engine oil RENAULT TWINGO RS 2009 2.G Engine Diesel Injection User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 269

Page 249 of 269

13B-249V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

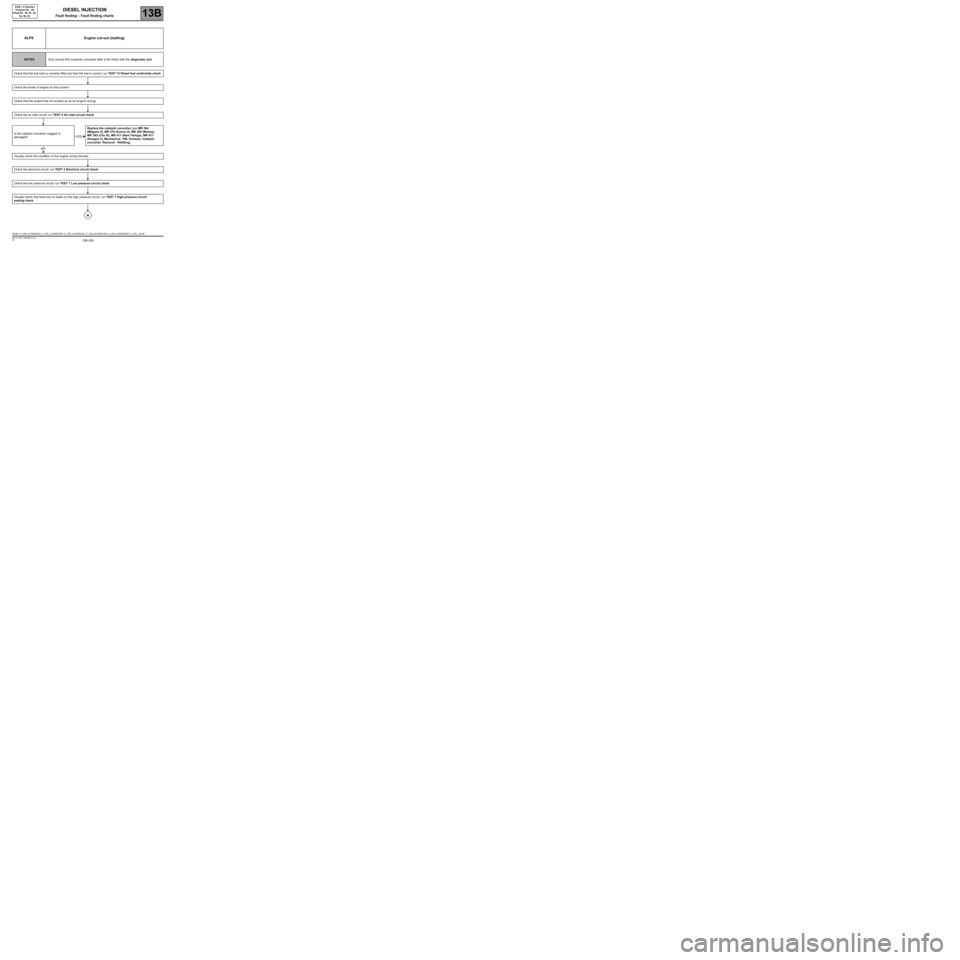

ALP9 Engine cut-out (stalling)

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check that the engine has not sucked up its oil (engine racing).

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

Is the catalytic converter clogged or

damaged?Replace the catalytic converter (see MR 364

(Mégane II), MR 370 (Scénic II), MR 385 (Modus),

MR 392 (Clio III), MR 411 (New Twingo), MR 417

(Kangoo 2), Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Visually check the condition of the engine wiring harness.

Check the electrical circuit: run TEST 2 Electrical circuit check.

Check the low pressure circuit: run TEST 1 Low pressure circuit check.

Visually check that there are no leaks on the high pressure circuit: run TEST 7 High pressure circuit

sealing check.

YES

NO

A

DCM1.2_V48_ALP9/DCM1.2_V4C_ALP9/DCM1.2_V50_ALP9/DCM1.2_V54_ALP9/DCM1.2_V58_ALP9/DCM1.2_V5C_ALP9

Page 254 of 269

13B-254V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

* OCR: opening cyclic ratio

ALP11

CONTINUED 1

Is the engine oil level correct? Top up the oil level.

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR

364 (Mégane II), MR 370 (Scénic II),

MR 385 (Modus), MR 392 (Clio III),

MR 411 (New Twingo), MR 417

(Kangoo 2), 19B, Exhaust, Catalytic

converter: Removal - Refitting).

A

NO

YES

YES

NO

B

Page 256 of 269

13B-256V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

In this case, the control solenoid valve is jammed: the vacuum can increase, but it cannot then be

decreased.

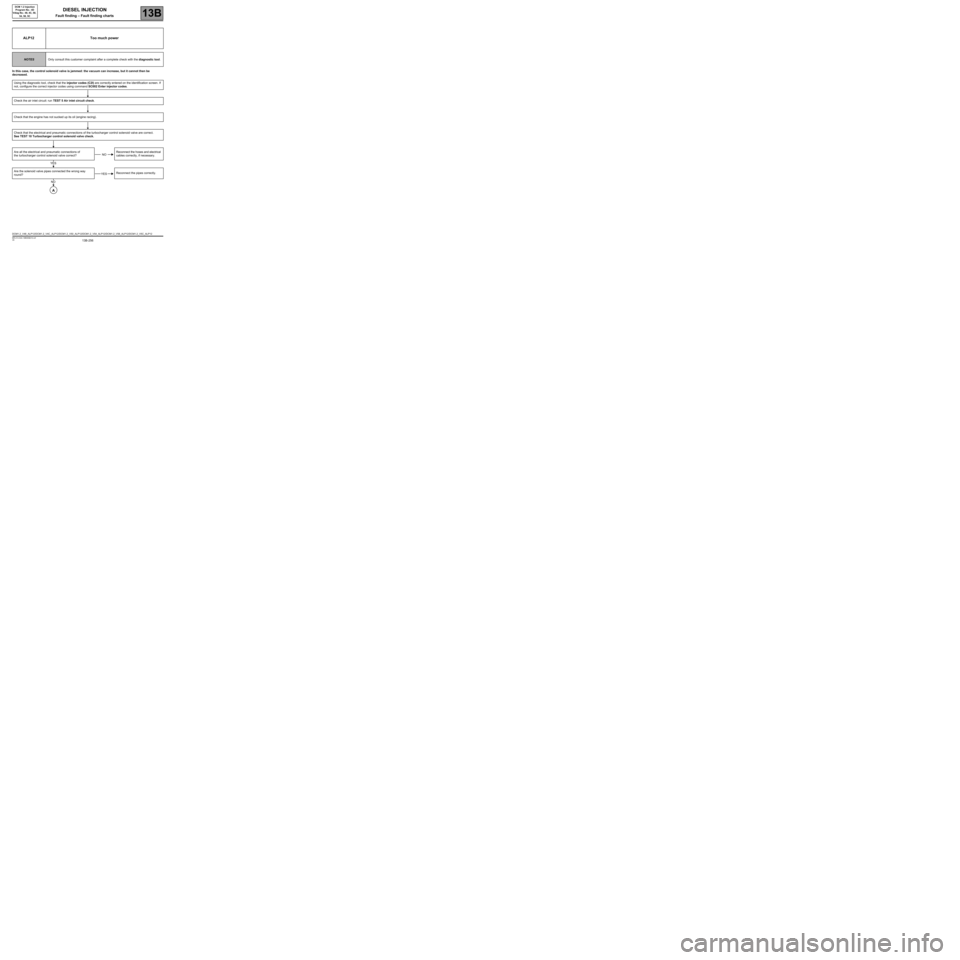

ALP12 Too much power

NOTESOnly consult this customer complaint after a complete check with the diagnostic tool.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

Check that the engine has not sucked up its oil (engine racing).

Check that the electrical and pneumatic connections of the turbocharger control solenoid valve are correct.

See TEST 10 Turbocharger control solenoid valve check.

Are all the electrical and pneumatic connections of

the turbocharger control solenoid valve correct?Reconnect the hoses and electrical

cables correctly, if necessary.

Are the solenoid valve pipes connected the wrong way

round?Reconnect the pipes correctly.

NO

YES

YES

NO

A

DCM1.2_V48_ALP12/DCM1.2_V4C_ALP12/DCM1.2_V50_ALP12/DCM1.2_V54_ALP12/DCM1.2_V58_ALP12/DCM1.2_V5C_ALP12

Page 258 of 269

13B-258V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

In this case, it may be the solenoid valve dynamic specification which is at fault (atmospheric pressure

resetting time). Final fault finding is carried out by measuring this specification on a special bench.

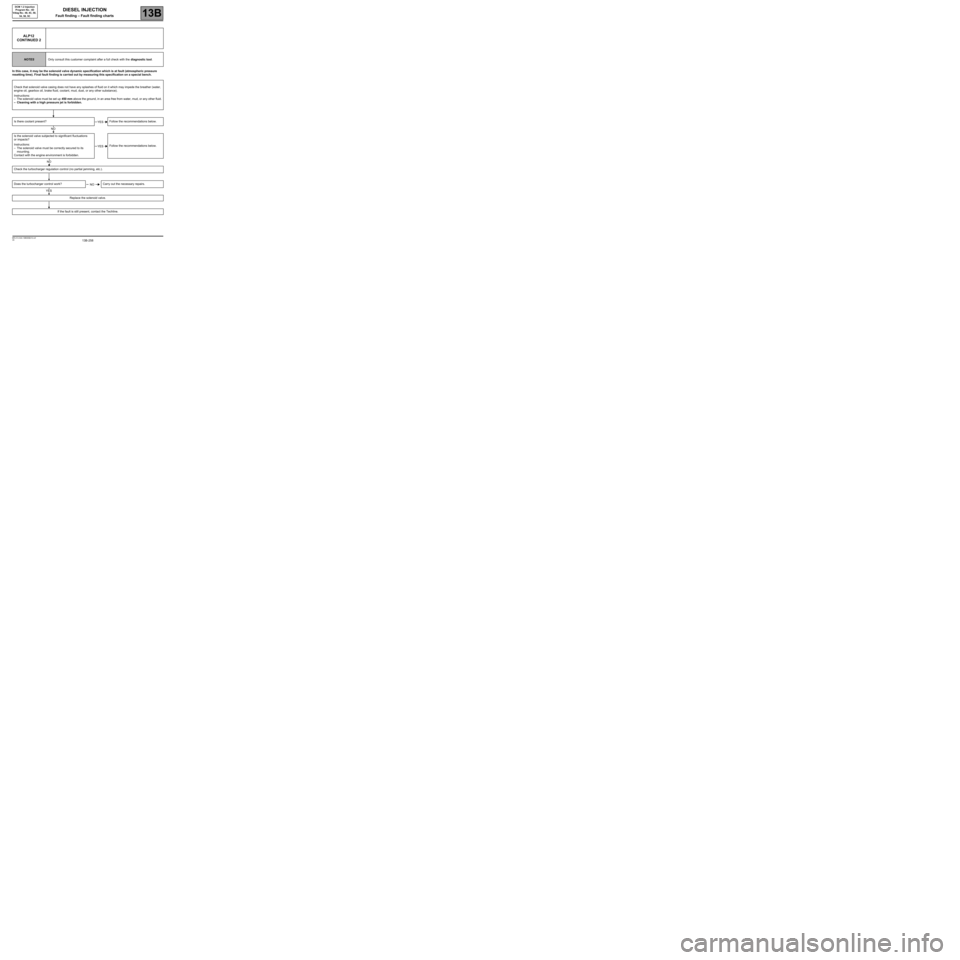

ALP12

CONTINUED 2

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that solenoid valve casing does not have any splashes of fluid on it which may impede the breather (water,

engine oil, gearbox oil, brake fluid, coolant, mud, dust, or any other substance).

Instructions:

–The solenoid valve must be set up 450 mm above the ground, in an area free from water, mud, or any other fluid.

–Cleaning with a high pressure jet is forbidden.

Is there coolant present? Follow the recommendations below.

Is the solenoid valve subjected to significant fluctuations

or impacts?

Instructions:

–The solenoid valve must be correctly secured to its

mounting.

Contact with the engine environment is forbidden.Follow the recommendations below.

Check the turbocharger regulation control (no partial jamming, etc.).

Does the turbocharger control work? Carry out the necessary repairs.

Replace the solenoid valve.

If the fault is still present, contact the Techline.

YES

NO

YES

NO

NO

YES

Page 259 of 269

13B-259V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

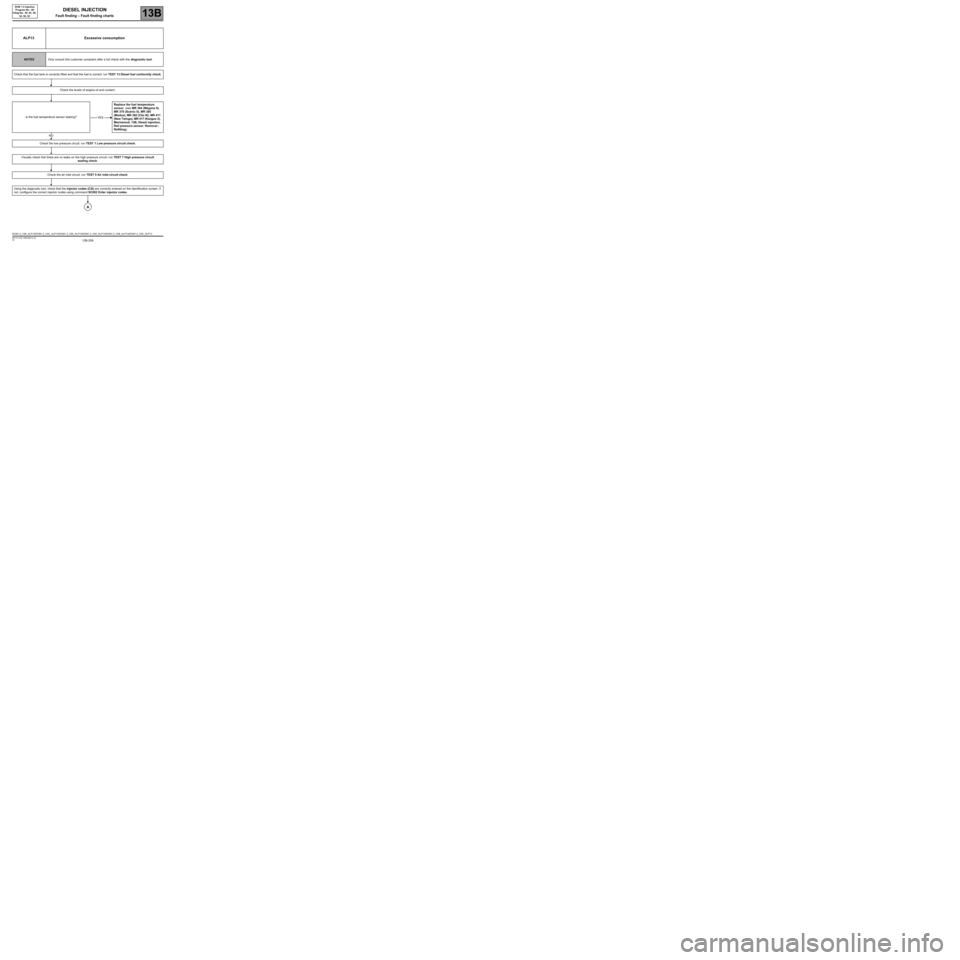

ALP13 Excessive consumption

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Is the fuel temperature sensor leaking? Replace the fuel temperature

sensor, (see MR 364 (Mégane II),

MR 370 (Scénic II), MR 385

(Modus), MR 392 (Clio III), MR 411

(New Twingo), MR 417 (Kangoo 2),

Mechanical, 13B, Diesel injection,

Rail pressure sensor: Removal -

Refitting).

Check the low pressure circuit: run TEST 1 Low pressure circuit check.

Visually check that there are no leaks on the high pressure circuit: run TEST 7 High pressure circuit

sealing check.

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

YES

NO

A

DCM1.2_V48_ALP13/DCM1.2_V4C_ALP13/DCM1.2_V50_ALP13/DCM1.2_V54_ALP13/DCM1.2_V58_ALP13/DCM1.2_V5C_ALP13

Page 261 of 269

13B-261V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

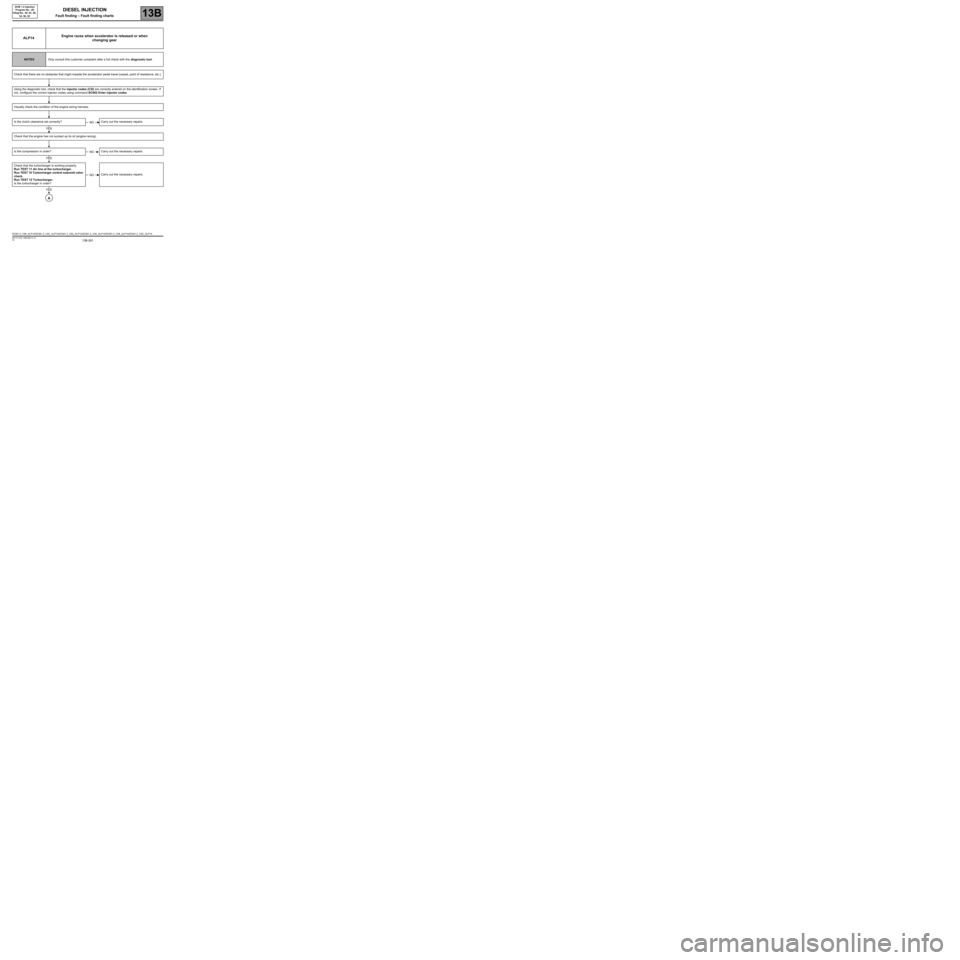

ALP14Engine races when accelerator is released or when

changing gear

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that there are no obstacles that might impede the accelerator pedal travel (carpet, point of resistance, etc.).

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Is the clutch clearance set correctly? Carry out the necessary repairs.

Check that the engine has not sucked up its oil (engine racing).

Is the compression in order? Carry out the necessary repairs.

Check that the turbocharger is working properly.

Run TEST 11 Air line at the turbocharger.

Run TEST 10 Turbocharger control solenoid valve

check.

Run TEST 12 Turbocharger.

Is the turbocharger in order?Carry out the necessary repairs.

NO

YES

NO

YES

NO

YES

A

DCM1.2_V48_ALP14/DCM1.2_V4C_ALP14/DCM1.2_V50_ALP14/DCM1.2_V54_ALP14/DCM1.2_V58_ALP14/DCM1.2_V5C_ALP14

Page 264 of 269

13B-264V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

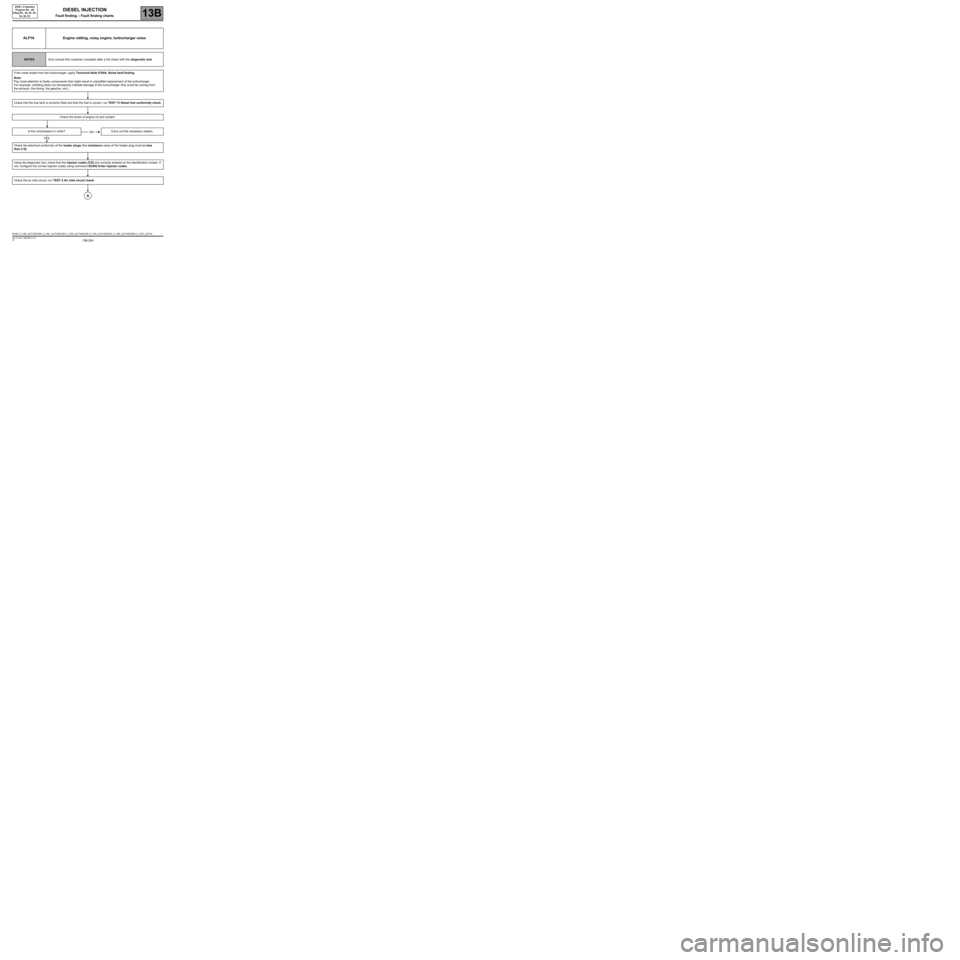

ALP16 Engine rattling, noisy engine, turbocharger noise

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

If the noise arises from the turbocharger, apply Technical Note 5164A, Noise fault finding.

Note:

Pay close attention to faulty components that might result in unjustified replacement of the turbocharger.

For example, whistling does not necessarily indicate damage to the turbocharger (this could be coming from

the exhaust, the timing, the gearbox, etc.).

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Is the compression in order? Carry out the necessary repairs.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less

than 2 ΩΩ Ω Ω

).

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

NO

YES

A

DCM1.2_V48_ALP16/DCM1.2_V4C_ALP16/DCM1.2_V50_ALP16/DCM1.2_V54_ALP16/DCM1.2_V58_ALP16/DCM1.2_V5C_ALP16

Page 266 of 269

13B-266V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

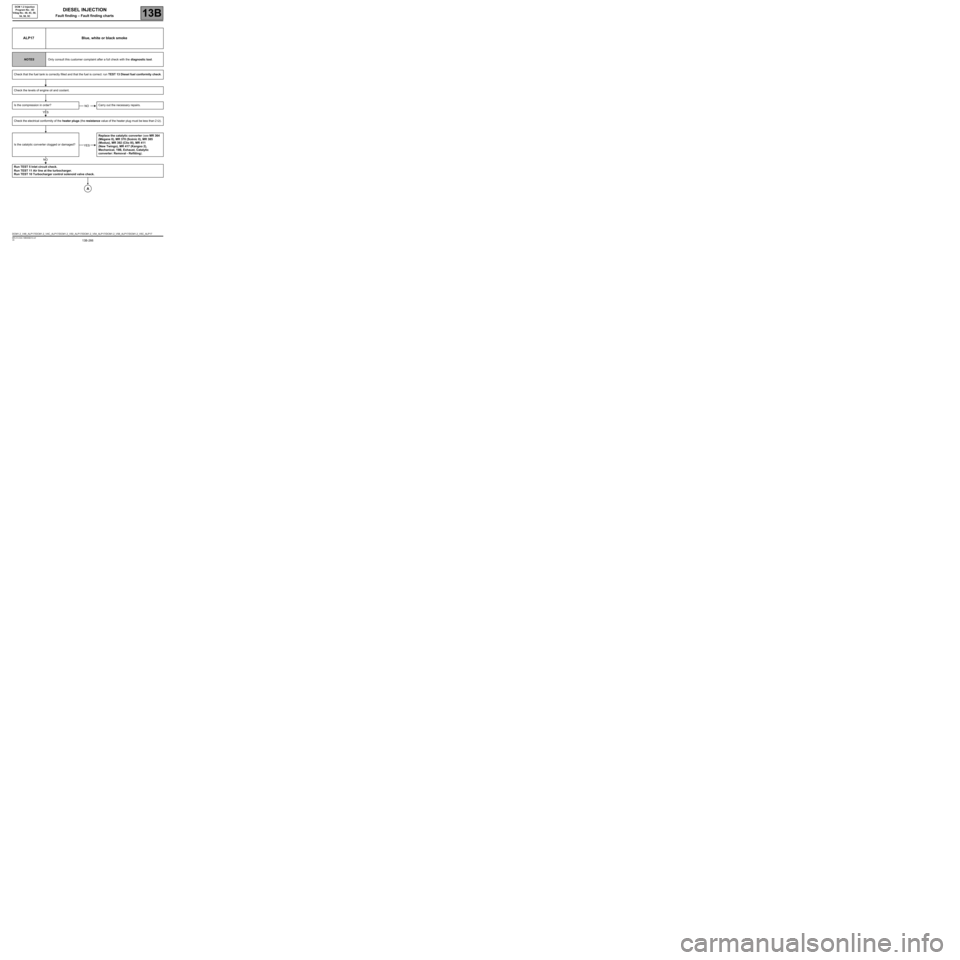

ALP17 Blue, white or black smoke

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Is the compression in order? Carry out the necessary repairs.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less than 2 Ω).

Is the catalytic converter clogged or damaged?Replace the catalytic converter (see MR 364

(Mégane II), MR 370 (Scénic II), MR 385

(Modus), MR 392 (Clio III), MR 411

(New Twingo), MR 417 (Kangoo 2),

Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Run TEST 5 Inlet circuit check.

Run TEST 11 Air line at the turbocharger.

Run TEST 10 Turbocharger control solenoid valve check.

NO

YES

YES

NO

A

DCM1.2_V48_ALP17/DCM1.2_V4C_ALP17/DCM1.2_V50_ALP17/DCM1.2_V54_ALP17/DCM1.2_V58_ALP17/DCM1.2_V5C_ALP17

Page 268 of 269

13B-268V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

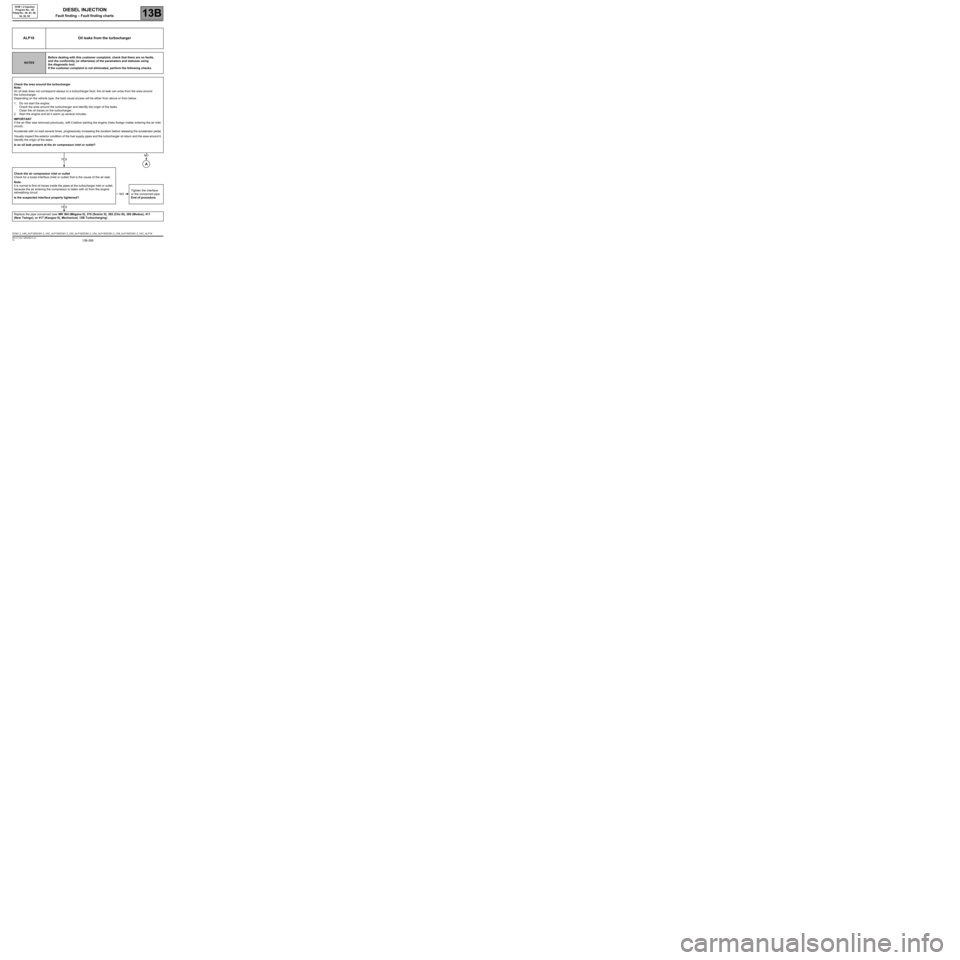

ALP18 Oil leaks from the turbocharger

NOTESBefore dealing with this customer complaint, check that there are no faults,

and the conformity (or otherwise) of the parameters and statuses using

the diagnostic tool.

If the customer complaint is not eliminated, perform the following checks.

Check the area around the turbocharger

Note:

An oil leak does not correspond always to a turbocharger fault, the oil leak can arise from the area around

the turbocharger.

Depending on the vehicle type, the best visual access will be either from above or from below.

1. Do not start the engine.

Check the area around the turbocharger and identify the origin of the leaks.

Clean the oil traces on the turbocharger.

2. Start the engine and let it warm up several minutes.

IMPORTANT

If the air filter was removed previously, refit it before starting the engine (risks foreign matter entering the air inlet

circuit).

Accelerate with no load several times, progressively increasing the duration before releasing the accelerator pedal.

Visually inspect the exterior condition of the fuel supply pipes and the turbocharger oil return and the area around it.

Identify the origin of the leaks.

Is an oil leak present at the air compressor inlet or outlet?

Check the air compressor inlet or outlet

Check for a loose interface (inlet or outlet) that is the cause of the air leak.

Note:

It is normal to find oil traces inside the pipes at the turbocharger inlet or outlet,

because the air entering the compressor is laden with oil from the engine

rebreathing circuit.

Is the suspected interface properly tightened?Tighten the interface

or the concerned pipe.

End of procedure.

Replace the pipe concerned (see MR 364 (Mégane II), 370 (Scénic II), 392 (Clio III), 385 (Modus), 411

(New Twingo), or 417 (Kangoo II), Mechanical, 12B Turbocharging).

YES

NO

A

NO

YES

DCM1.2_V48_ALP18/DCM1.2_V4C_ALP18/DCM1.2_V50_ALP18/DCM1.2_V54_ALP18/DCM1.2_V58_ALP18/DCM1.2_V5C_ALP18

Page 269 of 269

13B-269V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

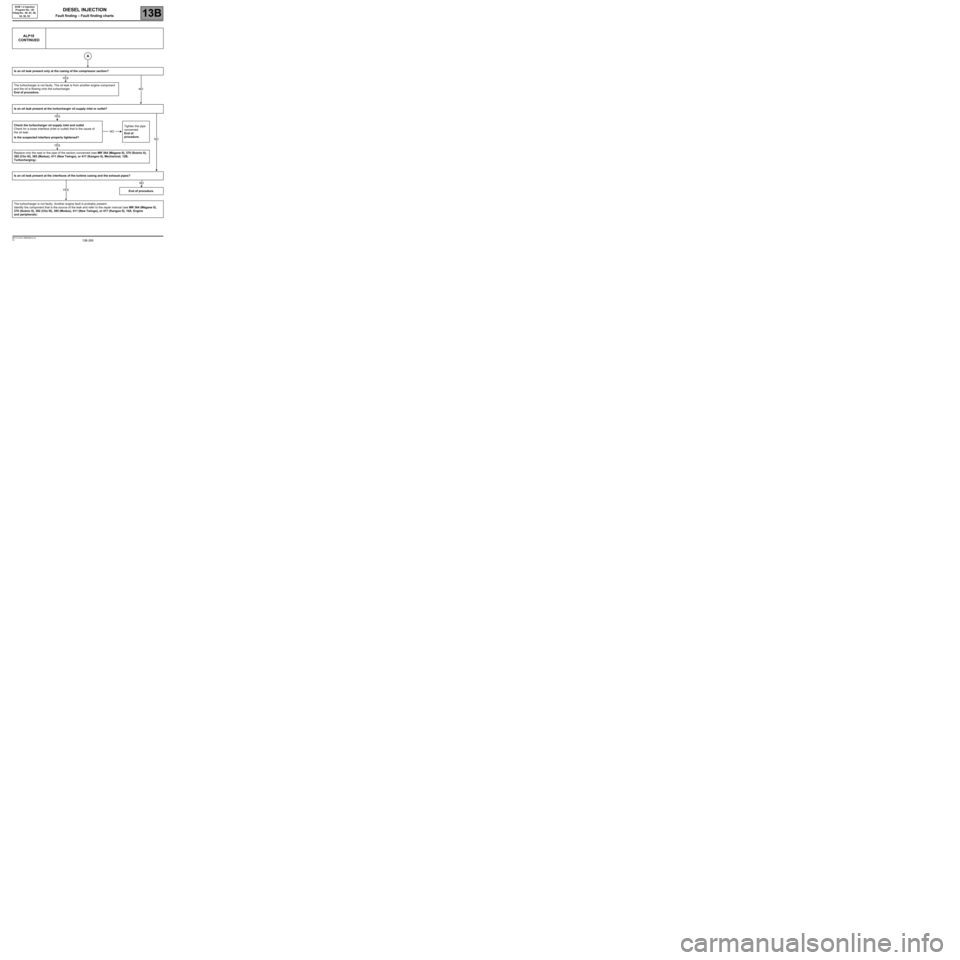

ALP18

CONTINUED

Is an oil leak present only at the casing of the compressor section?

The turbocharger is not faulty. The oil leak is from another engine component

and the oil is flowing onto the turbocharger.

End of procedure.

Is an oil leak present at the turbocharger oil supply inlet or outlet?

Check the turbocharger oil supply inlet and outlet

Check for a loose interface (inlet or outlet) that is the cause of

the oil leak.

Is the suspected interface properly tightened?Tighten the pipe

concerned.

End of

procedure.

`

Replace only the seal or the pipe of the section concerned (see MR 364 (Mégane II), 370 (Scénic II),

392 (Clio III), 385 (Modus), 411 (New Twingo), or 417 (Kangoo II), Mechanical, 12B,

Turbocharging).

Is an oil leak present at the interfaces of the turbine casing and the exhaust pipes?

End of procedure.

The turbocharger is not faulty. Another engine fault is probably present.

Identify the component that is the source of the leak and refer to the repair manual (see MR 364 (Mégane II),

370 (Scénic II), 392 (Clio III), 385 (Modus), 411 (New Twingo), or 417 (Kangoo II), 10A, Engine

and peripherals).

A

YES

NO

YES

NO

NO

YES

YES

NO