diagram RENAULT TWINGO RS 2009 2.G Heating And Air Conditioning - Manual Air Conditioning Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 63

Page 1 of 63

Heating and

air conditioning system

"The repair procedures given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The procedures may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories from

which his vehicles are constructed."

V1

All rights reserved by Renault s.a.s.

Edition Anglaise

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault s.a.s.

© Renault s.a.s.

V1 MR-413-X44-62C000$000_engTOC.mif

MANUAL AIR CONDITIONING

Fault finding - Introduction 62C - 2

Fault finding - List and location of components 62C - 7

Fault finding - Role of components 62C - 9

Fault finding - Operating diagram 62C - 14

Fault finding - Function 62C - 15

Diagnostics - Configuration and programming 62C - 21

Fault finding - Conformity check 62C - 22

Fault finding - Customer complaints 62C - 35

Fault finding - Fault finding charts 62C - 37

62C

MR-413-X44-62C000$000_engTOC.mif

Page 2 of 63

62C-2

MR-413-X44-62C000$091_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Fault finding - Introduction

1. SCOPE OF THIS DOCUMENT

This document presents the fault finding procedure applicable to all computers with the following specifications:

2. PREREQUISITES FOR FAULT FINDING

Documentation type

Fault finding procedures (this document and the Technical Notes concerning the injection system

fitted to the vehicle, and the UCH):

–Assisted fault finding (integrated into the diagnostic tool), Dialogys.

Wiring Diagrams:

–Visu Schéma (CD-ROM), paper.

Type of diagnostic tools

–CLIP + multiplex line sensor

Special tooling required

3. REMINDERS

Procedure

To run fault finding on the vehicle computers, proceed as follows:

–turn the ignition key to APC,

–Connect the diagnostic tool and carry out the required operations,

To cut off the + after ignition feed, proceed as follows:

–disconnect the diagnostic tool,

–turn the ignition key to OFF,

–switch off the ignition. Vehicle(s): New Twingo

Function concerned: Manual air conditioning

Special tooling required

Multimeter

Elé. 1681 Universal bornier

MR-413-X44-62C000$091_eng.mif

Page 14 of 63

62C-14

MR-413-X44-62C000$364_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Fault finding - Operating diagram

Summary diagram of all the components of the air conditioning system

1Evaporator

2Temperature sensor

3Compressor

4Condenser

5Fan assembly

6Pressure switch

7Dehydration canister

8Expansion valve

MR-413-X44-62C000$364_eng.mif

Page 19 of 63

62C-19

MR-413-X44-62C000$455_eng.mif

V1

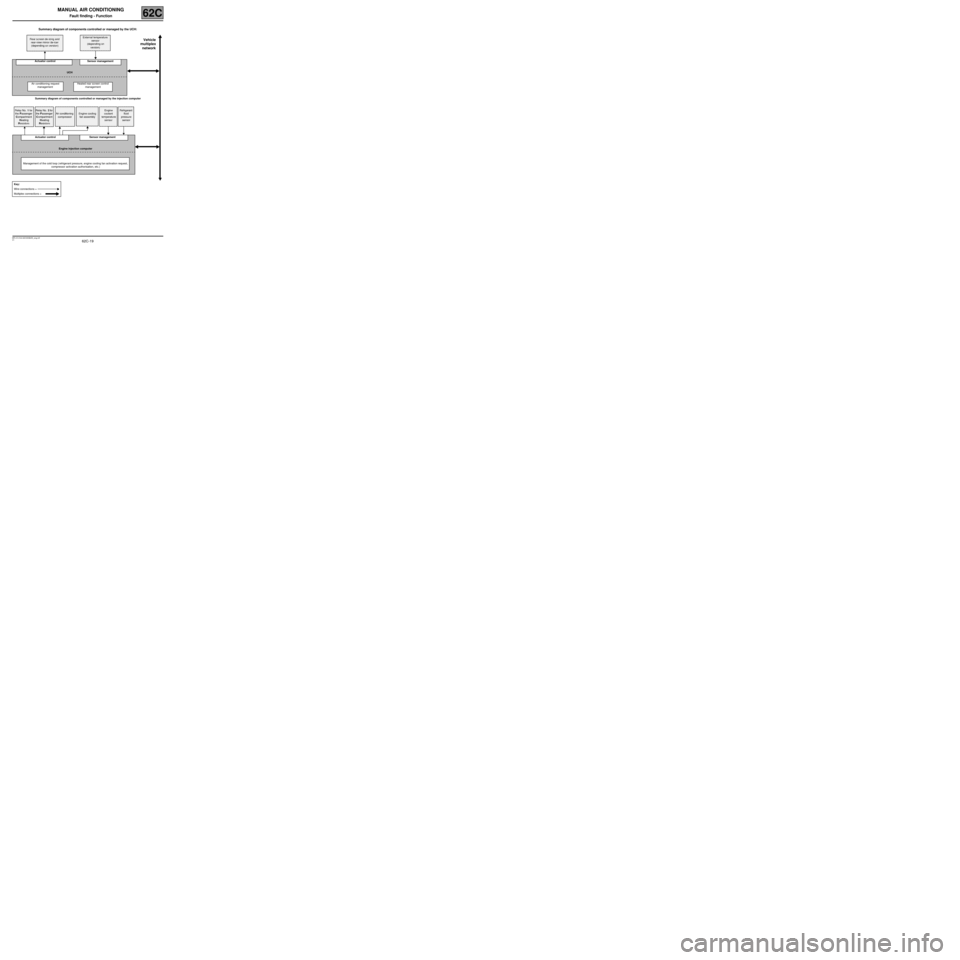

MANUAL AIR CONDITIONING

Fault finding - Function62C

Vehicle

multiplex

network

Summary diagram of components controlled or managed by the UCH:

Summary diagram of components controlled or managed by the injection computer Rear screen de-icing and

rear-view mirror de-icer

(depending on version)External temperature

sensor

(depending on

version)

Actuator control Sensor management

UCH

Air conditioning request

managementHeated rear screen control

management

Relay No. 1 for

the Passenger

Compartment

Heating

ResistorsRelay No. 2 for

the Passenger

Compartment

Heating

ResistorsAir conditioning

compressorEngine cooling

fan assemblyEngine

coolant

temperature

sensorRefrigerant

fluid

pressure

sensor

Actuator control Sensor management

Engine injection computer

Management of the cold loop (refrigerant pressure, engine cooling fan activation request,

compressor activation authorisation, etc.)

Key:

Wire connections =

Multiplex connections =

Page 48 of 63

62C-48

MR-413-X44-62C000$819_eng.mif

V1

MANUAL AIR CONDITIONING

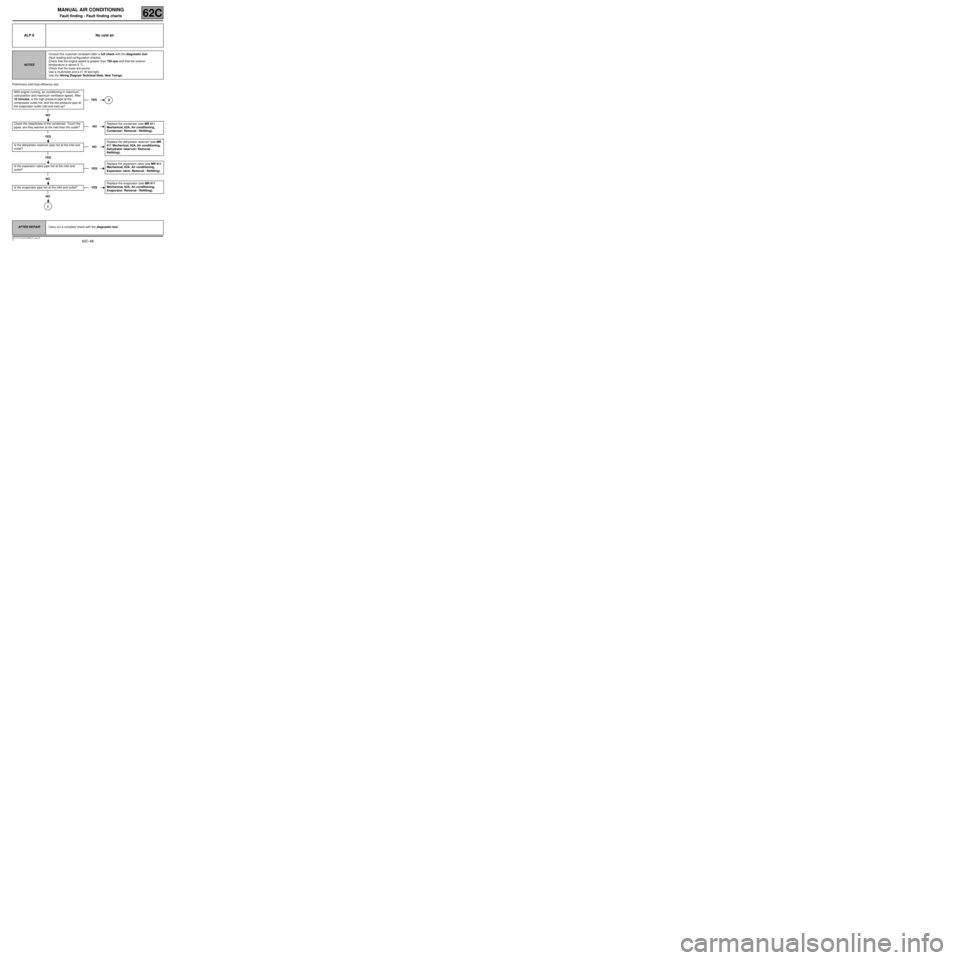

Fault finding - Fault finding charts62C

Preliminary cold loop efficiency test

ALP 8 No cold air

NOTESConsult this customer complaint after a full check with the diagnostic tool

(fault reading and configuration checks).

Check that the engine speed is greater than 750 rpm and that the exterior

temperature is above 3 ˚C.

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, New Twingo.

With engine running, air conditioning in maximum

cold position and maximum ventilation speed. After

10 minutes, is the high pressure pipe at the

compressor outlet hot, and the low pressure pipe at

the evaporator outlet cold and iced up?

NO

Check the cleanliness of the condenser. Touch the

pipes: are they warmer at the inlet than the outlet?

YES

Is the dehydrator reservoir pipe hot at the inlet and

outlet?

YES

Is the expansion valve pipe hot at the inlet and

outlet?

NO

Is the evaporator pipe hot at the inlet and outlet?

NO

1

YES2

NOReplace the condenser (see MR 411

Mechanical, 62A, Air conditioning,

Condenser: Removal - Refitting).

NOReplace the dehydrator reservoir (see MR

411 Mechanical, 62A, Air conditioning,

Dehydrator reservoir: Removal -

Refitting).

YESReplace the expansion valve (see MR 411

Mechanical, 62A, Air conditioning,

Expansion valve: Removal - Refitting).

YESReplace the evaporator (see MR 411

Mechanical, 62A, Air conditioning,

Evaporator: Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 56 of 63

62C-56

MR-413-X44-62C000$910_eng.mif

V1

62C

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts

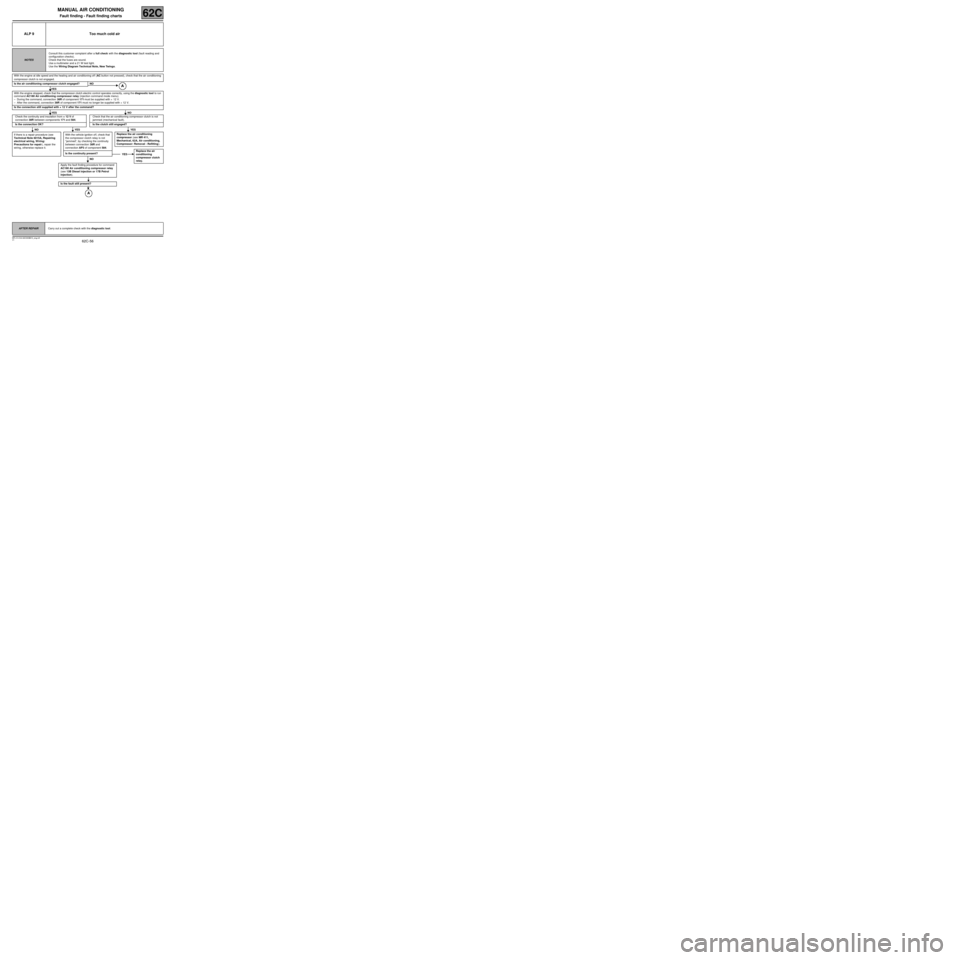

ALP 9 Too much cold air

NOTESConsult this customer complaint after a full check with the diagnostic tool (fault reading and

configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, New Twingo.

With the engine at idle speed and the heating and air conditioning off (AC button not pressed), check that the air conditioning

compressor clutch is not engaged.

Is the air conditioning compressor clutch engaged? NO

YES

With the engine stopped, check that the compressor clutch electric control operates correctly, using the diagnostic tool to run

command AC180 Air conditioning compressor relay (injection command mode menu).

–During the command, connection 38R of component 171 must be supplied with + 12 V.

–After the command, connection 38R of component 171 must no longer be supplied with + 12 V.

Is the connection still supplied with + 12 V after the command?

YES NO

Check the continuity and insulation from + 12 V of

connection 38R between components 171 and 584.Check that the air conditioning compressor clutch is not

jammed (mechanical fault).

Is the connection OK? Is the clutch still engaged?

NO YES YES

If there is a repair procedure (see

Technical Note 6015A, Repairing

electrical wiring, W iring:

Precautions for repair), repair the

wiring, otherwise replace it.With the vehicle ignition of f, check that

the compressor clutch relay is not

“jammed”, by checking the continuity

between connection 38R and

connection AP3 of component 584.

Is the continuity present?

NO

Apply the fault finding procedure for command

AC180 Air conditioning compressor relay

(see 13B Diesel injection or 17B Petrol

injection).

Is the fault still present?

Replace the air conditioning

compressor (see MR 411,

Mechanical, 62A, Air conditioning,

Compressor: Removal - Refitting).

YESReplace the air

conditioning

compressor clutch

relay.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

MR-413-X44-62C000$910_eng.mif

Page 58 of 63

62C-58

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

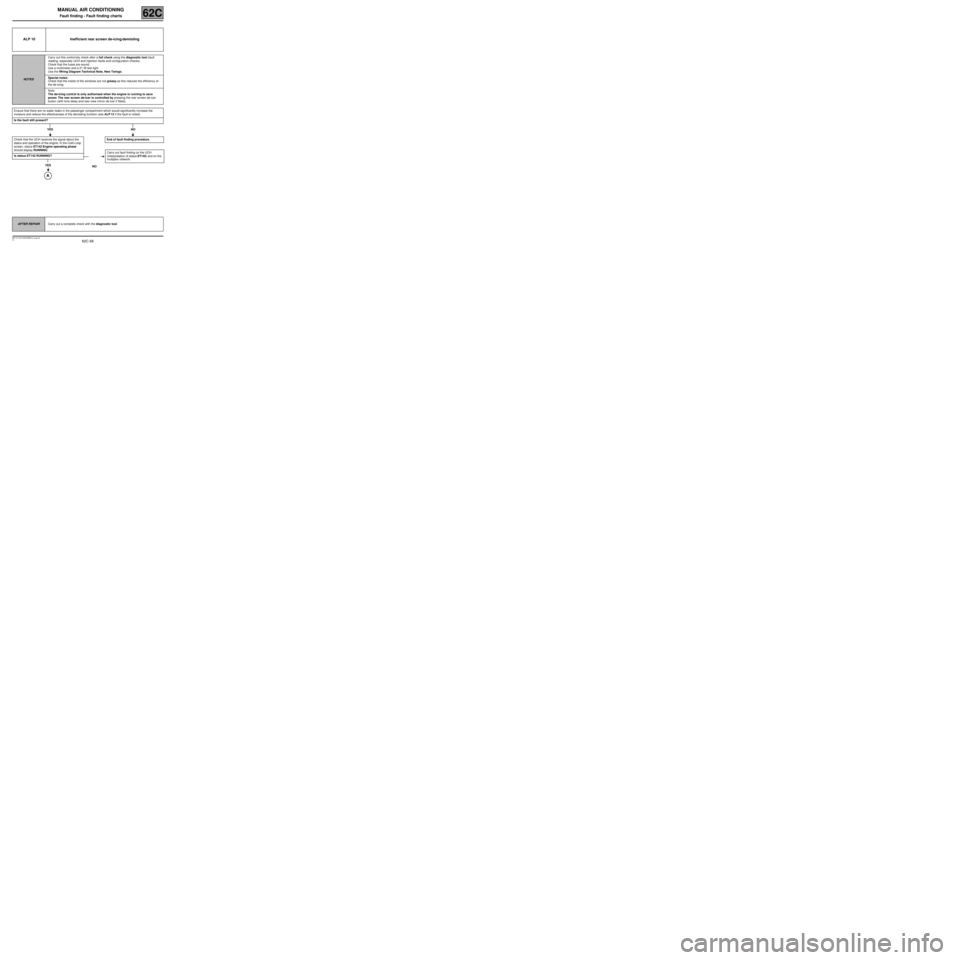

ALP 10 Inefficient rear screen de-icing/demisting

NOTESCarry out this conformity check after a full check using the diagnostic tool (fault

reading, especially UCH and injection faults and configuration checks).

Check that the fuses are sound.

Use a multimeter and a 21 W test light.

Use the Wiring Diagram Technical Note, New Twingo.

Special notes:

Check that the inside of the windows are not greasy as this reduces the efficiency of

the de-icing.

Note:

The de-icing control is only authorised when the engine is running to save

power. The rear screen de-icer is controlled by pressing the rear screen de-icer

button (with time delay and rear-view mirror de-icer if fitted).

Ensure that there are no water leaks in the passenger compartment which would significantly increase the

moisture and reduce the effectiveness of the demisting function (see ALP 12 if the fault is noted).

Is the fault still present?

YES NO

Check that the UCH receives the signal about the

status and operation of the engine. In the Cold Loop

screen, status ET142 Engine operating phase

should display RUNNING.

Is status ET142 RUNNING?

YES

End of fault finding procedure.

NOCarry out fault finding on the UCH

(interpretation of status ET142) and on the

multiplex network.

AFTER REPAIRCarry out a complete check with the diagnostic tool.