sensor RENAULT TWINGO RS 2009 2.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 89 of 652

10A-83

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

D4F or D7F

10A

aTorque tighten:

-the front subframe bolts (62 N.m),

-the rear subframe bolts (105 N.m),

-the subframe rear tie rod inner bolts (21 N.m),

-the subframe rear tie rod outer bolts (90 N.m),

-the engine tie-bar bolts on the gearbox (105

N.m),

-the engine tie-bar bolt on the subframe (105

N.m).

aRefit the control cables onto the gearbox.

aRemove the blanking plugs from the openings.

aClip the clutch pipe onto the gearbox.

aConnect the clutch slave cylinder.

aRemove the hose clamp (Ms. 583).

aBleed the clutch circuit (see Clutch circuit: Bleed) .

aRefit the gear control linkage.

aAttach the gear control linkage to:

-the gear lever,

-the control lever on the gearbox.

aRefit:

-the heat shield,

-the heat shield bolts.

aRefit the clutch control cable on the manual gearbox.

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .aRefit the exhaust downpipe.

aFit the clip.

aTighten the intermediate pipe clip.

aRefit the exhaust downpipe bolts.

aTorque tighten the exhaust downpipe bolts (9

N.m).

aRefit:

-the shock absorber base lower bolts,

-the ABS sensors,

-the ABS sensor bolts (if fitted to the vehicle),

-the brake callipers,

-the calliper mounting bolts,

-the brake pads,

-the lower guide pin bolts,

-track rod ends,

-the track rod end nuts,

-the tie rod upper bolts.

aTorque tighten:

-the shock absorber base lower bolts (105 N.m ),

-the calliper mounting bolts (105 N.m),

-the lower guide pin bolts (34 N.m),

-the track rod end nuts (37 N.m),

-the tie rod upper bolts (21 N.m),

-the tie rod lower bolts (62 N.m).

aClip the electrical wiring on to the cross member.

aFit the steering box universal joint.

aRefit the universal joint bolt.

aTorque tighten the universal joint (24 N.m).

aRemove the flywheel immobiliser.

aClip the fuel pipe on to the upper timing cover.

aConnect the fuel supply pipe union.

aConnect the air conditioning pressostat connector. JH3

JB1 or JH1

D4F, and 772 – D7F

D4F, and 780 or 782

AIR CONDITIONING

Page 107 of 652

10A-101

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

aRemove:

-the bolt (27) from the « compressor - intermediate

pipe » connecting pipe,

-the bolt (28) on the « compressor - condenser »

connecting pipe,

-the bolt (29) from the « compressor - intermediate

pipe » connecting pipe mounting.

aDisconnect:

-the pressure sensor connector (30) ,

-the « compressor - intermediate pipe » connecting

pipe,-the « compressor - condenser » connecting pipe.

aInsert the blanking plugs.

aDisconnect the brake servo vacuum pipe union (31)

.

131782

132335

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

121348

Page 109 of 652

10A-103

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

-the rubber pad mounting from the suspended en-

gine mounting on the gearbox.

aRemove the right-hand suspended engine mounting

(see 19D, Engine mounting, Right-hand sus-

pended engine mounting: Removal - Refitting,

page 19D-13) .

aLift the vehicle to remove the "engine and gearbox"

assembly.

REFITTING

I - REFITTING PREPARATION OPERATION

aFor standard engine replacement (see Standard re-

placement) (Technical Note 6023A, 10A, Engine

and peripherals).

II - REFITTING OPERATION

aPosition the "engine and gearbox" assembly in the

body.

aRefit the right-hand suspended engine mounting

(see 19D, Engine mounting, Right-hand sus-

pended engine mounting: Removal - Refitting,

page 19D-13) .

aRefit the rubber pad mounting from the suspended

engine mounting on the gearbox.

aTorque tighten the rubber pad mounting bolts for

the suspended engine mounting on the gearbox

(21 N.m).

aRefit the suspended engine mounting rubber pad.

aTorque tighten:

-the bolts of the suspended mounting rubber

pad (62 N.m),

-the suspended engine mounting shaft nut (62

N.m).

III - FINAL OPERATION

aRemove the.

aRemove the blanking plugs.

aConnect:

-the union of the brake servo vacuum pipe,

-the « compressor - condenser » connecting pipe,-the « compressor - intermediate pipe » connecting

pipe,

-the pressure sensor connector,

aConnect the hose on the coolant pump inlet pipe.

aFit the hose clip on the coolant pump inlet pipe using

the (Mot. 1448).

aRefit the earth nuts.

aClip:

-the relay plates on the engine compartment con-

nection unit,

-the fuse holders.

aConnect the fuses.

aRefit the engine compartment connection unit on the

body.

aConnect the connector to the engine compartment

connection unit.

aRefit the engine compartment connection unit cover.

aClip:

-the wiring on the engine cooling fan assembly,

-the cooling radiator top and bottom hoses on the

engine cooling fan assembly.

aConnect:

-the engine cooling fan assembly resistor connec-

tor,

-the engine cooling fan assembly connector.

aRemove the blanking plug from the fuel supply pipe

opening and the injector rail fuel opening.

aReconnect the fuel supply pipe.

aClip the fuel supply pipe in place.

aConnect:

-the fuel vapour absorber bleed solenoid valve con-

nector,

-the fuel vapour absorber bleed solenoid valve pipe.

aFit the gearbox control cables.

aClip the manual gearbox control cables onto:

-the gear selectors,

-the cable sleeve stops.

aRemove the blanking plug from the hydraulic clutch

control pipe opening and the opening of the clutch

thrust bearing.

aConnect the hydraulic clutch control pipe.

aClip the hydraulic clutch control pipe on the gearbox. Note:

Check no component obstructs the movement of

the body around the engine - gearbox assembly.

Page 140 of 652

11A-23

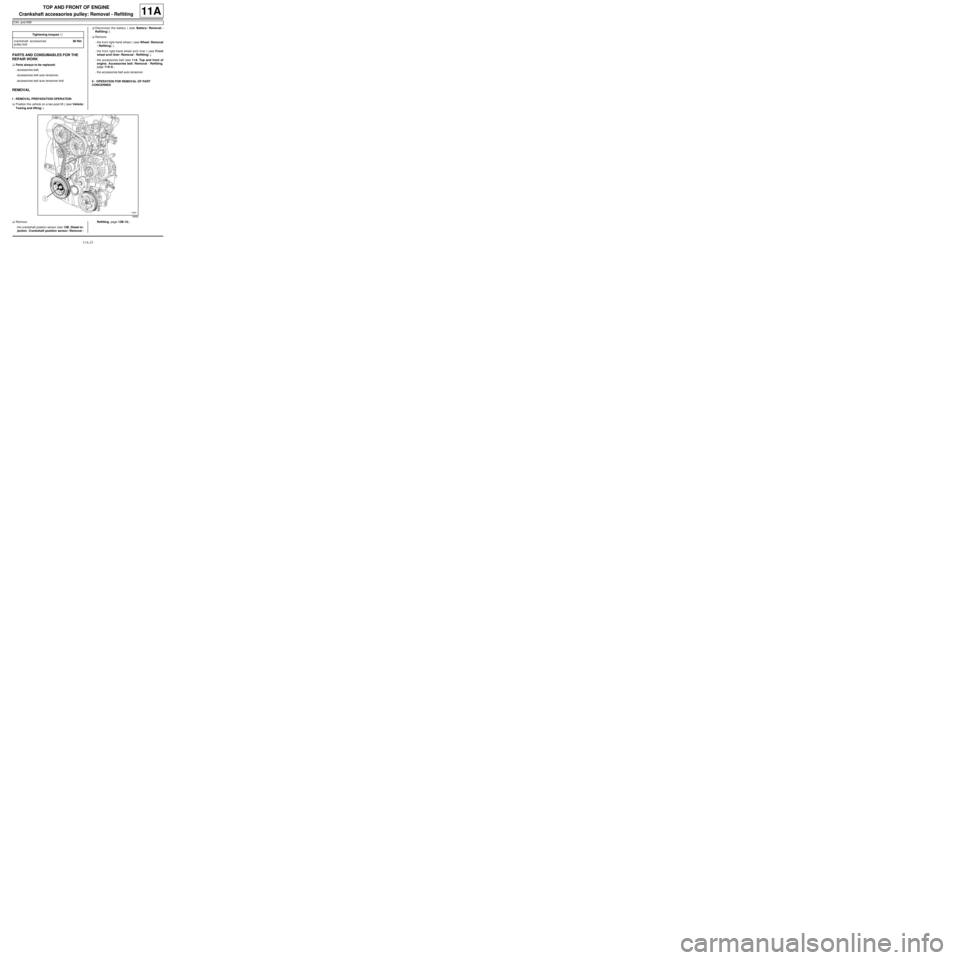

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

C44, and K9K

11A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced:

-accessories belt,

-accessories belt auto tensioner,

-accessories belt auto tensioner bolt.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

aRemove:

-the front right-hand wheel ( (see Wheel: Removal

- Refitting) ),

-the front right-hand wheel arch liner ( (see Front

wheel arch liner: Removal - Refitting) ),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the accessories belt auto tensioner.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the crankshaft position sensor (see 13B, Diesel in-

jection, Crankshaft position sensor: Removal -Refitting, page 13B-15) , Tightening torquesm

crankshaft accessories

pulley bolt80 Nm

19656

Page 141 of 652

11A-24

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

C44, and K9K

11A

-the crankshaft accessories pulley bolt (1) , locking

the flywheel using a flat screwdriver at the point of

the crankshaft position sensor,

-the crankshaft accessories pulley (2) .

REFITTING

I - REFITTING PREPARATIONS OPERATION

aIf reusing the crankshaft accessories pulley, clean

the pulley V-grooves with a brush to eliminate any

deposits.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the crankshaft accessories pulley,

-the crankshaft accessories pulley bolt.

aTorque tighten the crankshaft accessories pulley

bolt (80 Nm), locking the flywheel using a flat screw-

driver at the point of the crankshaft position sensor.

aRefit the crankshaft position sensor (see 13B, Die-

sel injection, Crankshaft position sensor: Re-

moval - Refitting, page 13B-15) .

III - FINAL OPERATION.

aRefit:

-the new accessories belt auto tensioner,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aRefit:

-the front right-hand wheel arch liner ( (see Front

wheel arch liner: Removal - Refitting) ),

-the front right-hand wheel ( (see Wheel: Removal

- Refitting) ).

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

Page 149 of 652

11A-32

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

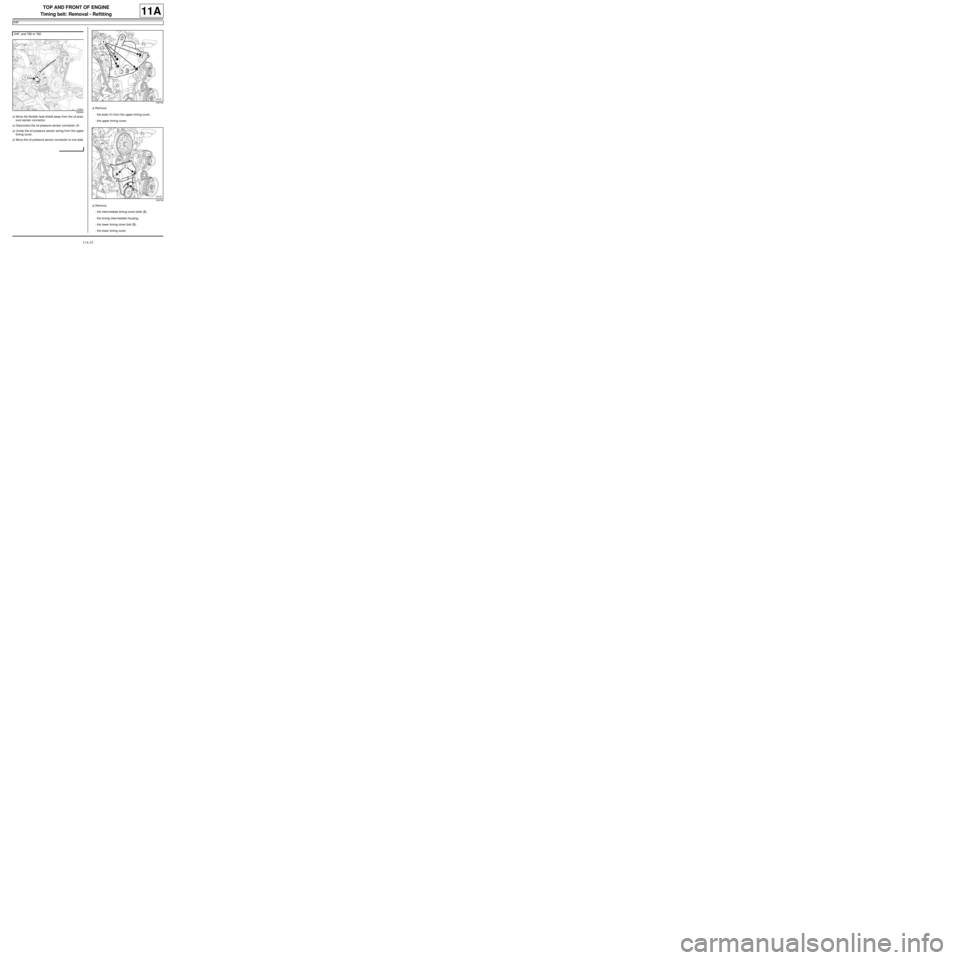

aMove the flexible heat shield away from the oil pres-

sure sensor connector.

aDisconnect the oil pressure sensor connector (1) .

aUnclip the oil pressure sensor wiring from the upper

timing cover.

aMove the oil pressure sensor connector to one side.aRemove:

-the bolts (1) from the upper timing cover,

-the upper timing cover.

aRemove:

-the intermediate timing cover bolts (2) ,

-the timing intermediate housing,

-the lower timing cover bolt (3) ,

-the lower timing cover. D4F, and 780 or 782

122664

109740

109739

Page 154 of 652

11A-37

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D4F

11A

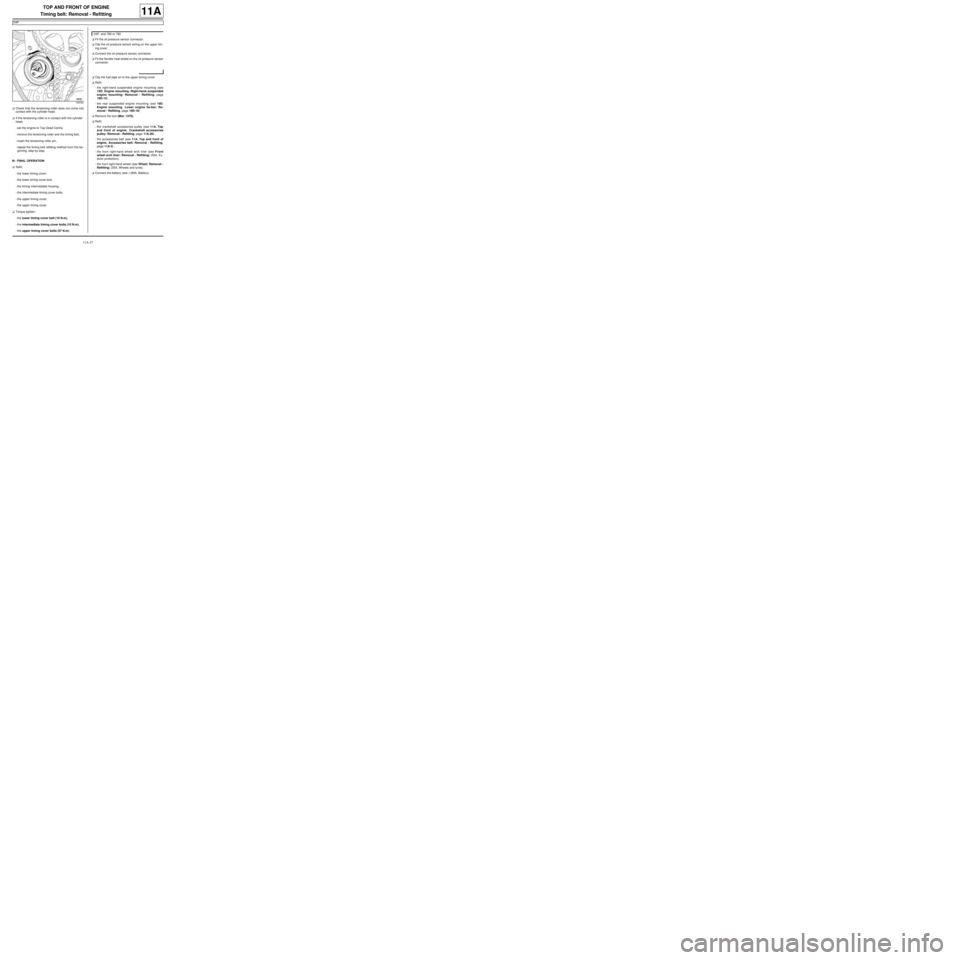

aCheck that the tensioning roller does not come into

contact with the cylinder head.

aIf the tensioning roller is in contact with the cylinder

head:

-set the engine to Top Dead Centre,

-remove the tensioning roller and the timing belt,

-insert the tensioning roller pin,

-repeat the timing belt refitting method from the be-

ginning, step by step.

III - FINAL OPERATION

aRefit:

-the lower timing cover,

-the lower timing cover bolt,

-the timing intermediate housing,

-the intermediate timing cover bolts,

-the upper timing cover,

-the upper timing cover.

aTorque tighten:

-the lower timing cover bolt (10 N.m),

-the intermediate timing cover bolts (10 N.m),

-the upper timing cover bolts (37 N.m)aFit the oil pressure sensor connector.

aClip the oil pressure sensor wiring on the upper tim-

ing cover.

aConnect the oil pressure sensor connector.

aFit the flexible heat shield on the oil pressure sensor

connector.

aClip the fuel pipe on to the upper timing cover.

aRefit:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the rear suspended engine mounting (see 19D,

Engine mounting, Lower engine tie-bar: Re-

moval - Refitting, page 19D-18) .

aRemove the tool (Mot. 1379).

aRefit:

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aConnect the battery (see ) (80A, Battery).

109765

D4F, and 780 or 782

Page 155 of 652

11A-38

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) . Special tooling required

Mot. 1672Low er engine support.

Mot. 1489TDC locating pin.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Tightening torquesm

tensioning roller bolt27 N.m

camshaft pulley wheel

bolts14 N.m

TDC setting pin plug25 N.m

cylinder head sus-

pended mounting bolts25 Nm

IMPORTANT

Wear protective gloves during the operation.

WARNING

The belt must be replaced with a new one if it has

been removed.

WARNING

When replacing the belt, always replace the tension

wheels and idler pulleys.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

Page 168 of 652

11A-51

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K9K

11A

aRemove:

-the (Mot. 1489),

-the (Mot. 1430).

aRotate the crankshaft twice clockwise (timing end)

before the camshaft pulley hole is opposite the cylin-

der head hole.

aScrew tool (Mot. 1489) into the cylinder block.

aBring the crankshaft slowly and smoothly against the

TDC setting pin.

aSet the camshaft pulley using the (Mot. 1430).

aIf this is not possible, repeat the operation for refit-

ting the timing belt.

aRemove:

-the (Mot. 1489),

-the (Mot. 1430).

III - FINAL OPERATION

aRefit the TDC pin plug, coating the thread with SILI-

CONE ADHESIVE SEALANT (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products).

aTorque tighten the TDC setting pin plug (25 N.m).

aRefit the cylinder head suspended mounting .

aTorque tighten the cylinder head suspended

mounting bolts (25 Nm).aRefit the lower timing cover, positioning the tab (35)

in the opening (36) of the inner timing cover.

aRefit:

-the upper timing cover,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

109049

19659

Page 171 of 652

11A-54

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

K4M

11A

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the rear suspended engine mounting bolt (1) from

the subframe,

-the rear suspended engine mounting bolt (2) from

the rear suspended engine mounting support,

-the rear suspended engine mounting reinforce-

ment bolt (3) ,

-the rear suspended engine mounting,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .aDisconnect the upstream oxygen sensor connector

(4) .

aUnclip the wiring from the upstream oxygen sensor

at (5) .

aMove the upstream oxygen sensor wiring aside.

aUnclip the connector (6) from the lifting eye.

aRemove the lifting eye bolts (7) .

131769

132373

103271