wheel torque RENAULT TWINGO RS 2009 2.G Engine And Peripherals Manual Online

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 570 of 652

19A-60

COOLING

Coolant pump inlet pipe: Removal - Refitting

K9K

19A

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

aRemove the (Mot. 1672).

aRefit:

-the new subframe front bolt,

-the new subframe rear bolt.

aTorque tighten:

-the subfame front bolt (62 Nm),

-the subframe rear bolt (105 Nm).

aRefit the engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) .

aFill the cooling system (see 19A, Cooling, Cooling

system: Draining - Refilling, page 19A-9) .

aRefit:

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (MR 412,

42A, Upper front structure),

-the headlights (see Halogen headlight: Removal

- Refitting) (MR 411, 80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (MR 411, 85A, Wip-

ers - Washers),

-the engine cover.

aConnect the battery (see ) (MR 411, 80A, Battery).

Page 624 of 652

19C-10

TANK

Fuel tank: Removal - Refitting

D4F or D7F or K4M or K9K

19C

aRefit:

-the heat shield under the tank,

-the heat shield clips under the tank

aTighten to torque:

-the exhaust pipe rubber mounting bush bolt (21

N.m),

-the clip between the catalytic converter and the

rear silencer (21 N.m).

aClip:

-the handbrake cable onto the flange,

-the handbrake cable onto the secondary brake

shoe.

aRefit the rear brake drums (see Rear brake drum:

Removal - Refitting) (33A,Rear axle components).

aRefit the rear wheels (see Wheel: Removal - Refit-

ting) (35A, Wheels and tyres).

aConnect:

-the fuel level sensor module pipe union,

-the fuel level sensor module connector.

aRefit the access flap for the fuel level sensor mod-

ule.

aRefit the rear bench seat.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery). D4F or D7F or K9K

Page 625 of 652

19C-11

TANK

Filler neck: Removal - Refitting

D4F or D7F or K4M or K9K

19C

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aDrain the fuel tank (see 19C, Tank, Fuel tank:

Draining, page 19C-1) .

aRemove the rear right-hand wheel (see Wheel: Re-

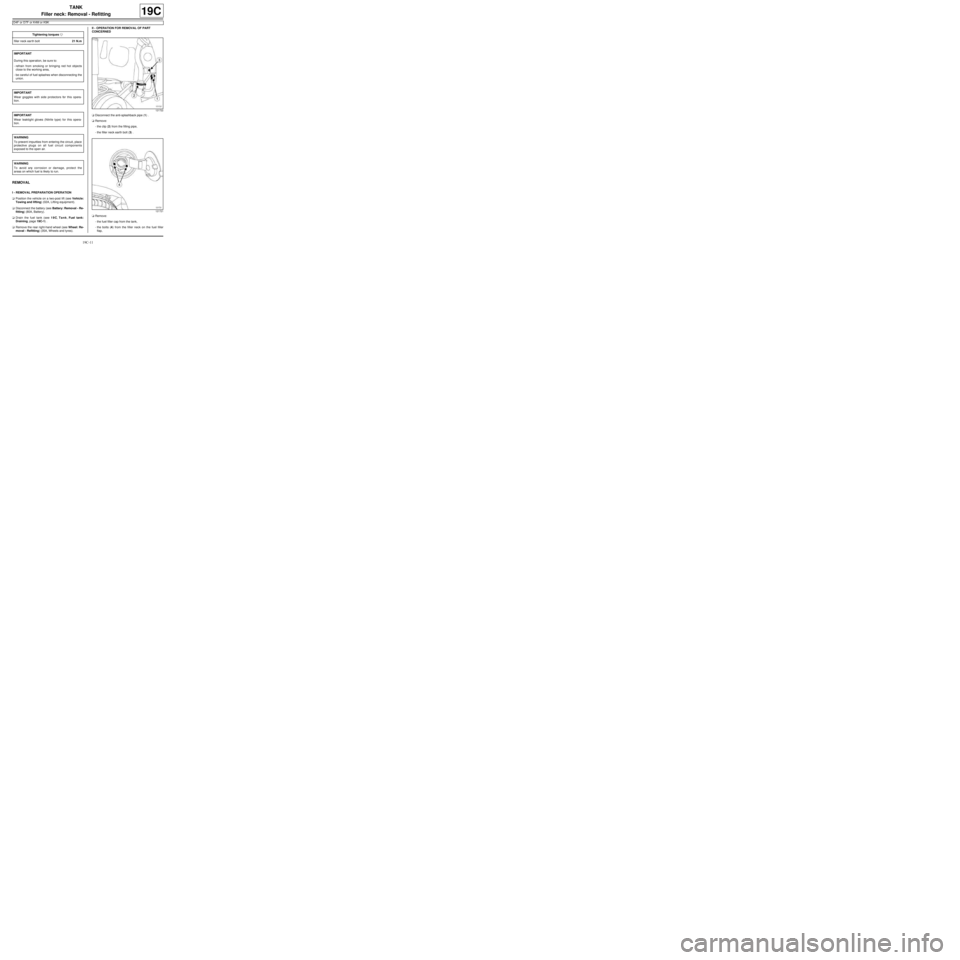

moval - Refitting) (35A, Wheels and tyres).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the anti-splashback pipe (1) .

aRemove:

-the clip (2) from the filling pipe,

-the filler neck earth bolt (3) .

aRemove:

-the fuel filler cap from the tank,

-the bolts (4) from the filler neck on the fuel filler

flap, Tightening torquesm

filler neck ear th bolt21 N.m

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To prevent impurities from entering the circuit, place

protective plugs on all fuel circuit components

exposed to the open air.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

121722

121721

Page 626 of 652

19C-12

TANK

Filler neck: Removal - Refitting

D4F or D7F or K4M or K9K

19C

-the filler neck.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the filler pipe clip.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the filler neck,

-the filler pipe clip,

-the tank filler cap.

aTorque tighten the filler neck earth bolt (21 N.m).

aConnect the anti-splashback pipe.

III - FINAL OPERATION.

aRefit the rear right-hand wheel (see Wheel: Remov-

al - Refitting) (35A, Wheels and tyres).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

Page 634 of 652

19D-4

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

D4F or D7F

19D

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see ) (80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the petrol injection computer mounting bolts,

-the petrol injection computer mounting nuts.

aRemove:

-the engine wiring nut,

-the petrol injection computer mounting.

aMark the position of the left-hand suspended engine

mounting using an indelible pencil.aPut a 20 mm shim between the gearbox and the

front axle subframe. Equipment required

indelible pencil

Tightening torquesm

bolts of the left-hand

suspended engine

mounting cover62 N.m

left-hand suspended

engine mounting shaft105 N.m

bolts of the left-hand

suspended engine

mounting rubber pad

support21 N.m

bolts of the left-hand

suspended engine

mounting r ubber pad62 N.m

central nut of the left-

hand suspended engine

mounting shaft62 N.m

120778

Page 636 of 652

19D-6

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

D4F or D7F

19D

aTorque tighten the left-hand suspended engine

mounting shaft (105 N.m) (7) .

aRefit the electro-hydraulic unit (see Electro-hydrau-

lic unit: Removal - Refitting) (21B, Sequential

gearbox).

aRefit the rubber pad support for the left-hand sus-

pended engine mounting.

aTorque tighten the bolts of the left-hand suspend-

ed engine mounting rubber pad support (21

N.m).

aRefit the wiring on the left-hand suspended engine

mounting rubber pad support.

aRefit:

-the left-hand suspended engine mounting rubber

pad,

-the central nut of the left-hand suspended engine

mounting shaft.

aTorque tighten:

-the bolts of the left-hand suspended engine

mounting rubber pad (62 N.m),

-the central nut of the left-hand suspended en-

gine mounting shaft (62 N.m).II - FINAL OPERATION

aRemove the shim between the gearbox and the front

axle subframe.

aRefit:

-the petrol injection computer mounting,

-the petrol engine wiring nut.

aRefit:

-the petrol injection computer mounting nuts,

-the petrol injection computer mounting bolts,

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the battery (see ) (80A, Battery).

130485

JH1

Page 640 of 652

19D-10

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

K4M

19D

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(80A, Battery),

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection).

aMark the position of the left-hand suspended engine

mounting.aPut a 20 mm shim between the gearbox and the

sub-frame. Tightening torquesm

bolts of the suspended

engine mounting sup-

por t on the gearbox62 N.m

gearbox suspended

engine mounting rubber

pad shaft105 N.m

bolts of the suspended

engine mounting sup-

por t on the body21 N.m

bolts of the suspended

mounting r ubber pad62 N.m

suspended engine

mounting shaft nut62 N.m

120778

Page 642 of 652

19D-12

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

K4M

19D

aTorque tighten:

-the gearbox suspended engine mounting rub-

ber pad shaft (105 N.m) (8) ,

-the bolts of the suspended engine mounting

support on the body (21 N.m).

aFit the wiring of the suspended engine mounting

support on the body.

aRefit the suspended engine mounting rubber pad.

aTorque tighten:

-the bolts of the suspended mounting rubber

pad (62 N.m),

-the suspended engine mounting shaft nut (62

N.m).

II - FINAL OPERATION

aRemove the shim between the gearbox and the sub-

frame.

aRefit:

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the battery (see Battery: Removal - Refitting)

(80A, Battery).

130485