clutch RENAULT TWINGO RS 2009 2.G Transmission Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 135

Page 42 of 135

21A-27

MANUAL GEARBOX

Manual gearbox: Removal - Refitting

D4F, and JB1 – D7F, and JB1

21A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove the air filter unit (see Air filter unit: Re-

moval - Refitting) (MR 411, 12A, Fuel mixture).

aRemove:

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment).aDisconnect the engine management computer con-

nectors.

aRemove:

-the engine management computer mounting bolts,

-the engine management computer mounting nuts.

aRemove the engine management computer mount-

ing.

aRemove the engine management computer wiring

harness nut from the engine management computer

mounting.

aRemove the engine management computer wiring

harness.

aRemove the engine management computer mount-

ing fitted with the engine management computer.

aUnclip:

-the clutch cable,

-the gearbox breather.

aRemove:

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection).

aDrain the gearbox oil (see 21A, Manual gearbox,

Manual gearbox oils: Draining - Filling, page

21A-2) .

aRemove:

-the hub carrier - front left-hand and front right-hand

driveshaft assemblies (see ) (MR 411, 31A, Front

axle components),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the starter (see Starter: Removal - Refitting) (MR

411, 16A, Starting - Charging). Special tooling required

Mot. 1453Engine anchorage support

with m ultiple adjustments and

retaining str aps.

Equipment required

component jack

Tightening torquesm

gearbox mountings44 Nm

D4F

Page 43 of 135

21A-28

MANUAL GEARBOX

Manual gearbox: Removal - Refitting

D4F, and JB1 – D7F, and JB1

21A

aFit the (Mot. 1453) :

-positioning it on the front wing opening stops and

on the headlight brackets,

-using the two engine lifting eyes to avoid the

« engine - gearbox » assembly tilting too much,

-making sure the tool is strapped to the vehicle.

aRemove:

-the left-hand suspended engine mounting (see

Left-hand suspended engine mounting: Re-

moval - Refitting) (MR 411, 19D, Engine mount-

ing),

-the subframe (see Front axle subframe: Removal

- Refitting) (MR 411, 31A, Front axle component).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the reverse gear switch connector.

aRemove:

-the earth strap bolt on the gearbox,

-the gearbox upper bolts,

-the engine speed and position sensor (see Crank-

shaft position sensor: Removal - Refitting) (MR

411, 17B, Petrol injection).

-the gearbox lower bolts,

-the flywheel protection plate bolts,

-the flywheel protection plate,

-the gearbox stud nuts,

-the gearbox using a component jack.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the gearbox using a component jack.

-the gearbox mountings.

aTorque tighten the gearbox mountings (44 Nm).

aRefit:

-the engine speed and position sensor (see Crank-

shaft position sensor: Removal - Refitting) (MR

411, 17B, Petrol injection),

-the earth strap bolt on the gearbox.

aConnect the reverse gear switch connector.

II - FINAL OPERATION.

aRefit:

-the subframe (see Front axle subframe: Removal

- Refitting) (MR 411, 31A, Front axle compo-

nents),

-the left-hand suspended engine mounting (see

Left-hand suspended engine mounting: Re-

moval - Refitting) (MR 411, 19D, Engine mount-

ing).

aRemove the (Mot. 1453).

aRefit:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the hub carrier - front left-hand and front right-hand

driveshaft assemblies (see ) (MR 411, 31A, Front

axle components),

-the starter (see Starter: Removal - Refitting) (MR

411, 16A, Starting - Charging),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres).

aClip:

-the clutch cable,

-the gearbox breather.

121415

Page 47 of 135

21A-32

MANUAL GEARBOX

Manual gearbox: Removal - Refitting

K4M, and JR5

21A

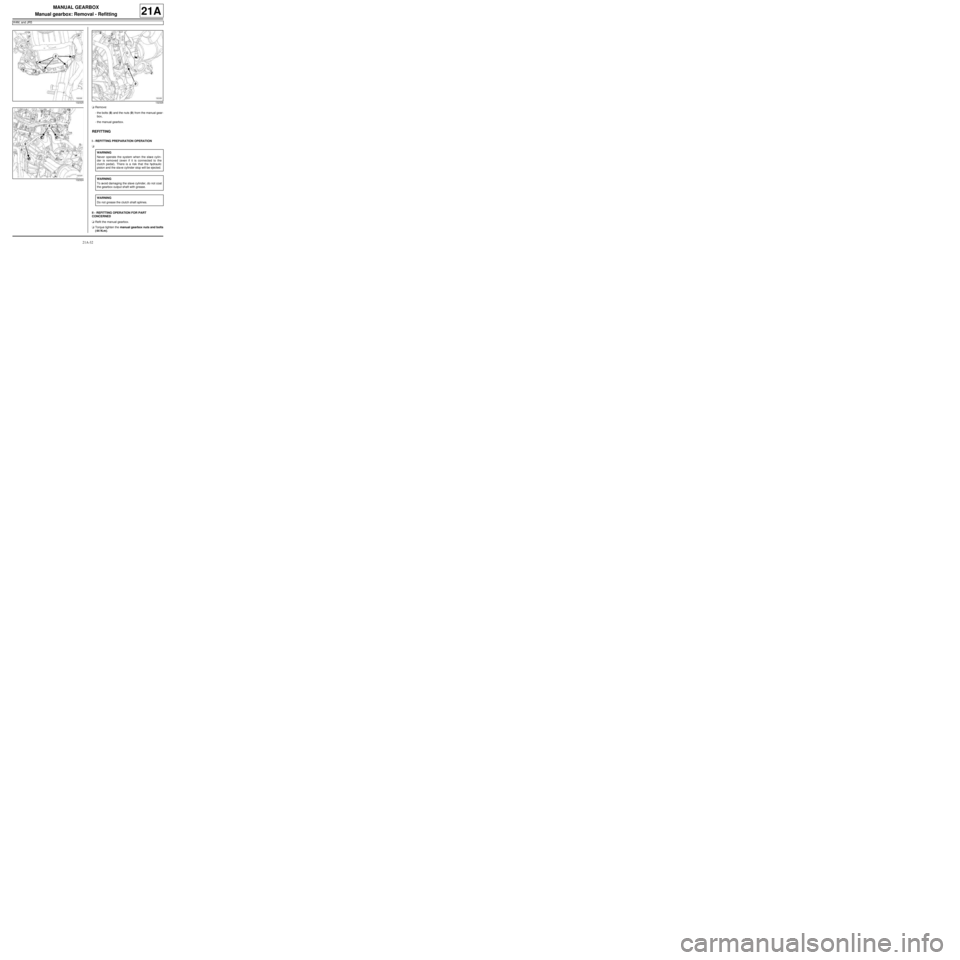

aRemove:

-the bolts (8) and the nuts (9) from the manual gear-

box,

-the manual gearbox.

REFITTING

I - REFITTING PREPARATION OPERATION

a

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the manual gearbox.

aTorque tighten the manual gearbox nuts and bolts

(44 N.m).

132325

132324132326

WARNING

Never operate the system when the slave cylin-

der is removed (even if it is connected to the

clutch pedal). There is a risk that the hydraulic

piston and the sla ve cylinder stop will be ejected.

WARNING

To avoid damaging the slave cylinder, do not coat

the gearbox output shaft with grease.

WARNING

Do not grease the clutch shaft splines.

Page 49 of 135

21A-34

MANUAL GEARBOX

Manual gearbox: Repair

JB1

21A

REMOVAL

I - REPAIR PREPARATION OPERATION

aRemove the gearbox (see 21A, Manual gearbox,

Manual gearbox: Removal - Refitting, page 21A-

24) .

aPosition the gearbox on the component support (see

Gearbox support equipment: Use) .

II - REMOVAL OPERATION.

aRemove:

-the fifth gear housing (see 5th gear housing: Re-

moval - Refitting) ,

-the fifth gear synchroniser and pinions (see 5th

gear sprockets and synchronisers: Removal -

Refitting) ,

-the mechanism housing (see Mechanism hous-

ing: Removal - Refitting) ,

-the gearbox shafts (see Gearbox shaft: Removal

- Refitting) ,

-the differential (see Manual gearbox differential:

Removal - Refitting) .

III - REPAIR OPERATION

aStrip down the output shaft (see Output shaft:

Stripping - Rebuilding) .

aCheck the shafts (see Manual gearbox: Check) .

aRemove:

-the differential bearings (see Manual gearbox dif-

ferential bearing: Removal - Refitting) ,

-the bearings of the mechanism housing (see

Mechanism housing bearing: Removal - Refit-

ting) ,

-the bearings of the clutch housing (see Clutch

housing bearing: Removal - Refitting) ,

-the manual gearbox selector shaft (see Manual

gearbox selector shaft: Removal - Refitting) .

REFITTING

I - REFITTING PREPARATION OPERATION

aClean all the removed parts (see Manual gearbox:

Precautions for the repair) .

aReplace worn or damaged parts.

aParts always to be replaced:

-the lip seals,

-the O-rings,

-the clutch thrust bearing guide,

-the gear lock rings,

-the roll pins,

-the input and output shaft bearing circlips,

-the synchroniser hub springs,

-the removed bearings,

-the selector shaft rings,

-the spy seals,

-the hydraulic clutch thrust bearing (if equipped),

-the magnet.

II - REFITTING OPERATION

aRefit:

-the gearbox selector shaft (see Manual gearbox

selector shaft: Removal - Refitting) ,

-the bearings of the clutch housing (see Clutch

housing bearing: Removal - Refitting) ,

-the bearings of the mechanism housing (see

Mechanism housing bearing: Removal - Refit-

ting) ,

-the differential bearings (see Manual gearbox dif-

ferential bearing: Removal - Refitting) ,

-the differential (see Manual gearbox differential:

Removal - Refitting) .

aRebuild the output shaft (see Output shaft: Strip-

ping - Rebuilding) .

aRefit:

-the gearbox shafts (see Gearbox shaft: Removal

- Refitting) ,

-the mechanism housing (see Mechanism hous-

ing: Removal - Refitting) ,

-the fifth gear synchroniser and pinions (see 5th

gear sprockets and synchronisers: Removal -

Refitting) , IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see Manual gearbox: Precautions for the

repair) .

Page 51 of 135

21A-36

MANUAL GEARBOX

Manual gearbox: Repair

JH1 or JH3 or JR5

21A

REMOVAL

I - REPAIR PREPARATION OPERATION

aRemove the gearbox (see 21A, Manual gearbox,

Manual gearbox: Removal - Refitting, page 21A-

24) .

aPosition the gearbox on the component support (see

Gearbox support equipment: Use) .

II - REMOVAL OPERATION

aRemove:

-the fifth gear housing (see 5th gear housing: Re-

moval - Refitting) ,

-the fifth gear synchroniser and pinions (see 5th

gear sprockets and synchronisers: Removal -

Refitting) ,

-the mechanism housing (see Mechanism hous-

ing: Removal - Refitting) ,

-the gearbox shafts (see Gearbox shaft: Removal

- Refitting) ,

-the differential (see Manual gearbox differential:

Removal - Refitting) .

III - REPAIR OPERATION

aStrip down the output shaft (see Output shaft:

Stripping - Rebuilding) .

aRemove:

-the differential bearings (see Manual gearbox dif-

ferential bearing: Removal - Refitting) ,

-the bearings of the mechanism housing (see

Mechanism housing bearing: Removal - Refit-

ting) ,

-the bearings of the clutch housing (see Clutch

housing bearing: Removal - Refitting) ,

-the gearbox selector shaft (see Manual gearbox

selector shaft: Removal - Refitting) .aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) to clean all of the

removed parts.

aCheck (see Manual gearbox: Check) :

-the pinions (teeth, claws, friction cone, inner wall),

-the synchroniser hubs,

-the synchroniser rings,

-the bearings.

aReplace worn or damaged parts.

REFITTING

I - REFITTING PREPARATION OPERATION

aParts always to be replaced:

-the lip seals,

-the O-rings,

-the clutch thrust bearing guide,

-the gear lock rings,

-the roll pins,

-the input and output shaft bearing circlips,

-the selector rod hub springs,

-the hydraulic clutch slave cylinder (if fitted),

-the magnet,

-the selector shaft rings,

-the lock ring of the differential,

-the differential retaining nut.

II - REFITTING OPERATION

aRefit:

-the gearbox selector shaft (see Manual gearbox

selector shaft: Removal - Refitting) ,

-the bearings of the clutch housing (see Clutch

housing bearing: Removal - Refitting) ,

-the bearings of the mechanism housing (see

Mechanism housing bearing: Removal - Refit-

ting) ,

-the differential bearings (see Manual gearbox dif-

ferential bearing: Removal - Refitting) .

aRebuild the output shaft (see Output shaft: Strip-

ping - Rebuilding) . IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair (see Manual gearbox: Precautions for the

repair) .

Page 57 of 135

21A-42

MANUAL GEARBOX

Input shaft lip seal: Removal - Refitting

JB1

21A

aPlace the tightening clamp (3) onto the tube.

aLock the tightening clamp using the spanner (4) .

aTighten the nut firmly (5) .

aPosition the sleeve (6) and the split ring (7) .

aTurn the upper nut (8) .

aGently extract the guide tube.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aPosition the new guide tube on the clutch housing.

aGently remove the guide tube with a press and the

(Bvi. 1828).

II - FINAL OPERATION.

aRefit the gearbox (see 21A, Manual gearbox, Man-

ual gearbox: Removal - Refitting, page 21A-24)

(MR 411, 21A, Manual gearbox).

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

98937

98938

98939

98935-1

Page 58 of 135

21A-43

MANUAL GEARBOX

Input shaft lip seal: Removal - Refitting

JH1 or JH3 or JR5

21A

aReplace the lip seal after having opened the gear-

box (see Clutch housing bearing: Removal - Re-

fitting) (Technical Note 6029A, 21A, Manual

gearbox).

Page 62 of 135

21B-2

SEQUENTIAL GEARBOX

Sequential gearbox: List and location of components

D4F, and JH1

21B

122171

(1) Actuator module high pressure

supply pipe

(2) Clutch stay high pressure supply

pipe

(3) Reservoir retur n hose

(4) Engagement solenoid v alve 2

(5) Solenoid valve unit pressure

sensor

(6) Clutch position sensor

(7) Tank

122172

(8) Pump unit

(9) Actuator module

(10) Gear selection sensor

(11) Clutch solenoid valve

(12) Engagement solenoid valve 1

(13) Selection solenoid valve 3

(14) Selection solenoid valve 4

(15) Engagement sensor

122160

(16) Sequential gearbox speed sen-

sor

Page 73 of 135

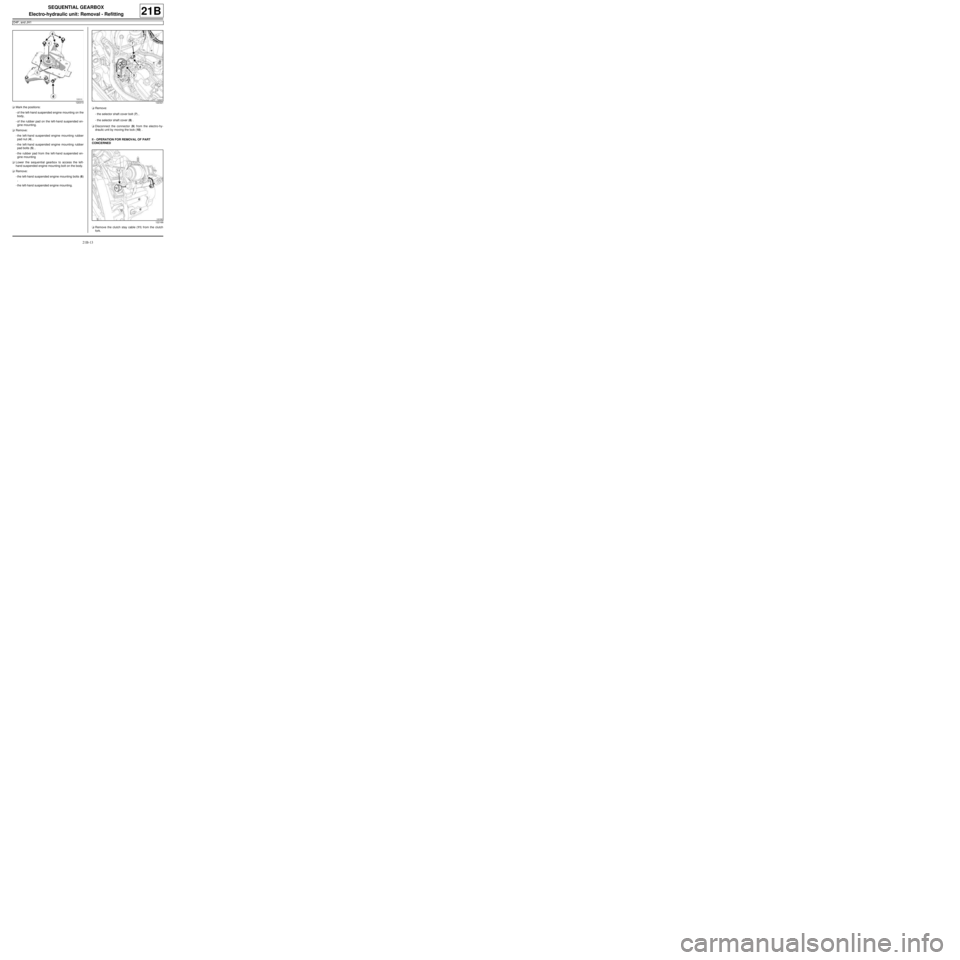

21B-13

SEQUENTIAL GEARBOX

Electro-hydraulic unit: Removal - Refitting

D4F, and JH1

21B

aMark the positions:

-of the left-hand suspended engine mounting on the

body,

-of the rubber pad on the left-hand suspended en-

gine mounting.

aRemove:

-the left-hand suspended engine mounting rubber

pad nut (4) ,

-the left-hand suspended engine mounting rubber

pad bolts (5) ,

-the rubber pad from the left-hand suspended en-

gine mounting

aLower the sequential gearbox to access the left-

hand suspended engine mounting bolt on the body.

aRemove:

-the left-hand suspended engine mounting bolts (6)

,

-the left-hand suspended engine mounting.aRemove:

-the selector shaft cover bolt (7) ,

-the selector shaft cover (8) .

aDisconnect the connector (9) from the electro-hy-

draulic unit by moving the lock (10) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the clutch stay cable (11) from the clutch

fork.

120310122321

122168

Page 76 of 135

21B-16

SEQUENTIAL GEARBOX

Electro-hydraulic unit: Removal - Refitting

D4F, and JH1

21B

aIt is essential to replace the electro-hydraulic unit

seal.

aPlace the actuator module selector shaft in a raised

and locked position.

II - REFITTING OPERATION FOR PART

CONCERNED

aFit:

-the new electro-hydraulic unit seal,

-the electro-hydraulic unit.

aRefit:

-the sequential gearbox lifting eye on the sequential

gearbox,

-the breather pipe on the sequential gearbox.

-the electro-hydraulic unit nuts,

-the electro-hydraulic unit bolts.

aConnect the sequential gearbox speed sensor con-

nector.

aAttach the breather pipe:

-to the cooling hose,

-to the sequential gearbox lifting eye.aPress on the selector shaft with a screwdriver to clip

the sequential gearbox selector shaft to the actuator

module.

aRefit the clutch stay cable to the clutch fork.

aConnect the electro-hydraulic unit connector by

moving the lock.

III - FINAL OPERATION

aRefit:

-the selector shaft cover,

-the selector shaft cover bolt.

aFit the left-hand suspended mounting on the body.

aFit the left-hand suspended engine mounting bolts

without tightening them.

aTorque tighten the left-hand suspended engine

mounting bolts (21 N.m).

aRaise the sequential gearbox to its original position.

aFit the left-hand suspended engine mounting rubber

pad.

aFit the left-hand suspended engine mounting rubber

pad bolts without tightening them.

aTorque tighten the left-hand suspended engine

mounting rubber pad bolts ( 62 N.m).

aFit the left-hand suspended engine mounting rubber

pad nut without tightening it.

aTorque tighten the left-hand suspended engine

mounting rubber pad nut (105 N.m ).

17970

17970