RENAULT TWINGO RS 2009 2.G Panelwork Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 209

Page 1 of 209

© Renault s.a.s 2007 "The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the manufacturer in

the production of the various component units and accessories from which the vehicles are

constructed".All rights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part reference

numbering system is forbidden without the prior written authority of Renault.

JUNE 2009 EDITION ANGLAISE

X44

4Panelwork

40AGENERAL INFORMATION

41AFRONT LOWER STRUCTURE

41BCENTRE LOWER STRUCTURE

41CSIDE LOWER STRUCTURE

41DREAR LOWER STRUCTURE

42AFRONT UPPER STRUCTURE

43ASIDE UPPER STRUCTURE

44AREAR UPPER STRUCTURE

45ATOP OF BODY

47ASIDE OPENING ELEMENTS

48ANON-SIDE OPENING ELEMENTS

Page 2 of 209

TWINGO - Section 4

Contents

Pages

TWINGO - Section 4 ContentsPages

40A GENERAL INFORMATION

Specialised bodywork tools:

Use 40A-1

Vehicle on repair bench:

Description 40A-5

Subframe: Specifications 40A-7

Hollow section inserts: List

and location of components 40A-9

Hollow section inserts:

Precautions for the repair 40A-11

Earths on body: List and

location of components 40A-12

Vehicle structure, front

section: Description 40A-15

Vehicle structure, side

section: Description 40A-17

Vehicle structure, centre

section: Description 40A-19

Vehicle structure, rear

section: Description 40A-21

Vehicle structure, removable

section: Description 40A-23

Structural components to be

positioned on the repair

bench: Description 40A-25

Structural bodywork

documentation: Description 40A-2941A FRONT LOWER STRUCTURE

Front end lower cross

member: General description 41A-1

Front end lower cross

member: Description 41A-2

Radiator mounting cross

member: General description 41A-4

Radiator mounting cross

member: Removal - Refitting 41A-5

Front side member: General

descr iption 41A-6

Front side member, front

section: Description 41A-8

Front side member closure

panel, front section: General

descr iption 41A-11

Front side member closure

panel, front section:

Description 41A-13

Front side member, rear

section: Description 41A-15

Front subframe front

mounting: General

descr iption 41A-17

Front subframe front

mounting: Description 41A-18

Engine stand: General

descr iption 41A-20

Engine stand: Description 41A-21

Page 3 of 209

Contents

Front half unit: General

descr iption 41A-23

Front half unit: Description 41A-24

41B CENTRE LOWER STRUCTURE

Centre floor, side section:

General description 41B-1

Centre floor, side section:

Description 41B-3

Centre floor front side cross

member: General description 41B-5

Centre floor front side cross

member: Description 41B-7

Front cross member under

front seat: General

descr iption 41B-8

Front cross member under

front seat: Description 41B-9

Rear cross member under

front seat: General

descr iption 41B-10

Rear cross member under

front seat: Description 41B-11

41C SIDE LOWER STRUCTURE

Sill panel: General

descr iption 41C-1

Sill panel: Description 41C-5

Sill panel closure panel:

General description 41C-8

Sill panel closure panel:

Description 41C-10

Sill panel reinforcement:

General description 41C-12 41A FRONT LOWER STRUCTURESill panel reinforcement:

Description 41C-13

Sill panel stiffener:

Description 41C-15

41D REAR LOWER STRUCTURE

Rear fl oor: Description 41D-1

Raised rear floor, front

section: Removal - Refitting 41D-4

Rear side member assembly:

Description 41D-5

Rear side member : General

descr iption 41D-7

Rear side member :

Description 41D-8

Rear fl oor front cross

member: General description 41D-10

Rear fl oor front cross

member: Description 41D-12

Rear fl oor centre cross

member: General description 41D-13

Rear fl oor centre cross

member: Description 41D-14

Rear towing eye: Description 41D-16

Rear impact lower cross

member: Removal - Refitting 41D-18

42A FRONT UPPER STRUCTURE

Front wing: General

descr iption 42A-1

Front wing: Removal -

Refitting 42A-3

Front wing: Adjustment 42A-4

Front wing upper mounting

support: General description 42A-6 41C SIDE LOWER STRUCTURE

Page 4 of 209

Contents

Front wing upper mounting

support: Removal - Refi tting 42A-7

Front end panel: General

descr iption 42A-8

Front end panel: Removal -

Refitting 42A-9

Headlight carrier panel:

Removal - Refitting 42A-11

Front upper cross member:

General description 42A-12

Front upper cross member:

Removal - Refitting 42A-13

Scuttle side panel: General

descr iption 42A-14

Scuttle side panel:

Description 42A-16

Upper reinforcement of

scuttle side panel: General

descr iption 42A-18

Upper reinforcement of

scuttle side panel:

Description 42A-19

Front wheel arch: General

descr iption 42A-21

Front wheel arch: Description 42A-22

Front wheel arch, front

section: General description 42A-25

Dashboard cross member:

Removal - Refitting 42A-26

Windscreen aperture lower

cross member closure panel:

Description 42A-28

43A SIDE UPPER STRUCTURE

A-pillar : General description 43A-1

A-pillar : Description 43A-2

A-pillar reinforcement:

General description 43A-5 42A FRONT UPPER STRUCTUREA-pillar reinforcement:

Description 43A-6

Windscreen pillar lining:

General description 43A-8

B-pillar reinforcement:

General description 43A-9

B-pillar reinforcement:

Description 43A-10

Body side: General

descr iption 43A-12

Body side: Description 43A-13

Upper body: General

descr iption 43A-15

Upper body: Description 43A-17

44A REAR UPPER STRUCTURE

Rear wing panel: General

descr iption 44A-1

Rear wing panel: Description 44A-2

Rear lights mounting:

General description 44A-5

Rear lights mounting:

Description 44A-6

Outer rear wheel arch:

General description 44A-8

Outer rear wheel arch:

Description 44A-10

Inner rear wheel arch:

General description 44A-13

Inner rear wheel arch:

Description 44A-14

Quar ter panel lining: General

descr iption 44A-16

Quar ter panel lining:

Description 44A-17

Rear end panel assembly:

Description 44A-22 43A SIDE UPPER STRUCTURE

Page 5 of 209

Contents

Rear end panel: General

descr iption 44A-24

Rear end panel: Description 44A-25

45A TOP OF BODY

Roof: General description 45A-1

Roof: Description 45A-2

Roof front section:

Description 45A-6

Roof rear section:

Description 45A-7

Roof front cross member:

General description 45A-8

Roof centre cross member:

General description 45A-9

Roof rear cross member:

General description 45A-10

47A SIDE OPENING ELEMENTS

Front side door: Removal -

Refitting 47A-1

Front side door: Stripping -

rebuilding 47A-3

Front side door: Adjustment 47A-5

Fuel filler flap co ver:

Removal - Refitting 47A-8

48A NON-SIDE OPENING ELEMENTS

Bonnet: Removal - Refitting 48A-1

Bonnet: Stripping -

Rebuilding 48A-3

Bonnet: Adjustment 48A-4

Tailgate: Removal - Refitting 48A-6 44A REAR UPPER STRUCTURETailgate: Stripping -

Rebuilding 48A-8

Tailgate: Adjustment 48A-10 48A NON-SIDE OPENING ELEMENTS

Page 6 of 209

40A-1

GENERAL INFORMATION

Specialised bodywork tools: Use

40A

I - DASHBOARD PROTECTOR CAR.1818

aWhen replacing the windscreen:

-remove the windscreen pillar trims,

-position the dashboard protector to avoid dama-

ging the dashboard when cutting the cement bead.

18263

Page 7 of 209

40A-2

GENERAL INFORMATION

Specialised bodywork tools: Use

40A

II - CRIMPED NUT FITTING TOOL CAR.1504

Page 8 of 209

40A-3

GENERAL INFORMATION

Specialised bodywork tools: Use

40A

111554

Page 9 of 209

40A-4

GENERAL INFORMATION

Specialised bodywork tools: Use

40A

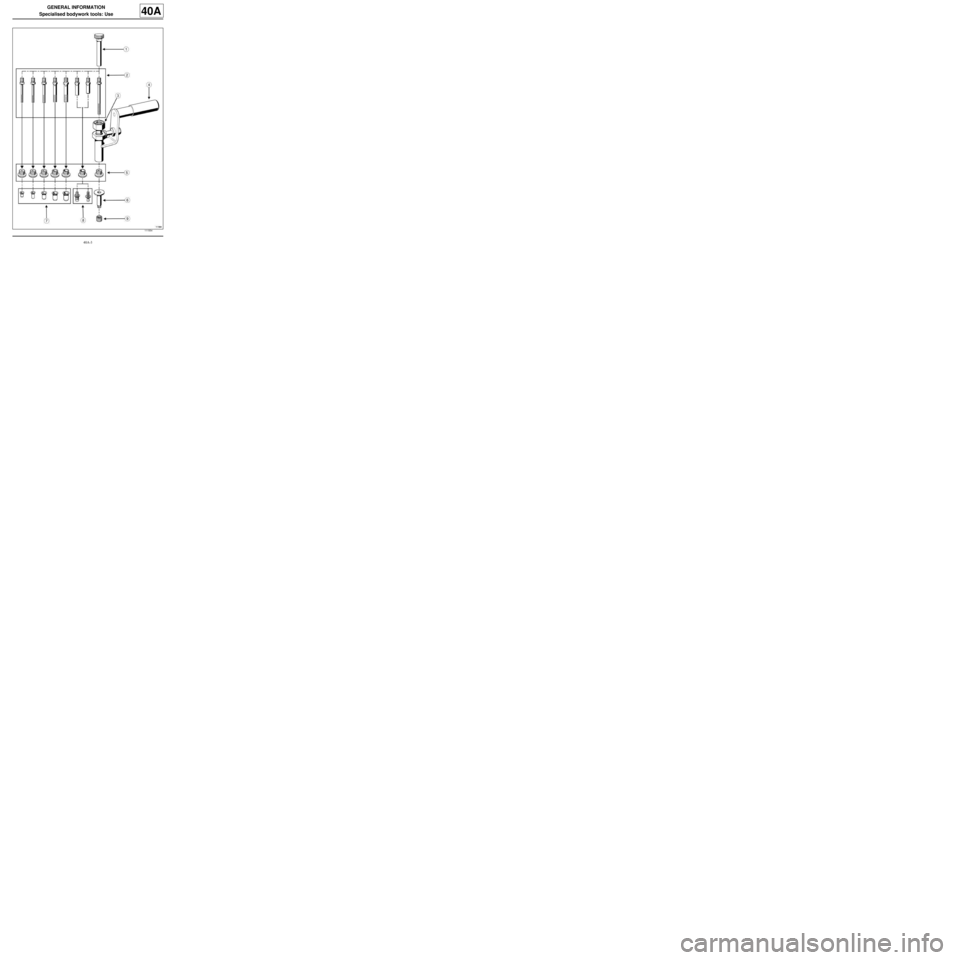

aComponents of tool Car. 1504 :

- (1) : Mandrel mounting,

- (2) : Mandrels,

- (3) : Tightening bolt,

- (4) : Body,

- (5) : Anvils,

- (6) : Special nut,

- (7) : Nut,

- (8) : Studs,

- (9) : Thrust nut.

1 - Tool preparation

aSelect the mandrel, anvil and insert assembly adap-

ted to the crimping operation to be carried out.

aScrew the mandrel (2) into the mandrel mounting (1)

(left-hand thread).

aTighten the bolt (3) onto the body (4) until the stop

(left-hand thread).

aScrew the anvil (5) into the body (4) (left-hand

thread)

aFit the assembly (1) and (2) into the body of the tool.

aScrew the insert (left-hand thread) onto the pull rod.2 - Using the tool

aTurn the tightening bolt (3) using a 24 mm wrench

while holding the tool handle.

Note:

To fi t the special nut (6) , insert the mandrel (2)

through the nut to be crimped and tighten it onto

the thrust nut (9) .

WARNING

Each time a panel is stripped in the workshop

(e.g. when drilling), degrease and wipe the area

and then use a fine paintbrush to apply the fol-

lowing:

-a pre-treatment primer,

-a two-part pr imer,

-paint in the vehicle body colour.

WARNING

The operator should be able to feel when the

crimping is complete (more force required for

tightening).

The insert has been crimped correctly when

there is no rotational play. Carry out this check

before unscrewing the « pull rod - mandrel »

assembly.

Page 10 of 209

40A-5

GENERAL INFORMATION

Vehicle on repair bench: Description

C44

40A

I - MAIN FRONT TRIM-SETTING REFERENCE

POINTS

1 - Front sub-frame in place

the jig covers the subframe bolt (A) .

Use this situation for a rear impact or a light frontal im-

pact without removing the mechanical components.

2 - Front sub-frame removed

The jig rests against the rear section of the side mem-

ber and is centred in the sub-frame rear mounting hole

(A) .Use this situation for a frontal impact with removal of

the mechanical components.

II - SECONDARY FRONT TRIM-SETTING

REFERENCE POINT

The jig covers the front subframe front mounting bolt

(C) .

Use this situation to confirm the trim-setting following a

rear impact, (e.g.: to replace a rear side member as-

sembly).

It is used to confirm the vehicle level in case of doubt

about the deformation of a main rear reference point.

120611

121747

Note:

If it is suspected that one of these points may be

deformed, use two additional points located in an

area not affected by the impact in order to confirm

trim-setting.

120610