf replacing with a complete wiring harness, lock the

unused connectors (see Connectors: Sealing and

locking) (Technical Note 6015A, 88A, Wiring).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the engine harness.

aConnect the engine cooling fan assembly connector.

aConnect:

-the engine cooling fan assembly connector,

-the engine cooling fan assembly resistor connec-

tor,

-the air conditioning compressor connector,

-the refrigerant fluid pressure sensor connector.

aConnect:

-the engine harness/front of engine wiring connec-

tor,-the connectors to the petrol injection computer,

-the crankshaft position sensor connector,

-the coolant temperature sensor connector,

-the motorised throttle valve connector,

-the air inlet pressure sensor connector,

-the pinking sensor connector,

-the air inlet temperature sensor connector,

-the engine harness/injection wiring connector,

-the alternator connector,

-the radio interference suppressor connector,

-the reversing lights switch connector,

-the downstream oxygen sensor connector,

-upstream oxygen sensor connector,

-the ignition coil connector,

-the fuel vapour absorber connector,

-the oil pressure sensor connector.

aRefit:

-the engine compartment connection unit supply

terminal nut,

-the wiring mounting nut on the battery protection

fuse board,

-the negative battery terminal wiring nuts,

-the positive battery terminal wiring nut,

-the earth wiring nut on the front left-hand side

member,

-the earth wiring nuts on the engine,

-the starter wiring nuts,

-the alternator earth wiring nut.

aClip:

-the section of wiring on the cylinder head,

-the section of wiring on the cylinder block and sub-

frame,

-the section of wiring on the engine cooling fan as-

sembly.

aRefit the engine harness. WARNING

To prevent any damage during the removal ope-

ration, check that the wiring is free from its moun-

tings (retaining clip, plastic clip, adhesive tape,

connector, etc.).

D7F

STANDARD HEATING

AIR CONDITIONING

D4F

Page 170 of 241

88A-34

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

aConnect:

-the engine harness/sequential gearbox wiring con-

nector,

-the sequential gearbox computer connectors.

aConnect the engine cooling fan assembly connector.

aConnect:

-the engine cooling fan assembly connector,

-the engine cooling fan assembly resistor connec-

tor,

-the air conditioning compressor connector,

-the refrigerant fluid pressure sensor connector.aConnect:

-the engine harness/front of engine wiring connec-

tor,

-the connectors to the petrol injection computer,

-the coolant temperature sensor connector,

-the crankshaft position sensor connector,

-the engine harness/injection wiring connector,

-the pinking sensor connector,

-the alternator connector,

-the motorised throttle valve connector,

-the reverse gear switch connector,

-upstream oxygen sensor connector,

-the downstream oxygen sensor connector,

-the oil pressure sensor connector,

-the radio interference suppressor connector,

-the ignition coil connector,

-the fuel vapour absorber connector,

-the air inlet pressure sensor connector.

aRefit:

-the engine compartment connection unit supply

terminal nut,

-the wiring mounting nut on the battery protection

fuse board,

-the negative battery terminal wiring nuts,

-the positive battery terminal wiring nut,

-the earth wiring nut on the front left-hand side

member,

-the earth wiring nuts on the engine,

-the starter wiring nuts,

-the alternator earth wiring nut.

aClip:

-the section of wiring on the cylinder head,

-the section of wiring on the cylinder block and sub-

frame,

-the section of wiring on the engine cooling fan as-

sembly. JH1

STANDARD HEATING

AIR CONDITIONING

Page 171 of 241

88A-35

WIRING HARNESS

Engine wiring: Removal - Refitting

D4F or D7F

88A

III - FINAL OPERATION.

aRefit:

-the battery tray (see 80A, Battery, Battery tray:

Removal - Refitting, page 80A-6) ,

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the battery (see 80A, Battery, Battery: Removal -

Refitting, page 80A-2) ,

-the engine cover,

-the cover from the engine compartment connection

unit,

-the engine compartment connection unit cover

bolts.

Page 172 of 241

88A-36

WIRING HARNESS

Engine wiring: Removal - Refitting

EQ UIPMENT LEVEL SPORT

88A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSwitch off the ignition.

aRemove:

-the engine undertray,

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the left-hand headlight (see 80B, Headlights,

Halogen headlight: Removal - Refitting, page

80B-7) ,

-the battery (see 80A, Battery, Battery: Removal -

Refitting, page 80A-2) ,

-the battery tray (see 80A, Battery, Battery tray:

Removal - Refitting, page 80A-6) ,

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture),

-the windscreen wiper arms (see 85A, Wiping -

Washing, Windscreen wiper arm: Removal - Re-

fitting, page 85A-6) ,

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove the air pipe at the air filter unit inlet (1) . Equipment required

indelible pencil

Diagnostic tool

Tightening torquesm

starter supply nut8 N.m

starter solenoid nut5 N.m

alter nator positive termi-

nal nut21 N.m

earth nuts on the front

left-hand side member8 N.m

earth bolt on the gear-

box44 N.m

engine compartment

connection unit supply

terminal nut12 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see 88A, Wiring harness, Wiring: Precau-

tions for the repair, page 88A-2) .

WARNING

To prevent any damage to the connectors, consult

the disconnection procedures (see Connectors:

Disconnection and reconnection) (Technical

Note 6015A, 88A, Wiring).

131763

Page 173 of 241

88A-37

WIRING HARNESS

Engine wiring: Removal - Refitting

EQ UIPMENT LEVEL SPORT

88A

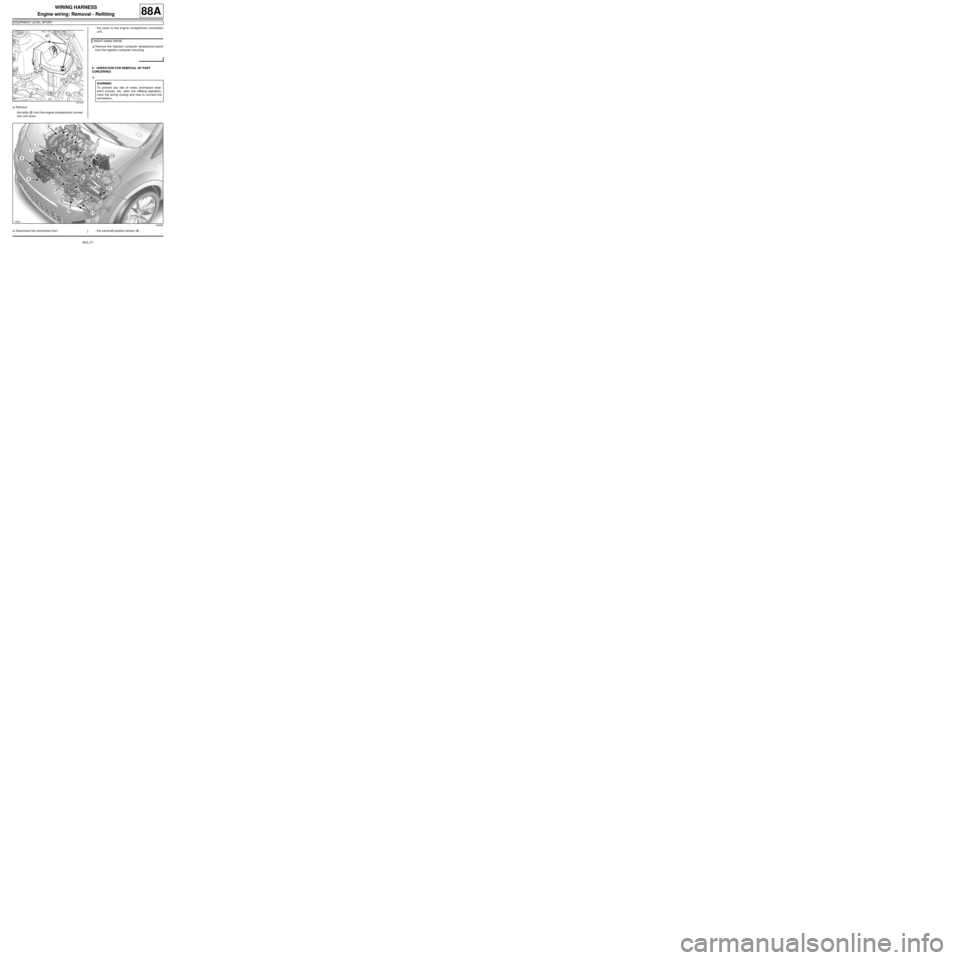

aRemove:

-the bolts (2) from the engine compartment connec-

tion unit cover,-the cover to the engine compartment connection

unit.

aRemove the injection computer tamperproof panel

from the injection computer mounting.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aDisconnect the connectors from: - the camshaft position sensor (4) ,

121212

RIGHT-HAND DRIVE

WARNING

To prevent any risk of noise, premature wear,

shor t circuits, etc. after the refitting operation,

mark the wiring routing and how to connect the

connectors.

140655