charging RENAULT TWINGO RS 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 453 of 652

16A-14

STARTING - CHARGING

Starter: Removal - Refitting

K9K

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove the front engine cover.

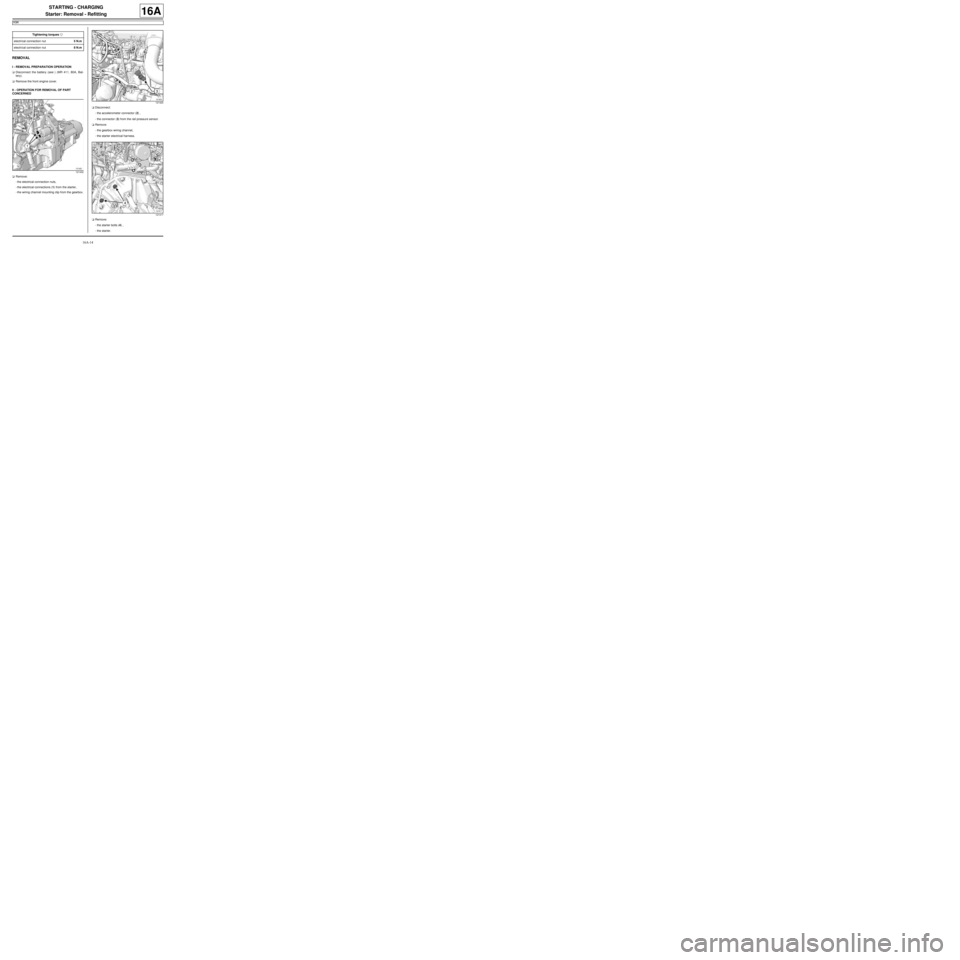

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the electrical connection nuts,

-the electrical connections (1) from the starter,

-the wiring channel mounting clip from the gearbox.aDisconnect:

-the accelerometer connector (2) ,

-the connector (3) from the rail pressure sensor.

aRemove:

-the gearbox wiring channel,

-the starter electrical harness.

aRemove:

-the starter bolts (4) ,

-the starter. Tightening torquesm

electr ical connection nut5 N.m

electr ical connection nut8 N.m

121432

121420

121417

Page 454 of 652

16A-15

STARTING - CHARGING

Starter: Removal - Refitting

K9K

16A

REFITTING

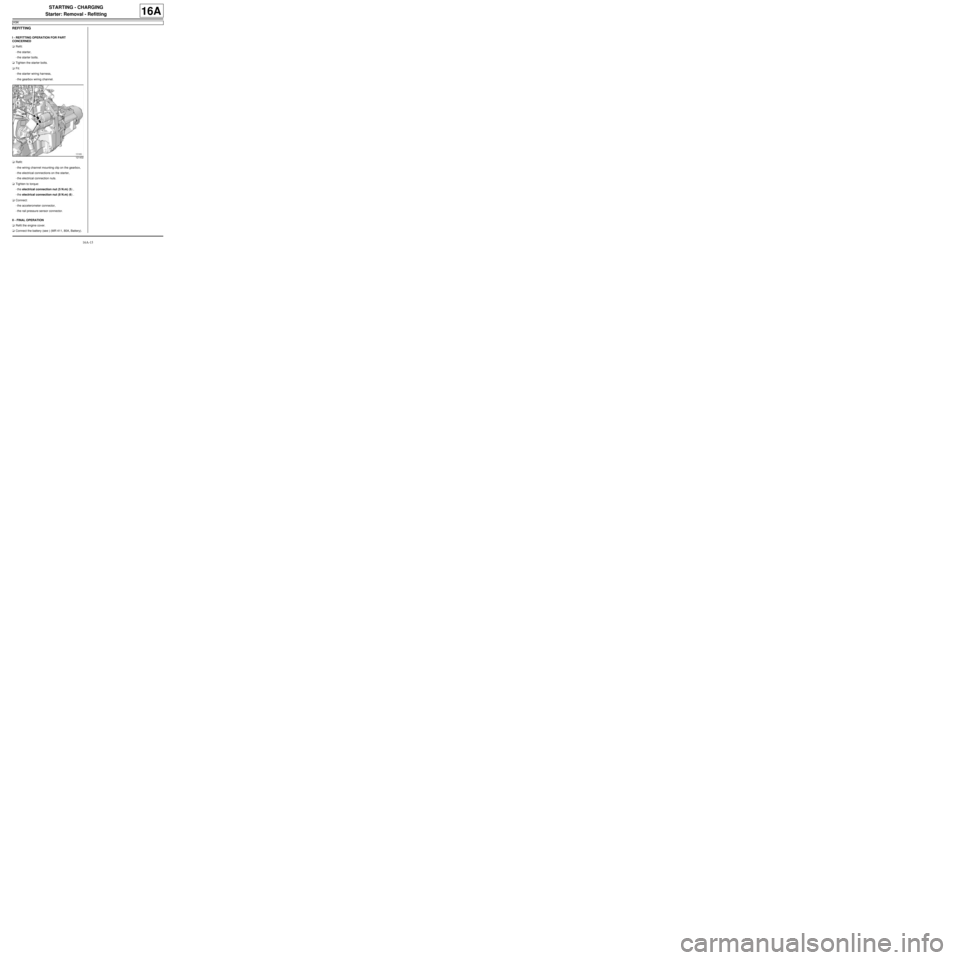

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the starter,

-the starter bolts.

aTighten the starter bolts.

aFit:

-the starter wiring harness,

-the gearbox wiring channel.

aRefit:

-the wiring channel mounting clip on the gearbox,

-the electrical connections on the starter,

-the electrical connection nuts.

aTighten to torque:

-the electrical connection nut (5 N.m) (5) ,

-the electrical connection nut (8 N.m) (6) .

aConnect:

-the accelerometer connector,

-the rail pressure sensor connector.

II - FINAL OPERATION

aRefit the engine cover.

aConnect the battery (see ) (MR 411, 80A, Battery).

121432

Page 455 of 652

16A-16

STARTING - CHARGING

Starter: Removal - Refitting

K4M

16A

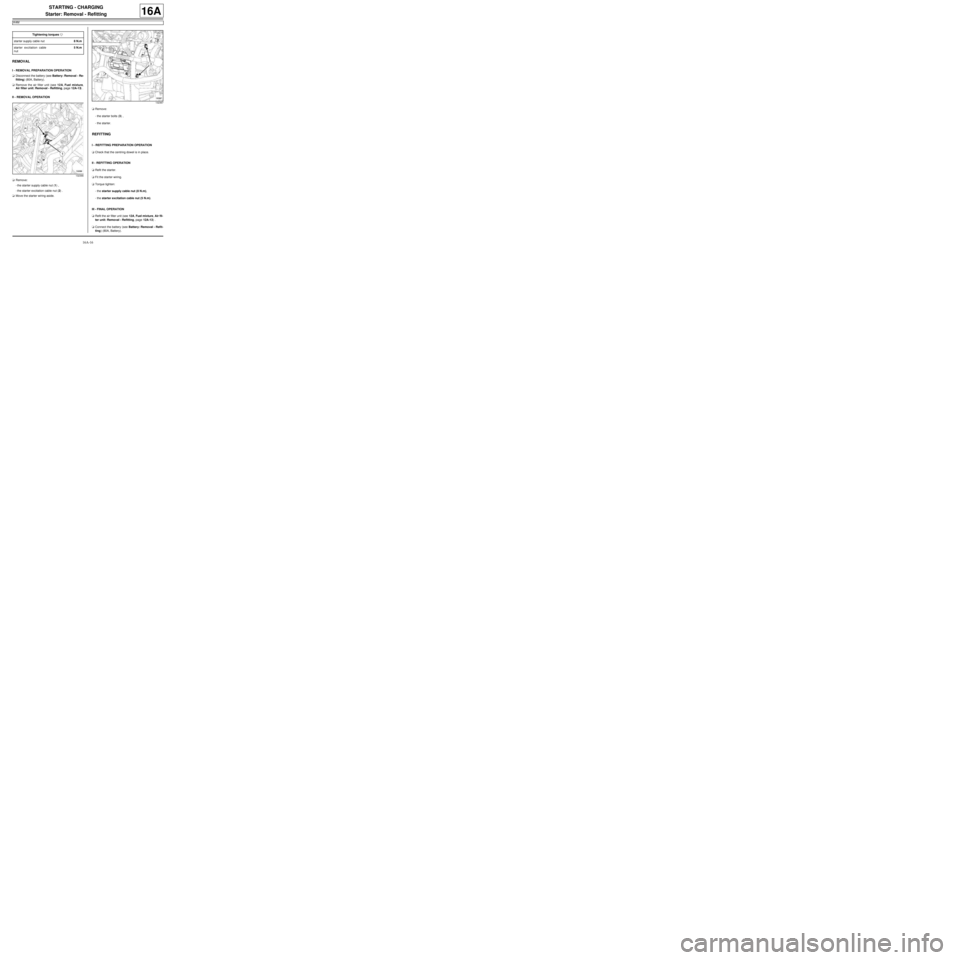

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - REMOVAL OPERATION

aRemove:

-the starter supply cable nut (1) ,

-the starter excitation cable nut (2) .

aMove the starter wiring aside.aRemove:

-the starter bolts (3) ,

-the starter.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the centring dowel is in place.

II - REFITTING OPERATION

aRefit the starter.

aFit the starter wiring.

aTorque tighten:

-the starter supply cable nut (8 N.m),

-the starter excitation cable nut (5 N.m).

III - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery). Tightening torquesm

starter supply cable nut8 N.m

starter excitation cable

nut5 N.m

132366

132367

Page 456 of 652

16A-17

STARTING - CHARGING

Alternator pulley: Removal - Refitting

K9K – K4M

16A

aTo remove and refit the alternator pulley (see 16A,

Starting - Charging, Alternator pulley: Removal -

Refitting, page 16A-17) (Technical Note 5008A,

16A, Starting - Charging).

Page 482 of 652

17B-7

PETROL INJECTION

Petrol injection: List and location of components

D4F, and 780 or 782

17B

121774

(14) Downstream oxygen sensor

109725

(15) Coolant temper ature sensor

(16) Crankshaft position sensor

121725

(17) Oil pressure sensor

122825

(18) Turbocharging pressure limiter

solenoid valve

Page 524 of 652

19A-14

COOLING

Cooling radiator: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDisconnect the pressostat connector (1) .

aRemove the plastic cover (2) from the condenser.

aUnscrew the condenser connecting pipe unions (3) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

safety strap(s)

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.AIR CONDITIONING

K9K, and 718, and AIR CONDITIONING

141214

Page 530 of 652

19A-20

COOLING

Cooling radiator: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aDrain the air conditioning circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the engine undertray bolts,

-the engine undertray,

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

safety strap(s)

Tightening torquesm

bolt of the dehydrator

reservoir - « expansion

valve connecting pipe » 8 N.m

compressor - con-

denser « connecting

pipe bolt » 8 N.m

air conditioning connect-

ing pipe bolts8 N.m

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

Page 533 of 652

19A-23

COOLING

Cooling radiator: Removal - Refitting

K4M

19A

aPerform the following operations:

-fill the air conditioning circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning),

-fill and bleed the coolant circuit (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) .

aRefit the engine undertray.

Page 553 of 652

19A-43

COOLING

Water chamber: Removal - Refitting

K9K

19A

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aPull the intercooler air inlet pipe clip (1) at the turbo-

charger end.

aDisconnect the intercooler air inlet pipe (2) at the tur-

bocharger end.

aRemove the nut (3) from the intercooler air inlet pipe

at the turbocharger end.

aMove aside the intercooler air inlet pipe (2) at the tur-

bocharger end.

aRemove the nut (4) from the intercooler air outlet

pipe at the damper valve end.

aDisconnect the turbocharging pressure regulator

vacuum pipe (5) .

aUnclip:

-the turbocharging pressure regulator vacuum pipe

at (6) ,

-the brake servo vacuum pipe at (7) .

aDisconnect the brake servo vacuum pipe (8) .

aLoosen the clamp (9) for the air-air intercooler air

outlet pipe at the damper valve end.

aDisconnect the intercooler air outlet pipe (10) at the

damper valve end.

aMove aside the intercooler air outlet pipe (10) at the

damper valve end. K9K, and 718

141222

141213

141217

Page 555 of 652

19A-45

COOLING

Water chamber: Removal - Refitting

K9K

19A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the thermostat to the water chamber.

aRefit:

-a new water chamber seal,

-the water chamber.

aTorque tighten the water chamber bolts (10 N.m).

III - FINAL OPERATION

aConnect the cooling hoses on the water chamber.

aPosition the cooling hose clips on the water chamber

using the tool (Mot. 1448).

aClip on the cooling hose of the coolant-oil heat ex-

changer.

aConnect the intercooler air outlet pipe on the side of

the damper valve.

aTorque tighten the intercooler air outlet pipe clip

at the damper valve end (5.5 N.m).

aConnect the brake servo vacuum pipe.

aClip:

-the turbocharging pressure regulator vacuum pipe,

-the vacuum pipe from the brake servo.

aConnect the turbocharging pressure regulator vacu-

um pipe.

aRefit the nuts of the air hoses on the lifting eye.

aConnect the intercooler air inlet pipe at the turbo-

charger end.

aClip on the intercooler air inlet pipe clip at the turbo-

charger end.

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit the engine cover. K9K, and 718