fuel pressure RENAULT TWINGO RS 2009 2.G Engine Diesel Injection Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 269

Page 208 of 269

13B-208V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

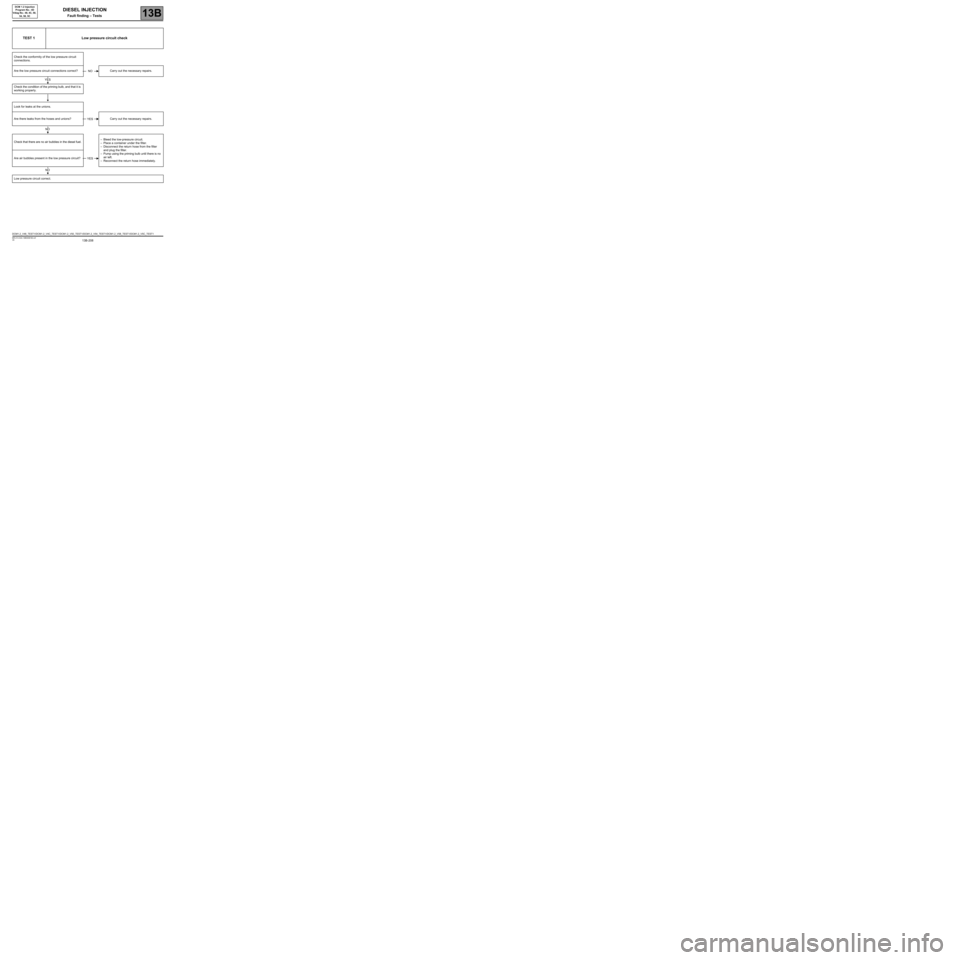

TEST 1 Low pressure circuit check

Check the conformity of the low pressure circuit

connections.

Are the low pressure circuit connections correct? Carry out the necessary repairs.

Check the condition of the priming bulb, and that it is

working properly.

Look for leaks at the unions.

Are there leaks from the hoses and unions? Carry out the necessary repairs.

Check that there are no air bubbles in the diesel fuel.–Bleed the low-pressure circuit.

–Place a container under the filter.

–Disconnect the return hose from the filter

and plug the filter.

–Pump using the priming bulb until there is no

air left.

–Reconnect the return hose immediately. Are air bubbles present in the low pressure circuit?

Low pressure circuit correct.

NO

YES

YES

NO

YES

NO

DCM1.2_V48_TEST1/DCM1.2_V4C_TEST1/DCM1.2_V50_TEST1/DCM1.2_V54_TEST1/DCM1.2_V58_TEST1/DCM1.2_V5C_TEST1

Page 212 of 269

13B-212V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

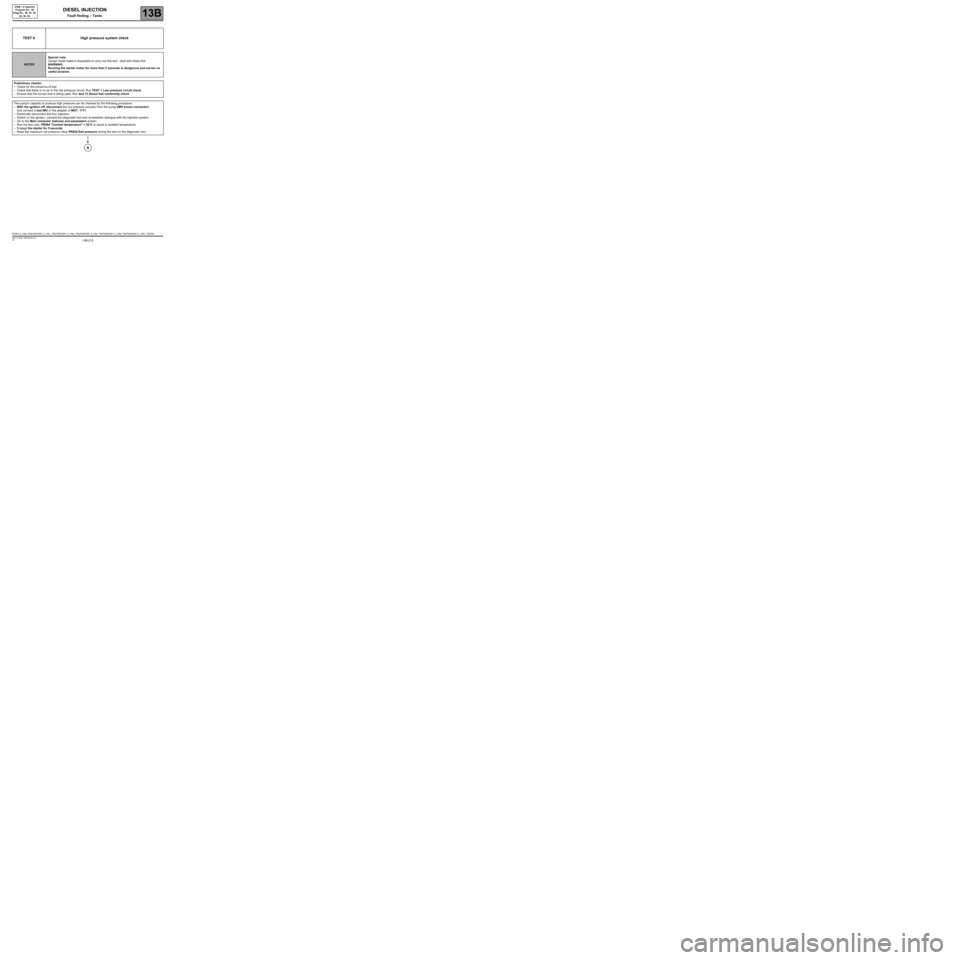

TEST 6 High pressure system check

NOTESSpecial note:

Certain faults make it impossible to carry out this test - deal with these first.

WARNING

Running the starter motor for more than 5 seconds is dangerous and serves no

useful purpose.

Preliminary checks:

–Check for the presence of fuel

–Check that there is no air in the low pressure circuit. Run TEST 1 Low pressure circuit check.

–Ensure that the correct fuel is being used. Run test 13 Diesel fuel conformity check.

The pump's capacity to produce high pressure can be checked by the following procedure:

–With the ignition off, disconnect the low pressure actuator from the pump (IMV brown connector)

and connect a test IMV or the adapter of MOT. 1711.

–Electrically disconnect the four injectors.

–Switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system.

–Go to the Main computer statuses and parameters screen.

–Run the test cold, PR064 "Coolant temperature" < 30

°C or equal to ambient temperature.

–Engage the starter for 5 seconds.

–Read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

A

DCM1.2_V48_TEST6/DCM1.2_V4C_TEST6/DCM1.2_V50_TEST6/DCM1.2_V54_TEST6/DCM1.2_V58_TEST6/DCM1.2_V5C_TEST6

Page 213 of 269

13B-213V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

IMV = fuel flow actuator

TEST 6

CONTINUED

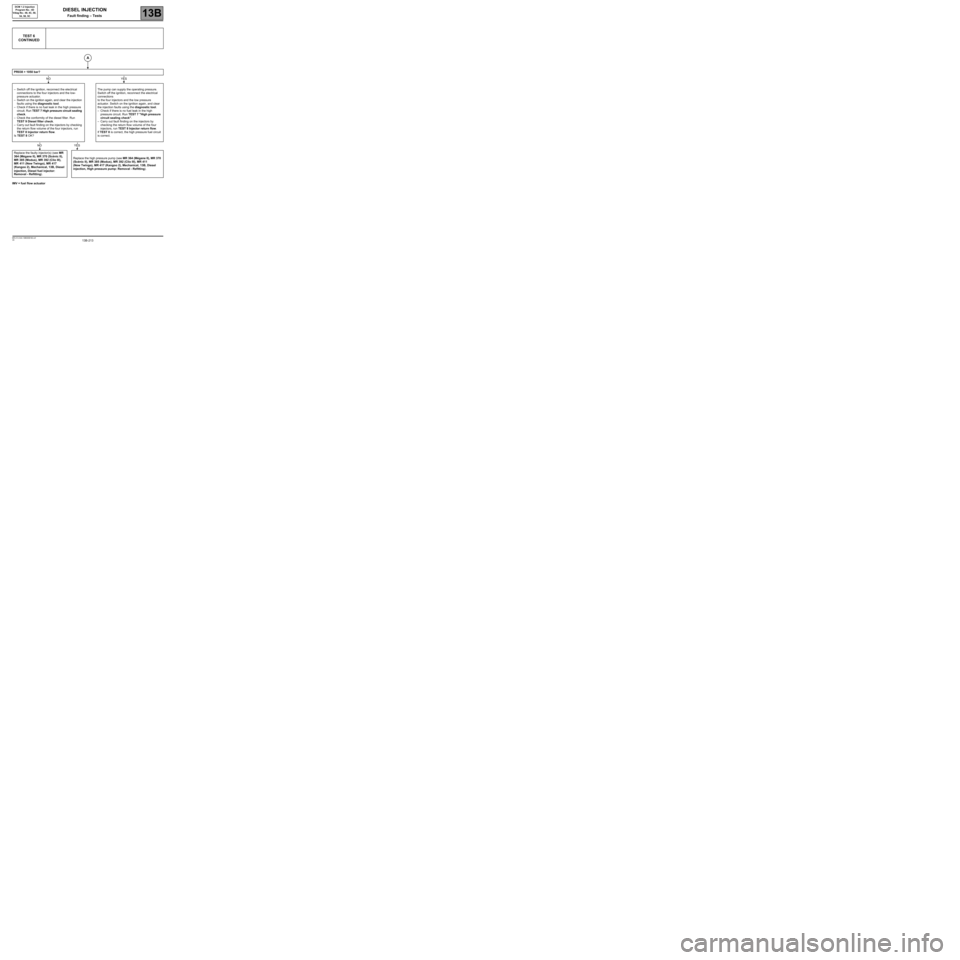

PR038 > 1050 bar?

–Switch off the ignition, reconnect the electrical

connections to the four injectors and the low-

pressure actuator.

–Switch on the ignition again, and clear the injection

faults using the diagnostic tool.

–Check if there is no fuel leak in the high pressure

circuit. Run TEST 7 High pressure circuit sealing

check.

–Check the conformity of the diesel filter. Run

TEST 9 Diesel filter check.

–Carry out fault finding on the injectors by checking

the return flow volume of the four injectors, run

TEST 8 Injector return flow.

Is TEST 8 OK?The pump can supply the operating pressure.

Switch off the ignition, reconnect the electrical

connections

to the four injectors and the low pressure

actuator. Switch on the ignition again, and clear

the injection faults using the diagnostic tool.

–Check if there is no fuel leak in the high

pressure circuit. Run TEST 7 "High pressure

circuit sealing check".

–Carry out fault finding on the injectors by

checking the return flow volume of the four

injectors, run TEST 8 Injector return flow.

If TEST 8 is correct, the high pressure fuel circuit

is correct.

Replace the faulty injector(s) (see MR

364 (Mégane II), MR 370 (Scénic II),

MR 385 (Modus), MR 392 (Clio III),

MR 411 (New Twingo), MR 417

(Kangoo 2), Mechanical, 13B, Diesel

injection, Diesel fuel injector:

Removal - Refitting).Replace the high pressure pump (see MR 364 (Mégane II), MR 370

(Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411

(New Twingo), MR 417 (Kangoo 2), Mechanical, 13B, Diesel

injection, High pressure pump: Removal - Refitting).

A

NOYES

NOYES

Page 216 of 269

13B-216V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

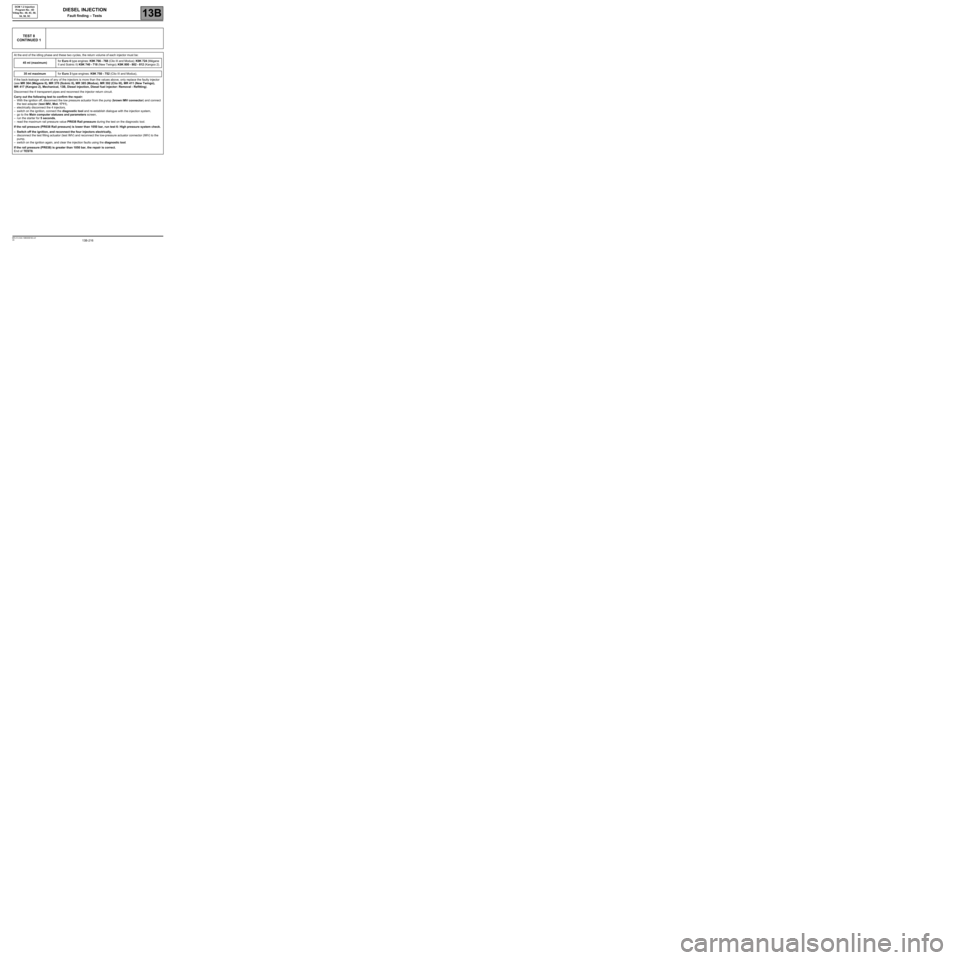

TEST 8

CONTINUED 1

At the end of the idling phase and these two cycles, the return volume of each injector must be:

45 ml (maximum)for Euro 4 type engines: K9K 766 - 768 (Clio III and Modus); K9K 724 (Mégane

II and Scénic II) K9K 740 - 718 (New Twingo); K9K 800 - 802 - 812 (Kangoo 2).

35 ml maximumfor Euro 3 type engines: K9K 750 - 752 (Clio III and Modus),

If the back-leakage volume of any of the injectors is more than the values above, only replace the faulty injector

(see MR 364 (Mégane II), MR 370 (Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo),

MR 417 (Kangoo 2), Mechanical, 13B, Diesel injection, Diesel fuel injector: Removal - Refitting).

Disconnect the 4 transparent pipes and reconnect the injector return circuit.

Carry out the following test to confirm the repair:

–With the ignition off, disconnect the low pressure actuator from the pump (brown IMV connector) and connect

the test adapter (test IMV, Mot. 1711),

–electrically disconnect the 4 injectors,

–switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system,

–go to the Main computer statuses and parameters screen,

–run the starter for 5 seconds,

–read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

If the rail pressure (PR038 Rail pressure) is lower than 1050 bar, run test 6: High pressure system check.

–Switch off the ignition, and reconnect the four injectors electrically,

–disconnect the test filling actuator (test IMV) and reconnect the low-pressure actuator connector (IMV) to the

pump,

–switch on the ignition again, and clear the injection faults using the diagnostic tool.

If the rail pressure (PR038) is greater than 1050 bar, the repair is correct.

End of TEST8.

Page 217 of 269

13B-217V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

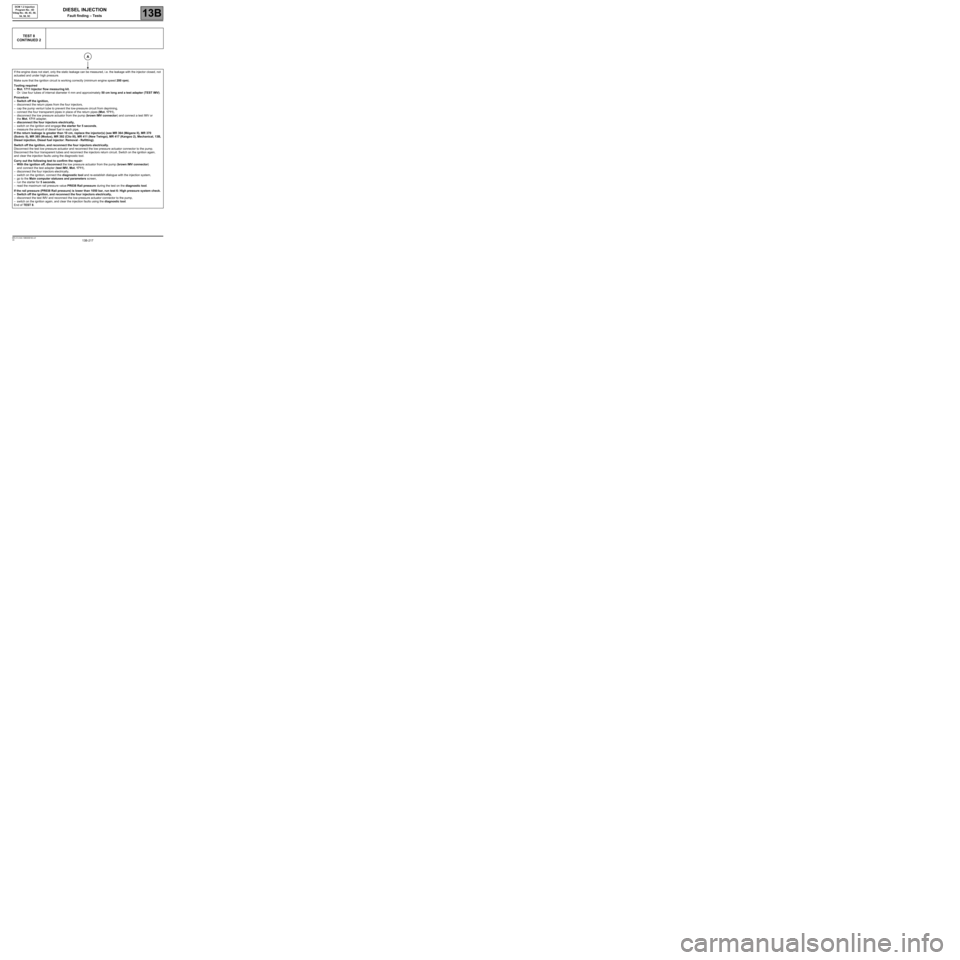

TEST 8

CONTINUED 2

If the engine does not start, only the static leakage can be measured, i.e. the leakage with the injector closed, not

actuated and under high pressure.

Make sure that the ignition circuit is working correctly (minimum engine speed 200 rpm).

Tooling required

–Mot. 1711 Injector flow measuring kit.

Or: Use four tubes of internal diameter 4 mm and approximately 50 cm long and a test adapter (TEST IMV).

Procedure

–Switch off the ignition,

–disconnect the return pipes from the four injectors,

–cap the pump venturi tube to prevent the low-pressure circuit from depriming,

–connect the four transparent pipes in place of the return pipes (Mot. 1711),

–disconnect the low pressure actuator from the pump (brown IMV connector) and connect a test IMV or

the Mot. 1711 adapter,

–disconnect the four injectors electrically,

–switch on the ignition and engage the starter for 5 seconds,

–measure the amount of diesel fuel in each pipe.

If the return leakage is greater than 10 cm, replace the injector(s) (see MR 364 (Mégane II), MR 370

(Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo), MR 417 (Kangoo 2), Mechanical, 13B,

Diesel injection, Diesel fuel injector: Removal - Refitting).

Switch off the ignition, and reconnect the four injectors electrically.

Disconnect the test low pressure actuator and reconnect the low pressure actuator connector to the pump.

Disconnect the four transparent tubes and reconnect the injectors return circuit. Switch on the ignition again,

and clear the injection faults using the diagnostic tool.

Carry out the following test to confirm the repair:

–With the ignition off, disconnect the low pressure actuator from the pump (brown IMV connector)

and connect the test adapter (test IMV, Mot. 1711),

–disconnect the four injectors electrically,

–switch on the ignition, connect the diagnostic tool and re-establish dialogue with the injection system,

–go to the Main computer statuses and parameters screen,

–run the starter for 5 seconds,

–read the maximum rail pressure value PR038 Rail pressure during the test on the diagnostic tool.

If the rail pressure (PR038 Rail pressure) is lower than 1050 bar, run test 6: High pressure system check.

–Switch off the ignition, and reconnect the four injectors electrically,

–disconnect the test IMV and reconnect the low-pressure actuator connector to the pump,

–switch on the ignition again, and clear the injection faults using the diagnostic tool.

End of TEST 8.

A

Page 223 of 269

13B-223V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

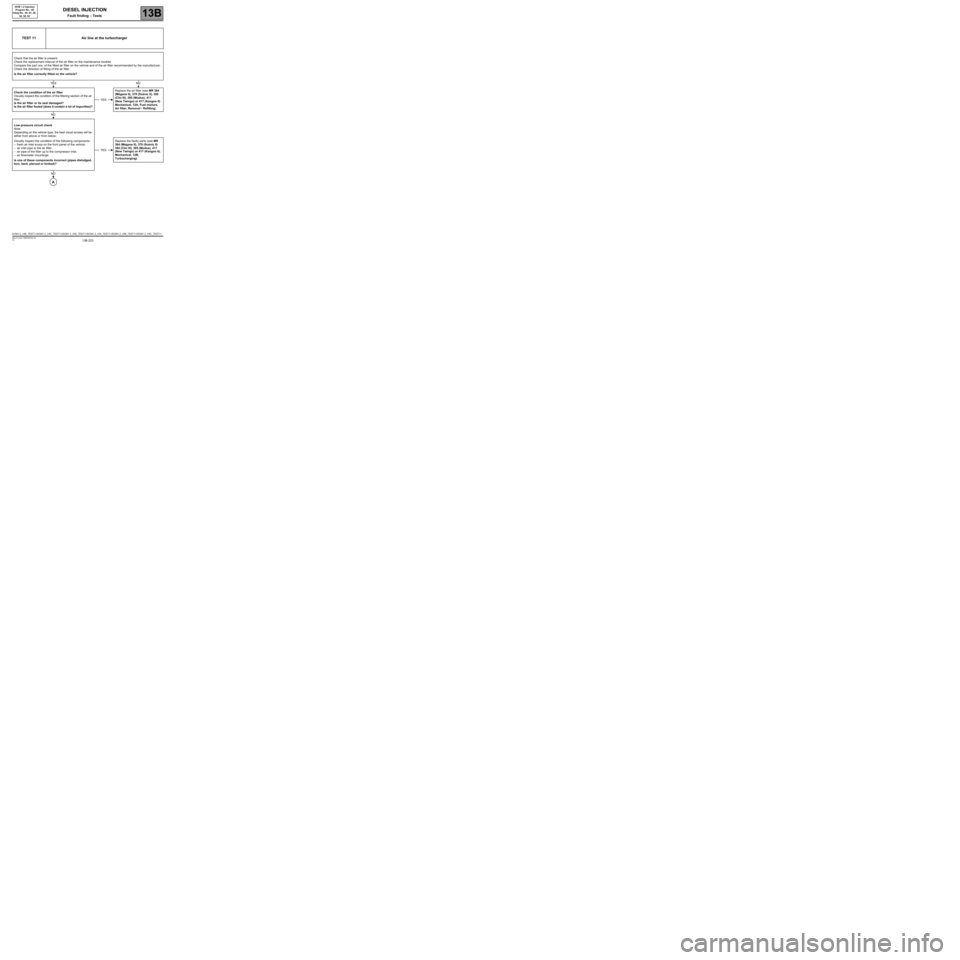

TEST 11 Air line at the turbocharger

Check that the air filter is present.

Check the replacement interval of the air filter on the maintenance booklet.

Compare the part nos. of the fitted air filter on the vehicle and of the air filter recommended by the manufacturer.

Check the direction of fitting of the air filter.

Is the air filter correctly fitted on the vehicle?

Check the condition of the air filter

Visually inspect the condition of the filtering section of the air

filter.

Is the air filter or its seal damaged?

Is the air filter fouled (does it contain a lot of impurities)?Replace the air filter (see MR 364

(Mégane II), 370 (Scénic II), 392

(Clio III), 385 (Modus), 411

(New Twingo) or 417 (Kangoo II)

Mechanical, 12A, Fuel mixture,

Air filter, Removal - Refitting).

Low pressure circuit check

Note:

Depending on the vehicle type, the best visual access will be

either from above or from below.

Visually inspect the condition of the following components:

–fresh air inlet scoop on the front panel of the vehicle,

–air inlet pipe to the air filter,

–air pipe of the filter up to the compressor inlet,

–air flowmeter mountings.

Is one of these components incorrect (pipes dislodged,

torn, bent, pierced or kinked)?Replace the faulty parts (see MR

364 (Mégane II), 370 (Scénic II)

392 (Clio III), 385 (Modus), 411

(New Twingo) or 417 (Kangoo II),

Mechanical, 12B,

Turbocharging).

YESNO

YES

NO

YES

NO

A

DCM1.2_V48_TEST11/DCM1.2_V4C_TEST11/DCM1.2_V50_TEST11/DCM1.2_V54_TEST11/DCM1.2_V58_TEST11/DCM1.2_V5C_TEST11

Page 230 of 269

13B-230V6 MR-413-X44-13B000$190.mif

DIESEL INJECTION

Fault finding – Tests13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

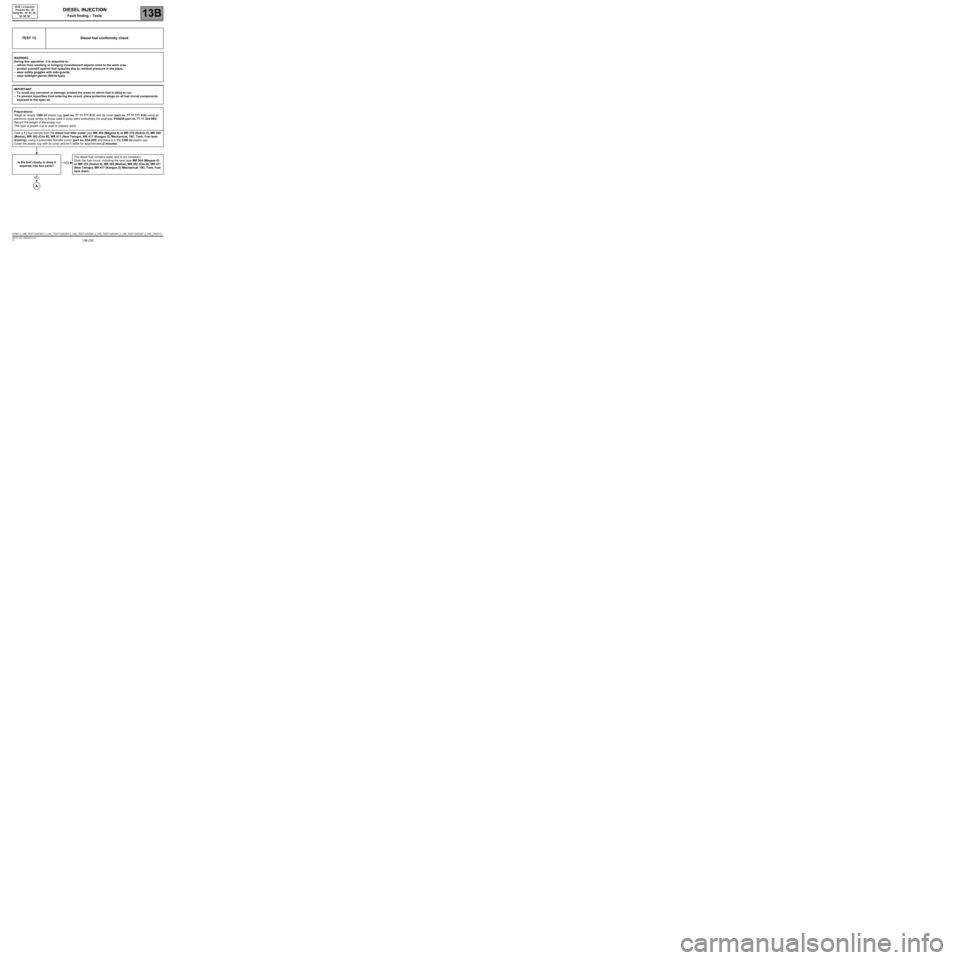

TEST 13 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

–refrain from smoking or bringing incandescent objects close to the work area,

–protect yourself against fuel splashes due to residual pressure in the pipes,

–wear safety goggles with side guards,

–wear leaktight gloves (Nitrile type).

IMPORTANT

–To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

–To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using an

electronic scale similar to those used in body paint workshops (for example: PANDA part no. 77 11 224 995).

Record the weight of the empty cup.

This type of plastic cup is used to prepare paint.

Take a 1 l fuel sample from the diesel fuel filter outlet (see MR 364 (Mégane II) or MR 370 (Scénic II), MR 385

(Modus), MR 392 (Clio III), MR 411 (New Twingo), MR 417 (Kangoo 2), Mechanical, 19C, Tank, Fuel tank

draining), using a pneumatic transfer pump (part no. 634-200) and place it in the 1300 ml plastic cup.

Cover the plastic cup with its cover and let it settle for approximately2 minutes.

Is the fuel cloudy or does it

separate into two parts?The diesel fuel contains water and is not compliant.

Drain the fuel circuit, including the tank (see MR 364 (Mégane II)

or MR 370 (Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411

(New Twingo), MR 417 (Kangoo 2), Mechanical, 19C, Tank, Fuel

tank drain).

YES

NO

A

DCM1.2_V48_TEST13/DCM1.2_V4C_TEST13/DCM1.2_V50_TEST13/DCM1.2_V54_TEST13/DCM1.2_V58_TEST13/DCM1.2_V5C_TEST13

Page 242 of 269

13B-242V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

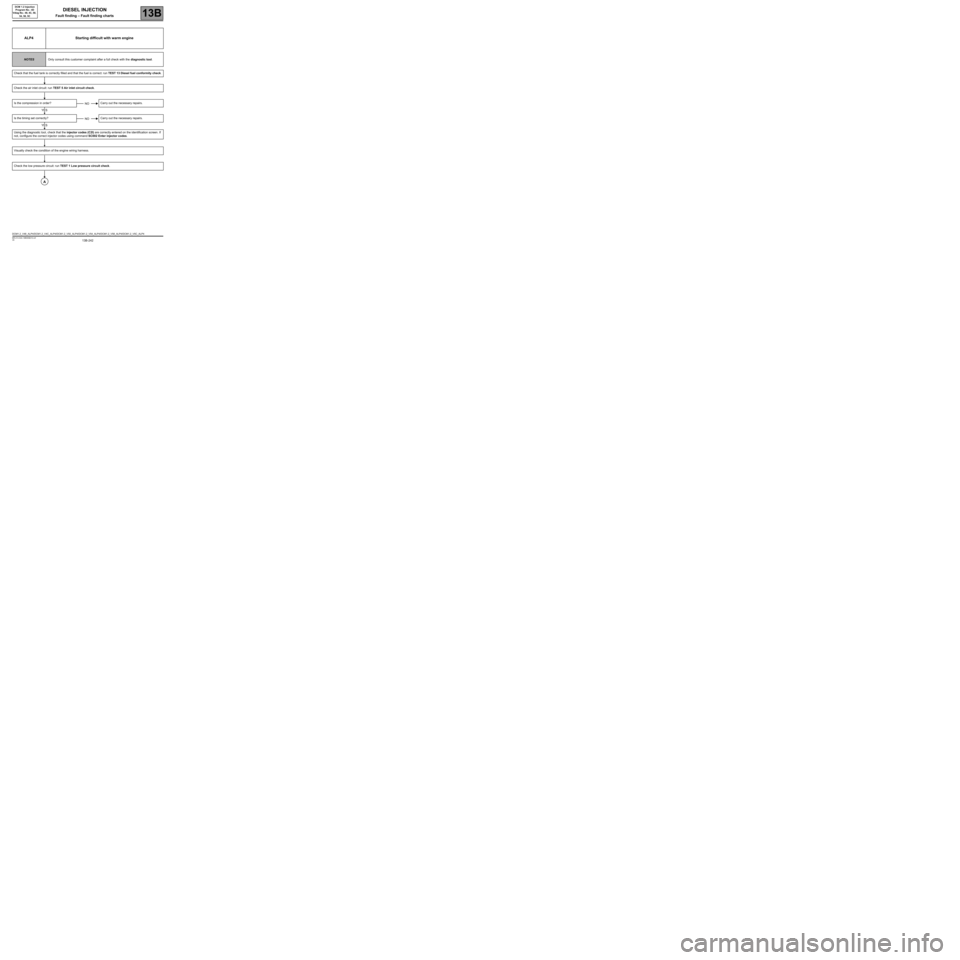

ALP4 Starting difficult with warm engine

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

Is the compression in order? Carry out the necessary repairs.

Is the timing set correctly? Carry out the necessary repairs.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Check the low pressure circuit: run TEST 1 Low pressure circuit check.

NO

YES

NO

YES

A

DCM1.2_V48_ALP4/DCM1.2_V4C_ALP4/DCM1.2_V50_ALP4/DCM1.2_V54_ALP4/DCM1.2_V58_ALP4/DCM1.2_V5C_ALP4

Page 244 of 269

13B-244V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

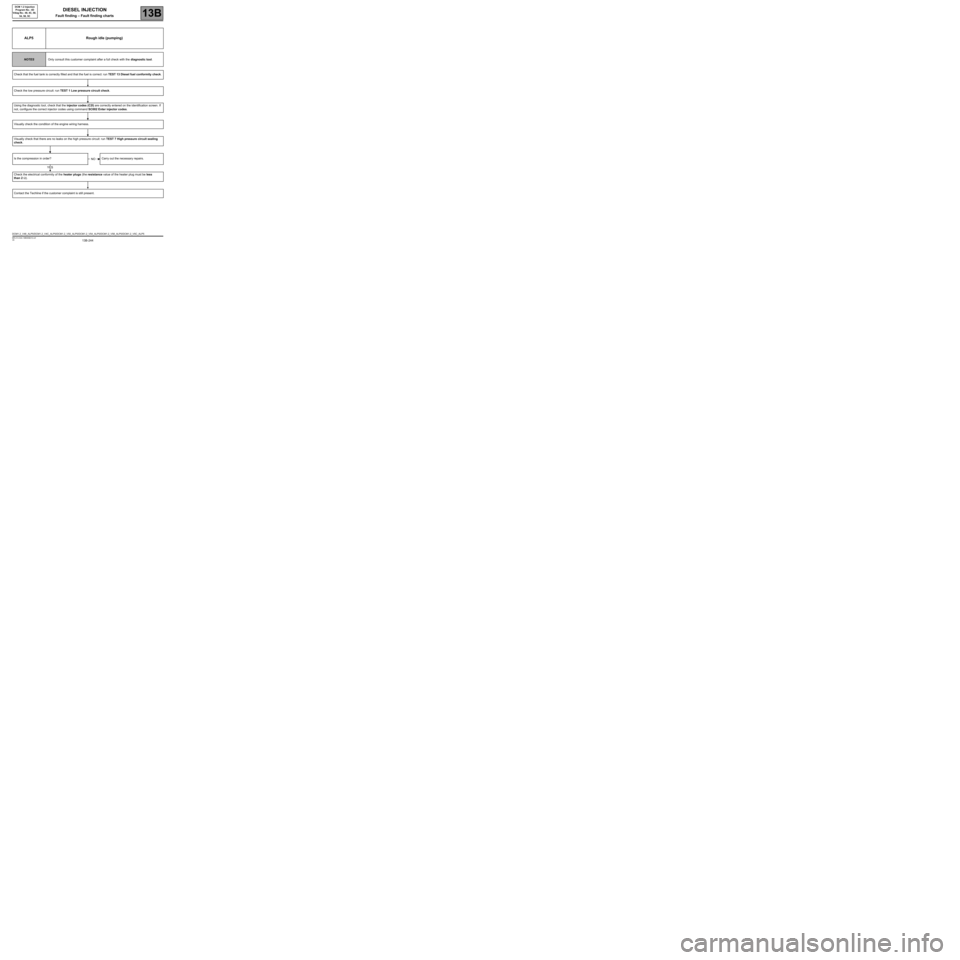

ALP5 Rough idle (pumping)

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the low pressure circuit: run TEST 1 Low pressure circuit check.

Using the diagnostic tool, check that the injector codes (C2I) are correctly entered on the identification screen. If

not, configure the correct injector codes using command SC002 Enter injector codes.

Visually check the condition of the engine wiring harness.

Visually check that there are no leaks on the high pressure circuit: run TEST 7 High pressure circuit sealing

check.

Is the compression in order? Carry out the necessary repairs.

Check the electrical conformity of the heater plugs (the resistance value of the heater plug must be less

than 2 Ω).

Contact the Techline if the customer complaint is still present.

NO

YES

DCM1.2_V48_ALP5/DCM1.2_V4C_ALP5/DCM1.2_V50_ALP5/DCM1.2_V54_ALP5/DCM1.2_V58_ALP5/DCM1.2_V5C_ALP5

Page 249 of 269

13B-249V6 MR-413-X44-13B000$210.mif

DIESEL INJECTION

Fault finding – Fault finding charts13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

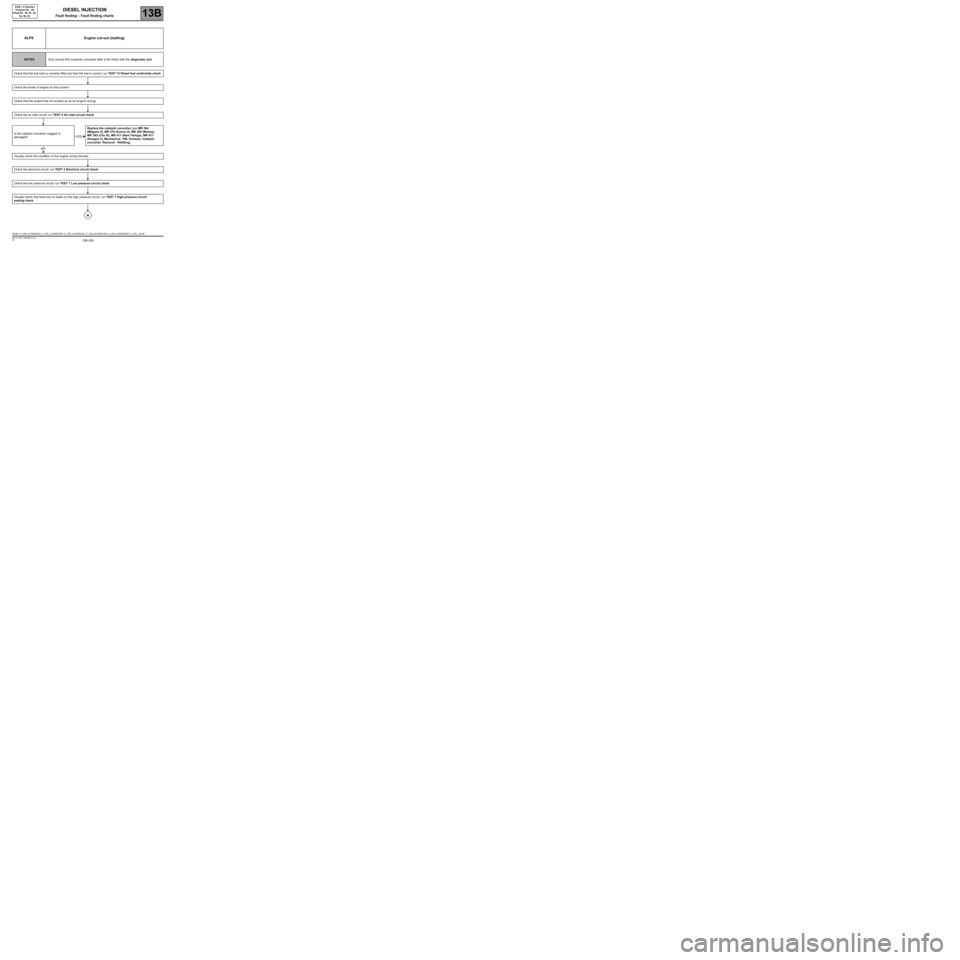

ALP9 Engine cut-out (stalling)

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check that the fuel tank is correctly filled and that the fuel is correct: run TEST 13 Diesel fuel conformity check.

Check the levels of engine oil and coolant.

Check that the engine has not sucked up its oil (engine racing).

Check the air inlet circuit: run TEST 5 Air inlet circuit check.

Is the catalytic converter clogged or

damaged?Replace the catalytic converter (see MR 364

(Mégane II), MR 370 (Scénic II), MR 385 (Modus),

MR 392 (Clio III), MR 411 (New Twingo), MR 417

(Kangoo 2), Mechanical, 19B, Exhaust, Catalytic

converter: Removal - Refitting).

Visually check the condition of the engine wiring harness.

Check the electrical circuit: run TEST 2 Electrical circuit check.

Check the low pressure circuit: run TEST 1 Low pressure circuit check.

Visually check that there are no leaks on the high pressure circuit: run TEST 7 High pressure circuit

sealing check.

YES

NO

A

DCM1.2_V48_ALP9/DCM1.2_V4C_ALP9/DCM1.2_V50_ALP9/DCM1.2_V54_ALP9/DCM1.2_V58_ALP9/DCM1.2_V5C_ALP9