RENAULT TWINGO RS 2009 2.G Heating And Air Conditioning - Climate Control Manual PDF

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 99

Page 71 of 99

62B-71

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

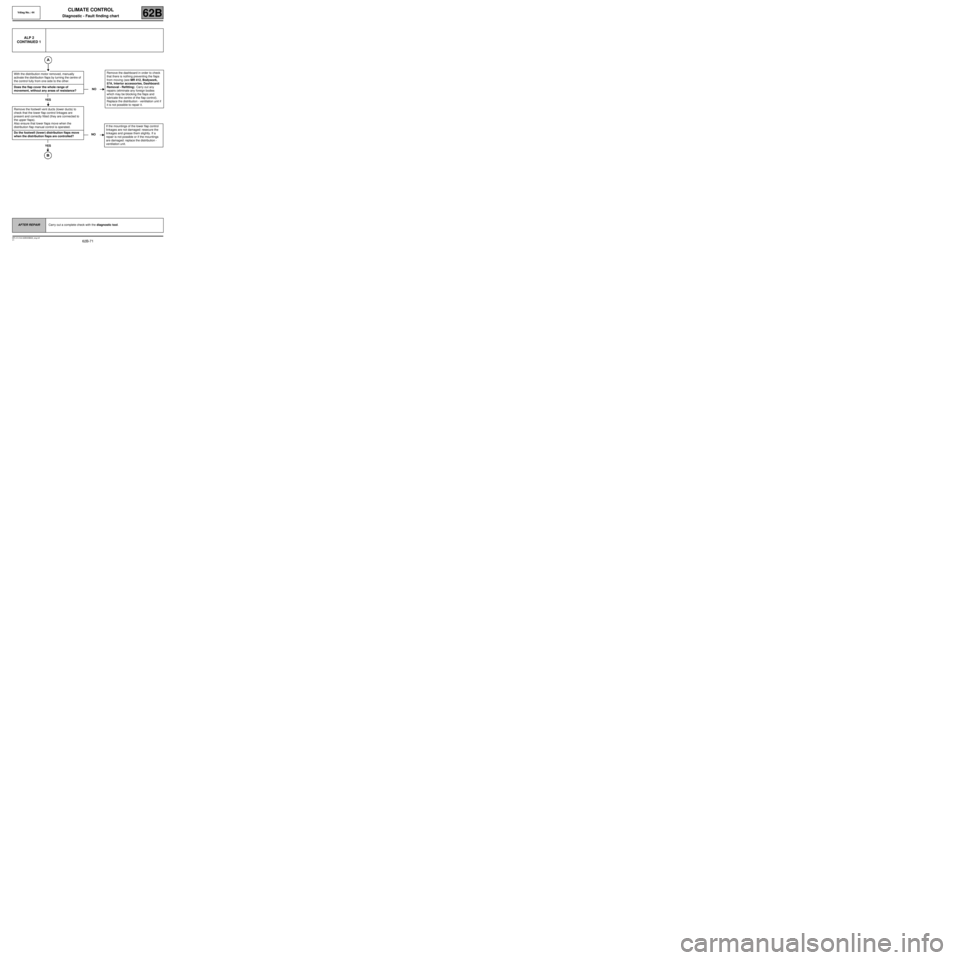

ALP 2

CONTINUED 1

With the distribution motor removed, manually

activate the distribution flaps by turning the centre of

the control fully from one side to the other.

Does the flap cover the whole range of

movement, without any areas of resistance?

YES

Remove the footwell vent ducts (lower ducts) to

check that the lower flap control linkages are

present and correctly fitted (they are connected to

the upper flaps).

Also ensure that lower flaps move when the

distribution flap manual control is operated.

Do the footwell (lower) distribution flaps move

when the distribution flaps are controlled?

YES

NORemove the dashboard in order to check

that there is nothing preventing the flaps

from moving (see MR 412, Bodywork,

57A, Interior accessories, Dashboard:

Removal - Refitting). Carry out any

repairs (eliminate any foreign bodies

which may be blocking the flaps and

lubricate the centre of the flap control).

Replace the distribution - ventilation unit if

it is not possible to repair it.

NOIf the mountings of the lower flap control

linkages are not damaged: resecure the

linkages and grease them slightly. If a

repair is not possible or if the mountings

are damaged: replace the distribution -

ventilation unit.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 72 of 99

62B-72

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

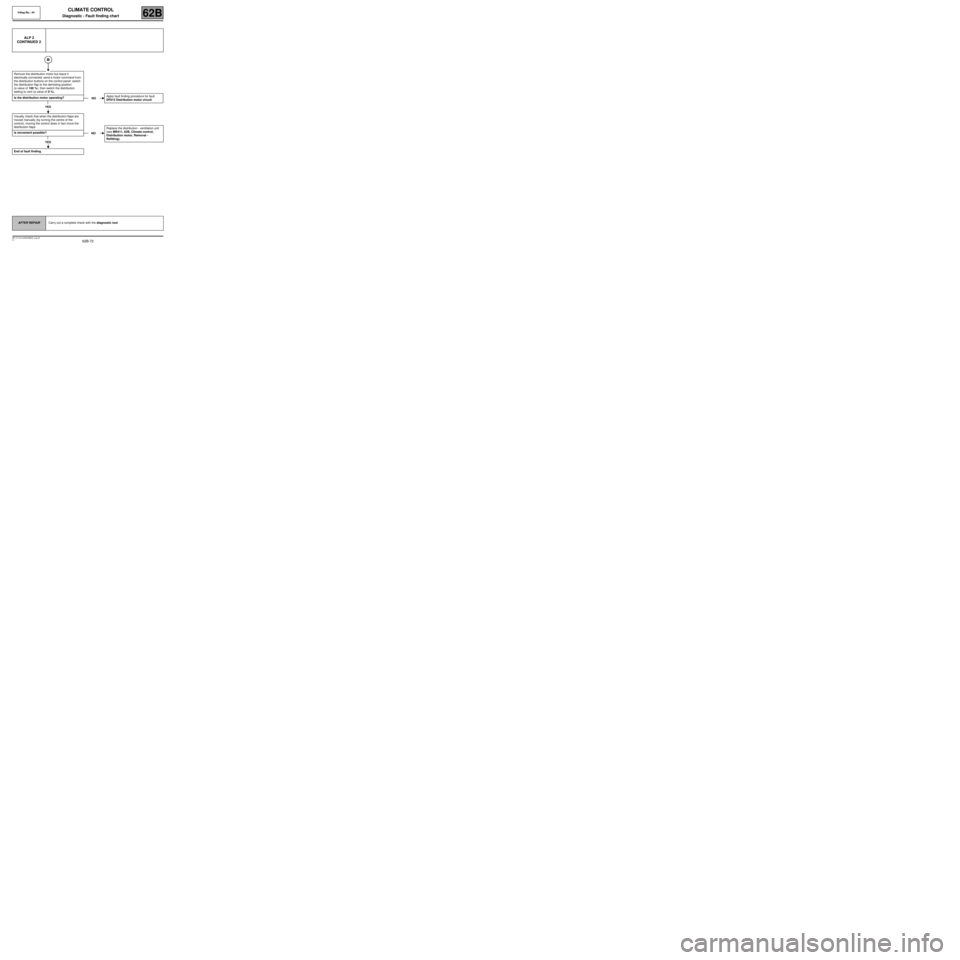

ALP 2

CONTINUED 2

Remove the distribution motor but leave it

electrically connected, send a motor command from

the distribution buttons on the control panel: switch

the distribution flap to the demisting position

(a value of 100 %), then switch the distribution

setting to vent (a value of 0 %).

Is the distribution motor operating?

YES

Visually check that when the distribution flaps are

moved manually (by turning the centre of the

control), moving the control does in fact move the

distribution flaps.

Is movement possible?

YES

End of fault finding.

NOApply fault finding procedure for fault

DF012 Distribution motor circuit.

NOReplace the distribution - ventilation unit

(see MR411, 62B, Climate control,

Distribution motor, Removal -

Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 73 of 99

62B-73

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

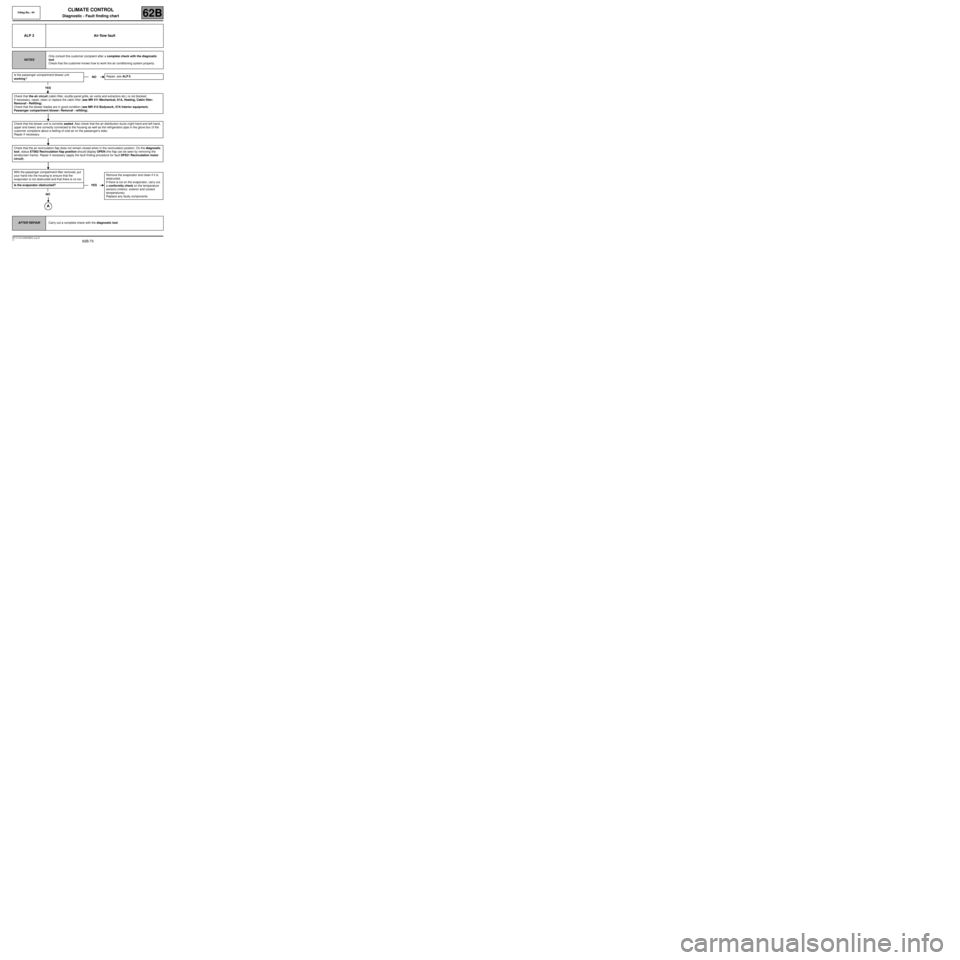

ALP 3 Air flow fault

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Check that the customer knows how to work the air conditioning system properly.

Is the passenger compartment blower unit

working?

YES

Check that the air circuit (cabin filter, scuttle panel grille, air vents and extractors etc.) is not blocked.

If necessary, repair, clean or replace the cabin filter (see MR 411 Mechanical, 61A, Heating, Cabin filter:

Removal - Refitting).

Check that the blower blades are in good condition (see MR 412 Bodywork, 57A Interior equipment,

Passenger compartment blower: Removal - refitting).

Check that the blower unit is correctly sealed. Also check that the air distribution ducts (right-hand and left-hand,

upper and lower) are correctly connected to the housing as well as the refrigeration pipe in the glove box (if the

customer complains about a feeling of cold air on the passenger's side).

Repair if necessary.

Check that the air recirculation flap does not remain closed when in the recirculation position. On the diagnostic

tool, status ET062 Recirculation flap position should display OPEN (the flap can be seen by removing the

windscreen frame). Repair if necessary (apply the fault finding procedure for fault DF021 Recirculation motor

circuit).

With the passenger compartment filter removed, put

your hand into the housing to ensure that the

evaporator is not obstructed and that there is no ice.

Is the evaporator obstructed?

NO

NORepair, see ALP 5.

YESRemove the evaporator and clean if it is

obstructed.

If there is ice on the evaporator, carry out

a conformity check on the temperature

sensors (interior, exterior and coolant

temperatures).

Replace any faulty components.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 74 of 99

62B-74

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

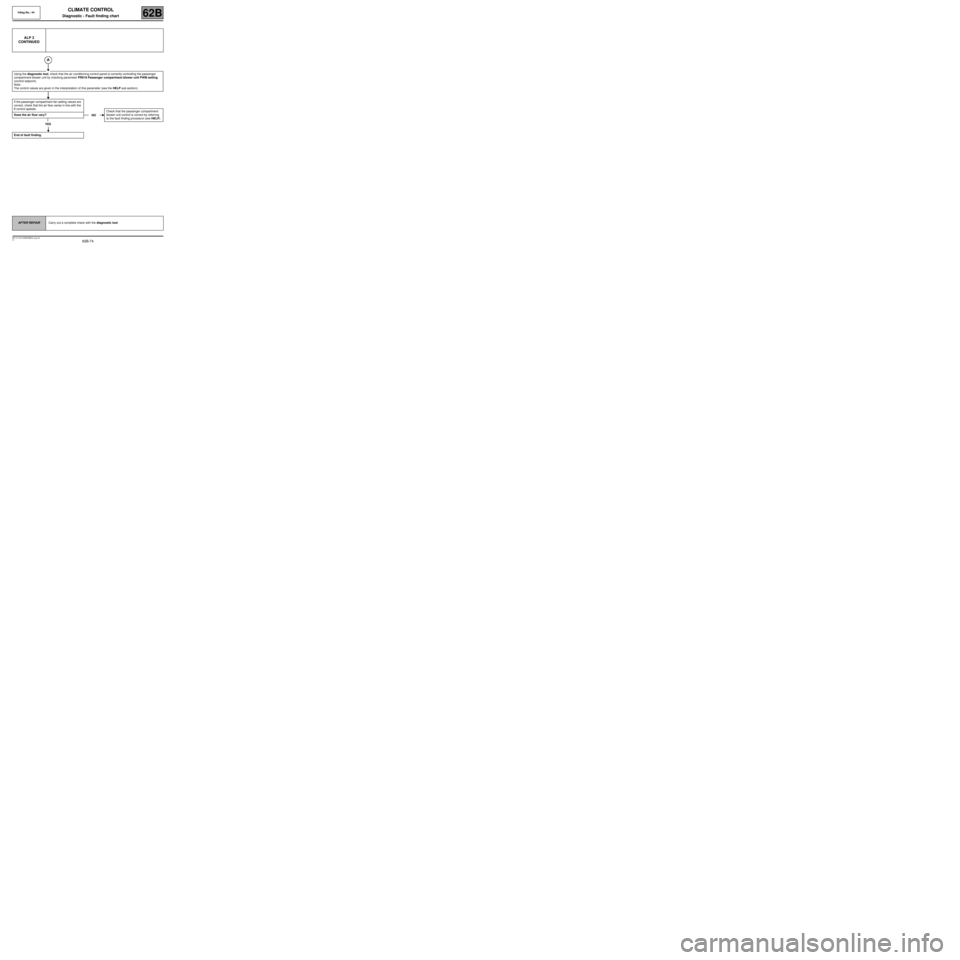

ALP 3

CONTINUED

Using the diagnostic tool, check that the air conditioning control panel is correctly controlling the passenger

compartment blower unit by checking parameter PR019 Passenger compartment blower unit PWM setting

(control setpoint).

Note:

The control values are given in the interpretation of this parameter (see the HELP sub-section).

If the passenger compartment fan setting values are

correct, check that the air flow varies in line with the

8 control speeds.

Does the air flow vary?

YES

End of fault finding.

NOCheck that the passenger compartment

blower unit control is correct by referring

to the fault finding procedure (see HELP).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 75 of 99

62B-75

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

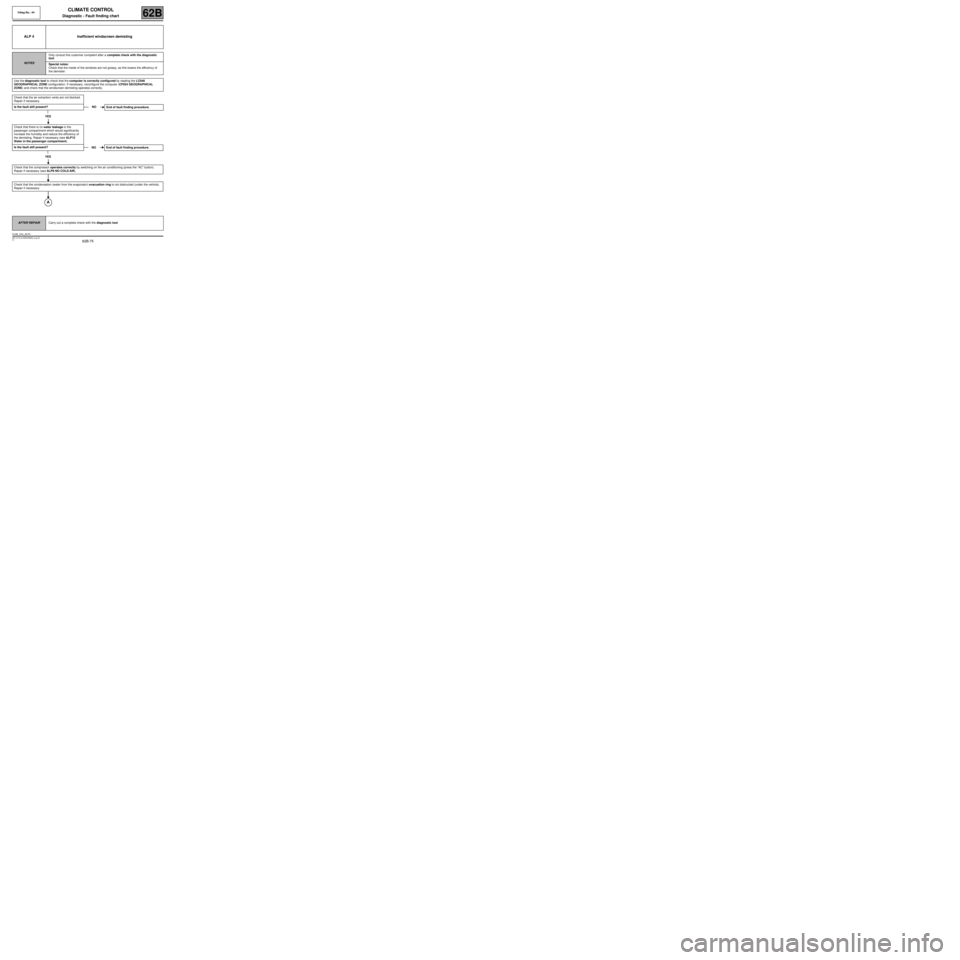

ALP 4 Inefficient windscreen demisting

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Special notes:

Check that the inside of the windows are not greasy, as this lowers the efficiency of

the demister.

Use the diagnostic tool to check that the computer is correctly configured by reading the LC046

GEOGRAPHICAL ZONE configuration. If necessary, reconfigure the computer (CF024 GEOGRAPHICAL

ZONE) and check that the windscreen demisting operates correctly.

Check that the air extraction vents are not blocked.

Repair if necessary.

Is the fault still present?

YES

Check that there is no water leakage in the

passenger compartment which would significantly

increase the humidity and reduce the efficiency of

the demisting. Repair if necessary (see ALP12

Water in the passenger compartment).

Is the fault still present?

YES

Check that the compressor operates correctly by switching on the air conditioning (press the “AC” button).

Repair if necessary (see ALP8 NO COLD AIR).

Check that the condensation (water from the evaporator) evacuation ring is not obstructed (under the vehicle).

Repair if necessary.

NO

End of fault finding procedure.

NO End of fault finding procedure.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

CLIM_V44_ALP4

Page 76 of 99

62B-76

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

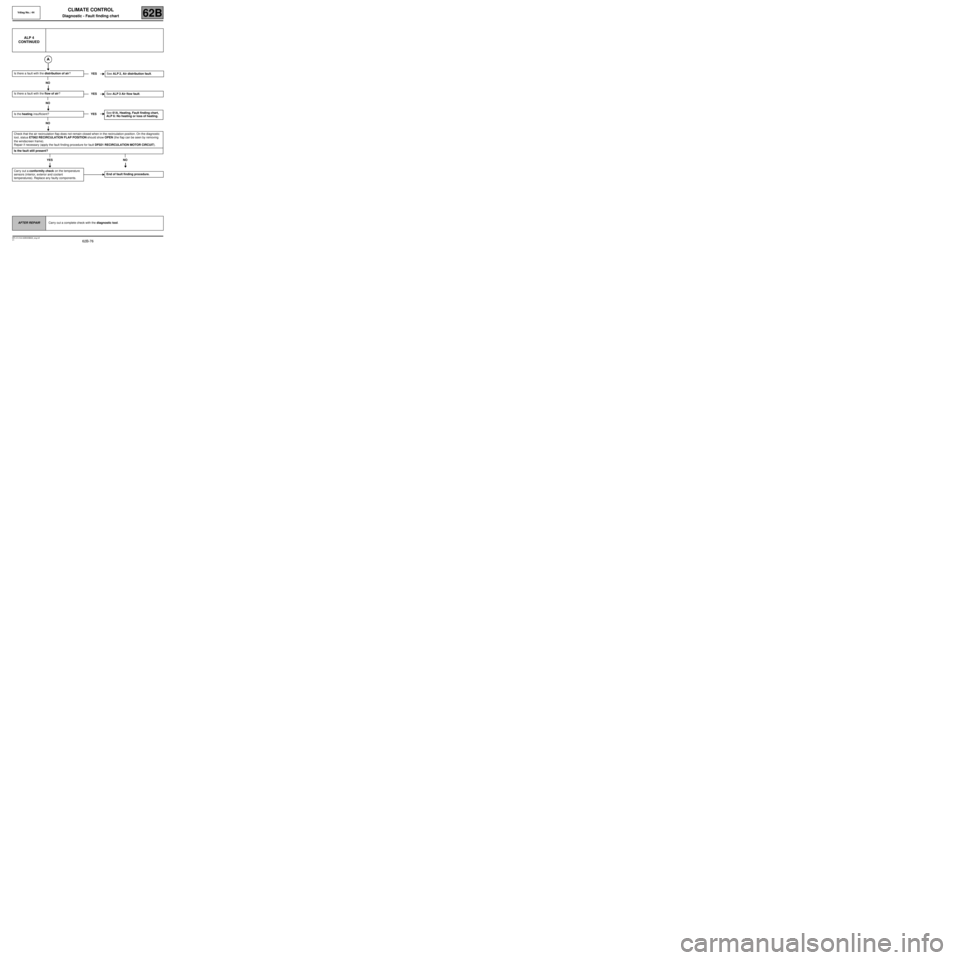

ALP 4

CONTINUED

Is there a fault with the distribution of air?

NO

Is there a fault with the flow of air?

NO

Is the heating insufficient?

NO

Check that the air recirculation flap does not remain closed when in the recirculation position. On the diagnostic

tool, status ET062 RECIRCULATION FLAP POSITION should show OPEN (the flap can be seen by removing

the windscreen frame).

Repair if necessary (apply the fault finding procedure for fault DF021 RECIRCULATION MOTOR CIRCUIT).

Is the fault still present?

YES NO

Carry out a conformity check on the temperature

sensors (interior, exterior and coolant

temperatures). Replace any faulty components.YESSee ALP 2, Air distribution fault.

YESSee ALP 3 Air flow fault.

YESSee 61A, Heating, Fault finding chart,

ALP 6: No heating or loss of heating.

End of fault finding procedure.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 77 of 99

62B-77

MR-413-X44-62B000$828_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

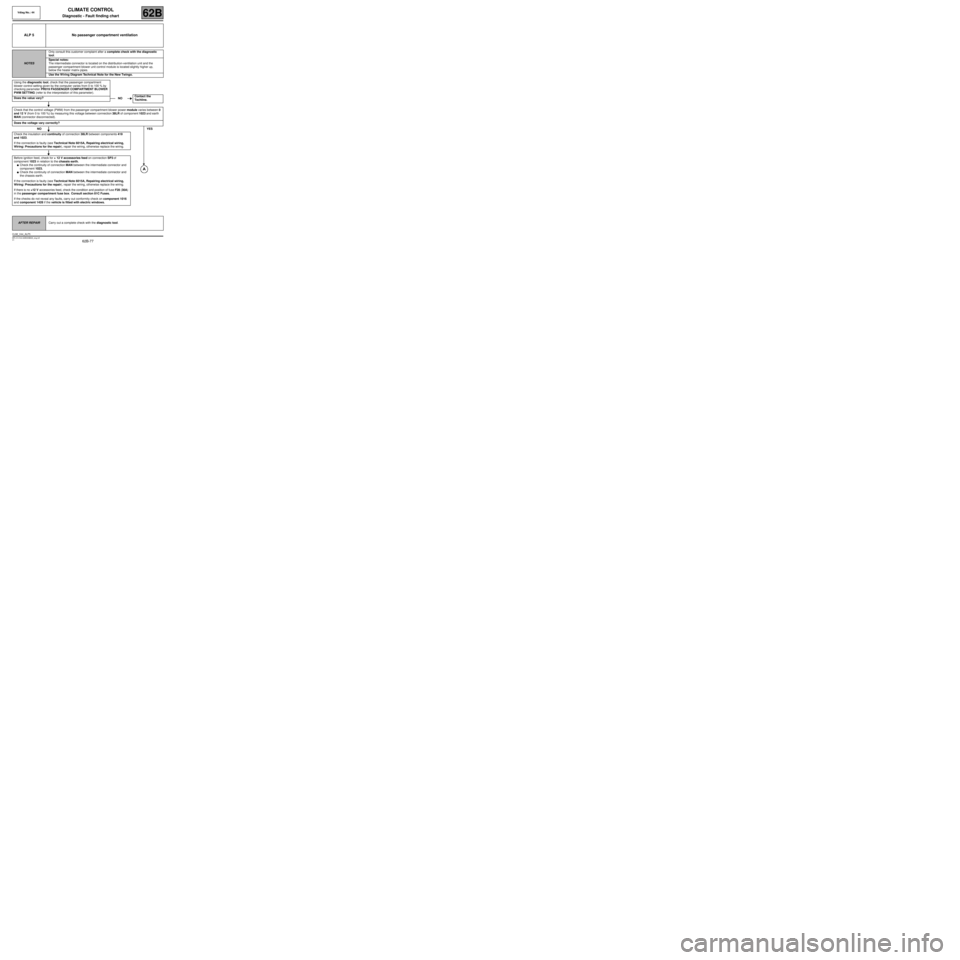

ALP 5 No passenger compartment ventilation

NOTESOnly consult this customer complaint after a complete check with the diagnostic

tool.

Special notes:

The intermediate connector is located on the distribution-ventilation unit and the

passenger compartment blower unit control module is located slightly higher up,

below the heater matrix pipes.

Use the W iring Diagram Technical Note for the New Twingo.

Using the diagnostic tool, check that the passenger compartment

blower control setting given by the computer varies from 0 to 100 % by

checking parameter PR019 PASSENGER COMPARTMENT BLOWER

PWM SETTING (refer to the interpretation of this parameter).

Does the value vary?

Check that the control voltage (PWM) from the passenger compartment blower power module varies between 0

and 12 V (from 0 to 100 %) by measuring this voltage between connection 38LR of component 1023 and earth

MAN (connector disconnected).

Does the voltage vary correctly?

NOYES

Check the insulation and continuity of connection 38LR between components 419

and 1023.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for the repair), repair the wiring, otherwise replace the wiring.

Before ignition feed, check for + 12 V accessories feed on connection SP3 of

component 1023 in relation to the chassis earth.

●Check the continuity of connection MAN between the intermediate connector and

component 1023.

●Check the continuity of connection MAN between the intermediate connector and

the chassis earth.

If the connection is faulty (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for the repair), repair the wiring, otherwise replace the wiring.

If there is no +12 V accessories feed, check the condition and position of fuse F28 (30A)

in the passenger compartment fuse box. Consult section 81C Fuses.

If the checks do not reveal any faults, carry out conformity check on component 1016

and component 1428 if the vehicle is fitted with electric windows.

NOContact the

Techline.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

CLIM_V44_ALP5

Page 78 of 99

62B-78

MR-413-X44-62B000$828_eng.mif

V1

CLIMATE CONTROL

Diagnostic - Fault finding chart

Vdiag No.: 44

62B

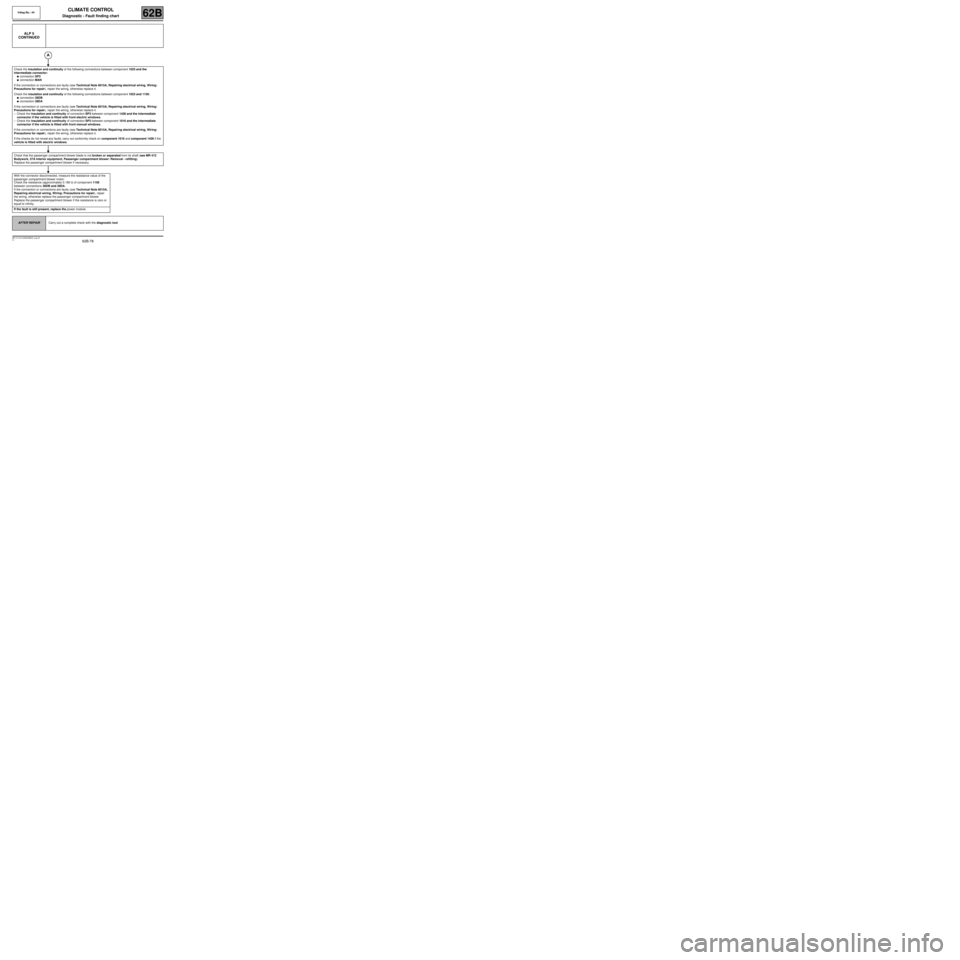

ALP 5

CONTINUED

Check the insulation and continuity of the following connections between component 1023 and the

intermediate connector:

●connection SP3

●connection MAN

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check the insulation and continuity of the following connections between component 1023 and 1156:

●connection 38DB

●connection 38DA

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

–Check the insulation and continuity of connection SP3 between component 1428 and the intermediate

connector if the vehicle is fitted with front electric windows.

–Check the insulation and continuity of connection SP3 between component 1016 and the intermediate

connector if the vehicle is fitted with front manual windows.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

If the checks do not reveal any faults, carry out conformity check on component 1016 and component 1428 if the

vehicle is fitted with electric windows.

Check that the passenger compartment blower blade is not broken or separated from its shaft (see MR 412

Bodywork, 57A Interior equipment, Passenger compartment blower: Removal - refitting).

Replace the passenger compartment blower if necessary.

With the connector disconnected, measure the resistance value of the

passenger compartment blower motor:

Check the resistance (approximately 0.180 Ω of component 1156

between connections 38DB and 38DA.

If the connection or connections are faulty (see Technical Note 6015A,

Repairing electrical wiring, Wiring: Precautions for repair), repair

the wiring, otherwise replace the passenger compartment blower.

Replace the passenger compartment blower if the resistance is zero or

equal to infinity.

If the fault is still present, replace the power module.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 79 of 99

62B-79

MR-413-X44-62B000$874_eng.mif

V1

62B

CLIMATE CONTROL

Diagnostic - Fault finding chart

Preliminary cold loop efficiency test

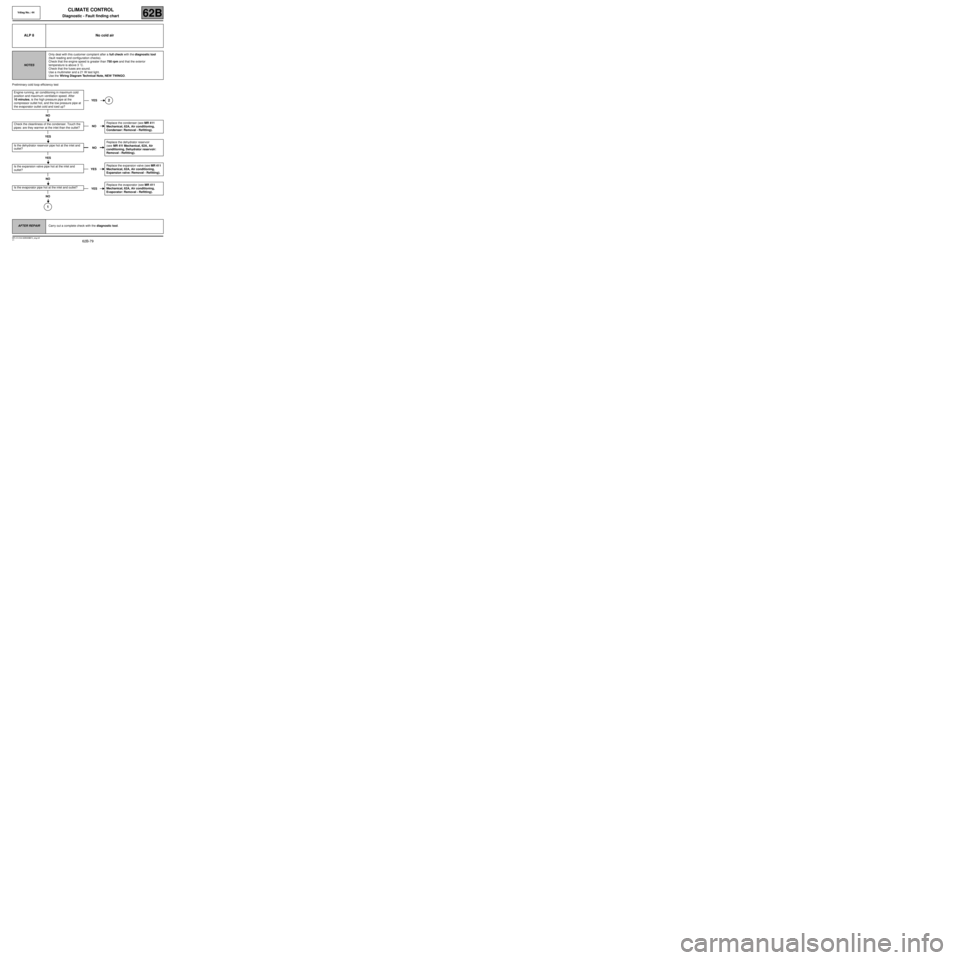

ALP 8 No cold air

NOTESOnly deal with this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the engine speed is greater than 750 rpm and that the exterior

temperature is above 3 ˚C.

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, NEW TWINGO.

Engine running, air conditioning in maximum cold

position and maximum ventilation speed. After

10 minutes, is the high pressure pipe at the

compressor outlet hot, and the low pressure pipe at

the evaporator outlet cold and iced up?

NO

Check the cleanliness of the condenser. Touch the

pipes: are they warmer at the inlet than the outlet?

YES

Is the dehydrator reservoir pipe hot at the inlet and

outlet?

YES

Is the expansion valve pipe hot at the inlet and

outlet?

NO

Is the evaporator pipe hot at the inlet and outlet?

NO

1

YES2

NOReplace the condenser (see MR 411

Mechanical, 62A, Air conditioning,

Condenser: Removal - Refitting).

NOReplace the dehydrator reservoir

(see MR 411 Mechanical, 62A, Air

conditioning, Dehydrator reservoir:

Removal - Refitting).

YESReplace the expansion valve (see MR 411

Mechanical, 62A, Air conditioning,

Expansion valve: Removal - Refitting).

YESReplace the evaporator (see MR 411

Mechanical, 62A, Air conditioning,

Evaporator: Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Vdiag No.: 44

MR-413-X44-62B000$874_eng.mif

Page 80 of 99

62B-80

MR-413-X44-62B000$874_eng.mif

V1

Vdiag No.: 44CLIMATE CONTROL

Diagnostic - Fault finding chart62B

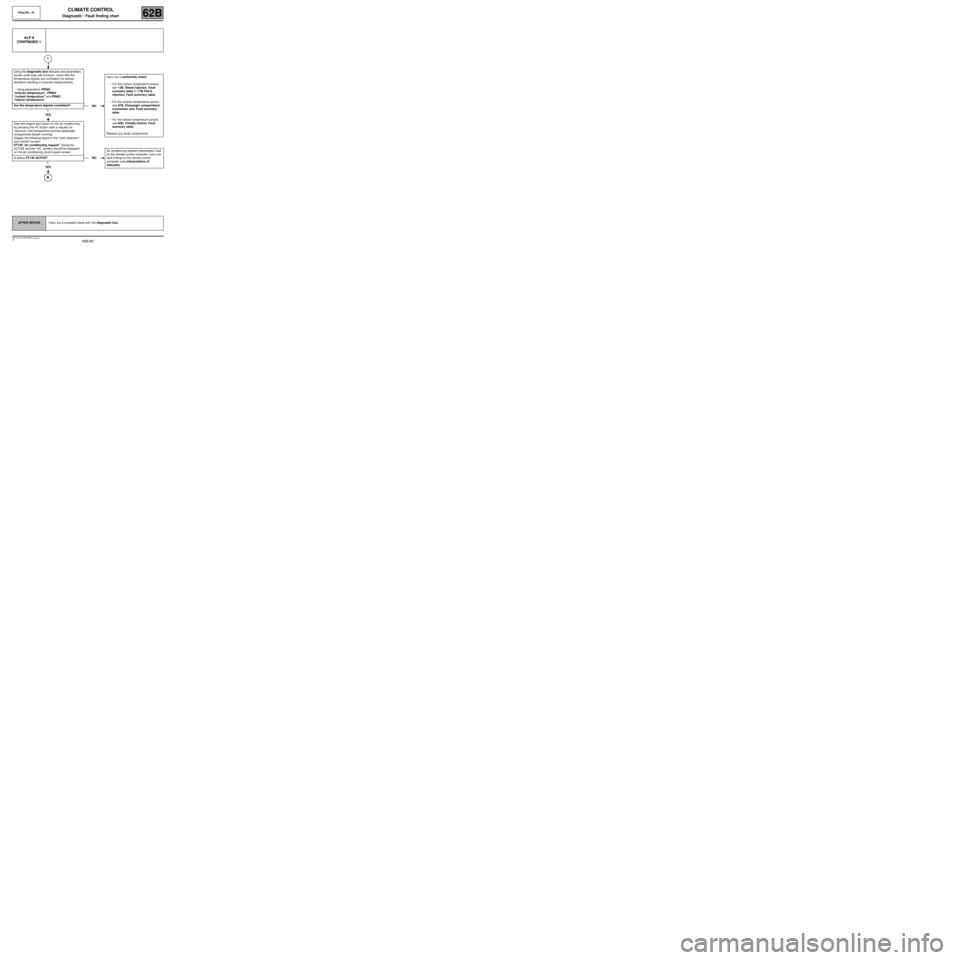

ALP 8

CONTINUED 1

1

Using the diagnostic tool statuses and parameters

screen (cold loop sub-function), check that the

temperature signals are consistent (no sensor

deviation resulting in incorrect measurement).

–Using parameters PR002

"exterior temperature", PR064

"coolant temperature" and PR001

"interior temperature".

Are the temperature signals consistent?

YES

Start the engine and switch on the air conditioning

by pressing the AC button (with a request for

maximum cold temperature and the passenger

compartment blower running).

Display the following status in the “User selection”

sub-function screen:

ET140 "air conditioning request" should be

ACTIVE and the “AC” symbol should be displayed

on the air conditioning control panel screen.

Is status ET140 ACTIVE?

YES

NOCarry out a conformity check:

–For the coolant temperature sensor,

see 13B, Diesel injection, Fault

summary table or 17B Petrol

injection, Fault summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary

table.

–For the interior temperature sensor,

see 62B, Climate control, Fault

summary table.

Replace any faulty components.

NOAir conditioning request interpretation fault

on the climate control computer. Carry out

fault finding on the climate control

computer (see interpretation of

statuses).

AFTER REPAIRCarry out a complete check with the diagnostic tool.