ESP RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 488 of 652

17B-13

PETROL INJECTION

Oxygen sensors: Removal - Refitting

D4F, and 772 – D7F

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).II - REMOVING THE UPSTREAM OXYGEN SENSOR

aDisconnect the upstream oxygen sensor connector

(1) .

aRemove the upstream oxygen sensor (2) using a

24mm open-ended spanner.

III - REMOVING THE DOWNSTREAM OXYGEN

SENSOR

aDisconnect the downstream oxygen sensor connec-

tor.

aRemove the downstream oxygen sensor (3) using a

24mm open-ended spanner. Equipment required

open-ended spanner

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice causes the oxygen

sensor to malfunction and results in failure to com-

ply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair)(Technical

Note 6015A, 88A, Wiring).

121732

120415

Page 490 of 652

17B-15

PETROL INJECTION

Oxygen sensors: Removal - Refitting

D4F, and 780 or 782

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

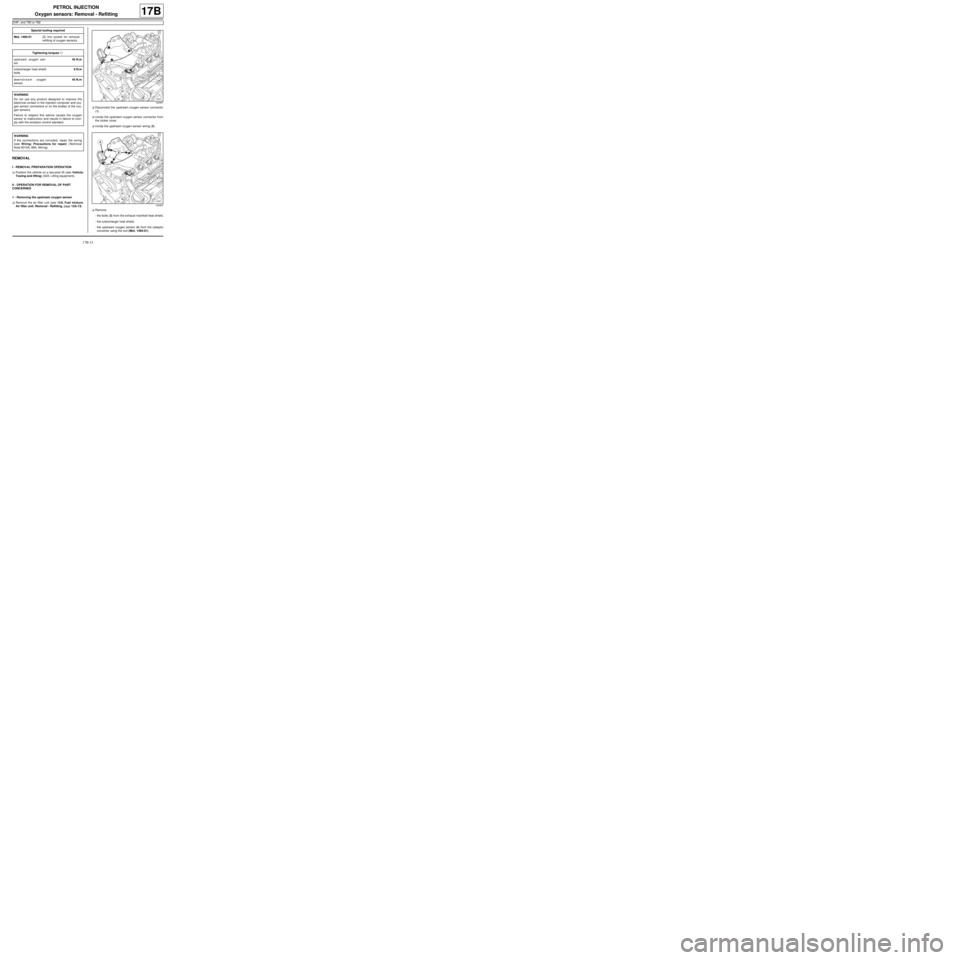

II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Removing the upstream oxygen sensor

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .aDisconnect the upstream oxygen sensor connector

(1) .

aUnclip the upstream oxygen sensor connector from

the rocker cover.

aUnclip the upstream oxygen sensor wiring (2) .

aRemove:

-the bolts (3) from the exhaust manifold heat shield,

-the turbocharger heat shield,

-the upstream oxygen sensor (4) from the catalytic

converter using the tool (Mot. 1495-01). Special tooling required

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Tightening torquesm

upstream oxygen sen-

sor45 N.m

turbocharger heat shield

bolts8 N.m

downstream oxygen

sensor45 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice causes the oxygen

sensor to malfunction and results in failure to com-

ply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

120957

120957

Page 492 of 652

17B-17

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

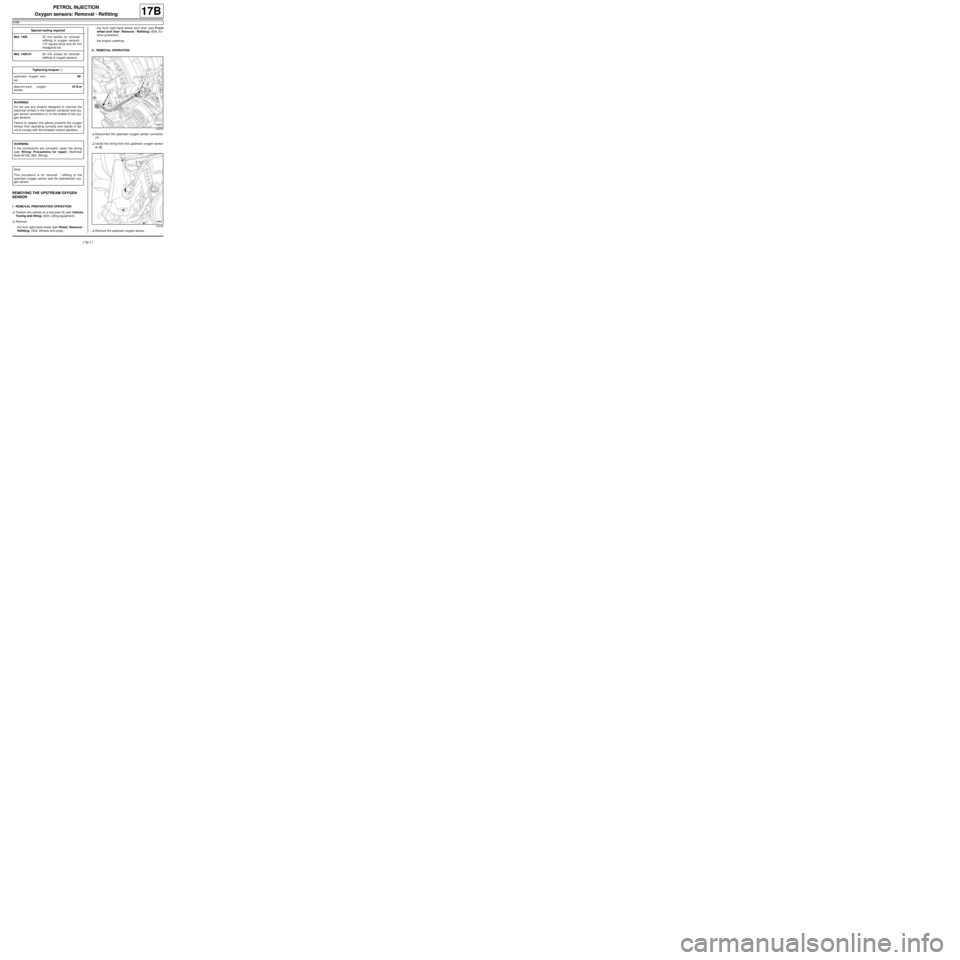

REMOVING THE UPSTREAM OXYGEN

SENSOR

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the engine undertray.

II - REMOVAL OPERATION

aDisconnect the upstream oxygen sensor connector

(1) .

aUnclip the wiring from the upstream oxygen sensor

at (2) .

aRemove the upstream oxygen sensor . Special tooling required

Mot. 149522 mm socket for removal -

refitting of oxygen sensors -

1/2" square dr ive and 24 mm

hexagonal ext.

Mot. 1495-0122 mm socket for removal -

refitting of oxygen sensors.

Tightening torquesm

upstream oxygen sen-

sor90˚

downstream oxygen

sensor45 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

Note:

This procedure is for removal - refitting of the

upstream oxygen sensor and the downstream oxy-

gen sensor.

132373

132539

Page 495 of 652

17B-20

PETROL INJECTION

Petrol injection computer: Removal - Refitting

D4F or D7F

17B

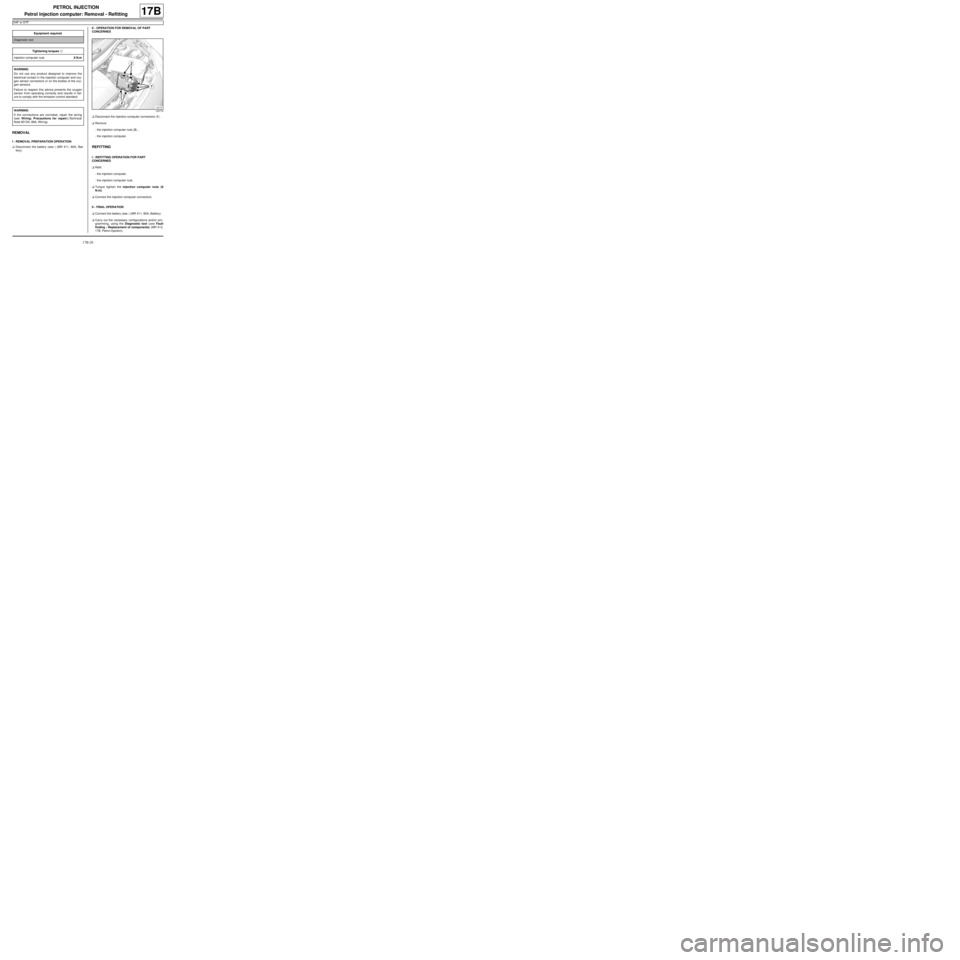

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the injection computer connectors (1) .

aRemove:

-the injection computer nuts (2) ,

-the injection computer.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the injection computer,

-the injection computer nuts.

aTorque tighten the injection computer nuts (8

N.m).

aConnect the injection computer connectors.

II - FINAL OPERATION

aConnect the battery (see ) (MR 411, 80A, Battery).

aCarry out the necessary configurations and/or pro-

gramming, using the Diagnostic tool (see Fault

finding - Replacement of components) (MR 413,

17B, Petrol injection). Equipment required

Diagnostic tool

Tightening torquesm

injection computer nuts8 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

120779

Page 496 of 652

17B-21

PETROL INJECTION

Petrol injection computer: Removal - Refitting

K4M

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).aRemove:

-the tamperproof bolts (1) using the tool (Mot. 1844)

(2) and a drill,

-the petrol injection computer protector. Special tooling required

Mot. 1844Drill bush for removing the

tamper-proof bolts from the

injection computer protective

cover

Equipment required

drill

Diagnostic tool

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical Note

6015A, 88A, Wiring).

RIGHT-HAND DRIVE

132448

Page 630 of 652

19C-16

TANK

Fuel level sensor module: Removal - Refitting

D4F or D7F or K4M or K9K

19C

aTighten the fuel level sensor module nut using the

tool (Mot. 1397) until the nut mark (11) corresponds

with the fuel tank mark (12) .

III - FINAL OPERATION

aConnect:

-the fuel pipe,

-the fuel level sensor module connector.

aConnect:

-the fuel pipes,

-the fuel level sensor module connector.

aRefit the inspection flap cover.

aFit:

-the carpet under the rear bench seat base.

-the rear bench seat base (see Rear bench seat

base: Removal - Refitting) (76A, Rear seat

frames and runners).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

102470

K4M

D4F or D7F or K9K