heater RENAULT TWINGO RS 2009 2.G Engine Diesel Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 269

Page 10 of 269

13B-10V6 MR-413-X44-13B000$030.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

High and low pressure pump:

This pump is located upstream of the common rail.

Solenoid injectors:

The injectors are fitted on the cylinder head after the common rail.

Turbocharger:

The turbocharger is located after the exhaust manifold.

Turbocharger control solenoid valve (K9K 724, 766, 802, and 812 only):

This solenoid valve is located close to the turbocharger, is position depends on the vehicle.

Air flowmeter:

The air mass flow meter is located at the air circuit inlet and integrates the air temperature sensor.

EGR valve:

The EGR valve is located between the inlet manifold and the exhaust manifold.

Accelerator pedal potentiometer:

The potentiometer is located on the accelerator pedal.

Clutch pedal switch:

The switch is located on the clutch pedal.

Catalytic converter:

The catalytic converter is located downstream of the turbocharger on the exhaust system.

Cruise control/speed limiter on/off switch:

This switch is located in the passenger compartment to the left of the steering wheel near the lighting dimmer.

Heater plugs:

The heater plugs are located on the cylinder head.

Inlet manifold pressure sensor:

The inlet manifold pressure sensor is located upstream of the turbocharger.

Air temperature sensor:

The air temperature sensor is located at the air circuit inlet, in place of the air flowmeter or integrated into it if

the flowmeter is present, and/or in the inlet manifold.

Water in diesel fuel sensor (New Twingo and Kangoo 2 only):

This sensor is located in the diesel filter.

Fuel temperature sensor:

This sensor is positioned on the injection pump.

Rail pressure sensor:

This sensor is fitted to the common rail.

Atmospheric pressure sensor:

This sensor is incorporated in the computer.

TDC sensor:

This sensor is located on the flywheel.

Camshaft sensor:

This sensor is located at the end of the camshaft.

DIESEL INJECTION

Fault finding – List and location of components

Page 21 of 269

13B-21V6 MR-413-X44-13B000$050.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

High and low pressure pump:

The pump draws in fuel from the tank, which passes through a fuel filter and supplies the fuel injectors.

Injector rail:

The injector rail receives and redistributes fuel under high pressure to the injectors.

Solenoid injectors:

These injectors enable rapid, precise metering of the quantity of fuel injected, with excellent injection process

repetitiveness.

Catalytic converter:

Its role is to convert pollutant gases into harmless gases.

Heater plugs:

The heater plugs create a hot point in the combustion chamber to improve starting in low temperature conditions.

They are also used to improve idle speed stability under some conditions.

Turbocharger:

The turbocharger is used to supply the engine with more air.

Turbocharger control solenoid valve (K9K 724, 766, 802, and 812 only):

This solenoid valve controls the turbocharger wastegate.

Air flowmeter (if present on the vehicle):

The flowmeter measures the amount of fresh air which goes back into the engine.

EGR valve:

The exhaust gas recirculation enables nitrogen oxide (NOx) emissions to be reduced significantly.

Cruise control - speed limiter on - off switch:

This switch turns the cruise control/speed limiter on or off.

Accelerator pedal potentiometer:

The accelerator potentiometer informs the computer about the position of the accelerator pedal (engine load).

Clutch pedal switch:

The clutch pedal switch informs the computer about the pedal status.

TDC sensor:

The angular position is measured using a magneto-inductive sensor triggered by machined teeth on the flywheel.

This sensor gives the engine speed as well as the position of the crankshaft for injection.

Camshaft sensor:

This sensor gives a signal to perform the injection cycle.

When the piston of cylinder 1 is at top dead centre (TDC), it can be either at the end of the compression stroke

or at the end of the exhaust stroke. The camshaft sensor enables a distinction to be made between these two states.

Refrigerant pressure sensor:

Its role is to measure the refrigerant pressure in the air conditioning circuit.

Engine coolant temperature sensor:

The engine coolant temperature sensor informs the computer about the engine coolant temperature.

Water in diesel fuel sensor (New Twingo and Kangoo 2 only):

This sensor determines if there is water present in the diesel fuel.

DIESEL INJECTION

Fault finding – Role of components

Page 50 of 269

13B-50

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$090.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

DF017

PRESENT

OR STOREDPREHEATING UNIT CONTROL CIRCUITC0.0: Open circuit or short circuit to earth

CC.1: Short circuit to +12 volts

NOTESSpecial notes:

If fault DF017 is present: starting is difficult (even impossible when cold). If CC.1:

heater plugs are permanently switched on with risk of engine damage or even failure.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the preheating unit connector, component code 257 or 980.

Check the connection and condition of connector C (grey 32-track) of the injection computer, component

code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–BP35 between components 777 (or 597 for New Twingo) and 257 (or 980),

–3FY between connections 257 (or 980) and 120,

–3FF between components 257 (or 980) and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

DCM1.2_V48_DF017/DCM1.2_V4C_DF017/DCM1.2_V50_DF017/DCM1.2_V54_DF017/DCM1.2_V58_DF017/DCM1.2_V5C_DF017

Page 54 of 269

13B-54

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$090.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

DF025

PRESENT

OR STOREDPRE-POSTHEATING UNIT DIAGNOSTIC LINEC0: Open circuit

NOTESSpecial notes:

This fault only directs the fault finding with an open circuit.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the heater plug connectors, component codes 680, 681, 682, and 683.

Check the connection and condition of the preheating unit connector, component code 257 or 980.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Measure the resistance of each heater plug, component code 680, 681, 682, or 683.

The resistance must be less than 2 Ω.

Replace the faulty plugs, component codes 680, 681, 682, and 683 (see MR 364 (Mégane II), MR 370 (Scénic II),

MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo), MR 417 (Kangoo 2), Mechanical, 13C, Preheating,

Heater plugs: Removal - Refitting).

Check the connection and condition of connector C (grey 32-track) of the injection computer, component

code 120.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check for +12 V battery on connection BP35 of component 257 (or 980).

Check for the control of the preheating unit on connection 3FF component 257 (or 980).

Check the insulation and continuity of the following connections:

–3FY between connections 257 (or 980) and 120,

–3FF between connections 257 (or 980) and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, replace the preheating unit, component code 257 or 980 (see MR 364 (Mégane II), MR

370 (Scénic II), MR 385 (Modus), MR 392 (Clio III), MR 411 (New Twingo), MR 417 (Kangoo 2), Mechanical,

13C, Preheating, Pre-postheating unit: Removal - Refitting).

If the fault is still present, contact the Techline.

DCM1.2_V48_DF025/DCM1.2_V4C_DF025/DCM1.2_V50_DF025/DCM1.2_V54_DF025/DCM1.2_V58_DF025/DCM1.2_V5C_DF025

Page 67 of 269

13B-67

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF032

PRESENT

OR

STOREDTHERMOPLUNGER 1 RELAY CONTROL CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present when the ignition is switched on.

See the Technical Note Wiring Diagrams for the vehicle.

For New Twingo

Check the connection and condition of the additional heater 1 relay connector, component code 1067 and the 80 A

maxi fuse in the engine fuse and relay box.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC250 Heating resistor 1 relay.

If the command does not run, check, with the ignition on, for earth on connection 3JA of component 1067.

Check for + 12 V on connection 3FB of component 1067.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JA between components 1067 and 120,

–3FB between components 1067 and 238,

–38LL between components 1067 and 1113,

–BP9 between components 1067 and 597.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

DCM1.2_V50_DF032/DCM1.2_V58_DF032

Page 68 of 269

13B-68

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF032

CONTINUED

For Mégane II

and Scénic II:

Check the connection and condition of the connector of the additional heater interface unit, component code 1550

and the 70 A maxi fuses on the power supply fuse board.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC250 Heating resistor 1 relay.

If the command does not run, check for + 12 V on connections BP27 and BP35 of component 1550.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JA between components 1550 and 120,

–3JAA between components 1550 and 120,

–3JAB between components 1550 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

Page 69 of 269

13B-69

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF033

PRESENT

OR

STOREDTHERMOPLUNGER 2 RELAY CONTROL CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present when the ignition is switched on.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the additional heater 2 relay connector, component code 1068

and the 80 A maxi fuse in the engine fuse and relay box.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC251 Heating resistor 2 relay.

If the command does not run, check, with the ignition on, for earth on connection 3JAA of component 1068.

Check for + 12 V on connection 3FB of component 1068.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JAA between components 1068 and 120,

–3FB between components 1068 and 238,

–38LM between components 1068 and 1113,

–BP9 between components 1068 and 597.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

DCM1.2_V50_DF033/DCM1.2_V58_DF033

Page 70 of 269

13B-70

AFTER REPAIRDeal with any faults displayed by the diagnostic tool.

Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V6 MR-413-X44-13B000$100.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 50, 58

DF034

PRESENT

OR

STOREDTHERMOPLUNGER 3 RELAY CONTROL CIRCUIT

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is present when the ignition is switched on.

See the Technical Note Wiring Diagrams for the vehicle.

Check the connection and condition of the additional heater 2 relay connector, component code 1068

and the 80 A maxi fuse in the engine fuse and relay box.

Check the connection and condition of the injection computer connector, component code 120.

If the connector(s) are faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run command AC251 Heating resistor 2 relay.

If the command does not run, check, with the ignition on, for earth on connection 3JAA of component 1068.

Check for + 12 V on connection 3FB of component 1068.

If the connector is faulty and if there is a repair procedure (see Technical Note 6015A, Repairing electrical

wiring, Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the insulation and continuity of the following connections:

–3JAA between components 1068 and 120,

–3FB between components 1068 and 238,

–38LM between components 1068 and 1113,

–BP9 between components 1068 and 597.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace the wiring.

If the fault is still present, check the relay and replace it if necessary.

If the fault is still present, contact the Techline.

DCM1.2_V50_DF034/DCM1.2_V58_DF034

Page 132 of 269

13B-132

AFTER REPAIRDeal with any faults. Clear the faults from the computer memory.

Switch off the ignition and carry out a road test followed by a test with the diagnostic

tool.

V6 MR-413-X44-13B000$150.mif

DIESEL INJECTION

Fault finding – Interpretation of statuses13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

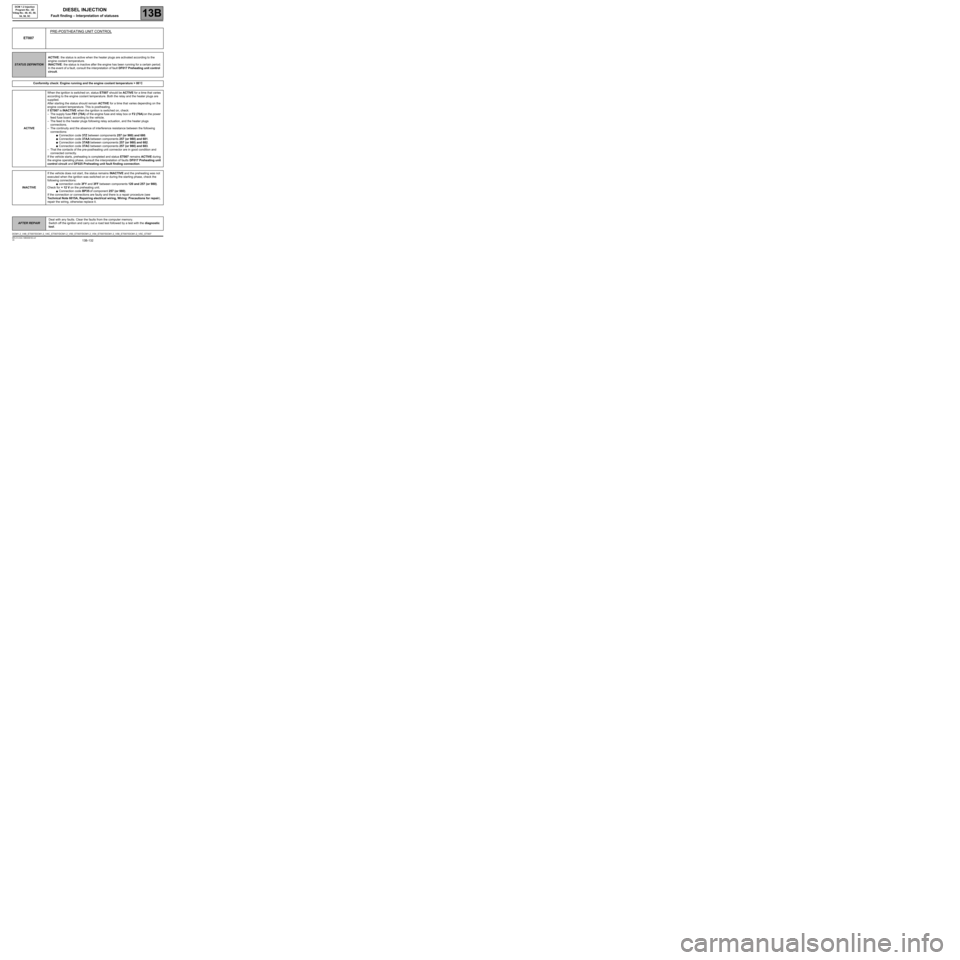

ET007PRE-POSTHEATING UNIT CONTROL

STATUS DEFINITIONACTIVE: the status is active when the heater plugs are activated according to the

engine coolant temperature.

INACTIVE: the status is inactive after the engine has been running for a certain period.

In the event of a fault, consult the interpretation of fault DF017 Preheating unit control

circuit.

Conformity check: Engine running and the engine coolant temperature > 80˚C

ACTIVEWhen the ignition is switched on, status ET007 should be ACTIVE for a time that varies

according to the engine coolant temperature. Both the relay and the heater plugs are

supplied.

After starting the status should remain ACTIVE for a time that varies depending on the

engine coolant temperature. This is postheating.

If ET007 is INACTIVE when the ignition is switched on, check:

–The supply fuse FB1 (70A) of the engine fuse and relay box or F2 (70A) on the power

feed fuse board, according to the vehicle.

–The feed to the heater plugs following relay actuation, and the heater plugs

connections.

–The continuity and the absence of interference resistance between the following

connections:

●Connection code 37Z between components 257 (or 980) and 680.

●Connection code 37AA between components 257 (or 980) and 681.

●Connection code 37AB between components 257 (or 980) and 682.

●Connection code 37AC between components 257 (or 980) and 683.

–That the contacts of the pre-postheating unit connector are in good condition and

connected correctly.

If the vehicle starts, preheating is completed and status ET007 remains ACTIVE during

the engine operating phase, consult the interpretation of faults DF017 Preheating unit

control circuit and DF025 Preheating unit fault finding connection.

INACTIVEIf the vehicle does not start, the status remains INACTIVE and the preheating was not

executed when the ignition was switched on or during the starting phase, check the

following connections:

●connection code 3FY and 3FF between components 120 and 257 (or 980).

Check for + 12 V on the preheating unit.

●Connection code BP35 of component 257 (or 980).

If the connection or connections are faulty and there is a repair procedure (see

Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for repair),

repair the wiring, otherwise replace it.

DCM1.2_V48_ET007/DCM1.2_V4C_ET007/DCM1.2_V50_ET007/DCM1.2_V54_ET007/DCM1.2_V58_ET007/DCM1.2_V5C_ET007

Page 205 of 269

13B-205V6 MR-413-X44-13B000$180.mif

13B

DCM 1.2 Injection

Program No.: 4D

Vdiag No.: 48, 4C, 50,

54, 58, 5C

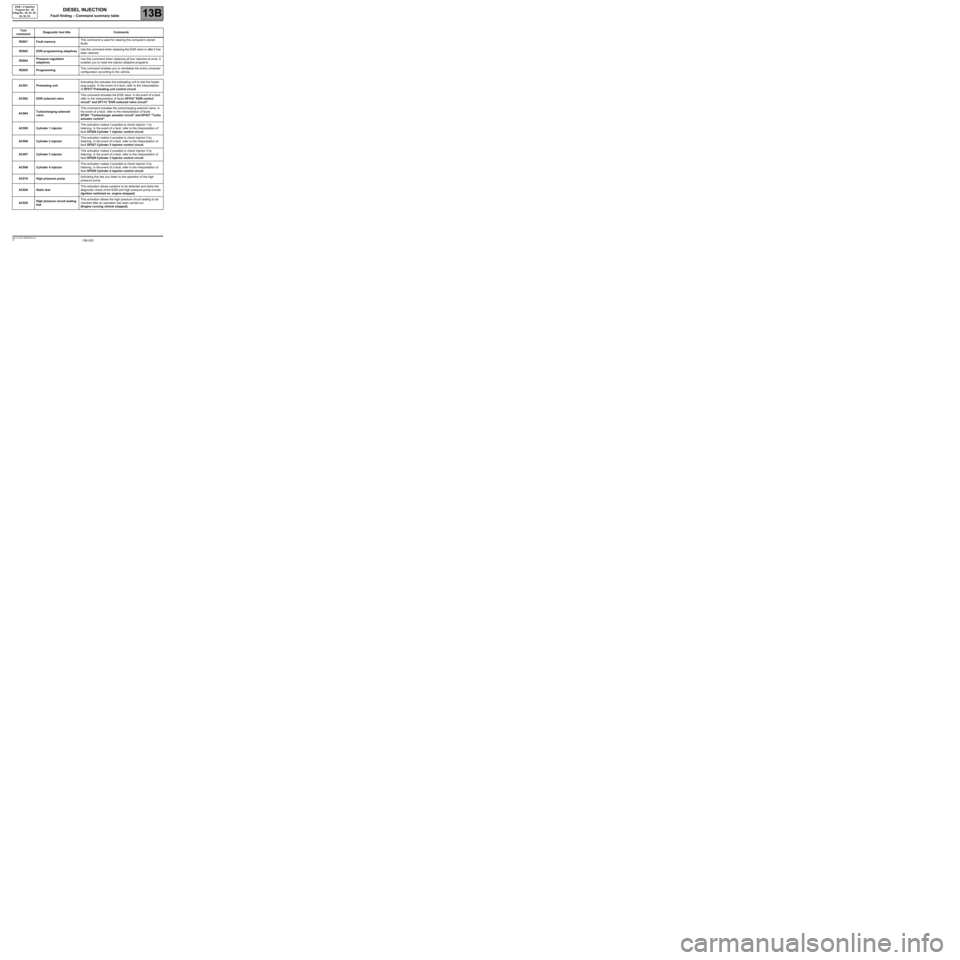

Tool

commandDiagnostic tool titleComments

RZ001 Fault memoryThis command is used for clearing the computer's stored

faults.

RZ002 EGR programming adaptivesUse this command when replacing the EGR valve or after it has

been cleaned.

RZ004Pressure regulation

adaptivesUse this command when replacing all four injectors at once. It

enables you to reset the injector adaptive programs.

RZ005 ProgrammingThis command enables you to reinitialise the entire computer

configuration according to the vehicle.

AC001 Preheating unitActivating this actuates the preheating unit to test the heater

plug supply. In the event of a fault, refer to the interpretation

of DF017 Preheating unit control circuit.

AC002 EGR solenoid valveThis command actuates the EGR valve. In the event of a fault,

refer to the interpretation of faults DF016 "EGR control

circuit" and DF114 "EGR solenoid valve circuit".

AC004Turbocharging solenoid

valveThis command actuates the turbocharging solenoid valve. In

the event of a fault, refer to the interpretation of faults

DF261 "Turbocharger actuator circuit" and DF427 "Turbo

actuator control".

AC005 Cylinder 1 injectorThis activation makes it possible to check injector 1 by

listening. In the event of a fault, refer to the interpretation of

fault DF026 Cylinder 1 injector control circuit.

AC006 Cylinder 2 injectorThis activation makes it possible to check injector 2 by

listening. In the event of a fault, refer to the interpretation of

fault DF027 Cylinder 2 injector control circuit.

AC007 Cylinder 3 injectorThis activation makes it possible to check injector 3 by

listening. In the event of a fault, refer to the interpretation of

fault DF028 Cylinder 3 injector control circuit.

AC008 Cylinder 4 injectorThis activation makes it possible to check injector 4 by

listening. In the event of a fault, refer to the interpretation of

fault DF029 Cylinder 4 injector control circuit.

AC010 High pressure pumpActivating this lets you listen to the operation of the high

pressure pump.

AC028 Static testThis activation allows systems to be detected and starts the

diagnostic check of the EGR and high pressure pump circuits

(Ignition switched on, engine stopped).

AC029High pressure circuit sealing

testThis activation allows the high pressure circuit sealing to be

checked after an operation has been carried out

(Engine running vehicle stopped).

DIESEL INJECTION

Fault finding – Command summary table