wheel Seat Alhambra 2006 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Alhambra, Model: Seat Alhambra 2006Pages: 299, PDF Size: 6.33 MB

Page 233 of 299

If and when231

Safety FirstOperating instructionsTips and MaintenanceTe c h n i c a l D a t a

If and when

Vehicle onboard tools*, spare wheel*,

puncture repair kit* and towing bracket

Location

The vehicle tools, the spare wheel and the removable towing

bracket ball coupling are stored in the luggage compartment.

Vehicle tool kit and removable ball coupling

The vehicle tool kit and removable towing bracket ball coupling are stored on

the right of the luggage compartment, behind a cover.

Spare wheel

The spare wheel is stored underneath the vehicle �Ÿpage 232.

Caution

Make sure that the spare wheel / removed wheel and the tools are stored

safely in the luggage compartment.

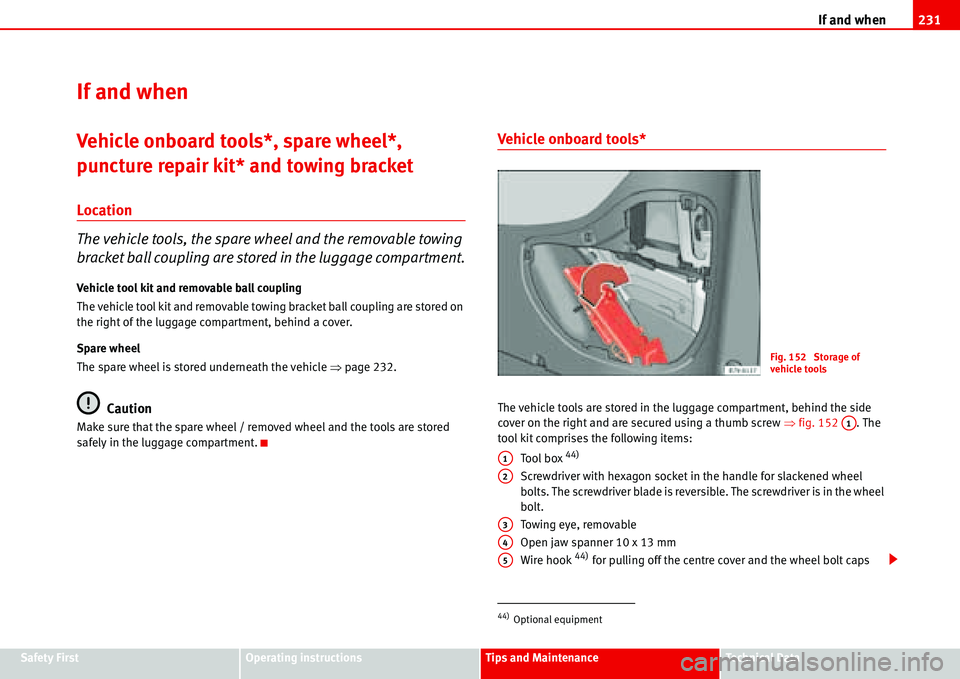

Vehicle onboard tools*

The vehicle tools are stored in the luggage compartment, behind the side

cover on the right and are secured using a thumb screw�Ÿfig. 152 . The

tool kit comprises the following items:

To ol b ox

44)

Screwdriver with hexagon socket in the handle for slackened wheel

bolts. The screwdriver blade is reversible. The screwdriver is in the wheel

bolt.

Towing eye, removable

Open jaw spanner 10 x 13 mm

Wire hook

44) for pulling off the centre cover and the wheel bolt caps

44)Optional equipment

Fig. 152 Storage of

vehicle tools

A1

A1

A2

A3

A4

A5

Page 234 of 299

If and when 232

Box spanner for wheel bolts

Jack. Before you return the jack to the tool box, you must fully wind in the

claw. The crank must then be folded tight against the side of the jack.

The removable towing bracket

44), the key for unlocking the sunroof in an

emergency44) and the anti-theft wheel bolt adaptor44) are stored next to the

vehicle tools.

Adapter for anti-theft wheel bolts

We recommend you carry the wheel bolt adapter

44) in the vehicle tool kit at

all times.

The code number of the anti-theft wheel bolt is stamped on the front of the

adapter. You will need this number to replace the adapter if lost. Make a note

the code number of the anti-theft wheel bolt and keep it in a safe place - but

not in your vehicle.

WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts. It is not suitable for tightening the bolts to the necessary

torque. This may cause an accident.

•The jack supplied by the factory is only designed for changing wheels

on this model. Never attempt to use it for lifting heavier vehicles or other

loads. Risk of injury.

•Use the jack only on firm, level ground.

•Never start the engine when you have raised the vehicle on the jack.

Risk of accident.

•Never place your body (e.g. arm or leg) underneath the vehicle if it is

only supported by the jack Risk of injury.

•If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle - Risk of accident!.

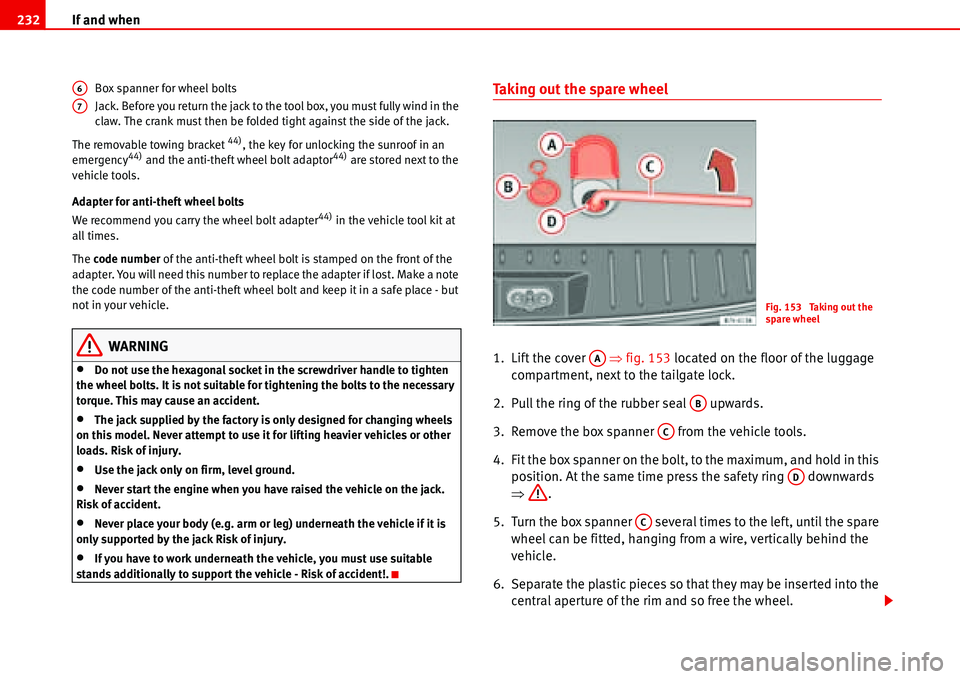

Taking out the spare wheel

1. Lift the cover �Ÿfig. 153 located on the floor of the luggage

compartment, next to the tailgate lock.

2. Pull the ring of the rubber seal upwards.

3. Remove the box spanner from the vehicle tools.

4. Fit the box spanner on the bolt, to the maximum, and hold in this

position. At the same time press the safety ring downwards

�Ÿ.

5. Turn the box spanner several times to the left, until the spare

wheel can be fitted, hanging from a wire, vertically behind the

vehicle.

6. Separate the plastic pieces so that they may be inserted into the

central aperture of the rim and so free the wheel.

A6

A7

Fig. 153 Taking out the

spare wheel

AA

AB

AC

AD

AC

Page 235 of 299

If and when233

Safety FirstOperating instructionsTips and MaintenanceTe c h n i c a l D a t a

WARNING

•If you are driving without the spare wheel, the cable should be rolled up

and the bracket fastened to the floor of the luggage compartment.

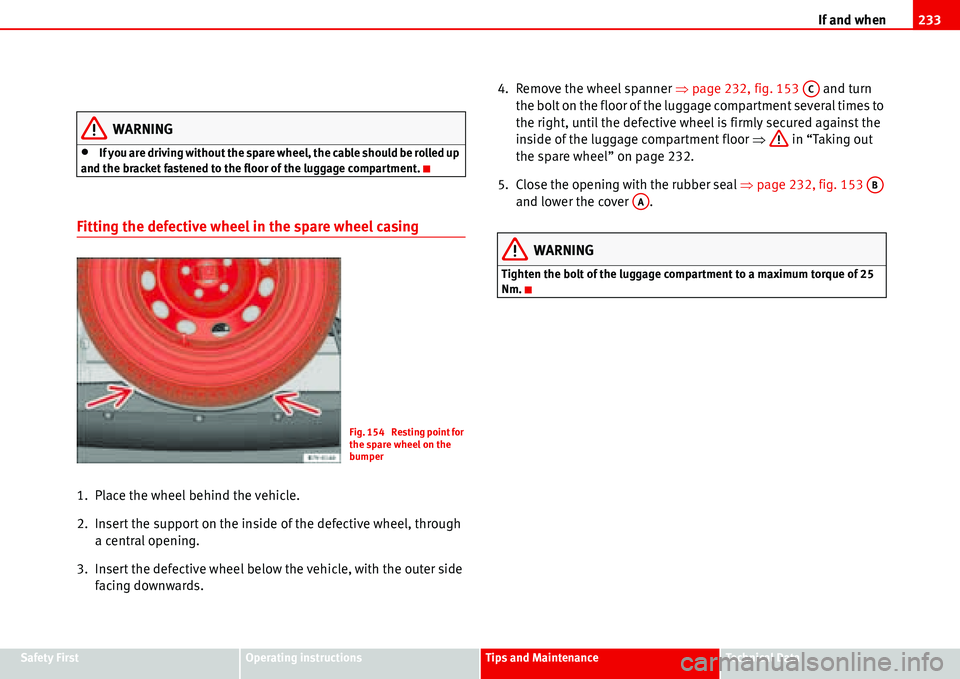

Fitting the defective wheel in the spare wheel casing

1. Place the wheel behind the vehicle.

2. Insert the support on the inside of the defective wheel, through

a central opening.

3. Insert the defective wheel below the vehicle, with the outer side

facing downwards.4. Remove the wheel spanner �Ÿpage 232, fig. 153 and turn

the bolt on the floor of the luggage compartment several times to

the right, until the defective wheel is firmly secured against the

inside of the luggage compartment floor �Ÿ in “Taking out

the spare wheel” on page 232.

5. Close the opening with the rubber seal �Ÿpage 232, fig. 153

and lower the cover .

WARNING

Tighten the bolt of the luggage compartment to a maximum torque of 25

Nm.

Fig. 154 Resting point for

the spare wheel on the

bumper

AC

AB

AA

Page 238 of 299

If and when 236

WARNING

•Do not allow the sealant to get onto your skin or into your eyes. Risk of

injury.

•Keep children away from the sealant.

Changing a wheel

Preparatory work

You must park the vehicle correctly before changing a tyre.

– If you have a flat tyre or puncture, park the car as far away from

the flow of traffic as possible on a flat surface.

– Switch off the engine. Switch on the hazard warning lights.

– Apply the handbrake firmly and engage a gear or put the selector

in the P position.

– Chock the wheel opposite the wheel being changed with a stone

or similar object.

– If you are towing a trailer, unhitch it from your vehicle.

– Remove the spare wheel and the vehicle tools from the luggage

compartment.

– All passengers should leave the car. They should wait in a safe

place (for instance behind the safety barrier).

WARNING

•If you have a puncture, stop the car well away from moving traffic.

Switch on the hazard warning lights and set the emergency triangle in

position. Please observe legal requirements when doing so.

•All passengers should leave the car.

•Apply the handbrake firmly and engage a gear or put the gear selector

in the P position. Chock the wheel opposite the wheel being changed with

a stone or similar object.

•If you are towing a trailer, unhitch it from your vehicle.

•Only use jacks which have been approved for your vehicle by SEAT.

•Never use other jacks, even if they have been approved for use on other

SEAT models. The jack could slip. Risk of injury.

•Never start the engine when the vehicle is raised. This may cause an

accident.

•Never place your body (e.g. arm or leg) underneath the vehicle if it is

only supported by the jack Risk of injury.

•If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle - Risk of accident!.

Page 239 of 299

If and when237

Safety FirstOperating instructionsTips and MaintenanceTe c h n i c a l D a t a

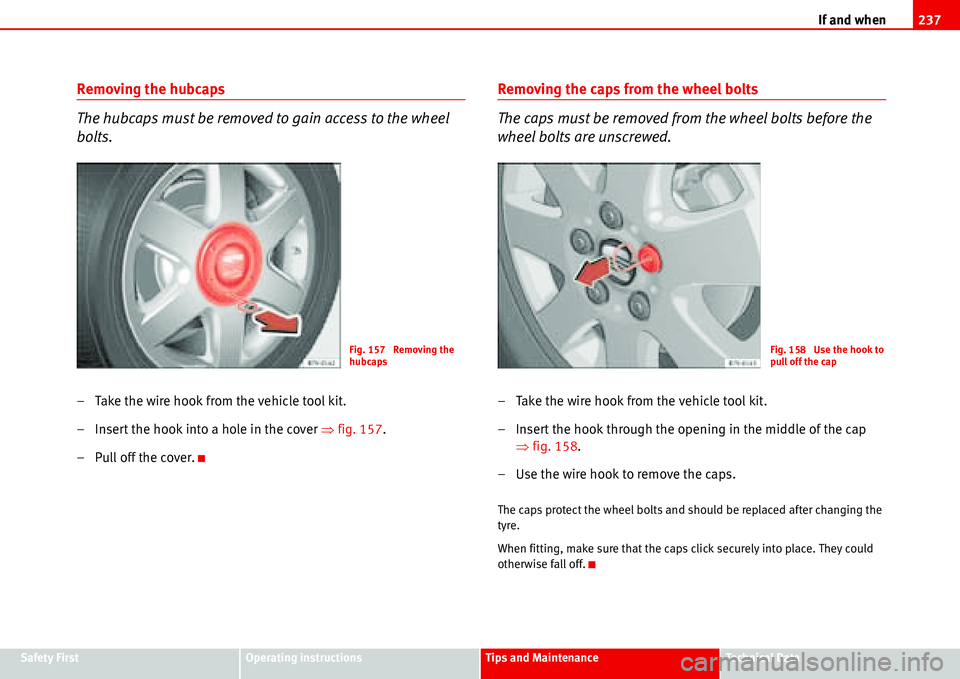

Removing the hubcaps

The hubcaps must be removed to gain access to the wheel

bolts.

– Take the wire hook from the vehicle tool kit.

– Insert the hook into a hole in the cover �Ÿfig. 157.

– Pull off the cover.

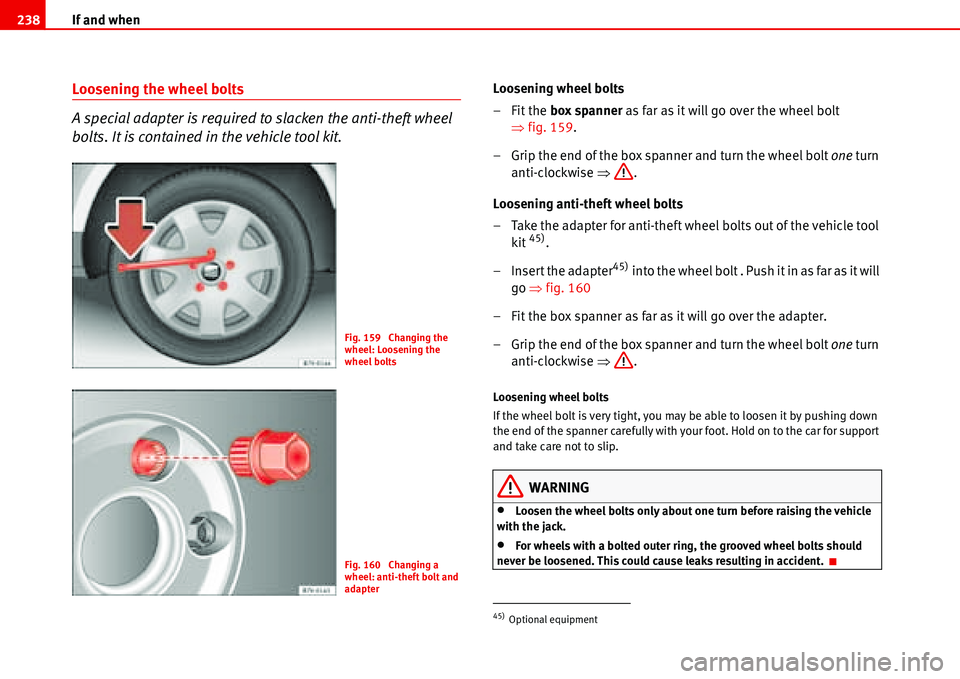

Removing the caps from the wheel bolts

The caps must be removed from the wheel bolts before the

wheel bolts are unscrewed.

– Take the wire hook from the vehicle tool kit.

– Insert the hook through the opening in the middle of the cap

�Ÿfig. 158.

– Use the wire hook to remove the caps.

The caps protect the wheel bolts and should be replaced after changing the

tyre.

When fitting, make sure that the caps click securely into place. They could

otherwise fall off.

Fig. 157 Removing the

hubcapsFig. 158 Use the hook to

pull off the cap

Page 240 of 299

If and when 238

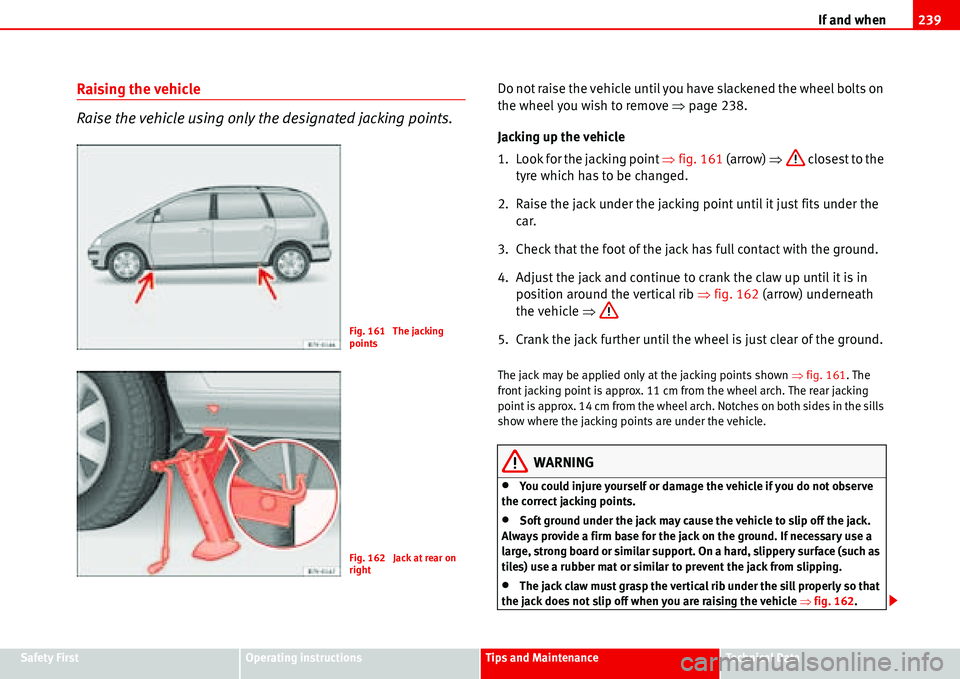

Loosening the wheel bolts

A special adapter is required to slacken the anti-theft wheel

bolts. It is contained in the vehicle tool kit.Loosening wheel bolts

– Fit the box spanner as far as it will go over the wheel bolt

�Ÿfig. 159.

– Grip the end of the box spanner and turn the wheel bolt one turn

anti-clockwise �Ÿ.

Loosening anti-theft wheel bolts

– Take the adapter for anti-theft wheel bolts out of the vehicle tool

kit

45).

– Insert the adapter

45) into the wheel bolt . Push it in as far as it will

go �Ÿfig. 160

– Fit the box spanner as far as it will go over the adapter.

– Grip the end of the box spanner and turn the wheel bolt one turn

anti-clockwise �Ÿ.

Loosening wheel bolts

If the wheel bolt is very tight, you may be able to loosen it by pushing down

the end of the spanner carefully with your foot. Hold on to the car for support

and take care not to slip.

WARNING

•Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

•For wheels with a bolted outer ring, the grooved wheel bolts should

never be loosened. This could cause leaks resulting in accident.

Fig. 159 Changing the

wheel: Loosening the

wheel bolts

Fig. 160 Changing a

wheel: anti-theft bolt and

adapter

45)Optional equipment

Page 241 of 299

If and when239

Safety FirstOperating instructionsTips and MaintenanceTe c h n i c a l D a t a

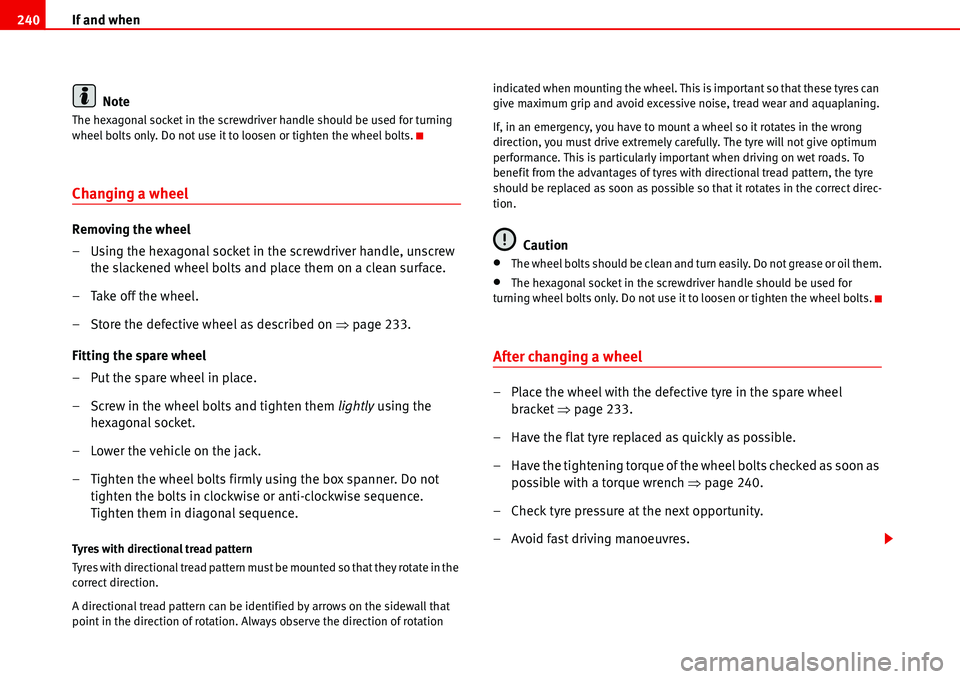

Raising the vehicle

Raise the vehicle using only the designated jacking points.Do not raise the vehicle until you have slackened the wheel bolts on

the wheel you wish to remove �Ÿpage 238.

Jacking up the vehicle

1. Look for the jacking point �Ÿfig. 161 (arrow) �Ÿ closest to the

tyre which has to be changed.

2. Raise the jack under the jacking point until it just fits under the

car.

3. Check that the foot of the jack has full contact with the ground.

4. Adjust the jack and continue to crank the claw up until it is in

position around the vertical rib �Ÿfig. 162 (arrow) underneath

the vehicle �Ÿ

5. Crank the jack further until the wheel is just clear of the ground.

The jack may be applied only at the jacking points shown �Ÿfig. 161. The

front jacking point is approx. 11 cm from the wheel arch. The rear jacking

point is approx. 14 cm from the wheel arch. Notches on both sides in the sills

show where the jacking points are under the vehicle.

WARNING

•You could injure yourself or damage the vehicle if you do not observe

the correct jacking points.

•Soft ground under the jack may cause the vehicle to slip off the jack.

Always provide a firm base for the jack on the ground. If necessary use a

large, strong board or similar support. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

•The jack claw must grasp the vertical rib under the sill properly so that

the jack does not slip off when you are raising the vehicle �Ÿfig. 162.

Fig. 161 The jacking

points

Fig. 162 Jack at rear on

right

Page 242 of 299

If and when 240

Note

The hexagonal socket in the screwdriver handle should be used for turning

wheel bolts only. Do not use it to loosen or tighten the wheel bolts.

Changing a wheel

Removing the wheel

– Using the hexagonal socket in the screwdriver handle, unscrew

the slackened wheel bolts and place them on a clean surface.

– Take off the wheel.

– Store the defective wheel as described on �Ÿpage 233.

Fitting the spare wheel

– Put the spare wheel in place.

– Screw in the wheel bolts and tighten them lightly using the

hexagonal socket.

– Lower the vehicle on the jack.

– Tighten the wheel bolts firmly using the box spanner. Do not

tighten the bolts in clockwise or anti-clockwise sequence.

Tighten them in diagonal sequence.

Tyres with directional tread pattern

Tyres with directional tread pattern must be mounted so that they rotate in the

correct direction.

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always observe the direction of rotation indicated when mounting the wheel. This is important so that these tyres can

give maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to mount a wheel so it rotates in the wrong

direction, you must drive extremely carefully. The tyre will not give optimum

performance. This is particularly important when driving on wet roads. To

benefit from the advantages of tyres with directional tread pattern, the tyre

should be replaced as soon as possible so that it rotates in the correct direc-

tion.

Caution

•The wheel bolts should be clean and turn easily. Do not grease or oil them.

•The hexagonal socket in the screwdriver handle should be used for

turning wheel bolts only. Do not use it to loosen or tighten the wheel bolts.

After changing a wheel

– Place the wheel with the defective tyre in the spare wheel

bracket �Ÿ page 233.

– Have the flat tyre replaced as quickly as possible.

– Have the tightening torque of the wheel bolts checked as soon as

possible with a torque wrench �Ÿpage 240.

– Check tyre pressure at the next opportunity.

– Avoid fast driving manoeuvres.

Page 243 of 299

If and when241

Safety FirstOperating instructionsTips and MaintenanceTe c h n i c a l D a t a

WARNING

•If the prescribed torque of the wheel bolts is too low, they could loosen

whilst the vehicle is in motion. Risk of accident! If the tightening torque is

too high, the wheel bolts and threads could be damaged.

Caution

The stipulated torque for the wheel bolts on steel wheels and alloy wheels is

170 Nm with a tolerance of ±10 Nm. You should visit a specialised workshop

as soon as possible to check the torque with a torque wrench.

Note

•The wheel bolts should be clean and turn easily. Do not grease or oil them.

•The hexagonal socket in the screwdriver handle should be used only for

turning wheel bolts which have been slackened off. Do not use it to loosen or

tighten the wheel bolts.

•If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before you have the tightening

torque checked.

•If the spare tyre is not the same as the tyres that are mounted on the car -

for example with winter tyres - you should only use the spare tyre for a short

period of time and drive with extra care. Refit the normal road wheel as soon

as possible.

•Have the flat tyre replaced as quickly as possible.

Fuses

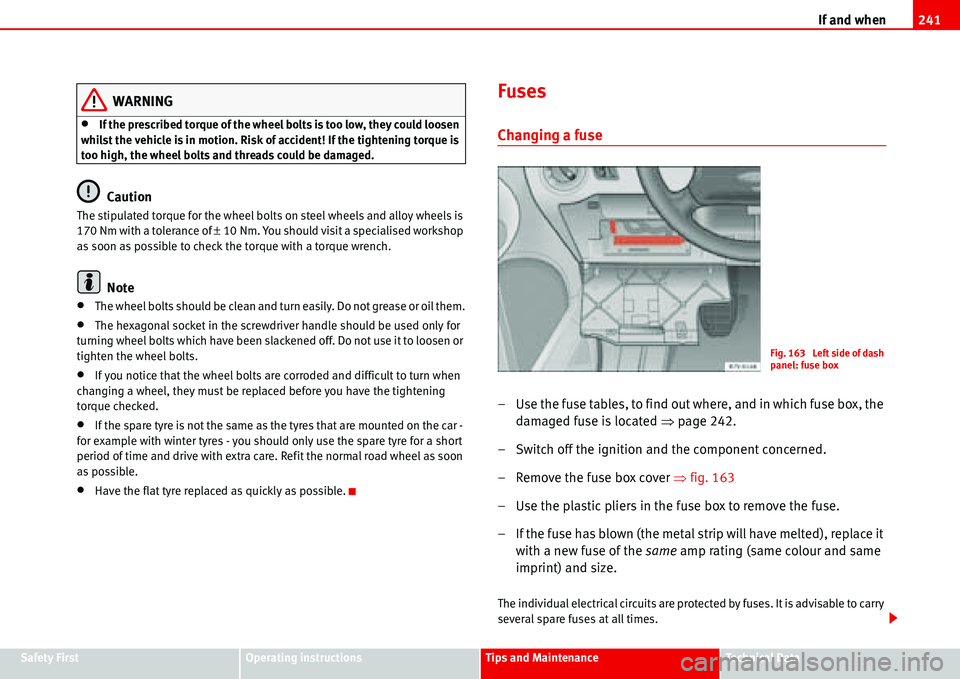

Changing a fuse

– Use the fuse tables, to find out where, and in which fuse box, the

damaged fuse is located �Ÿpage 242.

– Switch off the ignition and the component concerned.

– Remove the fuse box cover �Ÿfig. 163

– Use the plastic pliers in the fuse box to remove the fuse.

– If the fuse has blown (the metal strip will have melted), replace it

with a new fuse of the same amp rating (same colour and same

imprint) and size.

The individual electrical circuits are protected by fuses. It is advisable to carry

several spare fuses at all times.

Fig. 163 Left side of dash

panel: fuse box

Page 256 of 299

If and when 254

Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow-rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving tips

Towing requires some experience, especially when using a tow-rope. Both

drivers should be familiar with the technique required for towing. Inexperi-

enced drivers should not attempt to tow-start or tow away another vehicle.

Do not pull too hard with the towing vehicle and take care to avoid jerking the

tow-rope. When towing on an unpaved road, there is always a risk of over-

loading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

If the vehicle is towed, with the hazard warning lights on and the ignition

switched on, the turn signal may be used to indicate that you are going to

change direction. Move the turn signal lever accordingly. Meanwhile, the

hazard warning lights will go off. When the turn signal lever is returned to the

rest position, the hazard warning lights will automatically reconnect.

The brake servo works only when the engine is running. In this case the pedal

has to be pressed harder.

As the power assisted steering does not work if the engine is not running, you

will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

•Move the selector lever to N.

•Do not drive faster than 50 km/h when towing a vehicle.

•Do not tow further than 50 km.

•If a breakdown truck is used, the vehicle must be towed with the front

wheels raised.

WARNING

The braking behaviour and capacity of a vehicle changes when being towed

or when you are trying to start the vehicle by pulling. Please observe the

following notes in order to prevent injury and accident:

•Inexperienced drivers should refrain from trying in order to avoid acci-

dent.

•Notes for the driver of the towed vehicle

−The brake must be depressed must harder as the brake servo does

not operate. Take care not to bump into the towing vehicle.

−More strength is required at the steering wheel as the power

steering does not operate when the engine is switched off.

•Notes for the driver of the towing vehicle

−Accelerate smoothly and avoid any sudden movement.

−Brake more in advance than usual and brake gently.

Caution

When tow-starting, fuel could enter the catalytic converter and damage it

�Ÿpage 251

Note

•Observe legal requirements when towing or tow-starting.

•For technical reasons, vehicles with an automatic gearbox must not be

tow-started.