coolant temperature RENAULT TWINGO RS 2009 2.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 372 of 652

13B-11

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 718

13B

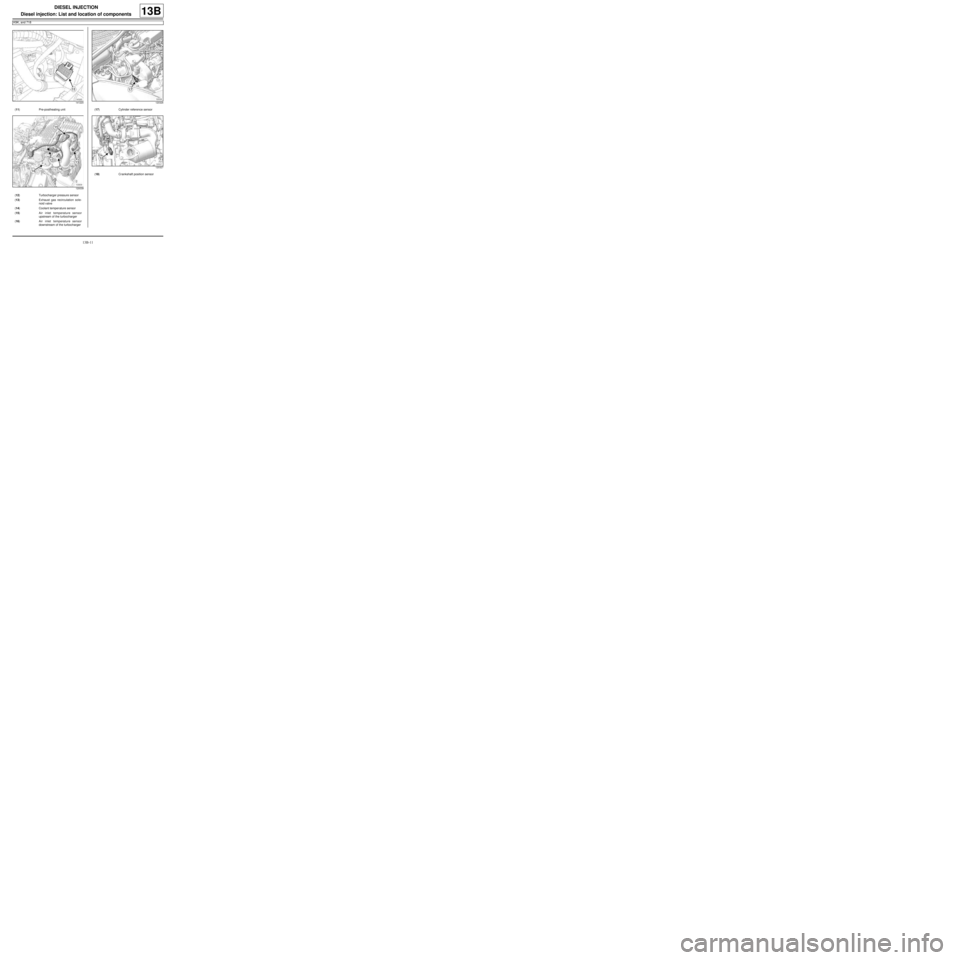

141220

(11) Pre-postheating unit

120039

(12) Turbocharger pressure sensor

(13) Exhaust gas recirculation sole-

noid valve

(14) Coolant temper ature sensor

(15) Air inlet temperature sensor

upstream of the turbocharger

(16) Air inlet temperature sensor

downstream of the turbocharger

120326

(17) Cylinder reference sensor

120327

(18) Crankshaft position sensor

Page 395 of 652

13B-34

DIESEL INJECTION

High pressure pipe: Check

K9K

13B

a

CHECK

aRemove the front engine cover.

aPrime the fuel circuit with the manual priming pump

until the disconnected pipes are filled with fuel (auto-

matic degassing).

aCheck that there are no fuel leaks.

aConnect the Diagnostic tool to the vehicle.aDeal with present faults,

aActivate command AC029 “high pressure circuit

sealing test”.

aCheck that there are no fuel leaks.

aDeal with the causes of any possible leaks.

aUse the Diagnostic tool to check for stored faults;

deal with these and clear them as necessary.

aDisconnect the Diagnostic tool.

aRefit the engine cover. Equipment required

Diagnostic tool

Note:

Check that there are no diesel leaks after each

operation.

Note:

The Diagnostic tool can be used to test the high

pressure circuit with the engine running. This

command can be used to run fault finding on a

leak due to an incorrectly fitted or tightened

union. This command only works if the engine

coolant temperature is greater than 60˚. The fault

finding procedure will not reveal small leaks due

to incorrect tightening.

IMPORTANT

Consult the safety and cleanliness advice and

operation recommendations before carrying out

any repair (see 13B, Diesel injection, Diesel

injection: Precautions for the repair, page

13B-1) .Note:

Certain faults will prevent this test from being

carr ied out: deal with them first.

Note:

The engine automatically runs a cycle of four

acceler ations and decelerations to lower the rail

pressure.

Note:

Do not leave anything on the engine compart-

ment dur ing the test phase (significant vibration).

Page 476 of 652

17B-1

PETROL INJECTION

Petrol injection: List and location of components

D4F, and 772

17B

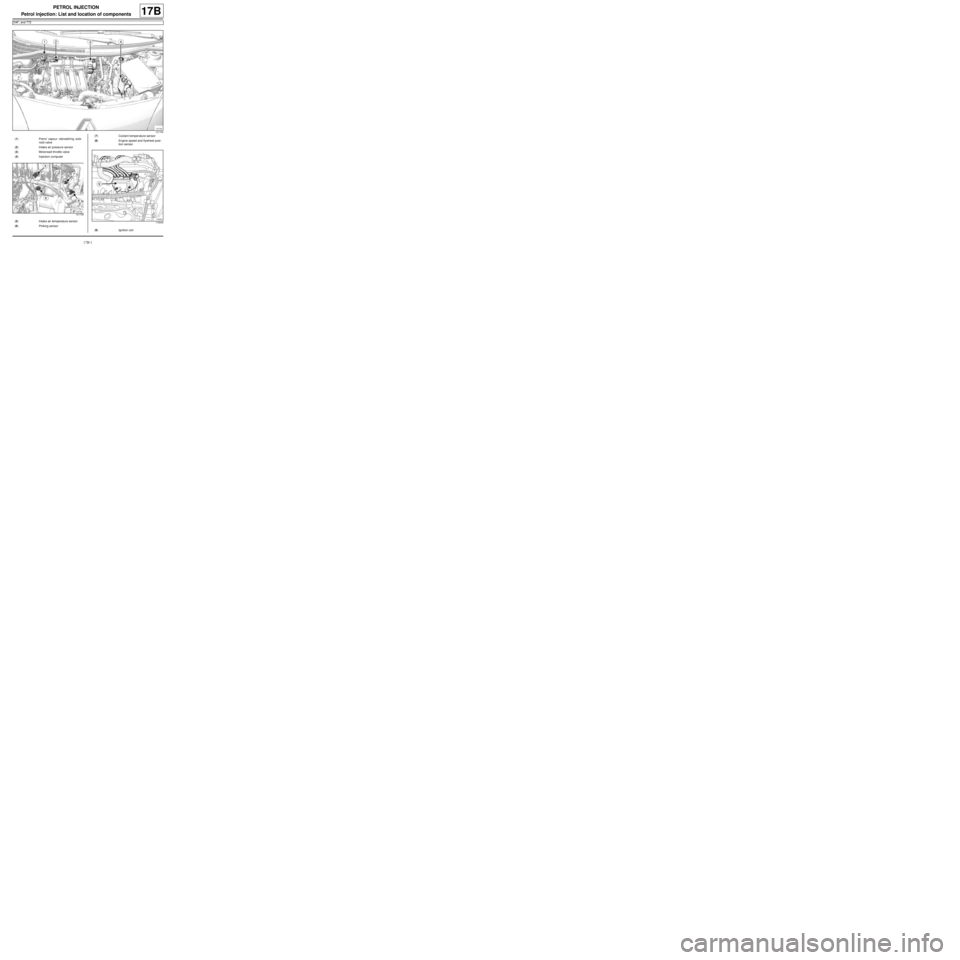

121740

(1) Petrol vapour rebreathing sole-

noid valve

(2) Intake air pressure sensor

(3) Motorised throttle valve

(4) Injection computer

121739

(5) Intake air temperature sensor

(6) Pinking sensor

(7) Coolant temper ature sensor

(8) Engine speed and flywheel posi-

tion sensor

113044

(9) Ignition coil

Page 484 of 652

17B-9

PETROL INJECTION

Petrol injection: List and location of components

K4M

17B

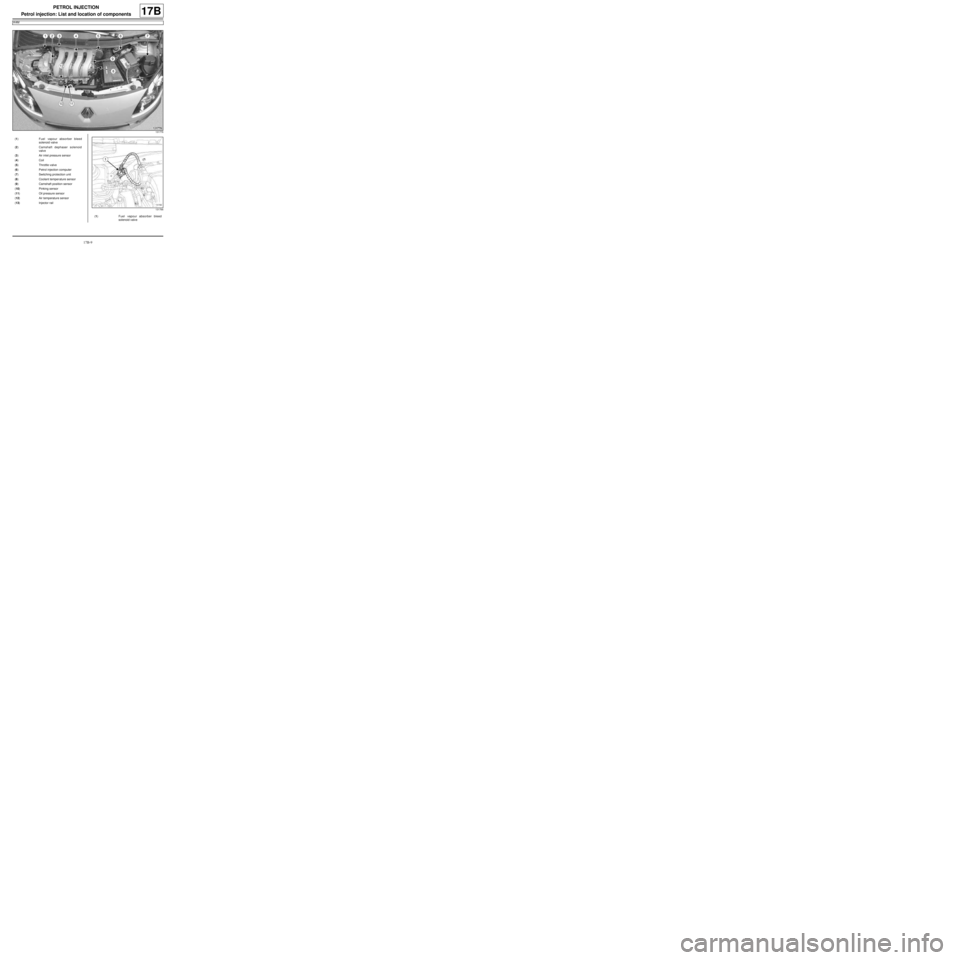

131776

(1) Fuel vapour absorber bleed

solenoid valve

(2) Camshaft dephaser solenoid

valve

(3) Air inlet pressure sensor

(4) Coil

(5) Throttle valve

(6) Petrol injection computer

(7) Switching protection unit

(8) Coolant temper ature sensor

(9) Camshaft position sensor

(10) Pinking sensor

(11) Oil pressure sensor

(12) Air temperature sensor

(13) Injector rail

131766

(1) Fuel vapour absorber bleed

solenoid valve

Page 511 of 652

19A-1

COOLING

Engine cooling system: Specifications

D4F or D7F or K4M or K9K

19A

Vehicles in the current range have cooling systems

with the following basic specifications:

-hermetically-sealed pressurised circuit (with expan-

sion bottle valve),

-circuit using only type « D » fluid,

-passenger compartment heating system equipped

with a « heater matrix » type radiator located under

the dashboard which helps to cool the engine.

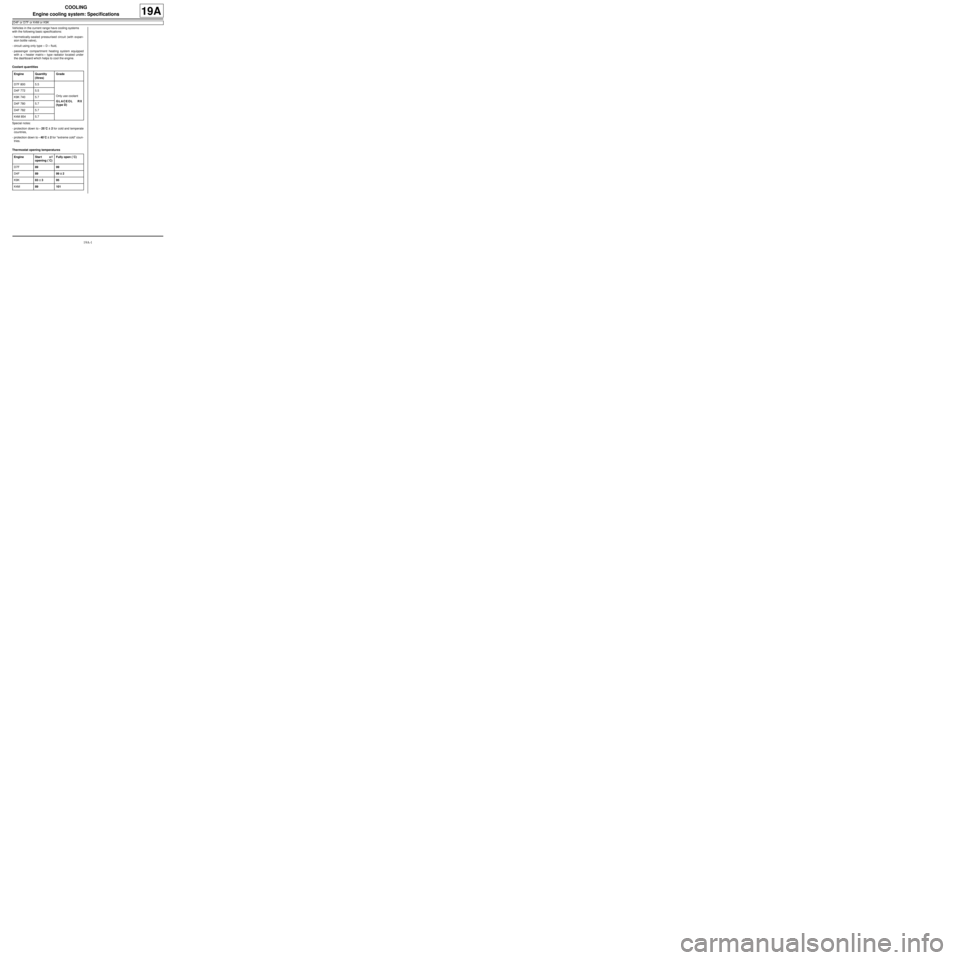

Coolant quantities

Special notes:

-protection down to - 25˚C ±± ± ±

2 for cold and temperate

countries,

-protection down to - 40˚C ±± ± ±

2 for "extreme cold" coun-

tries.

Thermostat opening temperaturesEngine Quantity

(litres)Grade

D7F 800 5.5

Only use coolant

GLACEOL RX

(type D) D4F 772 5.5

K9K 740 5.7

D4F 780 5.7

D4F 782 5.7

K4M 854 5.7

Engine Star t o f

opening (˚C)Fully open (˚C)

D7F89 99

D4F89 99 ±± ± ±

2

K9K83 ±± ± ±

395

K4M89 101

Page 554 of 652

19A-44

COOLING

Water chamber: Removal - Refitting

K9K

19A

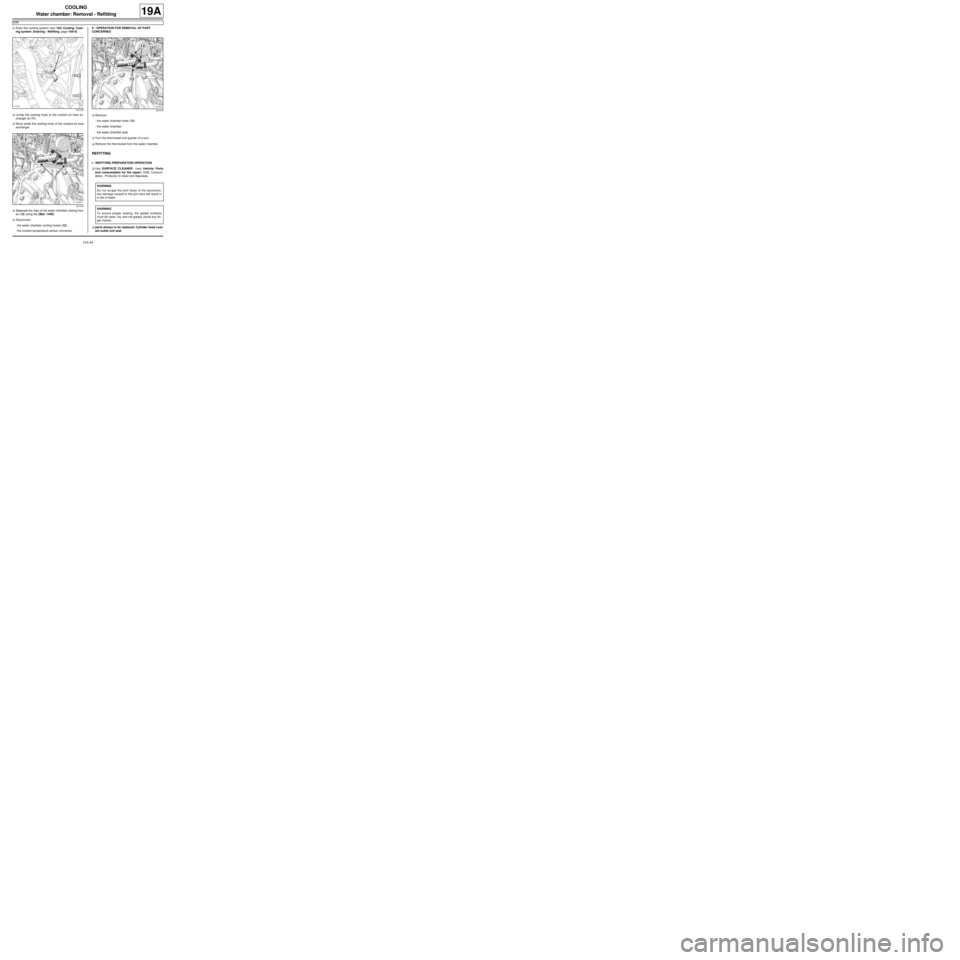

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aUnclip the cooling hose of the coolant-oil heat ex-

changer at (11) .

aMove aside the cooling hose of the coolant-oil heat

exchanger.

aSeparate the clips of the water chamber cooling hos-

es (12) using the (Mot. 1448).

aDisconnect:

-the water chamber cooling hoses (12) ,

-the coolant temperature sensor connector.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the water chamber bolts (13) ,

-the water chamber,

-the water chamber seal.

aTurn the thermostat one quarter of a turn.

aRemove the thermostat from the water chamber.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to clean and degrease.

aparts always to be replaced: Cylinder head cool-

ant outlet unit seal

141218

121416121416

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger mar ks).

Page 559 of 652

19A-49

COOLING

Water chamber: Removal - Refitting

K4M

19A

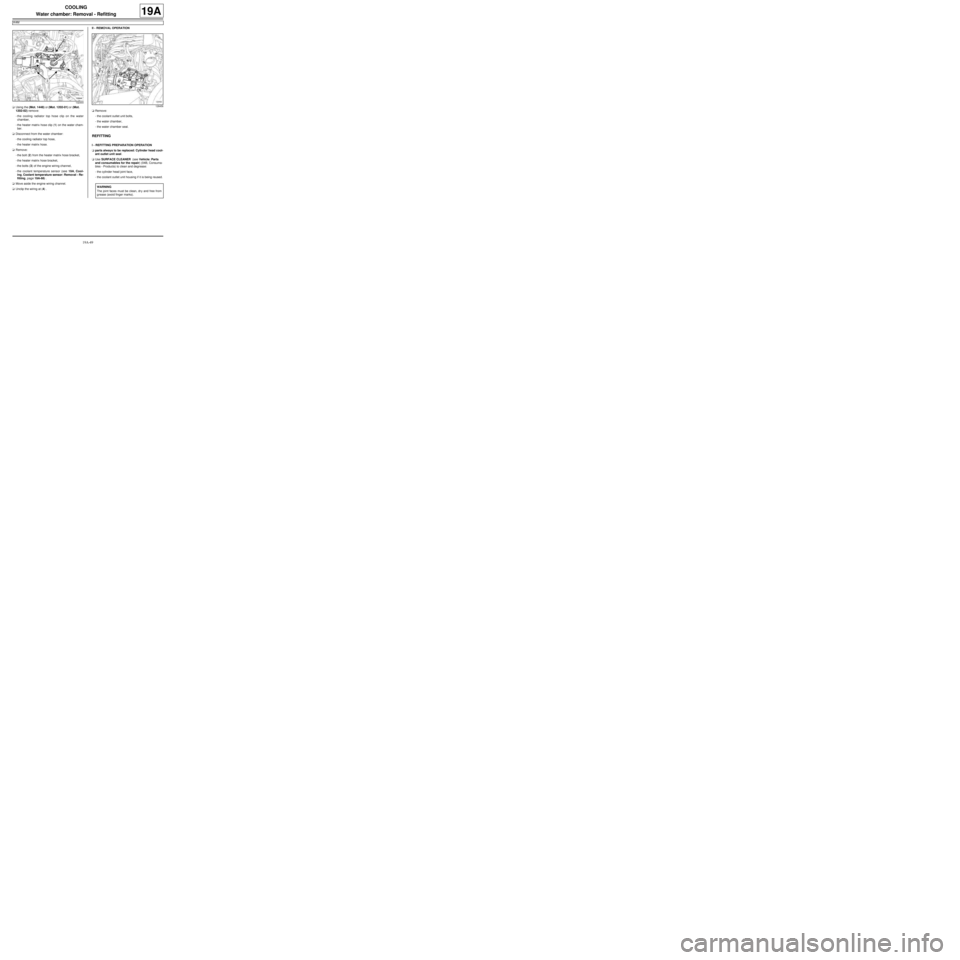

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) remove:

-the cooling radiator top hose clip on the water

chamber,

-the heater matrix hose clip (1) on the water cham-

ber.

aDisconnect from the water chamber:

-the cooling radiator top hose,

-the heater matrix hose.

aRemove:

-the bolt (2) from the heater matrix hose bracket,

-the heater matrix hose bracket,

-the bolts (3) of the engine wiring channel,

-the coolant temperature sensor (see 19A, Cool-

ing, Coolant temperature sensor: Removal - Re-

fitting, page 19A-66) .

aMove aside the engine wiring channel.

aUnclip the wiring at (4) .II - REMOVAL OPERATION

aRemove:

-the coolant outlet unit bolts,

-the water chamber,

-the water chamber seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Cylinder head cool-

ant outlet unit seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the cylinder head joint face,

-the coolant outlet unit housing if it is being reused.

132444

128456

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

Page 560 of 652

19A-50

COOLING

Water chamber: Removal - Refitting

K4M

19A

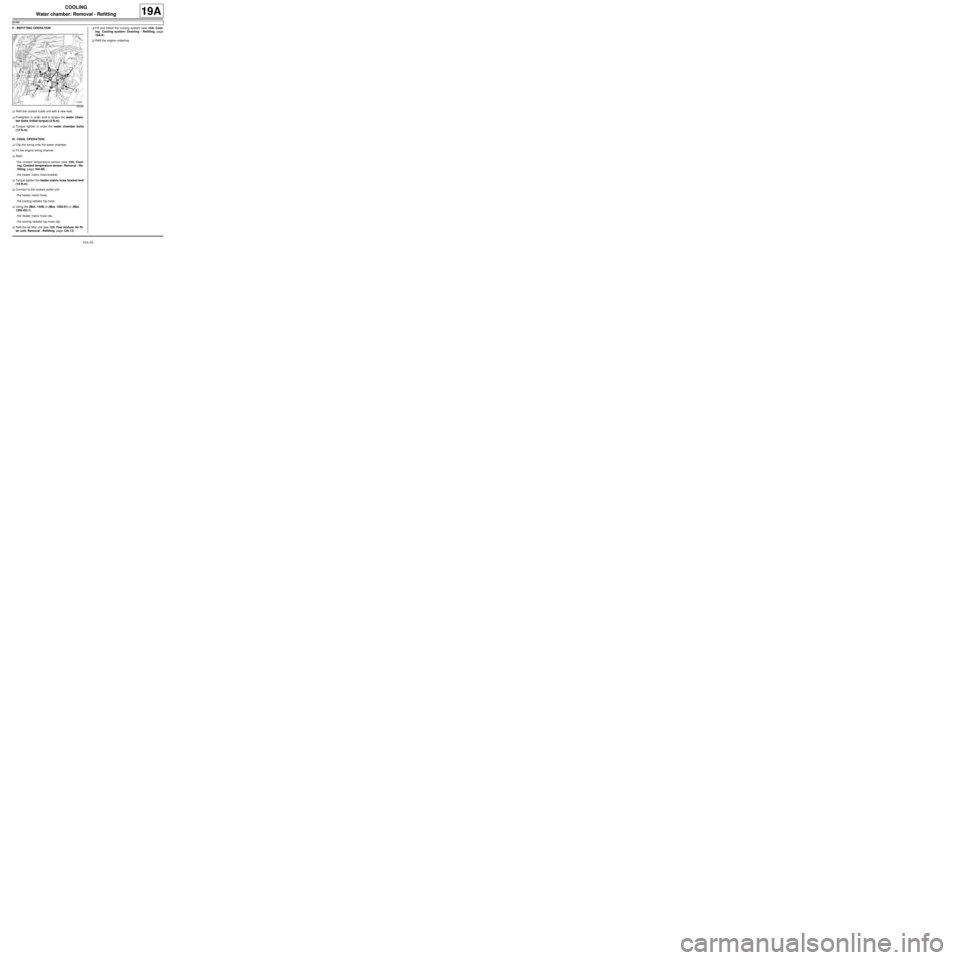

II - REFITTING OPERATION

aRefit the coolant outlet unit with a new seal.

aPretighten in order and to torque the water cham-

ber bolts (initial torque) (4 N.m).

aTorque tighten in order the water chamber bolts

(12 N.m).

III - FINAL OPERATION

aClip the wiring onto the water chamber.

aFit the engine wiring channel.

aRefit:

-the coolant temperature sensor (see 19A, Cool-

ing, Coolant temperature sensor: Removal - Re-

fitting, page 19A-66) ,

-the heater matrix hose bracket.

aTorque tighten the heater matrix hose bracket bolt

(10 N.m).

aConnect to the coolant outlet unit:

-the heater matrix hose,

-the cooling radiator top hose.

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) fit:

-the heater matrix hose clip,

-the cooling radiator top hose clip.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

128456

Page 576 of 652

19A-66

COOLING

Coolant temperature sensor: Removal - Refitting

D4F or D7F

19A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced :

-coolant temperature sensor seal.

aConsumable (see Vehicle: Parts and consuma-

bles for the repair) :

-COOLANT.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the coolant temperature sensor connec-

tor (1) .

aRemove the coolant temperature sensor.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new coolant temperature sensor seal,

-the coolant temperature sensor.

aTighten the coolant temperature sensor.

aConnect the coolant temperature sensor connector.

II - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aTop up the coolant fluid level.

aBleed the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . D4F

114326

D4F

Page 577 of 652

19A-67

COOLING

Coolant temperature sensor: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the front engine cover.

aUnclip the neck on the gearbox.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the coolant temperature sensor connec-

tor.

aRemove:

-the coolant temperature sensor clip,

-the coolant temperature sensor,

-the coolant temperature sensor seal.

REFITTING

I - REFITTING PREPARATIONS OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the new seal on the coolant temperature sensor,

-the coolant temperature sensor,

-the coolant temperature sensor clip.

aConnect the coolant temperature sensor connector.

III - FINAL OPERATION.

aClip the channel to the gearbox.

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit the engine cover. IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.

WARNING

The seals m ust always be replaced.