clutch RENAULT TWINGO RS 2009 2.G Transmission User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 135

Page 11 of 135

20A-8

CLUTCH

Pressure plate - Disc: Removal - Refitting

K4M

20A

aRefill:

-the engine cooling system (see Cooling system:

Draining - Refilling) (19A, Cooling),

-the gearbox (see 21A, Manual gearbox, Manual

gearbox oils: Draining - Filling, page 21A-2) ,

-the refrigerant circuit (see Refrigerant circuit:

Draining - Filling) (62A, Air conditioning).

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (17B, Petrol in-

jection),

-the air filter box (see Air filter unit: Removal - Re-

fitting) (12A, Fuel mixture),

-the battery (see Battery: Removal - Refitting)

(80A, Battery)

-the engine undertray.

Page 12 of 135

20A-9

CLUTCH

Clutch thrust bearing: Removal - Refitting

JH3 or JR5

20A

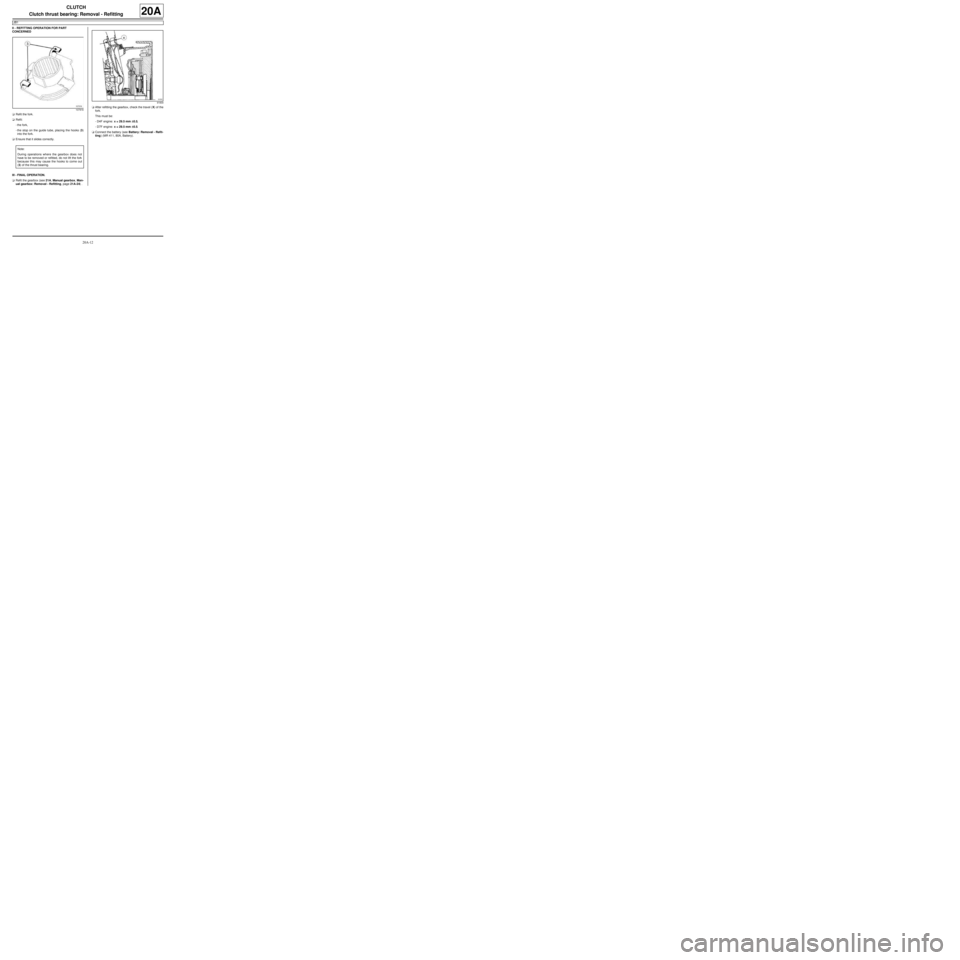

REMOVAL

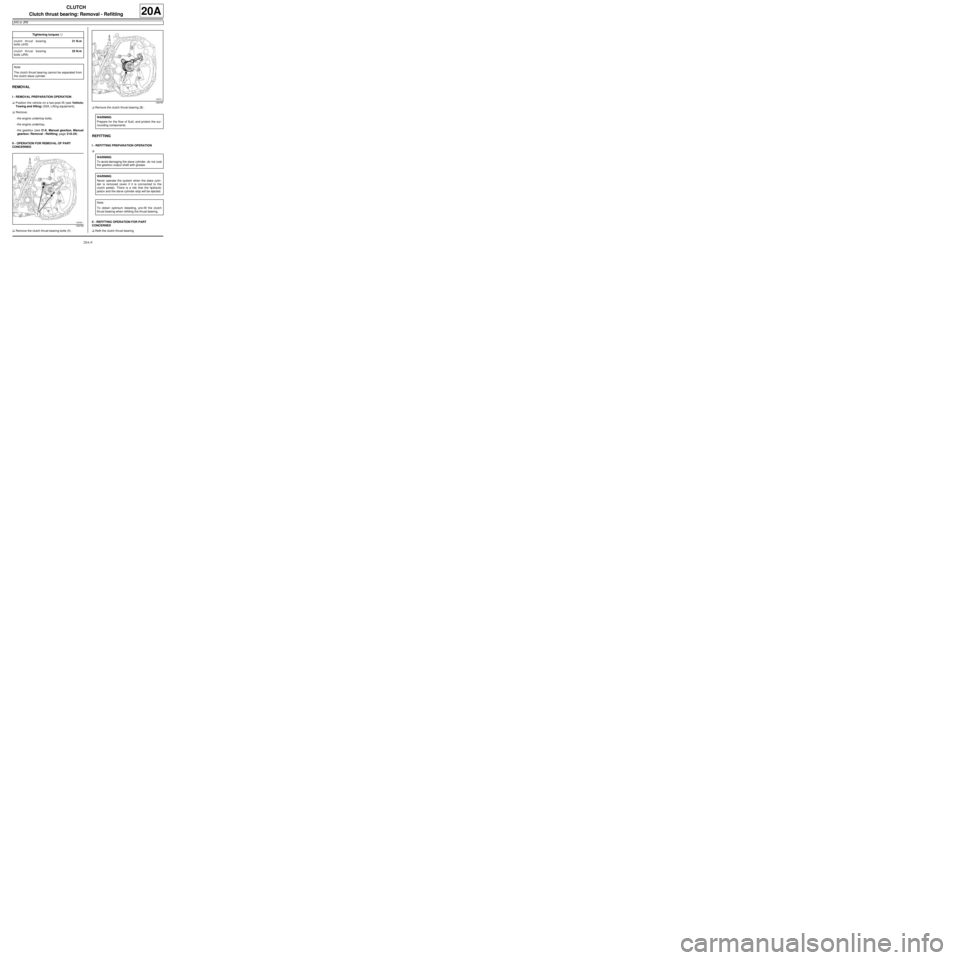

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray bolts,

-the engine undertray,

-the gearbox (see 21A, Manual gearbox, Manual

gearbox: Removal - Refitting, page 21A-24) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the clutch thrust bearing bolts (1) .aRemove the clutch thrust bearing (2) .

REFITTING

I - REFITTING PREPARATION OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the clutch thrust bearing. Tightening torquesm

clutch thrust bearing

bolts (JH3)21 N.m

clutch thrust bearing

bolts (JR5)25 N.m

Note:

The clutch thrust bear ing cannot be separated from

the clutch slave cylinder.

108796

108797

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

WARNING

To avoid damaging the slave cylinder, do not coat

the gearbox output shaft with grease.

WARNING

Never operate the system when the slave cylin-

der is removed (even if it is connected to the

clutch pedal). There is a risk that the hydraulic

piston and the sla ve cylinder stop will be ejected.

Note:

To obtain optimum bleeding, pre-fill the clutch

thrust bearing when refitting the thrust bearing.

Page 13 of 135

20A-10

CLUTCH

Clutch thrust bearing: Removal - Refitting

JH3 or JR5

20A

aTorque tighten the clutch thrust bearing bolts

(JH3) (21 N.m).

aTorque tighten the clutch thrust bearing bolts

(JR5) (25 N.m).

III - FINAL OPERATION.

aRefit the gearbox (see 21A, Manual gearbox, Man-

ual gearbox: Removal - Refitting, page 21A-24) .

aBleed the clutch control (see Clutch circuit: Bleed)

(37A, Mechanical component controls).

aRefit the engine undertray. JH3

JR5

Page 14 of 135

20A-11

CLUTCH

Clutch thrust bearing: Removal - Refitting

JB1

20A

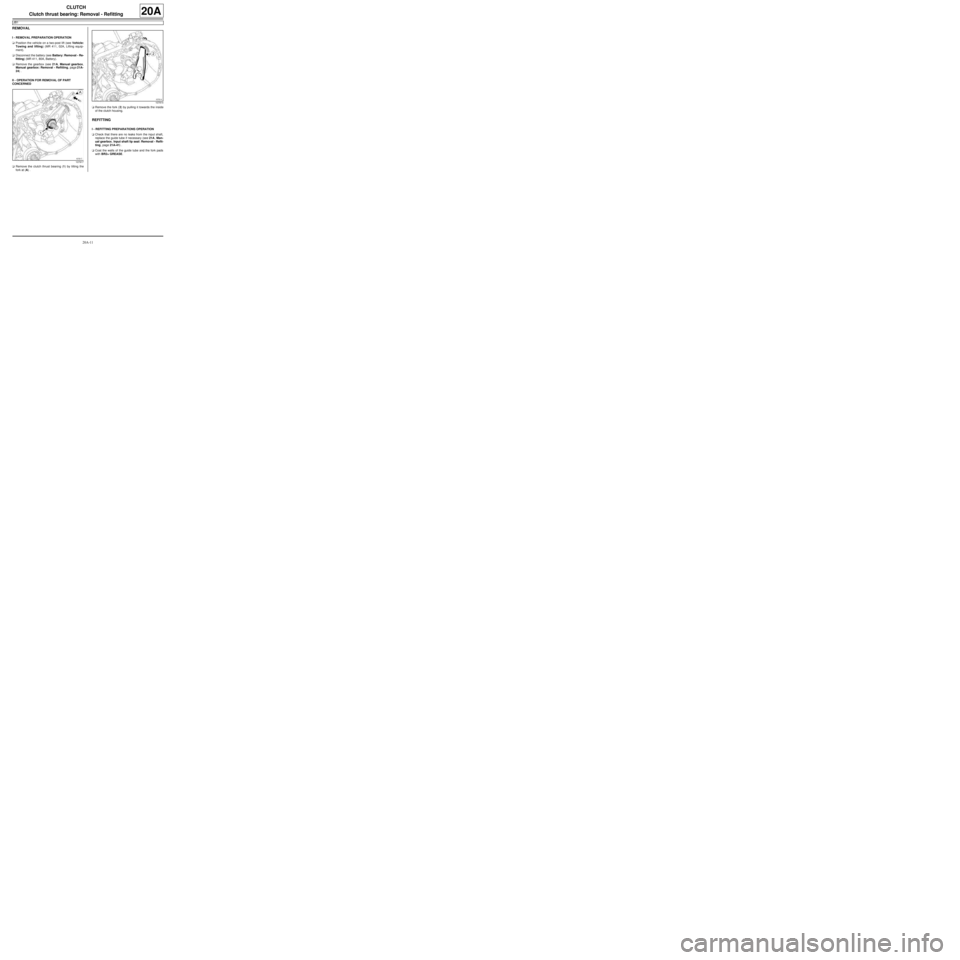

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove the gearbox (see 21A, Manual gearbox,

Manual gearbox: Removal - Refitting, page 21A-

24) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the clutch thrust bearing (1) by tilting the

fork at (A) .aRemove the fork (2) by pulling it towards the inside

of the clutch housing.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aCheck that there are no leaks from the input shaft,

replace the guide tube if necessary (see 21A, Man-

ual gearbox, Input shaft lip seal: Removal - Refit-

ting, page 21A-41) .

aCoat the walls of the guide tube and the fork pads

with BR2+ GREASE.

107917

107914

Page 15 of 135

20A-12

CLUTCH

Clutch thrust bearing: Removal - Refitting

JB1

20A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the fork.

aRefit:

-the fork,

-the stop on the guide tube, placing the hooks (3)

into the fork.

aEnsure that it slides correctly.

III - FINAL OPERATION.

aRefit the gearbox (see 21A, Manual gearbox, Man-

ual gearbox: Removal - Refitting, page 21A-24) .aAfter refitting the gearbox, check the travel (X) of the

fork.

This must be:

-D4F engine: x = 29.5 mm ±± ± ±

0.5,

-D7F engine: x = 29.5 mm ±± ± ±

0.5.

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

107916

Note:

During operations where the gearbox does not

have to be removed or refitted, do not lift the fork

because this may cause the hooks to come out

(3) of the thrust bearing.

91830

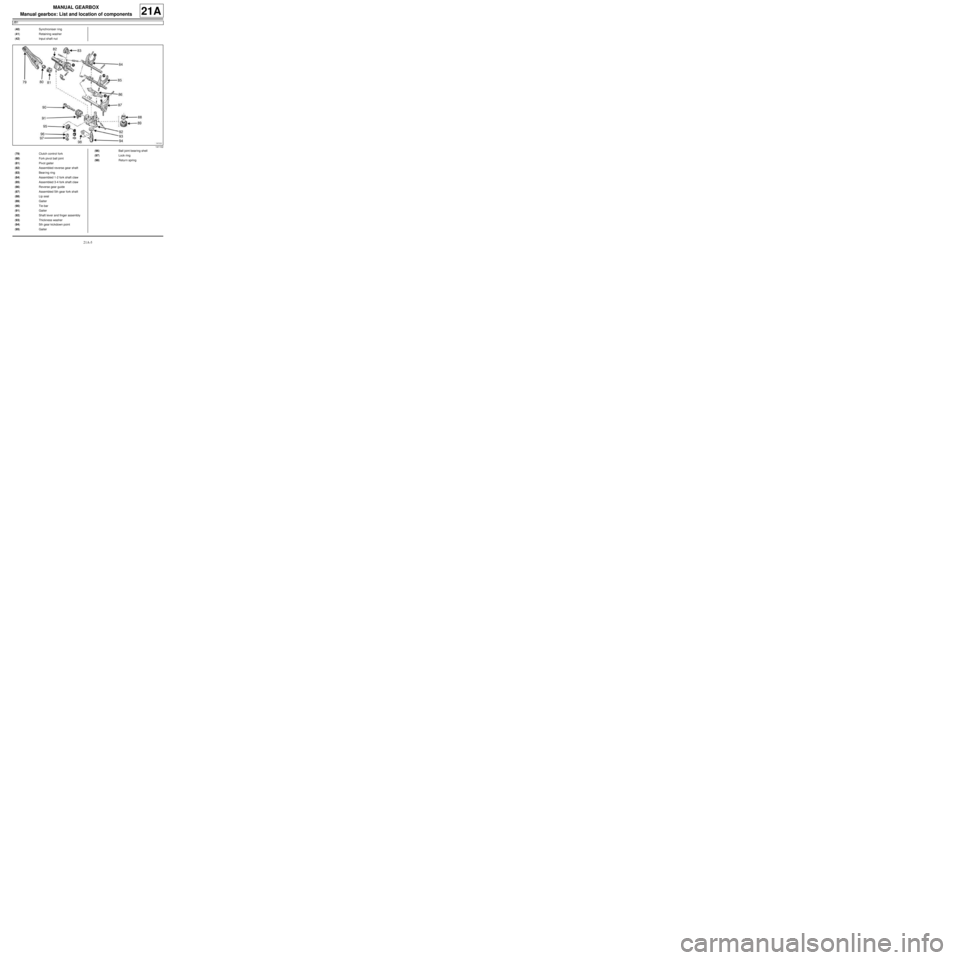

Page 20 of 135

21A-5

MANUAL GEARBOX

Manual gearbox: List and location of components

JB1

21A

(40) Synchroniser r ing

(41) Retaining washer

(42) Input shaft nut

141102

(79) Clutch control fork

(80) Fork pivot ball joint

(81) Pivot gaiter

(82) Assembled reverse gear shaft

(83) Bear ing ring

(84) Assembled 1-2 fork shaft claw

(85) Assembled 3-4 fork shaft claw

(86) Reverse gear guide

(87) Assembled 5th gear fork shaft

(88) Lip seal

(89) Gaiter

(90) Tie-bar

(91) Gaiter

(92) Shaft lever and finger assembly

(93) Thickness washer

(94) 5th gear kickdown point

(95) Gaiter (96) Ball joint bearing shell

(97) Lock ring

(98) Retur n spring

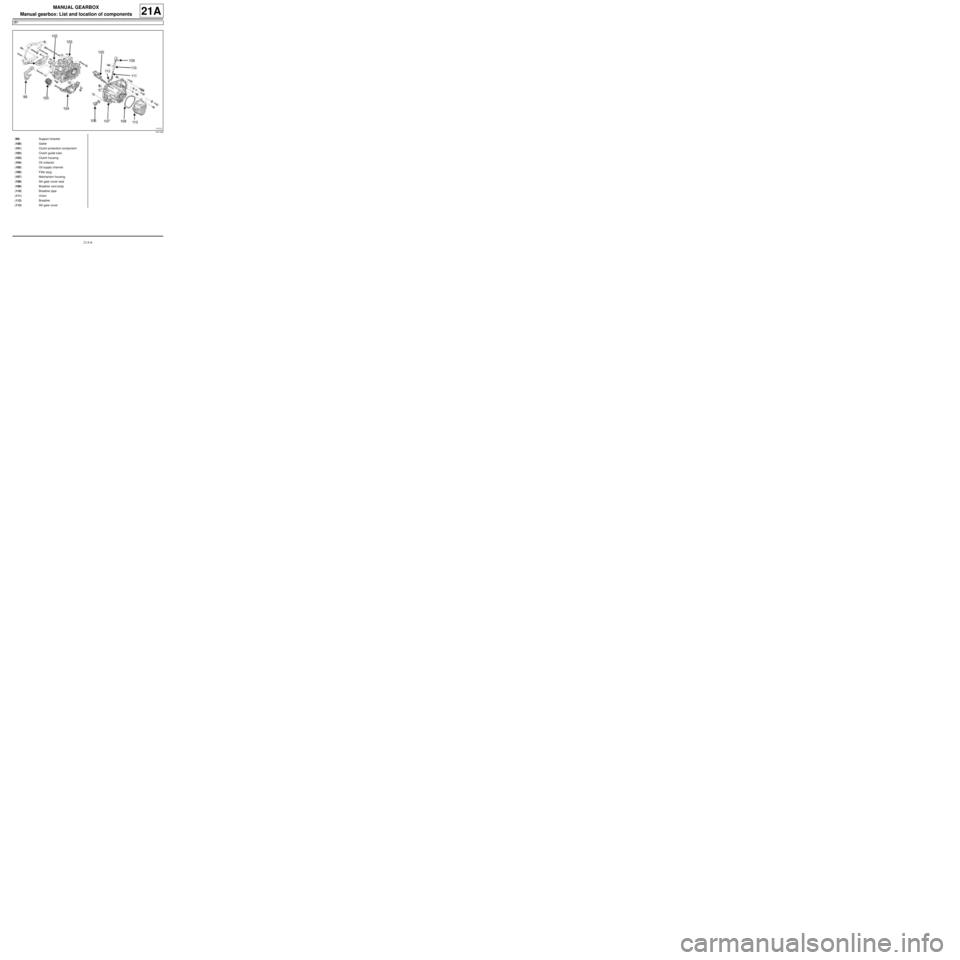

Page 21 of 135

21A-6

MANUAL GEARBOX

Manual gearbox: List and location of components

JB1

21A

141103

(99) Suppor t bracket

(100) Gaiter

(101) Clutch protection component

(102) Clutch guide tube

(103) Clutch housing

(104) Oil collector

(105) Oil supply channel

(106) Filler plug

(107) Mechanism housing

(108) 5th gear cover seal

(109) Breather vent body

(110) Breather pipe

(111) Union

(112) Breather

(113) 5th gear cover

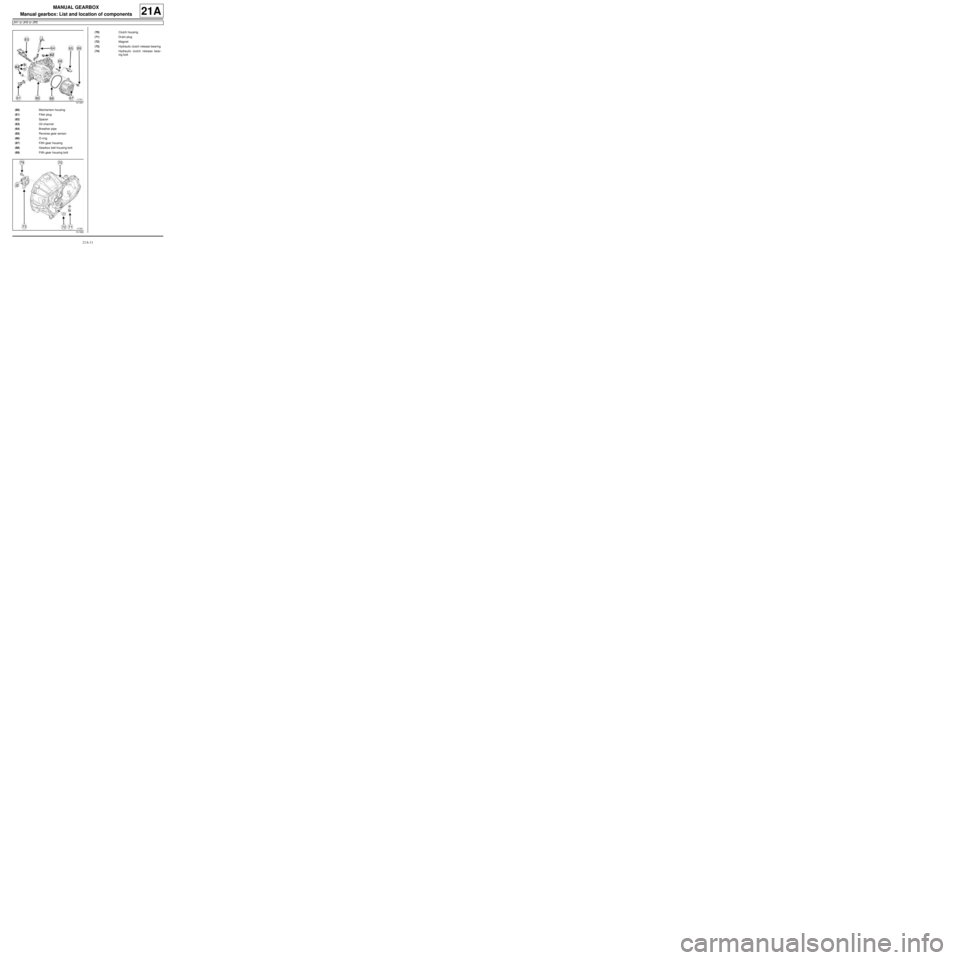

Page 26 of 135

21A-11

MANUAL GEARBOX

Manual gearbox: List and location of components

JH1 or JH3 or JR5

21A

101391

(60) Mechanism housing

(61) Filler plug

(62) Spacer

(63) Oil channel

(64) Breather pipe

(65) Reverse gear sensor

(66) O-r ing

(67) Fifth gear housing

(68) Gearbox bell housing bolt

(69) Fifth gear housing bolt

101392

(70) Clutch housing

(71) Drain plug

(72) Magnet

(73) Hydraulic clutch release bearing

(74) Hydraulic clutch release bear-

ing bolt

Page 39 of 135

21A-24

MANUAL GEARBOX

Manual gearbox: Removal - Refitting

K9K, and JH3 or JR5

21A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery).

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aDisconnect the engine management computer con-

nectors.

aRemove:

-the engine management computer mounting bolts,

-the engine management computer mounting nuts.

aRemove the engine management computer mount-

ing.

aRemove the engine management computer wiring

harness nut from the engine management computer

mounting.

aRemove the engine management computer wiring

harness.

aRemove the engine management computer mount-

ing fitted with the engine management computer.aUnclip:

-the clutch hydraulic control pipe on the gearbox (1)

,

-the union (2) on the hydraulic tappet slave cylinder,

-the gearbox breather.

aRemove:

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection).

aDrain the gearbox oil (see 21A, Manual gearbox,

Manual gearbox oils: Draining - Filling, page

21A-2) .

aRemove:

-the hub carrier - front left-hand and front right-hand

driveshaft assemblies (see ) (31A, Front axle com-

ponents),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting). Special tooling required

Mot. 1453Engine anchorage support

with m ultiple adjustments and

retaining str aps.

Equipment required

component jack

Tightening torquesm

lower gearbox bolts44 N.m

gearbox nuts and bolts44 N.m

gearbox upper bolts44 N.m

121410

Page 41 of 135

21A-26

MANUAL GEARBOX

Manual gearbox: Removal - Refitting

K9K, and JH3 or JR5

21A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the gearbox using a component jack,

-the gearbox stud nuts,

-the gearbox lower bolts.

aTorque tighten:

-the lower gearbox bolts (44 N.m),

-the gearbox nuts and bolts (44 N.m).

aRefit the upper gearbox bolts.

aTorque tighten the gearbox upper bolts (44 N.m).

aRefit the earth strap bolt on the gearbox.

aConnect:

-the reverse gear switch connector,

-the speed and position sensor connector.

aClip the gearbox controls into place.

II - FINAL OPERATION

aRefit:

-the subframe (see Front axle subframe: Removal

- Refitting) (31A, Front axle components),

-the left-hand suspended engine mounting (see

Left-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting).

aRemove the tool (Mot. 1453).

aRefit:

-the upstream strut of the catalytic converter by slid-

ing it upwards,

-the catalytic converter upstream strut bolt on the

catalytic converter.

aTighten the bolt and nut on the upstream strut of the

catalytic converter on the gearbox.

aRefit:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting),

-the hub carrier - front left-hand and front right-hand

driveshaft assemblies (see ) (31A, Front axle com-

ponents),

-the starter (see Starter: Removal - Refitting)

(16A, Starting - Charging),-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aClip:

-the union onto the hydraulic tappet slave cylinder,

-the hydraulic clutch control pipe,

-the gearbox breather.

aBleed the clutch (see Clutch circuit: Bleed) (37A,

Mechanical component controls).

aRefit the engine management computer mounting

fitted with the engine management computer.

aFit the engine management computer wiring har-

ness.

aRefit the engine management computer wiring har-

ness nut on the engine management computer

mounting.

aFit the engine management computer mounting.

aRefit:

-the engine management computer mounting bolts,

-the engine management computer mounting nuts.

aConnect the engine management computer connec-

tors.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

aFill up the gearbox oil (see 21A, Manual gearbox,

Manual gearbox oils: Draining - Filling, page

21A-2) .

aRefit:

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the battery (see Battery: Removal - Refitting)

(80A, Battery).