sensor RENAULT TWINGO RS 2009 2.G Transmission Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 135

Page 96 of 135

21B-36

SEQUENTIAL GEARBOX

Solenoid valve assembly pressure sensor: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection).

aUnclip:

-the cooling hose from the petrol injection computer

mounting,

-the sequential gearbox computer wiring harness

from the petrol injection computer mounting,

-the petrol injection computer wiring harness from

the petrol injection computer mounting,-the battery wiring harness from the petrol injection

computer mounting.

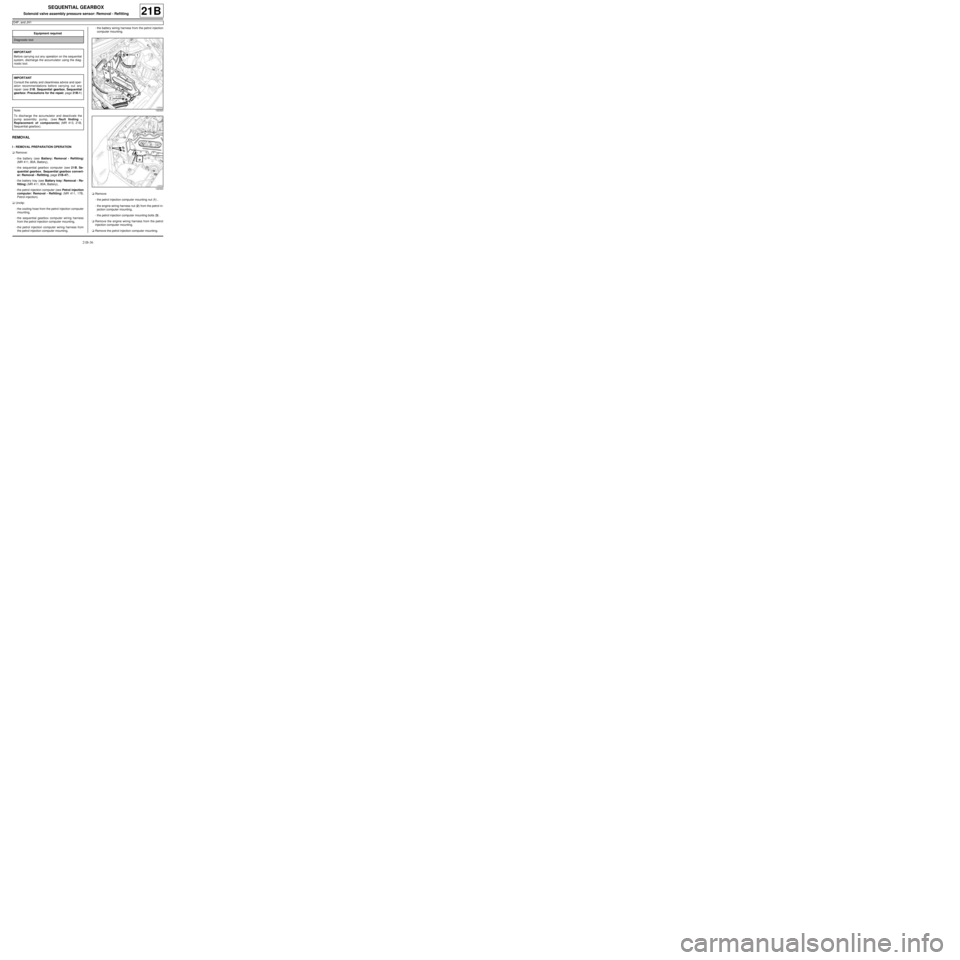

aRemove:

-the petrol injection computer mounting nut (1) ,

-the engine wiring harness nut (2) from the petrol in-

jection computer mounting,

-the petrol injection computer mounting bolts (3) .

aRemove the engine wiring harness from the petrol

injection computer mounting.

aRemove the petrol injection computer mounting. Equipment required

Diagnostic tool

IMPORTANT

Before carrying out any operation on the sequential

system, discharge the accumulator using the diag-

nostic tool.

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

Note:

To discharge the accumulator and deactivate the

pump assembly pump, (see Fault finding -

Replacement of components) (MR 413, 21B,

Sequential gearbox).

122323

122322

Page 97 of 135

21B-37

SEQUENTIAL GEARBOX

Solenoid valve assembly pressure sensor: Removal - Refitting

D4F, and JH1

21B

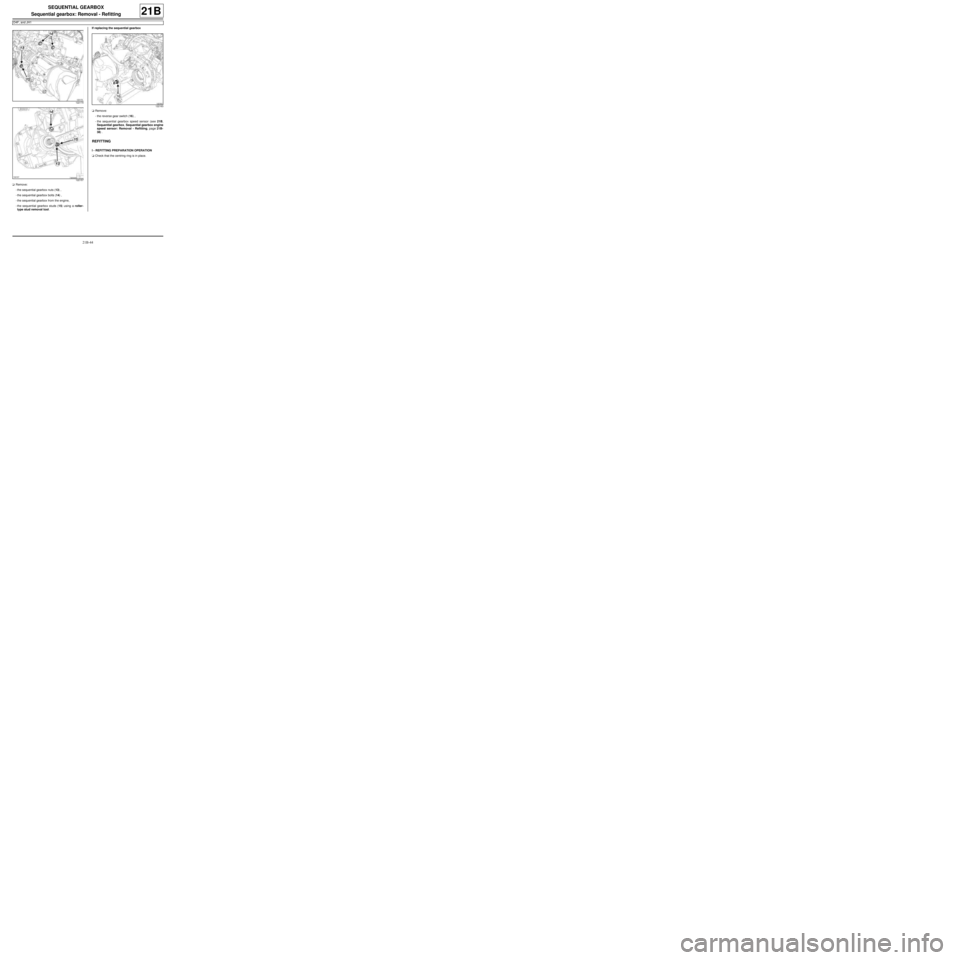

II - OPERATION FOR REMOVAL OF PART

CONCERNED

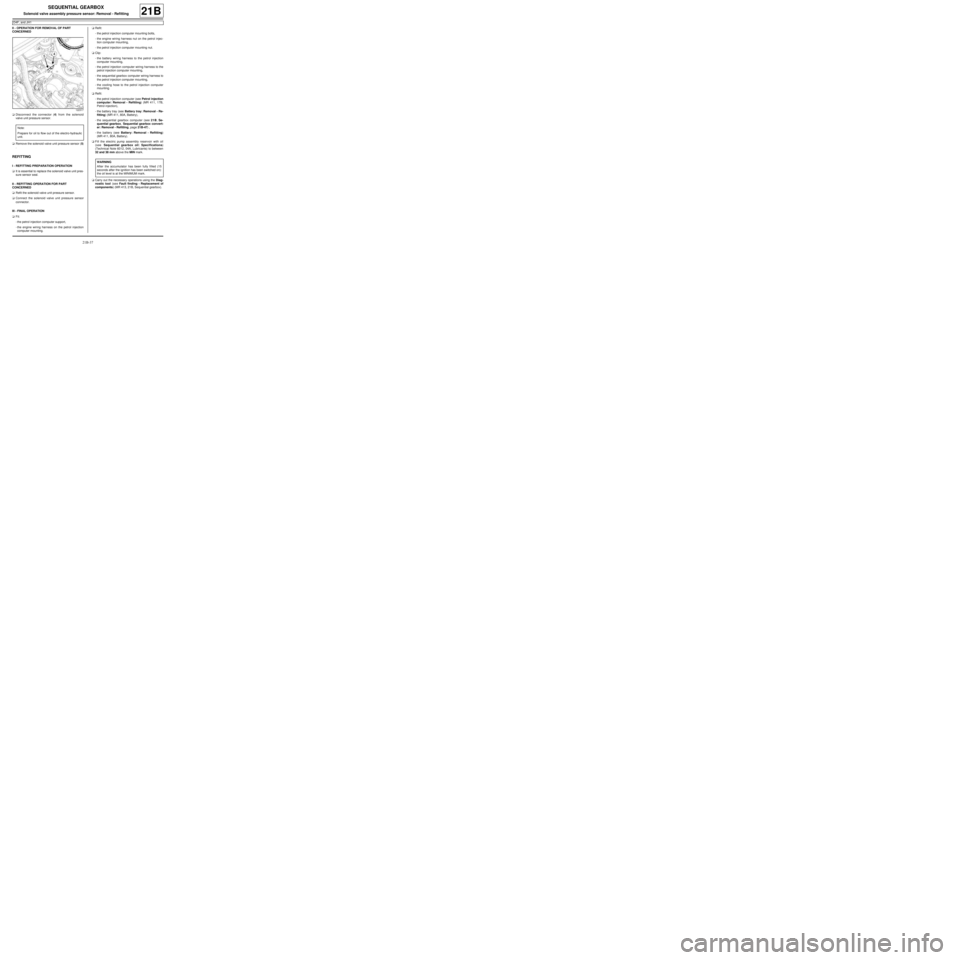

aDisconnect the connector (4) from the solenoid

valve unit pressure sensor.

aRemove the solenoid valve unit pressure sensor (5)

.

REFITTING

I - REFITTING PREPARATION OPERATION

aIt is essential to replace the solenoid valve unit pres-

sure sensor seal.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the solenoid valve unit pressure sensor.

aConnect the solenoid valve unit pressure sensor

connector.

III - FINAL OPERATION

aFit:

-the petrol injection computer support,

-the engine wiring harness on the petrol injection

computer mounting.aRefit:

-the petrol injection computer mounting bolts,

-the engine wiring harness nut on the petrol injec-

tion computer mounting,

-the petrol injection computer mounting nut.

aClip:

-the battery wiring harness to the petrol injection

computer mounting,

-the petrol injection computer wiring harness to the

petrol injection computer mounting,

-the sequential gearbox computer wiring harness to

the petrol injection computer mounting,

-the cooling hose to the petrol injection computer

mounting.

aRefit:

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

aFill the electric pump assembly reservoir with oil

(see Sequential gearbox oil: Specifications)

(Technical Note 6012, 04A, Lubricants) to between

32 and 38 mm above the MIN mark.

aCarry out the necessary operations using the Diag-

nostic tool (see Fault finding - Replacement of

components) (MR 413, 21B, Sequential gearbox).

122317

Note:

Prepare for oil to flow out of the electro-hydraulic

unit.

WARNING

After the accumulator has been fully filled (15

seconds after the ignition has been switched on):

the oil level is at the MINIMUM mark.

Page 98 of 135

21B-38

SEQUENTIAL GEARBOX

Sequential gearbox engine speed sensor: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Re-

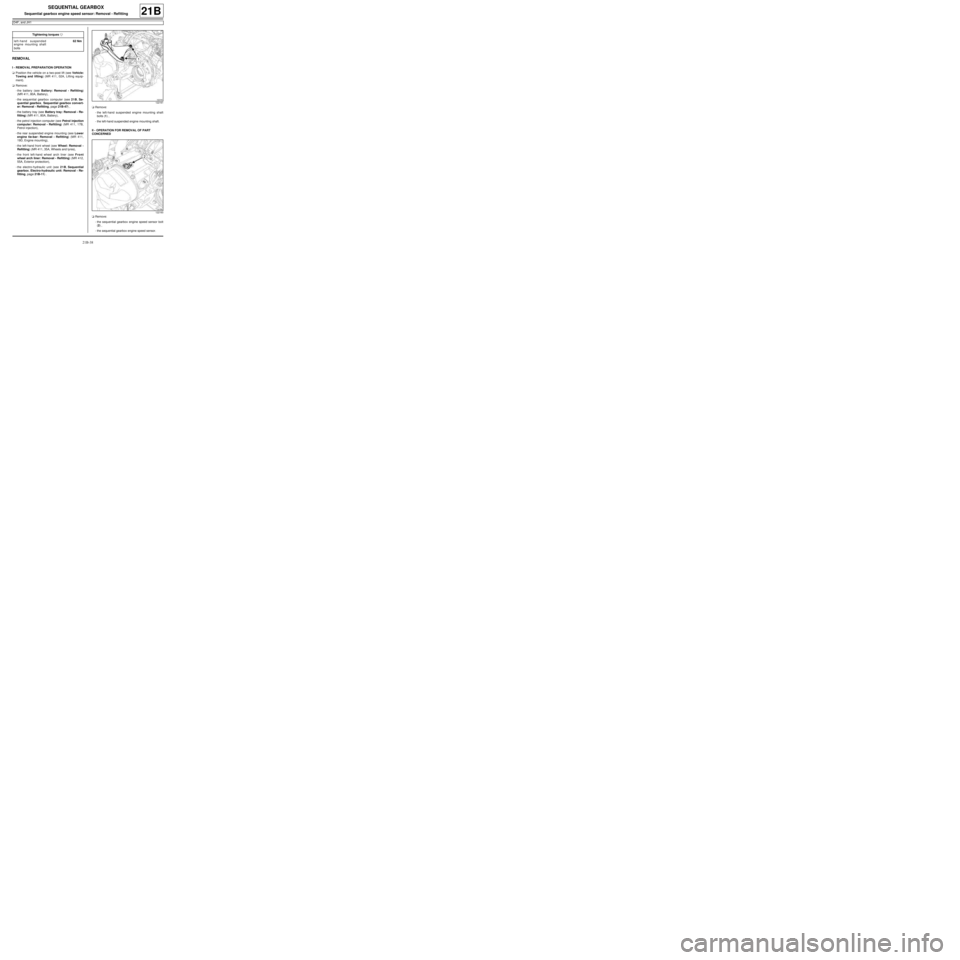

fitting, page 21B-11) .aRemove:

-the left-hand suspended engine mounting shaft

bolts (1) ,

-the left-hand suspended engine mounting shaft.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the sequential gearbox engine speed sensor bolt

(2) ,

-the sequential gearbox engine speed sensor. Tightening torquesm

left-hand suspended

engine mounting shaft

bolts62 Nm

122161

122160

Page 99 of 135

21B-39

SEQUENTIAL GEARBOX

Sequential gearbox engine speed sensor: Removal - Refitting

D4F, and JH1

21B

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the sequential gearbox engine speed sensor,

-the sequential gearbox engine speed sensor bolt.

II - FINAL OPERATION

aFit the left-hand suspended engine mounting shaft

onto the sequential gearbox.

aFit the left-hand suspended engine mounting shaft

bolts without tightening them.

aTorque tighten the left-hand suspended engine

mounting shaft bolts (62 Nm).

aRefit:

-the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Re-

fitting, page 21B-11) ,

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the left-hand front wheel (see Wheel: Removal -

Refitting) (MR 411, 35A, Wheels and tyres),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (MR 411,

19D, Engine mounting),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

Page 100 of 135

21B-40

SEQUENTIAL GEARBOX

Sequential gearbox: Removal - Refitting

D4F, and JH1

21B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the catalytic converter (see Catalytic converter:

Removal - Refitting) ,

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection).

aDrain:

-the cooling system (see Cooling system: Drain-

ing - Refilling) (MR 411, 19A, Cooling),

-the sequential gearbox (see 21A, Manual gear-

box, Manual gearbox oils: Draining - Filling,

page 21A-2) .

aDrain the refrigerant circuit (see Refrigerant circuit:

Draining - Filling) (MR 411, 62A, Air conditioning).

aRemove:

-the engine - gearbox assembly (see Engine -

gearbox assembly: Removal - Refitting) (MR

411, 10A, Engine and peripherals),

-the hub-carrier - driveshaft assembly (see ) (MR

411, 31A, Front axle components),

-the starter (see Starter: Removal - Refitting) (MR

411, 16A, Starting - Charging),

-the crankshaft position sensor (see Crankshaft

position sensor: Removal - Refitting) (MR 411,

17B, Petrol injection). Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

workshop hoist

load balancer

roller-type stud removal tool

Tightening torquesm

sequential gearbox

studs7 Nm

sequential gearbox bolts44 Nm

sequential gearbox nuts44 Nm

flywheel protection plate

bolts (18)44 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 21B, Sequential gearbox, Sequential

gearbox: Precautions for the repair, page 21B-1)

.

AIR CONDITIONING or CLIMATE CONTROL

Page 104 of 135

21B-44

SEQUENTIAL GEARBOX

Sequential gearbox: Removal - Refitting

D4F, and JH1

21B

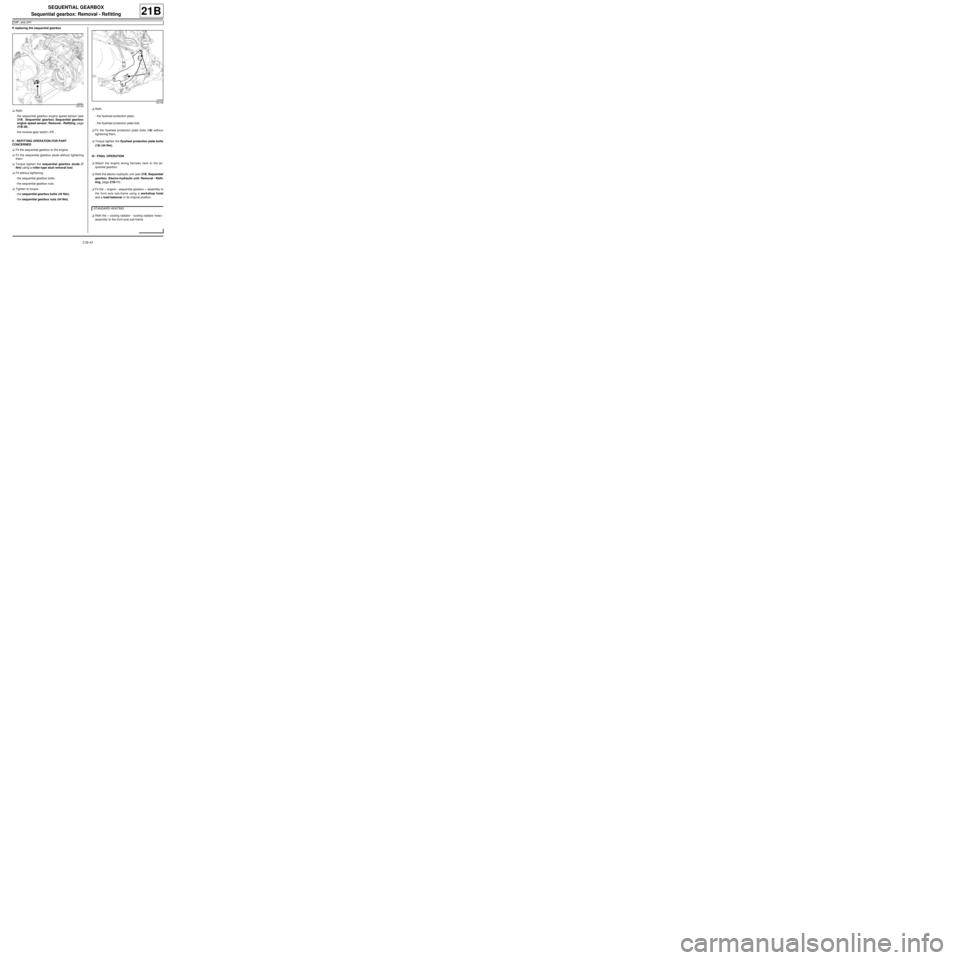

aRemove:

-the sequential gearbox nuts (13) ,

-the sequential gearbox bolts (14) ,

-the sequential gearbox from the engine,

-the sequential gearbox studs (15) using a roller-

type stud removal tool.If replacing the sequential gearbox

aRemove:

-the reverse gear switch (16) ,

-the sequential gearbox speed sensor (see 21B,

Sequential gearbox, Sequential gearbox engine

speed sensor: Removal - Refitting, page 21B-

38) .

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the centring ring is in place.

122170

122157

122163

Page 105 of 135

21B-45

SEQUENTIAL GEARBOX

Sequential gearbox: Removal - Refitting

D4F, and JH1

21B

If replacing the sequential gearbox

aRefit:

-the sequential gearbox engine speed sensor (see

21B, Sequential gearbox, Sequential gearbox

engine speed sensor: Removal - Refitting, page

21B-38) ,

-the reverse gear switch (17) .

II - REFITTING OPERATION FOR PART

CONCERNED

aFit the sequential gearbox to the engine.

aFit the sequential gearbox studs without tightening

them.

aTorque tighten the sequential gearbox studs (7

Nm) using a roller-type stud removal tool.

aFit without tightening:

-the sequential gearbox bolts,

-the sequential gearbox nuts.

aTighten to torque:

-the sequential gearbox bolts (44 Nm),

-the sequential gearbox nuts (44 Nm).aRefit:

-the flywheel protection plate,

-the flywheel protection plate bolt.

aFit the flywheel protection plate bolts (18) without

tightening them.

aTorque tighten the flywheel protection plate bolts

(18) (44 Nm).

III - FINAL OPERATION

aAttach the engine wiring harness neck to the se-

quential gearbox.

aRefit the electro-hydraulic unit (see 21B, Sequential

gearbox, Electro-hydraulic unit: Removal - Refit-

ting, page 21B-11) .

aFit the « engine - sequential gearbox » assembly to

the front axle sub-frame using a workshop hoist

and a load balancer in its original position.

aRefit the « cooling radiator - cooling radiator hose »

assembly to the front axle sub-frame.

122163

122158

STANDARD HEATING

Page 106 of 135

21B-46

SEQUENTIAL GEARBOX

Sequential gearbox: Removal - Refitting

D4F, and JH1

21B

aRefit the « cooling radiator - cooling radiator hose -

air conditioning condenser » assembly to the front

axle sub-frame.

aConnect the cooling radiator bottom hose to the

coolant pump inlet pipe.

aRefit the cooling radiator bottom hose clip using the

(Mot. 1448).

aRefit:

-the air conditioning condenser inlet pipe,

-the air conditioning condenser inlet pipe bolt.

aRefit the sequential gearbox earth cable bolt.

aConnect the reverse gear switch connector.

aClip the wiring harness to the motor-driven fan as-

sembly.

aConnect:

-the motor-driven fan assembly resistor unit con-

nector,

-the motor-driven fan assembly connector.

aConnect the cooling radiator top hose to the water

chamber.

aRefit the cooling radiator top hose clip using the

(Mot. 1448).

aRefit:

-the engine speed and position sensor (see Crank-

shaft position sensor: Removal - Refitting) (MR

411, 17B, Petrol injection),

-the starter (see Starter: Removal - Refitting) (MR

411, 16A, Starting - Charging),

-the hub-carrier - driveshaft assembly (see ) (MR

411, 31A, Front axle components),

-the engine - gearbox assembly (see Engine -

gearbox assembly: Removal - Refitting) (MR

411, 10A, Engine and peripherals).aFill the refrigerant circuit (see Refrigerant circuit:

Draining - Filling) (MR 411, 62A, Air conditioning).

aRefill:

-the sequential gearbox (see 21A, Manual gear-

box, Manual gearbox oils: Draining - Filling,

page 21A-2) ,

-the cooling system (see Cooling system: Drain-

ing - Refilling) (MR 411, 19A, Cooling).

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the catalytic converter (see Catalytic converter:

Removal - Refitting) ,

-the front wheels (see Wheel: Removal - Refitting)

(MR 411, 35A, Wheels and tyres),

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the petrol injection computer (see Petrol injection

computer: Removal - Refitting) (MR 411, 17B,

Petrol injection),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the sequential gearbox computer (see 21B, Se-

quential gearbox, Sequential gearbox convert-

er: Removal - Refitting, page 21B-47) ,

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery). AIR CONDITIONING or CLIMATE CONTROL

AIR CONDITIONING or CLIMATE CONTROL

AIR CONDITIONING or CLIMATE CONTROL

Page 110 of 135

29A-2

DRIVESHAFTS

Front left-hand driveshaft: Removal - Refitting

JB1 or JH1

29A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray bolts,

-the engine undertray.

aDrain the manual gearbox (see 21A, Manual gear-

box, Manual gearbox oils: Draining - Filling, page

21A-2) .

aRemove the front left-hand wheel (see Wheel: Re-

moval - Refitting) (35A, Wheels and tyres).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach the wiring from the wheel speed sensor (1) .

aRemove:

-the hub nut (2) by immobilising the hub using the

tool (Rou. 604-01),

-the track rod end nut (3) ,

-the track rod end from the stub axle carrier using

the (Tav. 476),

-the shock absorber base bolts (4) . Special tooling required

Rou. 604-01Hub locking tool.

Tav. 476Ball joint extractor.

Tightening torquesm

the flange mounting

bolts21 Nm

shock absorber base

bolts105 N.m

track rod end nut37 Nm

hub nut280 N.m

WARNING

In order to prevent irreversible damage to the front

hub bear ing:

-Do not loosen or tighten the driveshaft nut when

the wheels are on the ground.

-Do not place the vehicle with its wheels on the

ground when the driveshaft has been loosened or

removed.

130488

Page 112 of 135

29A-4

DRIVESHAFTS

Front left-hand driveshaft: Removal - Refitting

JB1 or JH1

29A

aThe seal (gearbox side) is made by pushing the gai-

ter lip (9) into its housing on the gearbox, moving the

flange (8) .

Wipe oil from:

-the flange (8) ,

-between the flange and the gaiter,

-the seal lip (9) ,

-the face of the lip on the gearbox.

Refit the driveshaft on the gearbox side (this opera-

tion requires two people):

-Person 1:

•position the driveshaft at the differential input,

•fit the flange (8) on the gaiter (7) ,

•fit the driveshaft into the gearbox whilst keeping

the flange (8) on the gaiter,

•push the flange (8) to insert the gaiter lip (9) in its

housing (do not pinch the gaiter (7) ).

-Person 2:

•tighten the 3 flange mounting bolts (8) but do not

tighten fully (the flange should still be loose).

-Person 1:

•keep the driveshaft as horizontal as possible (with

respect to the differential).

-Person 2:

•torque tighten the flange mounting bolts (21

Nm).

aFit the front left-hand driveshaft into the stub axle

carrier.

aRefit the bolts to the shock absorber base.

aTorque tighten the shock absorber base bolts(105 N.m).

aPosition the track rod.

Torque tighten the track rod end nut (37 Nm).

aRefit the hub nut.

aTorque tighten the hub nut (280 N.m ) using the tool

(Rou. 604-01).

aClip on the wheel speed sensor wiring harness.

II - FINAL OPERATION.

aRefit the front left-hand wheel (see Wheel: Removal

- Refitting) (35A, Wheels and tyres).

aFill the gearbox (see 21A, Manual gearbox, Manu-

al gearbox oils: Draining - Filling, page 21A-2) .

aRefit the engine undertray. WARNING

To ensure a correct seal when refi tting a gaiter to

a gearbox:

-the flange (8) must be fitted to the gaiter (7)

(see figure 107922) in order to support the seal

lip (9) and to fit it correctly into its holder on the

gearbox.

Note:

The driveshaft must fit freely into the stub-axle

carrier until it protrudes enough for the hub nut to

be fitted.