wheel SAAB 9-3 2003 Repair Manual

[x] Cancel search | Manufacturer: SAAB, Model Year: 2003, Model line: 9-3, Model: SAAB 9-3 2003Pages: 256, PDF Size: 21.66 MB

Page 215 of 256

215 Car care

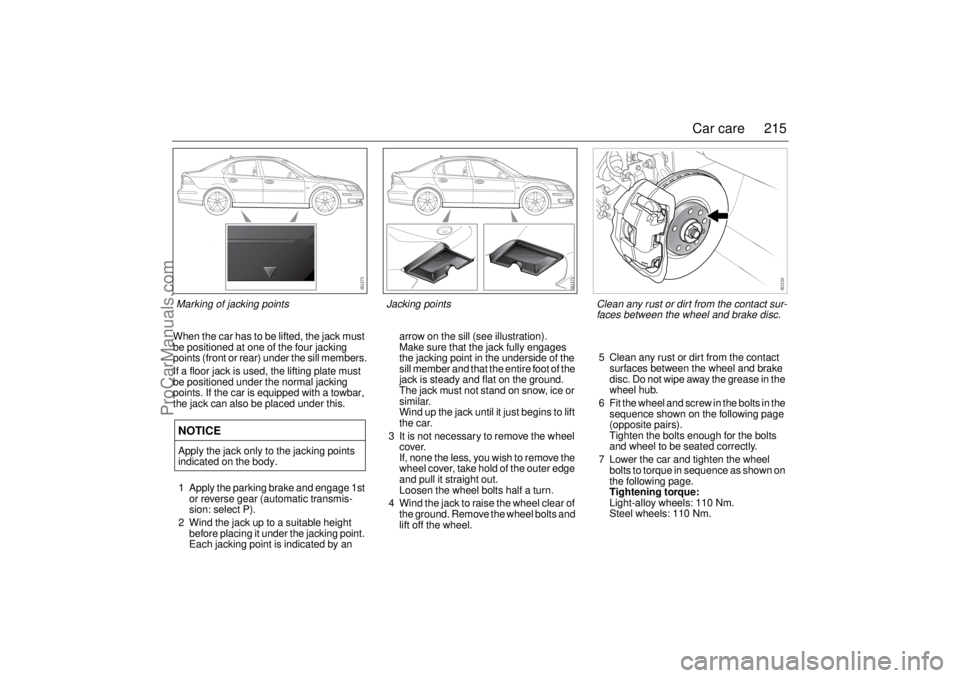

When the car has to be lifted, the jack must

be positioned at one of the four jacking

points (front or rear) under the sill members.

If a floor jack is used, the lifting plate must

be positioned under the normal jacking

points. If the car is equipped with a towbar,

the jack can also be placed under this.

1 Apply the parking brake and engage 1st

or reverse gear (automatic transmis-

sion: select P).

2 Wind the jack up to a suitable height

before placing it under the jacking point.

Each jacking point is indicated by an arrow on the sill (see illustration).

Make sure that the jack fully engages

the jacking point in the underside of the

sill member and that the entire foot of the

jack is steady and flat on the ground.

The jack must not stand on snow, ice or

similar.

Wind up the jack until it just begins to lift

the car.

3 It is not necessary to remove the wheel

cover.

If, none the less, you wish to remove the

wheel cover, take hold of the outer edge

and pull it straight out.

Loosen the wheel bolts half a turn.

4 Wind the jack to raise the wheel clear of

the ground. Remove the wheel bolts and

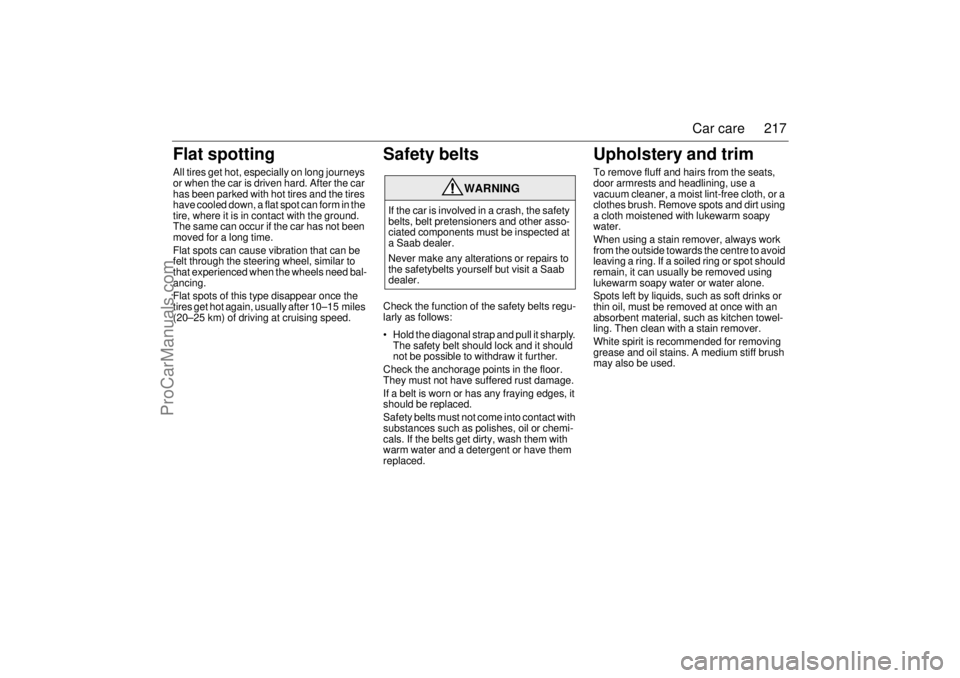

lift off the wheel.5 Clean any rust or dirt from the contact

surfaces between the wheel and brake

disc. Do not wipe away the grease in the

wheel hub.

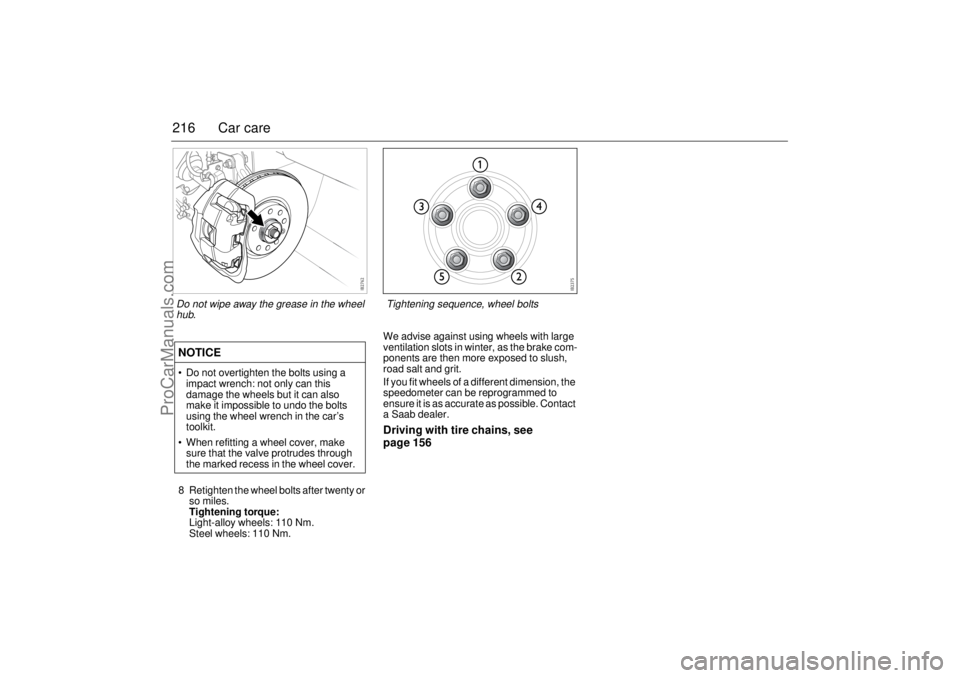

6 Fit the wheel and screw in the bolts in the

sequence shown on the following page

(opposite pairs).

Tighten the bolts enough for the bolts

and wheel to be seated correctly.

7 Lower the car and tighten the wheel

bolts to torque in sequence as shown on

the following page.

Tightening torque:

Light-alloy wheels: 110 Nm.

Steel wheels: 110 Nm.NOTICEApply the jack only to the jacking points

indicated on the body.

Jacking points

Marking of jacking points

Clean any rust or dirt from the contact sur-

faces between the wheel and brake disc.

ProCarManuals.com

Page 216 of 256

216 Car care8 Retighten the wheel bolts after twenty or

so miles.

Tightening torque:

Light-alloy wheels: 110 Nm.

Steel wheels: 110 Nm.We advise against using wheels with large

ventilation slots in winter, as the brake com-

ponents are then more exposed to slush,

road salt and grit.

If you fit wheels of a different dimension, the

speedometer can be reprogrammed to

ensure it is as accurate as possible. Contact

a Saab dealer.

Driving with tire chains, see

page 156 NOTICE

Do not overtighten the bolts using a

impact wrench: not only can this

damage the wheels but it can also

make it impossible to undo the bolts

using the wheel wrench in the car’s

toolkit.

When refitting a wheel cover, make

sure that the valve protrudes through

the marked recess in the wheel cover.

Tightening sequence, wheel bolts

Do not wipe away the grease in the wheel

hub.

ProCarManuals.com

Page 217 of 256

217 Car care

Flat spottingAll tires get hot, especially on long journeys

or when the car is driven hard. After the car

has been parked with hot tires and the tires

have cooled down, a flat spot can form in the

tire, where it is in contact with the ground.

The same can occur if the car has not been

moved for a long time.

Flat spots can cause vibration that can be

felt through the steering wheel, similar to

that experienced when the wheels need bal-

ancing.

Flat spots of this type disappear once the

tires get hot again, usually after 10–15 miles

(20–25 km) of driving at cruising speed.

Safety beltsCheck the function of the safety belts regu-

larly as follows:

Hold the diagonal strap and pull it sharply.

The safety belt should lock and it should

not be possible to withdraw it further.

Check the anchorage points in the floor.

They must not have suffered rust damage.

If a belt is worn or has any fraying edges, it

should be replaced.

Safety belts must not come into contact with

substances such as polishes, oil or chemi-

cals. If the belts get dirty, wash them with

warm water and a detergent or have them

replaced.

Upholstery and trimTo remove fluff and hairs from the seats,

door armrests and headlining, use a

vacuum cleaner, a moist lint-free cloth, or a

clothes brush. Remove spots and dirt using

a cloth moistened with lukewarm soapy

water.

When using a stain remover, always work

from the outside towards the centre to avoid

leaving a ring. If a soiled ring or spot should

remain, it can usually be removed using

lukewarm soapy water or water alone.

Spots left by liquids, such as soft drinks or

thin oil, must be removed at once with an

absorbent material, such as kitchen towel-

ling. Then clean with a stain remover.

White spirit is recommended for removing

grease and oil stains. A medium stiff brush

may also be used.

WARNING

If the car is involved in a crash, the safety

belts, belt pretensioners and other asso-

ciated components must be inspected at

a Saab dealer.

Never make any alterations or repairs to

the safetybelts yourself but visit a Saab

dealer.

ProCarManuals.com

Page 220 of 256

220 Car careTwo-coat enamelAs the name implies, two-coat enamel is

applied in two operations. The first coat, the

base color, contains the pigment, metal

flakes and binder. The second coat consists

of a clear enamel, which provides the final

gloss for the paintwork and protects the

base from moisture and environmental con-

taminants.

Touch-up stone-chip damage as follows:

1 Thoroughly clean the damaged area.

2 Then apply the primer, base colour and

finally, the clear enamel. To achieve the

best finish, apply two or three coats of

primer.

Anti-corrosion

treatmentThe entire car undergoes a series of anti-

corrosion processes during production.

These include electrophoretic priming,

polyester-based coating to protect against

stone chip damage and corrosion, and

treatment of body cavities and members

with thin, penetrating rustproofing oil.

In addition, most body panels, such as the

hood, doors and floor pan are galvanized.

The anti-corrosion treatment on some parts

of the car is constantly exposed to wear and

prone to damage. This applies particularly

to the underside of the car and inside the

wheel arches, where grit, road salt and the

like that are thrown up can give rise to cor-

rosion where the underseal has worn away.

The extent of this obviously depends on the

conditions in which the car is used.

Accordingly, make it a habit to hose the

underside of the car often and to inspect the

condition of the underseal. The anti-corro-

sion warranty does not relieve the car owner

of the need to carry out normal maintenance

to the rustproofing and to make good any

damage.

Surface treatment composition1 Body panel

2 Zinc (certain components only) 7.5 µm

3 Phosphate coating 3 –5 µm

4 Cathodic ED 30 µm

5 Intermediate coat 40 –45 µm

6 Metallic base/solid base 13 µm

7 Clear enamel 45 µm

ProCarManuals.com

Page 222 of 256

222 Car care2Clean the underside of the car during

the winter. Use high pressure water to

clean the car’s underside (floor panels,

wheel wells) at least at mid-winter and in

the spring.

3Inspect the car frequently for leaks or

damage, and arrange for needed

repairs promptly. After washing or after

heavy rain, check for leaks. When wash-

ing the car inspect body surfaces for

paint damage. While checking for leaks,

lift the floor mats and check underneath

them. Water can collect in these areas

and remain for prolonged periods. Dry

any wet areas including the floor mats.

Have leaks repaired as soon as possi-

ble.

Use touch-up paint to repair small

scratches or minor finish damage. Areas

where metal is exposed will rust quickly

and MUST be repaired immediately by

touch-up or professional repainting.

Rust must be removed, the bare metal

primed and painted. Major body

damage should be repaired immediately

and new panels or exposed areas

should be undercoated with anti- corro-

sion material.

Repairs of this type are the owner’s

responsibility and are not covered under

warranty.Inspect the undercoating and touch up if

necessary. Pay particular attention to the

fenders and wheel housings, which are

exposed to abrasion by flying gravel, etc. If

the composition has worn or flaked off, the

steel must be thoroughly cleaned and dried

before a fresh coat is applied. The cleaning

is best done with a scraper and a steel wire

brush, followed by washing with solvent.

Apply the new coating thinly, otherwise it

may run off or fall off when dry.

Recovery and/or

recycling of automotive

materialsA typical car consists of metals (65–75 %),

plastics (10–15 %), rubber (5 %) and small

quantities of glass, wood, paper and tex-

tiles. The recycling of metals has been com-

monplace for a long time now.

To facilitate the sorting of other materials,

plastic parts, for instance, have been

marked to identify the precise nature of the

plastic.

ProCarManuals.com

Page 223 of 256

223 Car care

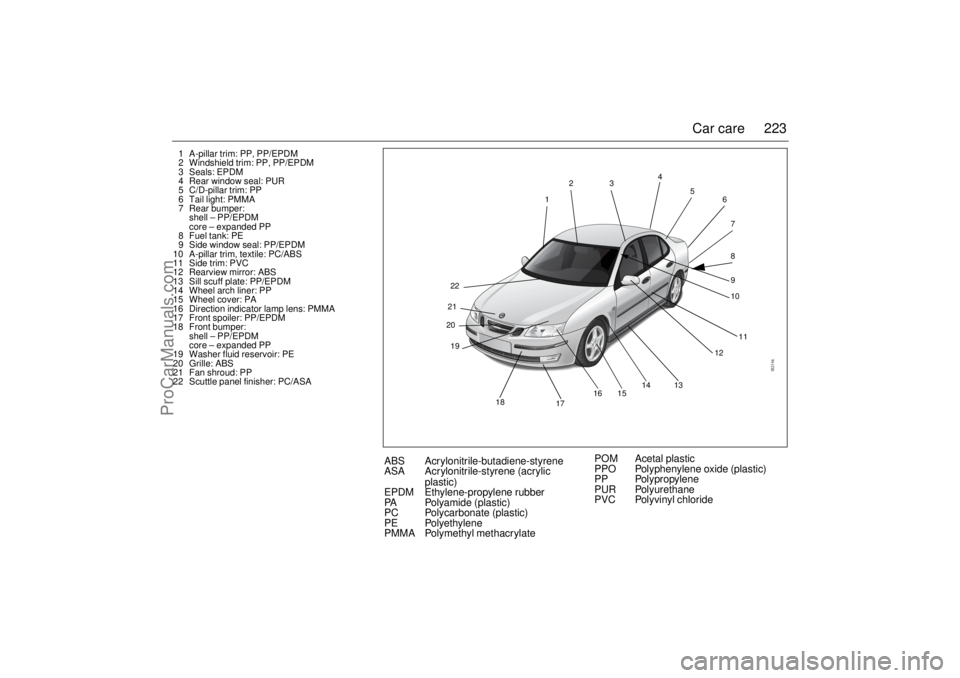

1 A-pillar trim: PP, PP/EPDM

2 Windshield trim: PP, PP/EPDM

3 Seals: EPDM

4 Rear window seal: PUR

5 C/D-pillar trim: PP

6 Tail light: PMMA

7 Rear bumper:

shell – PP/EPDM

core – expanded PP

8 Fuel tank: PE

9 Side window seal: PP/EPDM

10 A-pillar trim, textile: PC/ABS

11 Side trim: PVC

12 Rearview mirror: ABS

13 Sill scuff plate: PP/EPDM

14 Wheel arch liner: PP

15 Wheel cover: PA

16 Direction indicator lamp lens: PMMA

17 Front spoiler: PP/EPDM

18 Front bumper:

shell – PP/EPDM

core – expanded PP

19 Washer fluid reservoir: PE

20 Grille: ABS

21 Fan shroud: PP

22 Scuttle panel finisher: PC/ASA

19 2022

211234

18

1716 151412

1311 7

10 9 8 6 5

ABS Acr ylonitrile-butadiene-styrene

ASA Acrylonitrile-styrene (acrylic

plastic)

EPDM Ethylene-propylene rubber

PA Polyamide (plastic)

PC Polycarbonate (plastic)

PE Polyethylene

PMMA Polymethyl methacrylatePOM Acetal plastic

PPO Polyphenylene oxide (plastic)

PP Polypropylene

PUR Polyurethane

PVC Polyvinyl chloride

ProCarManuals.com

Page 226 of 256

226 Car careHeadlight aimingThe vehicle has a visual optical headlight

aiming system equipped with vertical

aiming device. The aim has been preset at

the factory and should normally not need

further adjustments.

If your headlights are damaged in a crash,

the headlight aim may be affected. If you

believe your headlights need to be re-

aimed, we recommend that you take it to

your Saab dealer for service. However, it is

possible for you to re-aim your headlights as

described in the following procedure.To check the aim, the vehicle should be

properly prepared as follows:

The vehicle shall be placed so that the

headlights are 25 ft (7.6 m) from a light

colored wall or other flat surface. The

aiming area should be darkened, this will

improve your ability to see the beam of the

low beam headlight being aimed.

An optical headlamp aimer can also be

used and will than replace the wall.

The vehicle must have all four wheels on

a perfectly level surface which is level all

the way to the wall or other flat surface.

The vehicle should be placed so it is per-

pendicular to the wall or other flat surface.

The vehicle should be unloaded and fuel

tank full, and one person or 160 lbs.

(75 kg) on the drivers seat. The vehicle should be fully assembled

and all other work stopped while headlight

aiming is being done.

The vehicle should not have any snow, ice

or mud attached to it.

Tires should be inflated to the prescribed

pressure.

Close all doors.

Rock the vehicle to stabilize the suspen-

sion.

Headlight aiming is done with the vehicle

low beam lamps. The high beam lamps will

be correctly aimed if the low beam lamps

are aimed properly.

WARNING

Before checking/adjusting the headlight

aiming, switch off the engine to avoid

danger of fingers and hands being injured

by moving parts.

The radiator fan can start up even when

the engine is switched off.NOTICETo make sure that your headlights are

aimed properly read all instructions

before beginning. Failure to follow these

instructions could cause damage to

headlight parts or a not correctly aimed

headlight.

ProCarManuals.com

Page 235 of 256

235 Technical data

General particulars _____ 236

Engine _______________ 238

Engine oil _____________ 238

Fuel__________________ 240

Engines ______________ 240

Electrical system_______ 240

Drive belt _____________ 240

Manual transmission ___ 241

Automatic transmission _ 241

Suspension ___________ 242

Steering ______________ 242

Brake system__________ 242

Wheels and tires _______ 243

Plates and labels _______ 246

Technical data

ProCarManuals.com

Page 236 of 256

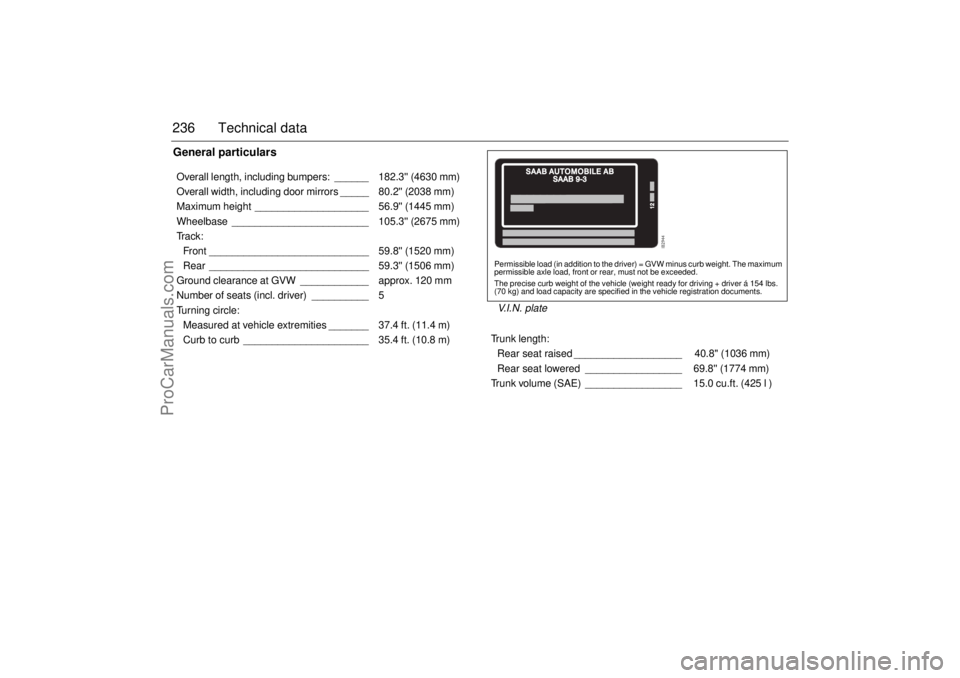

236 Technical dataGeneral particularsOverall length, including bumpers: ______ 182.3'' (4630 mm)

Overall width, including door mirrors _____ 80.2'' (2038 mm)

Maximum height ____________________ 56.9'' (1445 mm)

Wheelbase ________________________ 105.3'' (2675 mm)

Tr a c k :

Front ____________________________ 59.8'' (1520 mm)

Rear ____________________________ 59.3'' (1506 mm)

Ground clearance at GVW ____________ approx. 120 mm

Number of seats (incl. driver) __________ 5

Turning circle:

Measured at vehicle extremities _______ 37.4 ft. (11.4 m)

Curb to curb ______________________ 35.4 ft. (10.8 m)

Permissible load (in addition to the driver) = GVW minus curb weight. The maximum

permissible axle load, front or rear, must not be exceeded.

The precise curb weight of the vehicle (weight ready for driving + driver á 154 lbs.

(70 kg) and load capacity are specified in the vehicle registration documents.V.I.N. plateTrunk length:

Rear seat raised ___________________ 40.8'' (1036 mm)

Rear seat lowered _________________ 69.8'' (1774 mm)

Trunk volume (SAE) _________________ 15.0 cu.ft. (425 l )

ProCarManuals.com

Page 237 of 256

237 Technical data

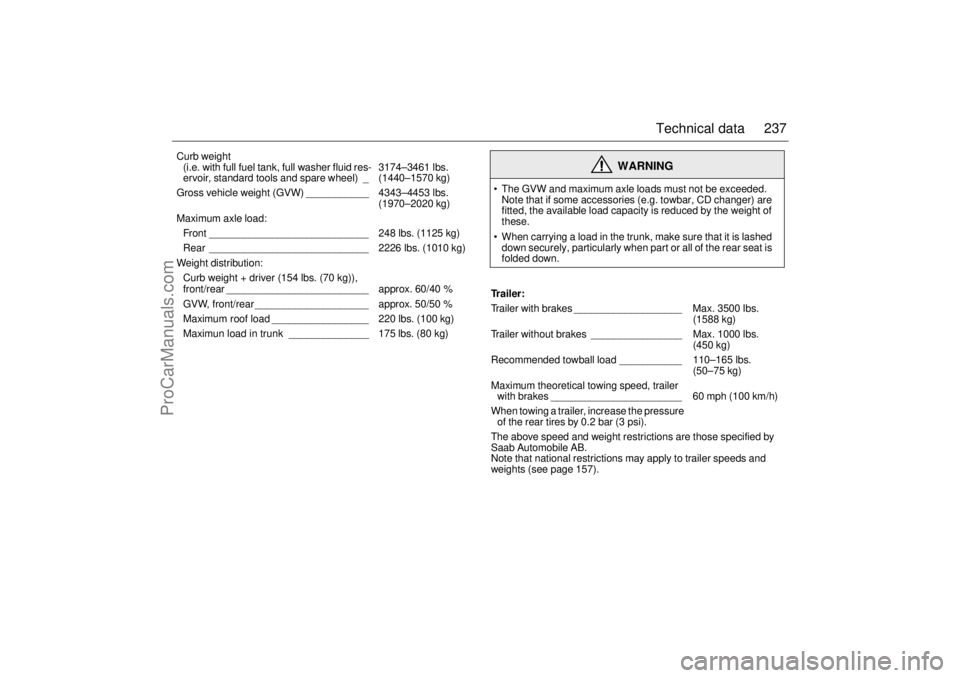

Curb weight

(i.e. with full fuel tank, full washer fluid res-

ervoir, standard tools and spare wheel) _3174–3461 lbs.

(1440–1570 kg)

Gross vehicle weight (GVW) ___________ 4343–4453 lbs.

(1970–2020 kg)

Maximum axle load:

Front ____________________________ 248 lbs. (1125 kg)

Rear ____________________________ 2226 lbs. (1010 kg)

Weight distribution:

Curb weight + driver (154 lbs. (70 kg)),

front/rear _________________________ approx. 60/40 %

GVW, front/rear ____________________ approx. 50/50 %

Maximum roof load _________________ 220 lbs. (100 kg)

Maximun load in trunk ______________ 175 lbs. (80 kg)

WARNING

The GVW and maximum axle loads must not be exceeded.

Note that if some accessories (e.g. towbar, CD changer) are

fitted, the available load capacity is reduced by the weight of

these.

When carrying a load in the trunk, make sure that it is lashed

down securely, particularly when part or all of the rear seat is

folded down.

Trailer:

Trailer with brakes ___________________ Max. 3500 lbs.

(1588 kg)

Trailer without brakes ________________ Max. 1000 lbs.

(450 kg)

Recommended towball load ___________ 110–165 lbs.

(50–75 kg)

Maximum theoretical towing speed, trailer

with brakes _______________________ 60 mph (100 km/h)

When towing a trailer, increase the pressure

of the rear tires by 0.2 bar (3 psi).

The above speed and weight restrictions are those specified by

Saab Automobile AB.

Note that national restrictions may apply to trailer speeds and

weights (see page 157).

ProCarManuals.com