drain bolt RENAULT TWINGO RS 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 554 of 652

19A-44

COOLING

Water chamber: Removal - Refitting

K9K

19A

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

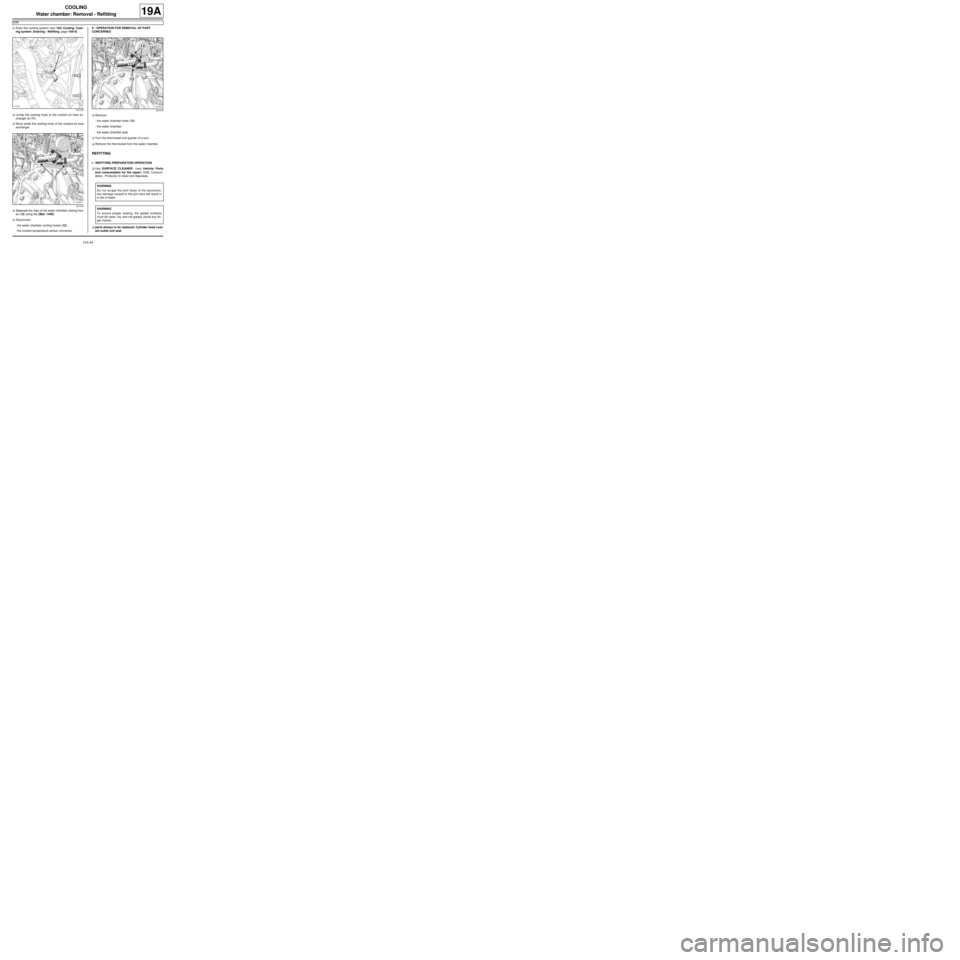

aUnclip the cooling hose of the coolant-oil heat ex-

changer at (11) .

aMove aside the cooling hose of the coolant-oil heat

exchanger.

aSeparate the clips of the water chamber cooling hos-

es (12) using the (Mot. 1448).

aDisconnect:

-the water chamber cooling hoses (12) ,

-the coolant temperature sensor connector.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the water chamber bolts (13) ,

-the water chamber,

-the water chamber seal.

aTurn the thermostat one quarter of a turn.

aRemove the thermostat from the water chamber.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to clean and degrease.

aparts always to be replaced: Cylinder head cool-

ant outlet unit seal

141218

121416121416

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger mar ks).

Page 555 of 652

19A-45

COOLING

Water chamber: Removal - Refitting

K9K

19A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the thermostat to the water chamber.

aRefit:

-a new water chamber seal,

-the water chamber.

aTorque tighten the water chamber bolts (10 N.m).

III - FINAL OPERATION

aConnect the cooling hoses on the water chamber.

aPosition the cooling hose clips on the water chamber

using the tool (Mot. 1448).

aClip on the cooling hose of the coolant-oil heat ex-

changer.

aConnect the intercooler air outlet pipe on the side of

the damper valve.

aTorque tighten the intercooler air outlet pipe clip

at the damper valve end (5.5 N.m).

aConnect the brake servo vacuum pipe.

aClip:

-the turbocharging pressure regulator vacuum pipe,

-the vacuum pipe from the brake servo.

aConnect the turbocharging pressure regulator vacu-

um pipe.

aRefit the nuts of the air hoses on the lifting eye.

aConnect the intercooler air inlet pipe at the turbo-

charger end.

aClip on the intercooler air inlet pipe clip at the turbo-

charger end.

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit the engine cover. K9K, and 718

Page 556 of 652

19A-46

COOLING

Water chamber: Removal - Refitting

D4F, and 780 or 782

19A

REMOVAL - REFITTING

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

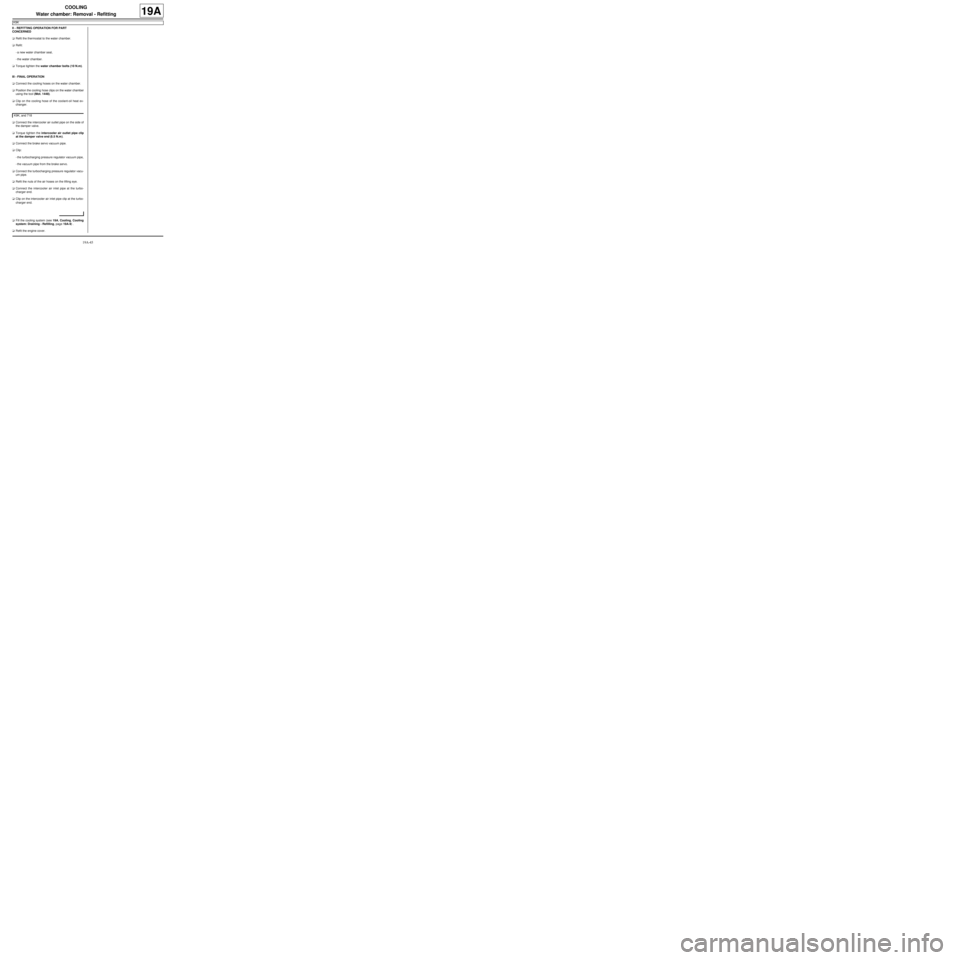

aDetach the turbocharger cooling pipe from the cylin-

der head.

aRemove the water chamber hose clips using the

(Mot. 1448).

aDisconnect the water chamber hoses.

aRemove the pipe from the heater matrix under the

water chamber.aRemove:

-the water chamber bolts (1) ,

-the water chamber (2) ,

-the water chamber seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the water chamber seal.

II - REFITTING OPERATION FOR PART

CONCERNED

aPosition the water chamber with a new seal.

aScrew on the water chamber bolts without tightening

them.

aTorque tighten the water chamber bolts (10 N.m).

aConnect the water chamber hoses.

aFit the heater matrix pipe under the water chamber.

aRefit the water chamber hose clips using the (Mot.

1448).

aClip the turbocharger cooling pipe onto the cylinder

head. Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

water chamber bolts10 N.m

Note:

Use a cloth to protect the TDC sensor to prevent

any coolant entering the opening on the gearbox.

113372

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

Page 558 of 652

19A-48

COOLING

Water chamber: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Mot. 1202-01Clip pliers for hose clips

(large size).

Mot. 1202-02Clip pliers for hose clips

(small size)

Tightening torquesm

water chamber bolts

(initial torque)4 N.m

water chamber bolts12 N.m

heater matrix hose

bracket bolt10 N.m

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

Page 560 of 652

19A-50

COOLING

Water chamber: Removal - Refitting

K4M

19A

II - REFITTING OPERATION

aRefit the coolant outlet unit with a new seal.

aPretighten in order and to torque the water cham-

ber bolts (initial torque) (4 N.m).

aTorque tighten in order the water chamber bolts

(12 N.m).

III - FINAL OPERATION

aClip the wiring onto the water chamber.

aFit the engine wiring channel.

aRefit:

-the coolant temperature sensor (see 19A, Cool-

ing, Coolant temperature sensor: Removal - Re-

fitting, page 19A-66) ,

-the heater matrix hose bracket.

aTorque tighten the heater matrix hose bracket bolt

(10 N.m).

aConnect to the coolant outlet unit:

-the heater matrix hose,

-the cooling radiator top hose.

aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) fit:

-the heater matrix hose clip,

-the cooling radiator top hose clip.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

128456

Page 564 of 652

19A-54

COOLING

Engine cooling fan assembly: Removal - Refitting

D4F, and 780 or 782

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection).

aDisconnect the air filter unit air inlet pipe (1) from the

air filter unit cover.

aRemove:

-the air filter unit air inlet pipe bolt (2) from the cross

member,

-the air filter unit air inlet pipe.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .aRemove using the (Mot. 1448) :

-the radiator top hose clip,

-the radiator degassing hose clip.

aDisconnect:

-the radiator top hose,

-the radiator degassing hose.

aUnclip:

-the lower hose from the engine cooling fan assem-

bly,

-the wiring harness from the engine cooling fan as-

sembly.

aDisconnect the engine cooling fan assembly con-

nectors.

II - REMOVAL OPERATION FOR PART

CONCERNED

a

aRemove:

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(MR 412, 41A, Front lower structure),

-the « radiator / engine cooling fan assembly » unit. Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

122833

Note:

Hold the radiator during the removal of the radia-

tor lo wer cross member.

Page 565 of 652

19A-55

COOLING

Engine cooling fan assembly: Removal - Refitting

D4F, and 780 or 782

19A

aRemove the tabs (3) .

aRemove the engine cooling fan assembly.

REFITTING

I - REFITTING PREPARATIONS OPERATION

Rebuilding the cooling radiator

aRefit the engine cooling fan assembly.

aClip on the engine cooling fan assembly tabs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the « radiator / engine cooling fan assembly » unit,

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(MR 412, 41A, Front lower structure).

III - FINAL OPERATION

aConnect the engine cooling fan assembly connec-

tors.

aClip:

-the wiring harness to the engine cooling fan as-

sembly,

-the bottom hose to the engine cooling fan assem-

bly.aConnect:

-the radiator degassing hose,

-the radiator top hose.

aUsing the (Mot. 1448), fit:

-the radiator degassing hose clip,

-the radiator top hose clip.

aRefit:

-the air filter box air inlet pipe,

-the air filter unit air inlet pipe bolt on the cross

member.

aConnect the air filter unit air inlet pipe to the air filter

unit cover.

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres).

aConnect the battery (see ) (MR 411, 80A, Battery).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

121770

Page 568 of 652

19A-58

COOLING

Coolant pump inlet pipe: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (MR 411, 85A, Wip-

ers - Washers),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (MR 411, 80B, Headlights),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (MR 412,

42A, Upper front structure).

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove the engine tie-bar (see 19D, Engine

mounting, Lower engine tie-bar: Removal - Refit-

ting, page 19D-18) . Special tooling required

Mot. 1672Low er engine support.

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

subfame front bolt62 Nm

subframe rear bolt105 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see ) .

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system must not operate using pure water.

Page 570 of 652

19A-60

COOLING

Coolant pump inlet pipe: Removal - Refitting

K9K

19A

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

aRemove the (Mot. 1672).

aRefit:

-the new subframe front bolt,

-the new subframe rear bolt.

aTorque tighten:

-the subfame front bolt (62 Nm),

-the subframe rear bolt (105 Nm).

aRefit the engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) .

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit:

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (MR 412,

42A, Upper front structure),

-the headlights (see Halogen headlight: Removal

- Refitting) (MR 411, 80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (MR 411, 85A, Wip-

ers - Washers),

-the engine cover.

aConnect the battery (see ) (MR 411, 80A, Battery).

Page 571 of 652

19A-61

COOLING

Coolant pump inlet pipe: Removal - Refitting

D4F, and 780 or 782

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine undertray.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aSeparate the clips on the coolant pump inlet pipe

hoses using the tool (Mot. 1448).

aDisconnect the coolant pump inlet pipe hoses.

aRemove:

-the bolts (1) from the coolant pump inlet pipe,

-the coolant pump inlet pipe,-the coolant pump inlet pipe seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: seal between cool-

ant pump inlet pipe and coolant pump.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to clean the bearing surfaces of

the coolant pump inlet pipe.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the coolant pump inlet pipe,

-the coolant pump inlet pipe,

-the coolant pump inlet pipe bolts.

aTorque tighten the coolant pump inlet pipe bolts

(10 N.m).

aConnect the hoses to the coolant pump inlet pipe.

aRefit the clips on the coolant pump inlet pipe hoses

using the tool (Mot. 1448).

III - FINAL OPERATION

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

aRefit the engine undertray.

aConnect the battery (see ) (80A, Battery). Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

coolant pump inlet pipe

bolts10 N.m

120956