wiring RENAULT TWINGO RS 2009 2.G Mechanism And Accessories Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 95

Page 31 of 95

54A-1

WINDOWS

Windscreen: Removal - Refitting

54A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the windscreen wiper arms (see Winds-

creen wiper arm: Removal - Refitting) (MR 411,

85A, Washing - Wiping).

aRemove the lower trim pieces (1) from the winds-

creen.

aRemove:

-the scuttle panel grille (see 56A, Exterior equip-

ment, Scuttle panel grille: Removal - Refitting,

page 56A-1) ,

-the interior rear-view mirror (see 57A, Interior

equipment, Interior rear-view mirror: Removal -

Refitting, page 57A-14) ,

-the A-pillar trims (see Windscreen pillar trim: Re-

moval - Refitting) (MR 412, 71A, Body internal

trim).

aDisconnect the rain and light sensor (depending on

the equipment level).II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the seal (2) from the windscreen.

aProtect the windscreen surround using masking ta-

pe.

aPosition the dashboard protector (Car. 1818).

a

aCut the cement bead. Special tooling required

Car. 1818Instr ument panel protector

Note:

Leave the rain sensor in place on the old winds-

creen during the replacement operation (depen-

ding on the equipment level).

119268

119271

108156

Note:

When cutting the cement bead, take care not to

cut the wiring harness.

Page 41 of 95

55A-3

EXTERIOR PROTECTION

Front bumper: Stripping - Rebuilding

55A

STRIPPING

I - STRIPPING PREPARATION OPERATION

aRemove the front bumper (see 55A, Exterior pro-

tection, Front bumper: Removal - Refitting, page

55A-1) .

II - STRIPPING OPERATION FOR PART

CONCERNED

aRemove the front fog lights (depending on equip-

ment level) (see Front fog light: Removal - Refit-

ting) (MR 411, 80B, Headlights).

aNote the position of the electrical wiring (depending

on equipment level).

aRemove the electrical wiring (depending on equip-

ment level).

aRemove the bolts (1) .

aUnclip the badge.aUnclip the centre absorber (2) .

aDrill out rivets (3) .

aRemove the lower cover.

120886

120888

120887

Page 43 of 95

55A-5

EXTERIOR PROTECTION

Front bumper: Stripping - Rebuilding

55A

aInsert rivets into the lower cover at (3) .

aClip on:

-the central absorber (2) ,

-the badge.

aRefit:

-the bolts (1) ,

-the electrical wiring (depending on equipment le-

vel),

-the front fog lights (depending on the equipment le-

vel) (see Front fog light: Removal - Refitting)

(MR 411, 80B, Headlights).

II - FINAL OPERATION.

aRefit the front bumper (see 55A, Exterior protec-

tion, Front bumper: Removal - Refitting, page

55A-1) .

Page 51 of 95

55A-13

EXTERIOR PROTECTION

Rear bumper: Stripping - Rebuilding

55A

STRIPPING

I - STRIPPING PREPARATION OPERATION

aRemove the rear bumper (see 55A, Exterior pro-

tection, Rear bumper: Removal - Refitting, page

55A-10) .

II - STRIPPING OPERATION FOR PART

CONCERNED

aRemove the proximity radars (see Proximity radar:

Removal - Refitting) (87F, Parking distance con-

trol).

aRemove:

-the number plate lights (see Number plate light:

Removal - Refitting) (81A, Rear lighting),

-the electrical wiring.

aUnclip the outer impact strips.

REBUILDING

I - REBUILDING OPERATION FOR PART

CONCERNED

aClip on the outer impact strips.

aRefit:

-the electrical wiring,

-the number plate lights (see Number plate light:

Removal - Refitting) (81A, Rear lighting).

aRefit the proximity radars (see Proximity radar: Re-

moval - Refitting) (87F, Parking distance control).

II - FINAL OPERATION.

aRefit the rear bumper (see 55A, Exterior protec-

tion, Rear bumper: Removal - Refitting, page

55A-10) . REAR PROXIMITY RADAR

EQUIPMENT LEVEL EA0 or EQUIPMENT LEVEL

EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT

LEVEL EA5

120801

EQUIPMENT LEVEL EA0 or EQUIPMENT LEVEL

EA1 or EQUIPMENT LEVEL EA3 or EQUIPMENT

LEVEL EA5

REAR PROXIMITY RADAR

Page 76 of 95

57A-3

INTERIOR EQUIPMENT

Dashboard: Removal - Refitting

57A

aPartially remove the dashboard (this operation re-

quires two people).

aDetach the various wiring from the dashboard.

aRemove the dashboard (this operation requires two

people).

aNote the route of the cabling.

REFITTING

I - REFITTING PREPARATION OPERATION

aEnsure that the wiring is in good condition.

II - REFITTING OPERATION FOR PART

CONCERNED

aPartially refit the dashboard (this operation requires

two people).

aRefit:

-the various cable harnesses,

-the dashboard (this operation requires two people).

III - FINAL OPERATION.

aClip:

-the diagnostic socket (2) ,

-the access flap (1) .

aConnect the passenger airbag deactivation connec-

tor.

aClip on the dashboard side faces.

aRefit:

-the control panel (see Control panel: Removal -

Refitting) (61A, Heating),

-the instrument panel (see Instrument panel: Re-

moval - Refitting) (83A, Instrument panel),-the tweeters (see Tweeter: Removal - Refitting)

(86A, Radio),

-the centre front panel (see 57A, Interior equip-

ment, Centre front panel: Removal - Refitting,

page 57A-7) ,

-the centre console (see 57A, Interior equipment,

Centre console: Removal - Refitting, page 57A-

12) ,

-the steering column switch assembly (see Stee-

ring column switch assembly: Removal - Refit-

ting) (84A, Control - Signals).

aRefit the rev counter (see Rev counter: Removal -

Refitting) (83A, Instrument panel).

aRefit:

-the steering wheel (see Steering wheel: Removal

- Refitting) (36B, Power-assisted steering),

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (88C, Airbags and pre-

tensioners),

-the windscreen pillar trims (see Windscreen pillar

trim: Removal - Refitting) (71A, Body internal

trim).

aRefit the passenger front airbag (see Passenger's

frontal airbag: Removal - Refitting) (88C, Airbags

and pretensioners).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aCarry out a function test on all functions.

aUnlock the airbag computer using the Diagnostic

tool (see Fault finding - Replacement of compo-

nents) (88C, Airbags and pretensioners).

121157ENGINE REV COUNTER

FRONT SIDE AIRBAG

IMPORTANT

To avoid a fault with or even triggering of pyro-

technic components (airbags or pretensioners),

check the airbag computer using the diagnostic

tool.

Page 77 of 95

57A-4

INTERIOR EQUIPMENT

Dashboard: Conversion

57A

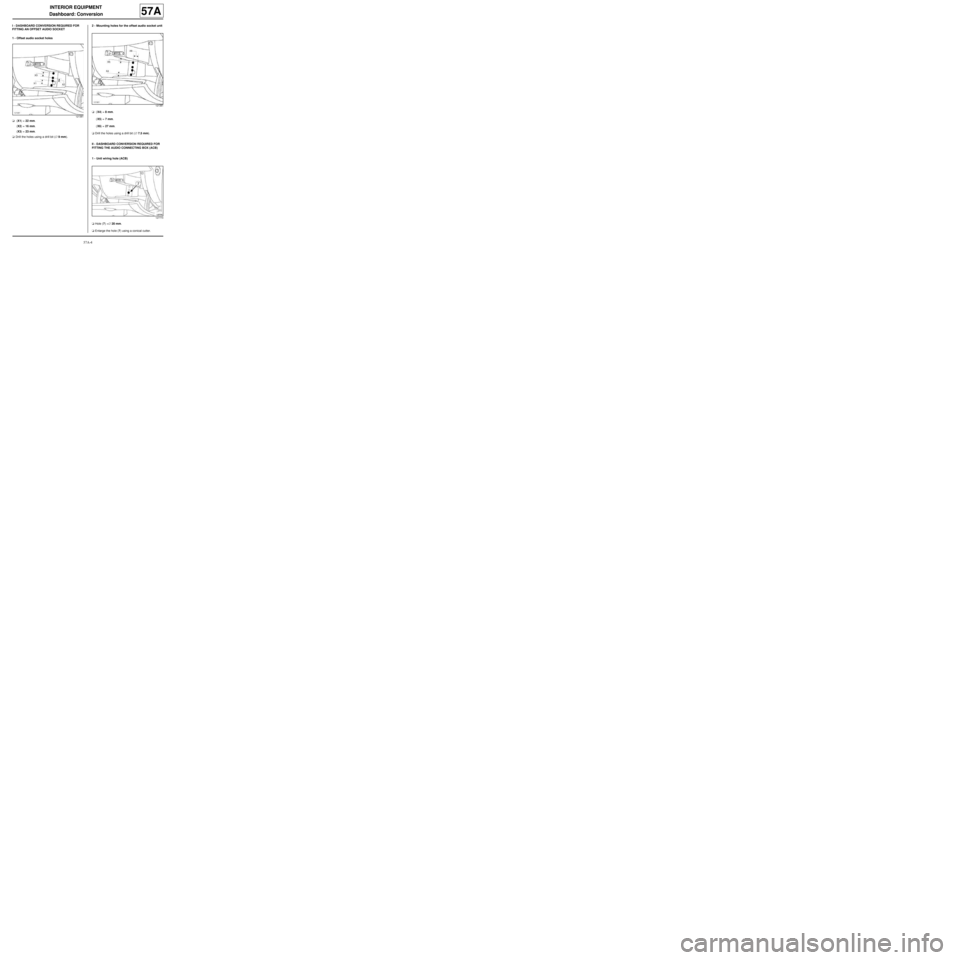

I - DASHBOARD CONVERSION REQUIRED FOR

FITTING AN OFFSET AUDIO SOCKET

1 - Offset audio socket holes

a (X1) = 22 mm.

(X2) = 16 mm.

(X3) = 23 mm.

aDrill the holes using a drill bit (∅ 9 mm).2 - Mounting holes for the offset audio socket unit

a (X4) = 8 mm.

(X5) = 7 mm.

(X6) = 27 mm.

aDrill the holes using a drill bit (∅ 7.5 mm).

II - DASHBOARD CONVERSION REQUIRED FOR

FITTING THE AUDIO CONNECTING BOX (ACB)

1 - Unit wiring hole (ACB)

aHole (7) =∅ 20 mm.

aEnlarge the hole (7) using a conical cutter.

121381

121381

127770