light RENAULT TWINGO RS 2009 2.G Heating And Air Conditioning - Climate Control User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 99

Page 60 of 99

62B-60

MR-413-X44-62B000$644_eng.mif

V1

CLIMATE CONTROL

Fault finding - Interpretation of parameters

Vdiag No.: 44

62B

PR122

NIGHT LIGHTING LEVEL

NOTESThe climate control computer receives the dimmer lighting level via the instrument

panel through the multiplex line.

This parameter indicates the dimmer lighting level as a percentage.

If this parameter appears inconsistent with the air conditioning control panel lighting, contact Techline.

AFTER REPAIRRepeat the conformity check from the start.

CLIM_V44_PR122

Page 67 of 99

62B-67

MR-413-X44-62B000$782_eng.mif

V1

CLIMATE CONTROL

Fault finding - Customer complaints62B

PASSENGER COMPARTMENT ODOURS

UNPLEASANT ODOURS IN PASSENGER COMPARTMENT ALP 11

WATER IN PASSENGER COMPARTMENT

WATER IS PRESENT IN PASSENGER COMPARTMENT ALP 12

CONTROL PANEL FAULT

NO CONTROL PANEL LIGHTING ALP 13

COMPRESSOR NOISES

COMPRESSOR NOISES ALP 14

Page 71 of 99

62B-71

MR-413-X44-62B000$828_eng.mif

V1

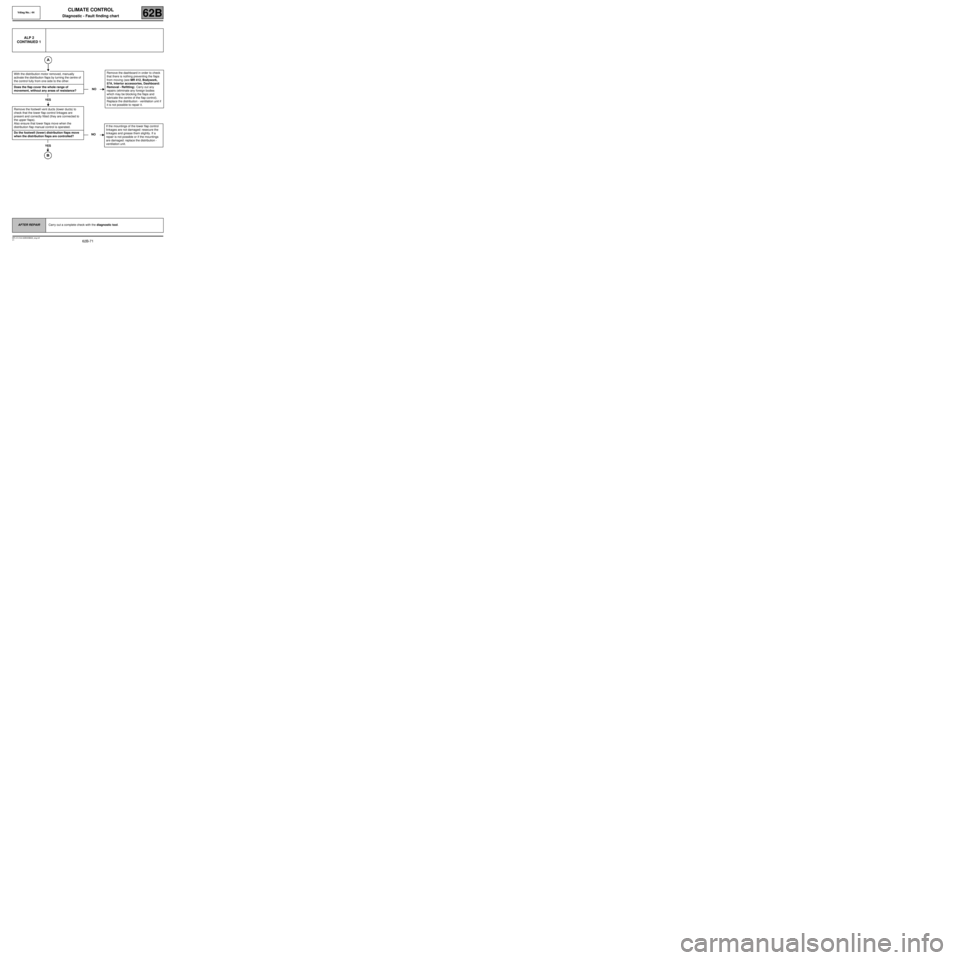

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 2

CONTINUED 1

With the distribution motor removed, manually

activate the distribution flaps by turning the centre of

the control fully from one side to the other.

Does the flap cover the whole range of

movement, without any areas of resistance?

YES

Remove the footwell vent ducts (lower ducts) to

check that the lower flap control linkages are

present and correctly fitted (they are connected to

the upper flaps).

Also ensure that lower flaps move when the

distribution flap manual control is operated.

Do the footwell (lower) distribution flaps move

when the distribution flaps are controlled?

YES

NORemove the dashboard in order to check

that there is nothing preventing the flaps

from moving (see MR 412, Bodywork,

57A, Interior accessories, Dashboard:

Removal - Refitting). Carry out any

repairs (eliminate any foreign bodies

which may be blocking the flaps and

lubricate the centre of the flap control).

Replace the distribution - ventilation unit if

it is not possible to repair it.

NOIf the mountings of the lower flap control

linkages are not damaged: resecure the

linkages and grease them slightly. If a

repair is not possible or if the mountings

are damaged: replace the distribution -

ventilation unit.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 77 of 99

62B-77

MR-413-X44-62B000$828_eng.mif

V1

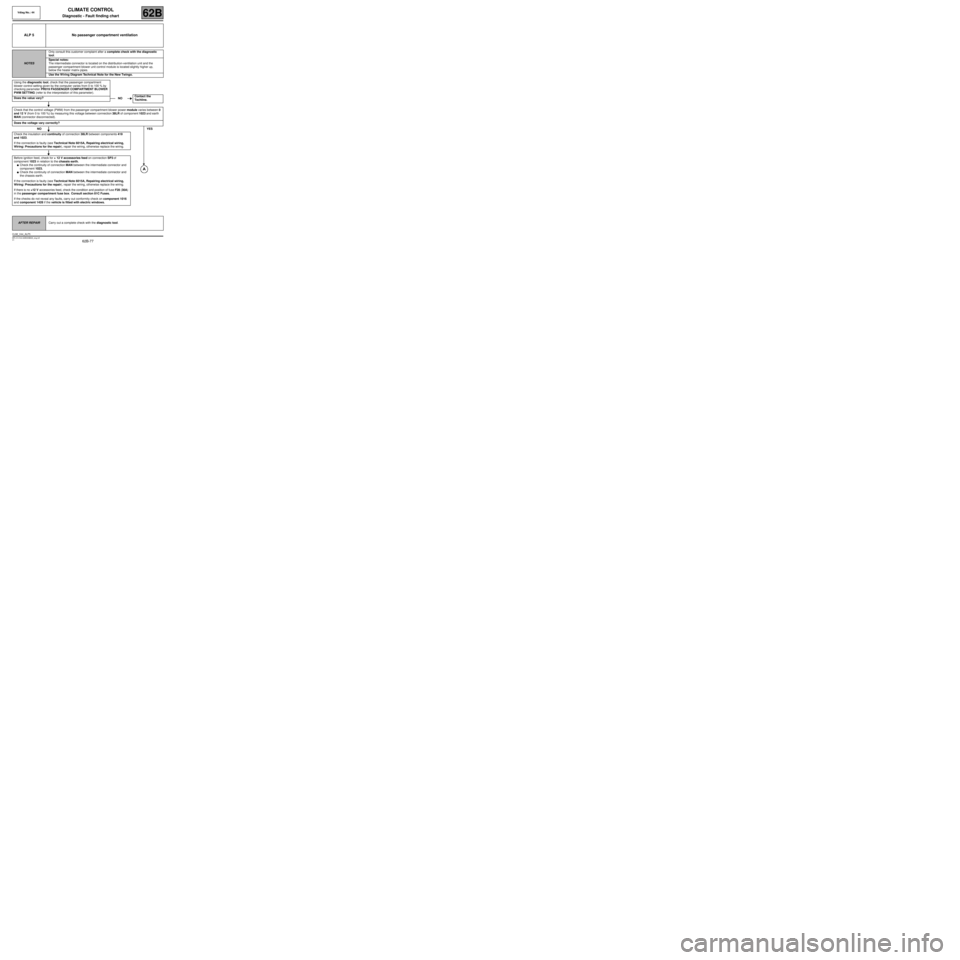

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 5 No passenger compartment ventilation

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Special notes:

The intermediate connector is located on the distribution-ventilation unit and the

passenger compartment blower unit control module is located slightly higher up,

below the heater matrix pipes.

Use the W iring Diagram Technical Note for the New Twingo.

Using the diagnostic tool, check that the passenger compartment

blower control setting given by the computer varies from 0 to 100 % by

checking parameter PR019 PASSENGER COMPARTMENT BLOWER

PWM SETTING (refer to the interpretation of this parameter).

Does the value vary?

Check that the control voltage (PWM) from the passenger compartment blower power module varies between 0

and 12 V (from 0 to 100 %) by measuring this voltage between connection 38LR of component 1023 and earth

MAN (connector disconnected).

Does the voltage vary correctly?

NOYES

Check the insulation and continuity of connection 38LR between components 419

and 1023.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for the repair), repair the wiring, otherwise replace the wiring.

Before ignition feed, check for + 12 V accessories feed on connection SP3 of

component 1023 in relation to the chassis earth.

●Check the continuity of connection MAN between the intermediate connector and

component 1023.

●Check the continuity of connection MAN between the intermediate connector and

the chassis earth.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for the repair), repair the wiring, otherwise replace the wiring.

If there is no +12 V accessories feed, check the condition and position of fuse F28 (30A)

in the passenger compartment fuse box. Consult section 81C Fuses.

If the checks do not reveal any faults, carry out conformity check on component 1016

and component 1428 if the vehicle is fitted with electric windows.

NOContact the

Techline.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

CLIM_V44_ALP5

Page 79 of 99

62B-79

MR-413-X44-62B000$874_eng.mif

V1

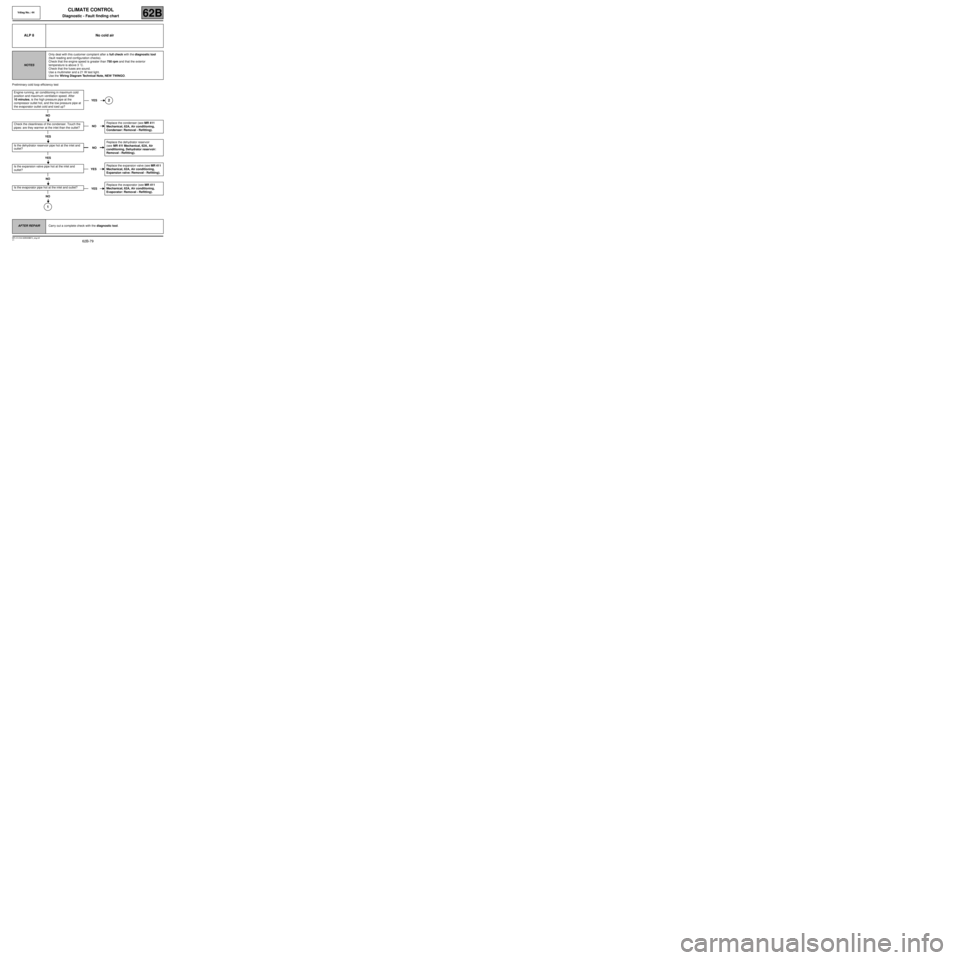

62B

CLIMATE CONTROL

Diagnostic - Fault finding chart

Preliminary cold loop efficiency test

ALP 8 No cold air

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the engine speed is greater than 750 rpm and that the exterior

temperature is above 3 ˚C.

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, NEW TWINGO.

Engine running, air conditioning in maximum cold

position and maximum ventilation speed. After

10 minutes, is the high pressure pipe at the

compressor outlet hot, and the low pressure pipe at

the evaporator outlet cold and iced up?

NO

Check the cleanliness of the condenser. Touch the

pipes: are they warmer at the inlet than the outlet?

YES

Is the dehydrator reservoir pipe hot at the inlet and

outlet?

YES

Is the expansion valve pipe hot at the inlet and

outlet?

NO

Is the evaporator pipe hot at the inlet and outlet?

NO

1

YES2

NOReplace the condenser (see MR 411

Mechanical, 62A, Air conditioning,

Condenser: Removal - Refitting).

NOReplace the dehydrator reservoir

(see MR 411 Mechanical, 62A, Air

conditioning, Dehydrator reservoir:

Removal - Refitting).

YESReplace the expansion valve (see MR 411

Mechanical, 62A, Air conditioning,

Expansion valve: Removal - Refitting).

YESReplace the evaporator (see MR 411

Mechanical, 62A, Air conditioning,

Evaporator: Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Vdiag No.: 44

MR-413-X44-62B000$874_eng.mif

Page 82 of 99

62B-82

MR-413-X44-62B000$874_eng.mif

V1

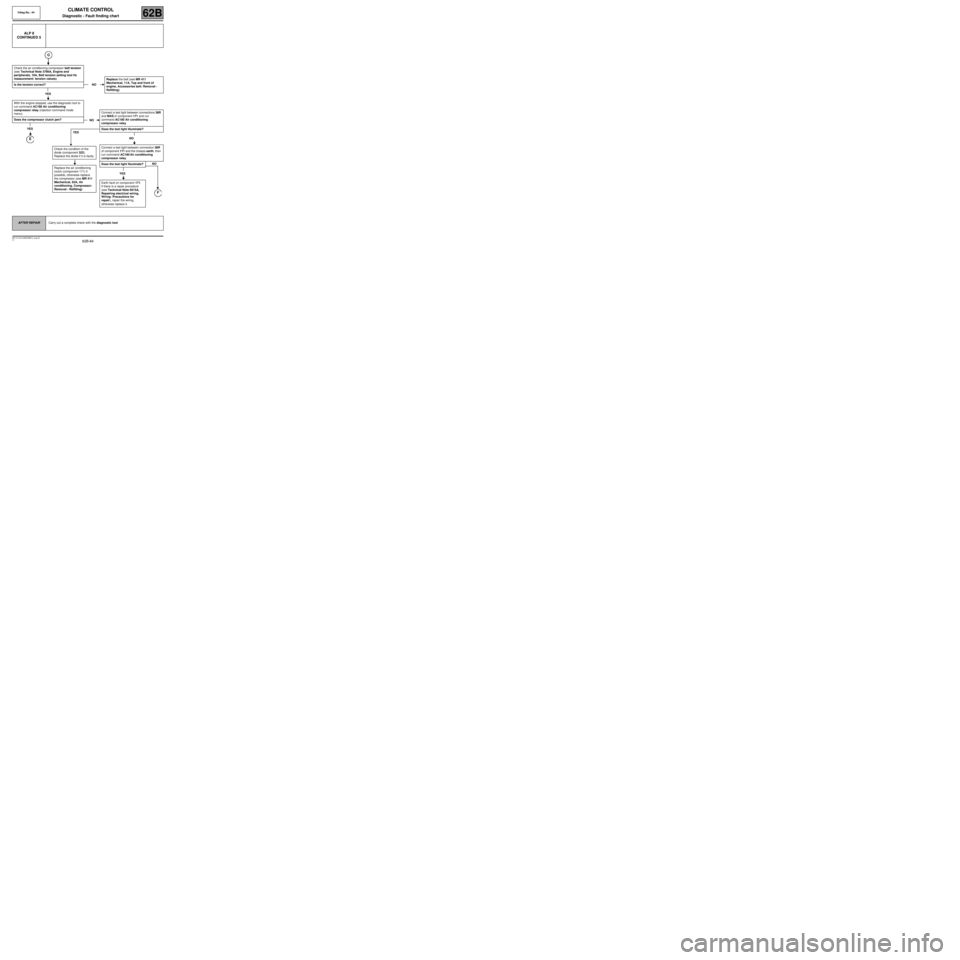

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 8

CONTINUED 3

Carry out fault finding on the injection system to ensure that no fault is present (if faults are displayed by the injection

computer, engagement of the air conditioning may be inhibited). If there are present or stored faults, carry out the necessary

repairs (see 13B, Diesel injection or 17B, Petrol injection).

Check that the refrigerant fluid pressure is correct (neither too low nor too high) using the PR037 Refrigerant fluid

pressure parameter (see Conformity check, Cold loop sub-function).

Check that the engine cooling fan assembly is at speed 1 by

viewing the following status on the cold loop sub-function

screen:

- Status ET022 Low-speed fan assembly request should

display ACTIVE.

Note:

These statuses are not displayed by all types of injection

(see Conformity check, Cold loop sub-function).

Does the engine cooling fan operate at low speed?

YES

NO

Using the diagnostic tool, run command

AC154 Low speed fan assembly relay.

Does the engine cooling fan operate at

low speed?

NO YES

Connector of component 321 disconnected. Connect a test

light between connection 49L of component 321 and the

chassis earth and run command AC154 Low speed fan

assembly relay.

Does the test light illuminate?

YES NO

Carry out fault finding

on the injection

system (sub-function:

cold loop and engine

cooling for low speed

fan assembly

activation).

Measure the resistance of component 321, between connections

49L and 49B of component 321. If the resistance measured is

infinite, replace the fan assembly resistor (component 321).D

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 84 of 99

62B-84

MR-413-X44-62B000$874_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 8

CONTINUED 5

Check the air conditioning compressor belt tension

(see Technical Note 3786A, Engine and

peripherals, 10A, Belt tension setting tool Hz

measurement: tension values).

Is the tension correct?

YES

With the engine stopped, use the diagnostic tool to

run command AC180 Air conditioning

compressor relay (injection command mode

menu).

Does the compressor clutch jam?

YES

E

NOReplace the belt (see MR 411

Mechanical, 11A, Top and front of

engine, Accessories belt: Removal -

Refitting).

NOConnect a test light between connections 38R

and MAS of component 171 and run

command AC180 Air conditioning

compressor relay.

Does the test light illuminate?

NO

Connect a test light between connection 38R

of component 171 and the chassis earth, then

run command AC180 Air conditioning

compressor relay.

Does the test light illuminate?

YES

Earth fault on component 171.

If there is a repair procedure

(see Technical Note 6015A,

Repairing electrical wiring,

Wiring: Precautions for

repair), repair the wiring,

otherwise replace it.

NO

F

YES

Check the condition of the

diode (component 322).

Replace the diode if it is faulty.

Replace the air conditioning

clutch (component 171) if

possible, otherwise replace

the compressor (see MR 411

Mechanical, 62A, Air

conditioning, Compressor:

Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 87 of 99

62B-87

MR-413-X44-62B000$874_eng.mif

V1

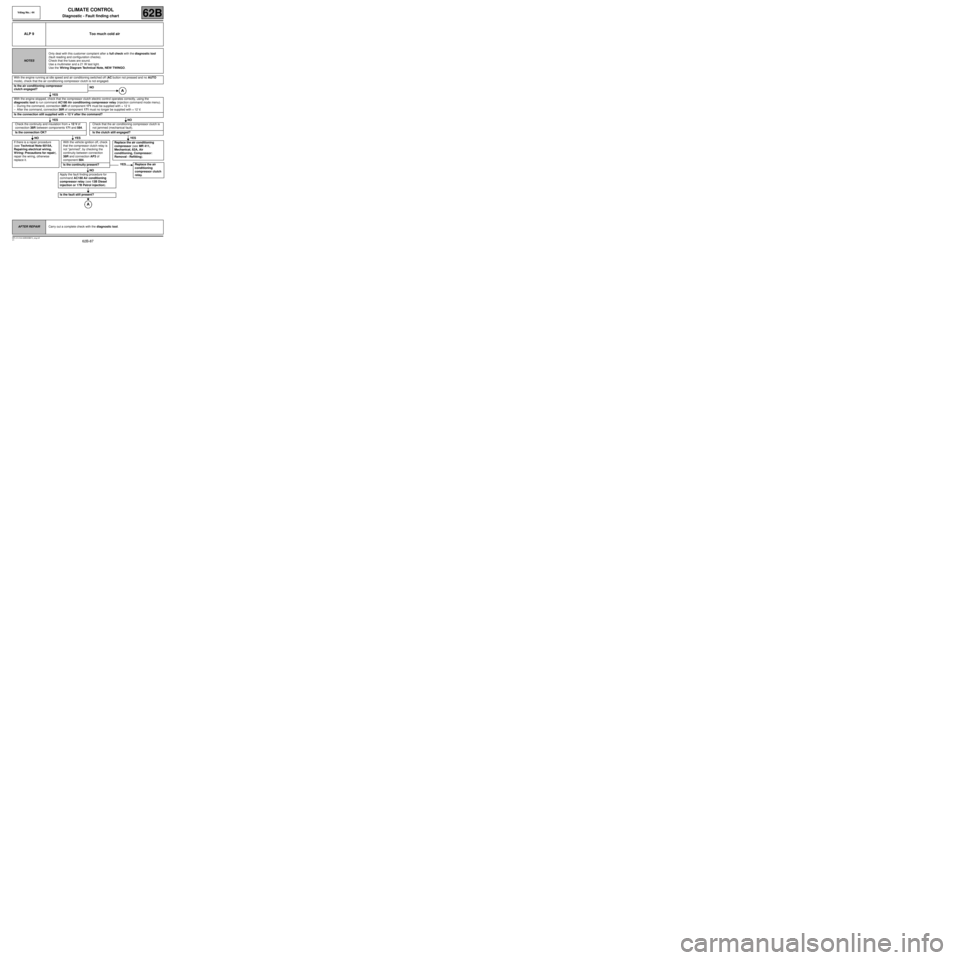

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 9 Too much cold air

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, NEW TWINGO.

With the engine running at idle speed and air conditioning switched off (AC button not pressed and no AUTO

mode), check that the air conditioning compressor clutch is not engaged.

Is the air conditioning compressor

clutch engaged?NO

YES

With the engine stopped, check that the compressor clutch electric control operates correctly, using the

diagnostic tool to run command AC180 Air conditioning compressor relay (injection command mode menu).

–During the command, connection 38R of component 171 must be supplied with + 12 V.

–After the command, connection 38R of component 171 must no longer be supplied with + 12 V.

Is the connection still supplied with + 12 V after the command?

YES NO

Check the continuity and insulation from + 12 V of

connection 38R between components 171 and 584.Check that the air conditioning compressor clutch is

not jammed (mechanical fault).

Is the connection OK? Is the clutch still engaged?

NO YES YES

If there is a repair procedure

(see Technical Note 6015A,

Repairing electrical wiring,

Wiring: Precautions for repair),

repair the wiring, otherwise

replace it.With the vehicle ignition off, check

that the compressor clutch relay is

not “jammed”, by checking the

continuity between connection

38R and connection AP3 of

component 584.

Is the continuity present?

NO

Apply the fault finding procedure for

command AC180 Air conditioning

compressor relay (see 13B Diesel

injection or 17B Petrol injection).

Is the fault still present?

Replace the air conditioning

compressor (see MR 411,

Mechanical, 62A, Air

conditioning, Compressor:

Removal - Refitting).

YES Replace the air

conditioning

compressor clutch

relay.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 89 of 99

62B-89

MR-413-X44-62B000$920_eng.mif

V1

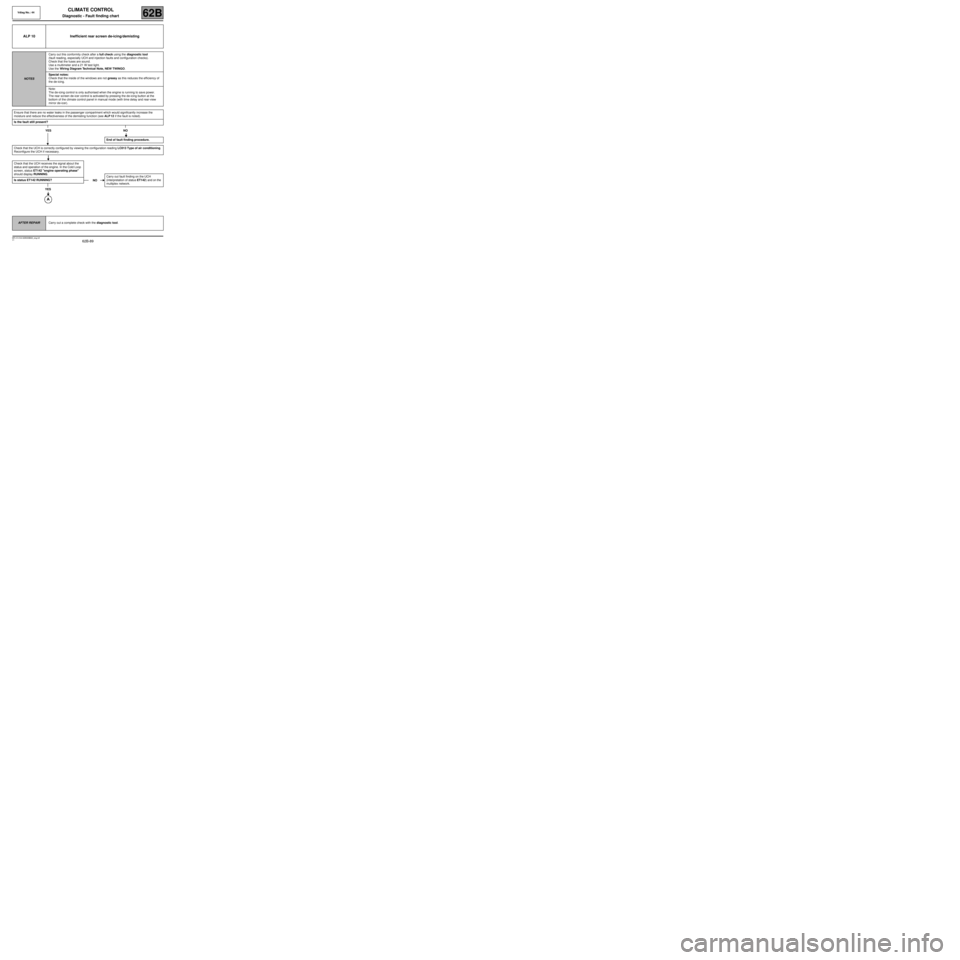

62B

CLIMATE CONTROL

Diagnostic - Fault finding chart

ALP 10 Inefficient rear screen de-icing/demisting

NOTESCarry out this conformity check after a full check using the diagnostic tool

(fault reading, especially UCH and injection faults and configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, NEW TWINGO.

Special notes:

Check that the inside of the windows are not greasy as this reduces the efficiency of

the de-icing.

Note:

The de-icing control is only authorised when the engine is running to save power.

The rear screen de-icer control is activated by pressing the de-icing button at the

bottom of the climate control panel in manual mode (with time delay and rear-view

mirror de-icer).

Ensure that there are no water leaks in the passenger compartment which would significantly increase the

moisture and reduce the effectiveness of the demisting function (see ALP 12 if the fault is noted).

Is the fault still present?

YES NO

Check that the UCH is correctly configured by viewing the configuration reading LC013 Type of air conditioning.

Reconfigure the UCH if necessary.

Check that the UCH receives the signal about the

status and operation of the engine. In the Cold Loop

screen, status ET142 "engine operating phase"

should display RUNNING.

Is status ET142 RUNNING?

YES

End of fault finding procedure.

NOCarry out fault finding on the UCH

(interpretation of status ET142) and on the

multiplex network.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Vdiag No.: 44

MR-413-X44-62B000$920_eng.mif

Page 90 of 99

62B-90

MR-413-X44-62B000$920_eng.mif

V1

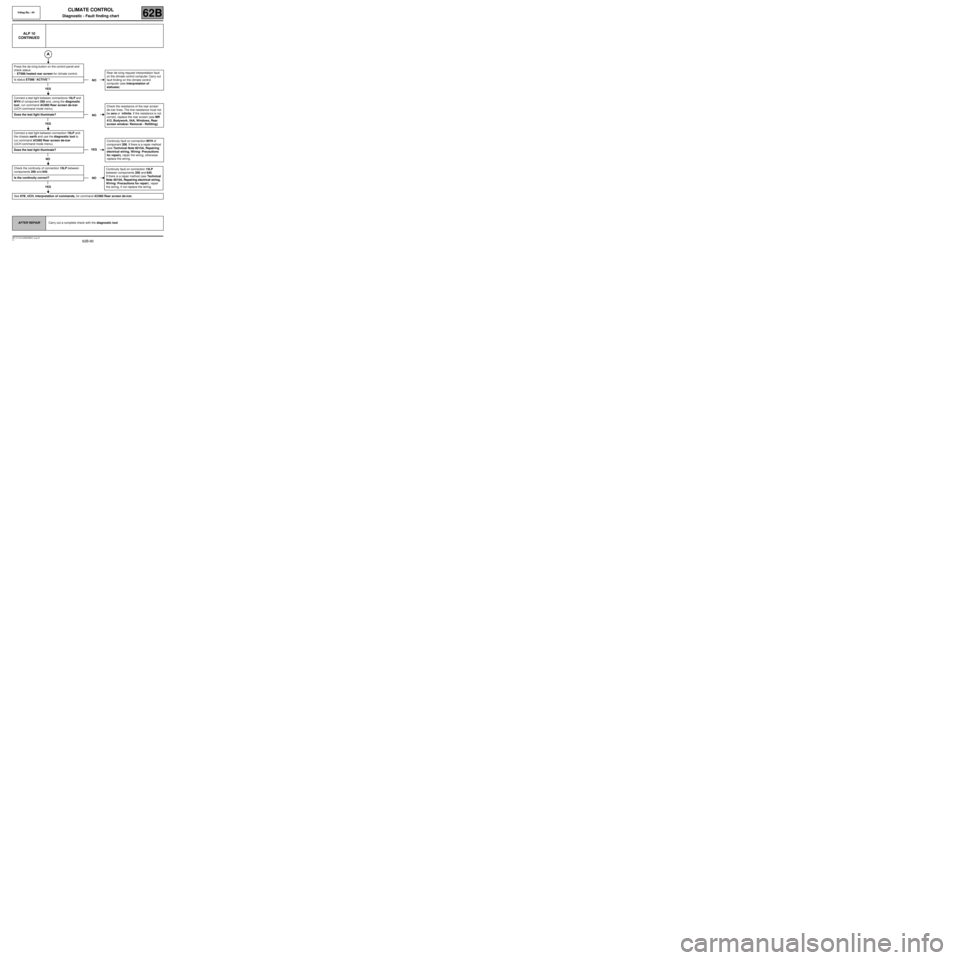

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

ALP 10

CONTINUED

Press the de-icing button on the control panel and

check status:

–ET086 heated rear screen for climate control.

Is status ET086 “ACTIVE”?

YES

Connect a test light between connections 15LP and

MYH of component 200 and, using the diagnostic

tool, run command AC060 Rear screen de-icer

(UCH command mode menu).

Does the test light illuminate?

YES

Connect a test light between connection 15LP and

the chassis earth and use the diagnostic tool to

run command AC060 Rear screen de-icer

(UCH command mode menu).

Does the test light illuminate?

NO

Check the continuity of connection 15LP between

components 200 and 645.

Is the continuity correct?

YES

See 87B, UCH, Interpretation of commands, for command AC060 Rear screen de-icer.

NORear de-icing request interpretation fault

on the climate control computer. Carry out

fault finding on the climate control

computer (see Interpretation of

statuses).

NOCheck the resistance of the rear screen

de-icer lines. The line resistance must not

be zero or infinite. If the resistance is not

correct, replace the rear screen (see MR

412, Bodywork, 54A, Windows, Rear

screen window: Removal - Refitting).

YESContinuity fault on connection MYH of

component 200. If there is a repair method

(see Technical Note 6015A, Repairing

electrical wiring, Wiring: Precautions

for repair), repair the wiring, otherwise

replace the wiring.

NOContinuity fault on connection 15LP

between components 200 and 645.

If there is a repair method (see Technical

Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair

the wiring, if not replace the wiring.

AFTER REPAIRCarry out a complete check with the diagnostic tool.