towing Seat Alhambra 2009 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Alhambra, Model: Seat Alhambra 2009Pages: 285, PDF Size: 7.62 MB

Page 195 of 285

Driving and the environment193

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

•

Towing a trailer places additional demands on the vehicle. We recom-

mend additional services between the normal inspection intervals if the

vehicle is used frequently for towing a trailer.

•

Find out whether special regulations apply to towing a trailer in your

country.

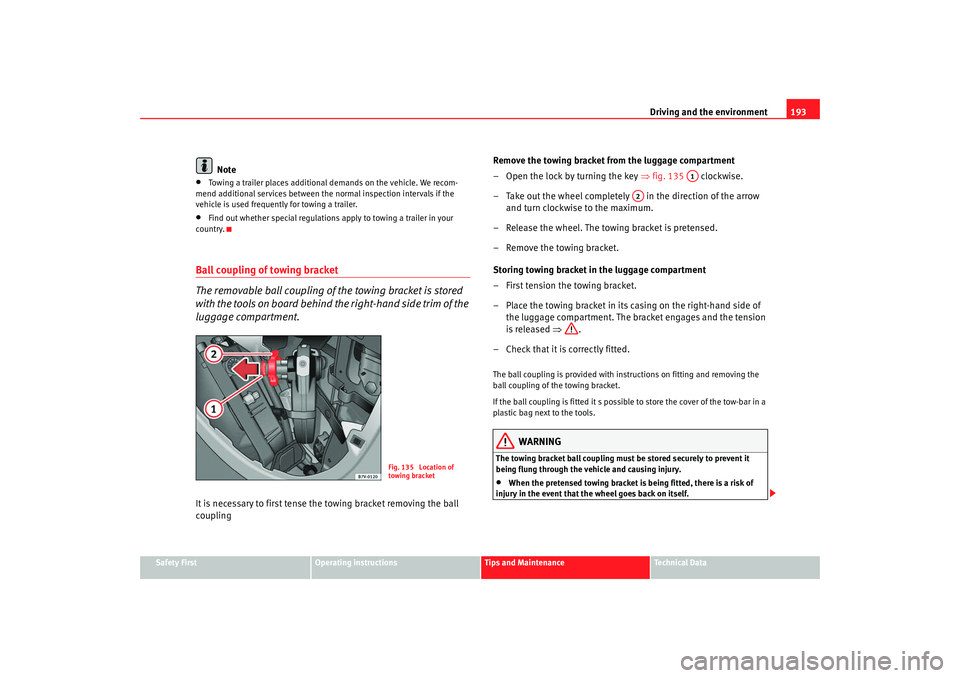

Ball coupling of towing bracket

The removable ball coupling of the towing bracket is stored

with the tools on board behind the right-hand side trim of the

luggage compartment.It is necessary to first tense the towing bracket removing the ball

coupling Remove the towing bracket from the luggage compartment

– Open the lock by turning the key

⇒fig. 135 clockwise.

– Take out the wheel completely in the direction of the arrow and turn clockwise to the maximum.

– Release the wheel. The towing bracket is pretensed.

– Remove the towing bracket.

Storing towing bracket in the luggage compartment

– First tension the towing bracket.

– Place the towing bracket in its casing on the right-hand side of the luggage compartment. The bracket engages and the tension

is released ⇒ .

– Check that it is correctly fitted.

The ball coupling is provided with instructions on fitting and removing the

ball coupling of the towing bracket.

If the ball coupling is fitted it s possible to store the cover of the tow-bar in a

plastic bag next to the tools.

WARNING

The towing bracket ball coupling must be stored securely to prevent it

being flung through the vehicle and causing injury.•

When the pretensed towing bracket is being fitted, there is a risk of

injury in the event that the wheel goes back on itself.

Fig. 135 Location of

towing bracket

A1

A2

alhambra_aleman.book Seite 193 Montag, 23. M‰ rz 2009 1:12 13

Page 196 of 285

Driving and the environment

194

NoteBy law, the ball coupling must be removed if a trailer is not being towed and

it obscures the number plate.•

When placing the towing bracket in the casing check that it is no longer

tensed and securely fastened.

Driving tips

Driving with a trailer always requires extra care.Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slowly to allow

for the unbalanced weight distribution.

Speed

The stability of the car and trailer is reduced with increasing speed. For this

reason it is advisable not to drive at the maximum permissible top speed in

unfavourable road, weather or wind conditions. This applies especially when

driving downhill.

You should always reduce speed immediately if the trailer shows the slightest

sign of snaking . Never try to stop the “snaking” by increasing speed.

Always brake in good time. If the trailer has an overrun brake, apply the

brakes gently at first and then firmly. This will prevent the jerking that can be

caused by the trailer wheels locking. Select a low gear (in both manual and

automatic gearboxes) in good time before going down a steep hill. This

enables you to use the engine braking effect to slow down the vehicle. Overheating

At very high temperatures and during prolonged ascents, driving in a low gear

and high engine speed, always monitor the temperature indicator for the

coolant.

Electronic Stabilisation Program

Do not switch off the ESP when towing a trailer. The ESP makes it easier to

stabilise if the trailer starts to snake.

alhambra_aleman.book Seite 194 Montag, 23. M‰

rz 2009 1:12 13

Page 208 of 285

Accessories, parts replacement and modifications

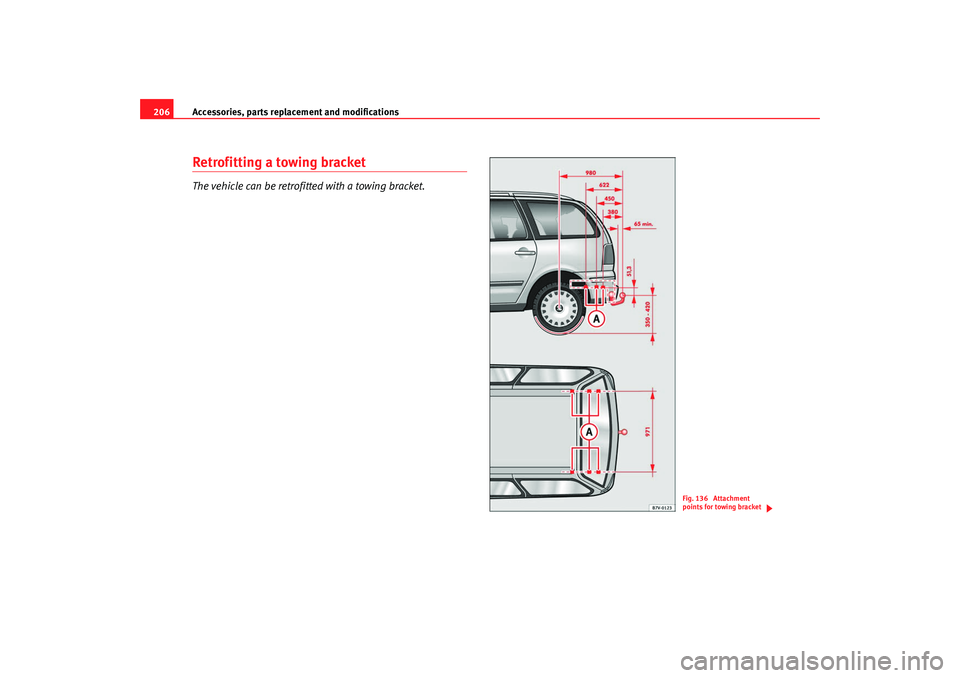

206Retrofitting a towing bracketThe vehicle can be retrofitted with a towing bracket.

Fig. 136 Attachment

points for towing bracket

alhambra_aleman.book Seite 206 Montag, 23. M‰ rz 2009 1:12 13

Page 209 of 285

Accessories, parts replacement and modifications207

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

If a towing bracket is to be retro-fitted to the car, it must be done according to

the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket ⇒

page 206, fig. 136 are

underneath the vehicle.

Always observe the minimum distance from the middle of the ball coupling to

the ground (350 to 420 mm). This also applies when the vehicle is fully laden,

including maximum drawbar load.

Fitting a towing bracket

•

Driving with a trailer implies additional work for the vehicle. Therefore,

before fitting a towing bracket, please contact an Authorised Service Centre

to check whether your cooling system needs modification.

•

Observe the legal requirements in your country (e.g. the fitting of a sepa-

rate pilot lamp).

•

Certain vehicle components, e.g. the rear bumper must be removed and

reinstalled. The towing bracket securing bolts have to be tightened using a

torque wrench, and a socket connected to the vehicle's electrical system. This

requires specialist knowledge and tools.

•

The figures in the illustration show the dimensions and attachment points

which must be observed if you are retrofitting a towing bracket.

WARNING

If a towing bracket is retrofitted, it should be done by a qualified dealer.•

If the towing bracket is incorrectly fitted, this could cause a safety risk.

•

For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.Caution

If the connector socket is not fitted correctly, this could cause damage to the

vehicle's electrical system.

AA

alhambra_aleman.book Seite 207 Montag, 23. M‰ rz 2009 1:12 13

Page 218 of 285

Checking and refilling levels

216

NoteBefore a long trip, we recommend finding an engine oil that conforms to the

corresponding VW specifications and keeping it in the vehicle. This way, the

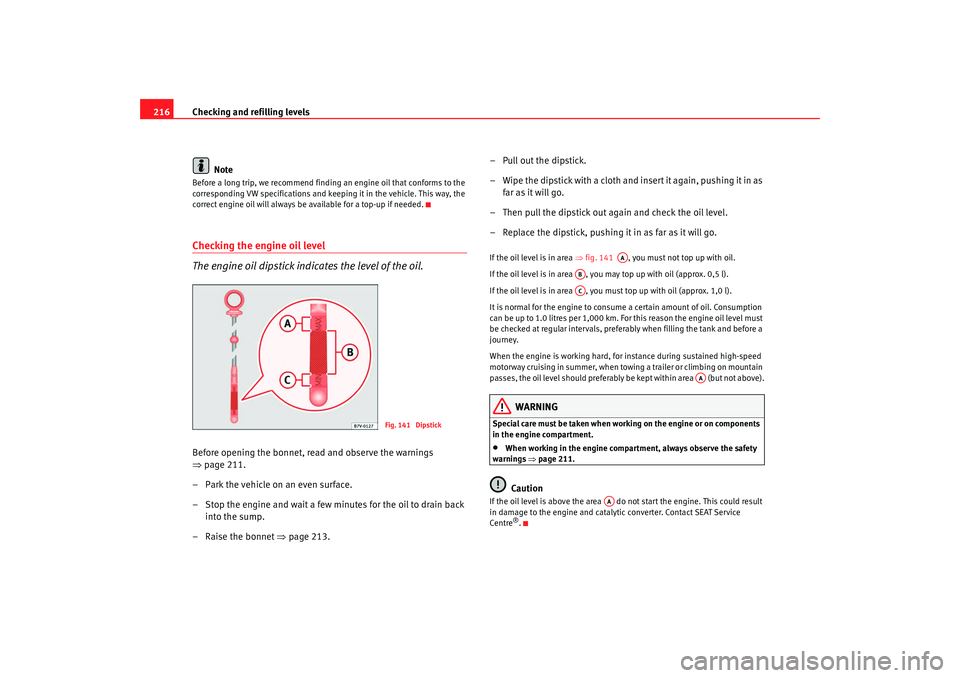

correct engine oil will always be available for a top-up if needed.Checking the engine oil level

The engine oil dipstick indicates the level of the oil.Before opening the bonnet, read and observe the warnings

⇒page 211.

– Park the vehicle on an even surface.

– Stop the engine and wait a few minutes for the oil to drain back into the sump.

–Raise the bonnet ⇒ page 213. – Pull out the dipstick.

– Wipe the dipstick with a cloth and insert it again, pushing it in as

far as it will go.

– Then pull the dipstick out again and check the oil level.

– Replace the dipstick, pushing it in as far as it will go.

If the oil level is in area ⇒fig. 141 , you must not top up with oil.

If the oil level is in area , you may top up with oil (approx. 0,5 l).

If the oil level is in area , you must top up with oil (approx. 1,0 l).

It is normal for the engine to consume a certain amount of oil. Consumption

can be up to 1.0 litres per 1,000 km. For this reason the engine oil level must

be checked at regular intervals, preferably when filling the tank and before a

journey.

When the engine is working hard, for instance during sustained high-speed

motorway cruising in summer, when towing a trailer or climbing on mountain

passes, the oil level should preferably be kept within area (but not above).

WARNING

Special care must be taken when working on the engine or on components

in the engine compartment.•

When working in the engine compartment, always observe the safety

warnings ⇒page 211.Caution

If the oil level is above the area do not start the engine. This could result

in damage to the engine and catalytic converter. Contact SEAT Service

Centre

®.

Fig. 141 Dipstick

AA

ABAC

AA

AA

alhambra_aleman.book Seite 216 Montag, 23. M‰ rz 2009 1:12 13

Page 235 of 285

If and when233

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

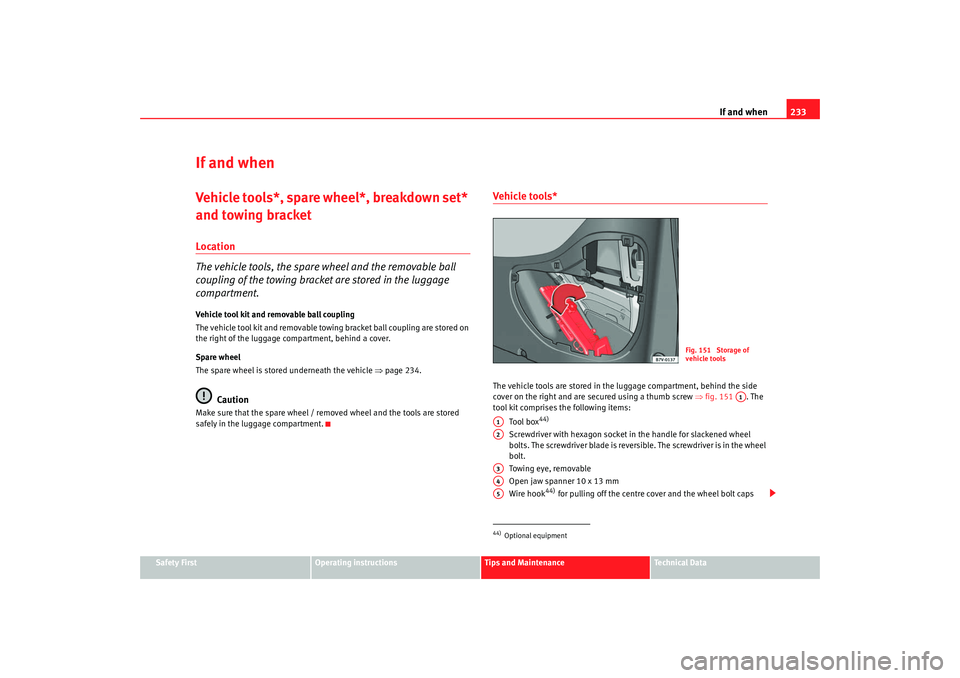

If and whenVehicle tools*, spare wheel*, breakdown set*

and towing bracketLocation

The vehicle tools, the spare wheel and the removable ball

coupling of the towing bracket are stored in the luggage

compartment.Vehicle tool kit and removable ball coupling

The vehicle tool kit and removable towing bracket ball coupling are stored on

the right of the luggage compartment, behind a cover.

Spare wheel

The spare wheel is stored underneath the vehicle ⇒page 234.

Caution

Make sure that the spare wheel / removed wheel and the tools are stored

safely in the luggage compartment.

Vehicle tools*The vehicle tools are stored in the luggage compartment, behind the side

cover on the right and are secured using a thumb screw ⇒fig. 151 . The

tool kit comprises the following items:

To ol b ox

44)

Screwdriver with hexagon socket in the handle for slackened wheel

bolts. The screwdriver blade is reversible. The screwdriver is in the wheel

bolt.

Towing eye, removable

Open jaw spanner 10 x 13 mm

Wire hook

44) for pulling off the centre cover and the wheel bolt caps

44)Optional equipment

Fig. 151 Storage of

vehicle tools

A1

A1A2A3A4A5

alhambra_aleman.book Seite 233 Montag, 23. M‰ rz 2009 1:12 13

Page 236 of 285

If and when

234

Box spanner for wheel bolts

Jack. Before you return the jack to the tool box, you must fully wind in the

claw. The crank must then be folded tight against the side of the jack.

The removable towing bracket

44), the key for unlocking the sunroof in an

emergency

44) and the anti-theft wheel bolt adaptor

44) are stored next to the

vehicle tools.

Adapter for anti-theft wheel bolts

We recommend you carry the wheel bolt adapter

44) in the vehicle tool kit at

all times.

The code number of the anti-theft wheel bolt is stamped on the front of the

adapter. You will need this number to replace the adapter if lost. Make a note

the code number of the anti-theft wheel bolt and keep it in a safe place - but

not in your vehicle.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts. It is not suitable for tightening the bolts to the necessary

torque. This may cause an accident.

•

The jack supplied by the factory is only designed for changing wheels

on this model. Never attempt to use it for lifting heavier vehicles or other

loads. Risk of injury.

•

Use the jack only on firm, level ground.

•

Never start the engine when you have raised the vehicle on the jack.

Risk of accident.

•

Never place your body (e.g. arm or leg) underneath the vehicle if it is

only supported by the jack Risk of injury.

•

If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle - Risk of accident!.

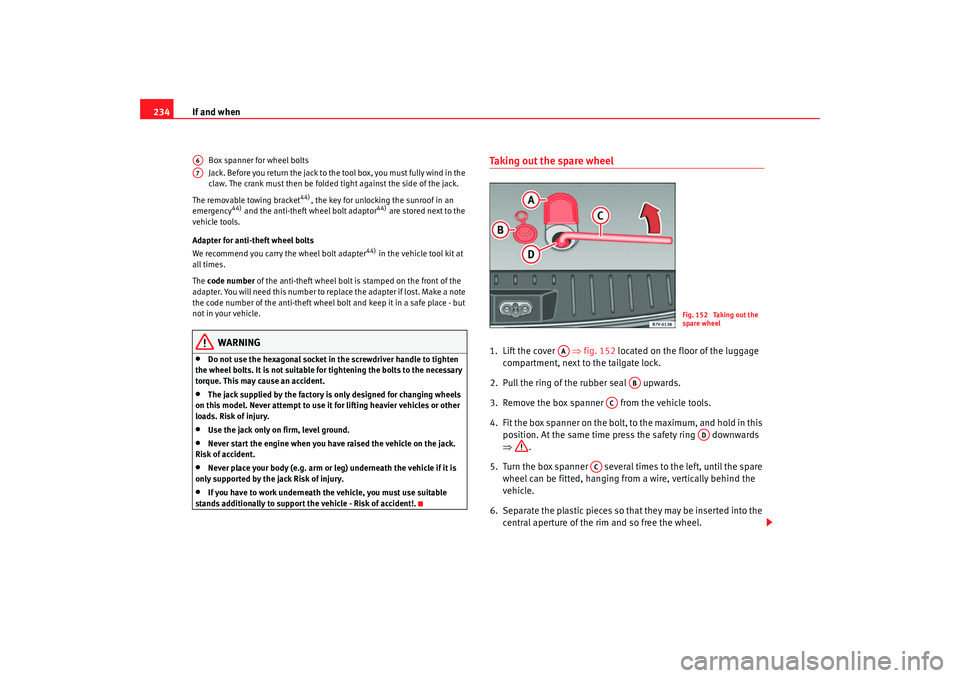

Taking out the spare wheel1. Lift the cover ⇒fig. 152 located on the floor of the luggage

compartment, next to the tailgate lock.

2. Pull the ring of the rubber seal upwards.

3. Remove the box spanner from the vehicle tools.

4. Fit the box spanner on the bolt, to the maximum, and hold in this position. At the same time press the safety ring downwards

⇒ .

5. Turn the box spanner several times to the left, until the spare wheel can be fitted, hanging from a wire, vertically behind the

vehicle.

6. Separate the plastic pieces so that they may be inserted into the central aperture of the rim and so free the wheel.

A6A7

Fig. 152 Taking out the

spare wheel

AA

AB

AC

AD

AC

alhambra_aleman.book Seite 234 Montag, 23. M‰ rz 2009 1:12 13

Page 238 of 285

If and when

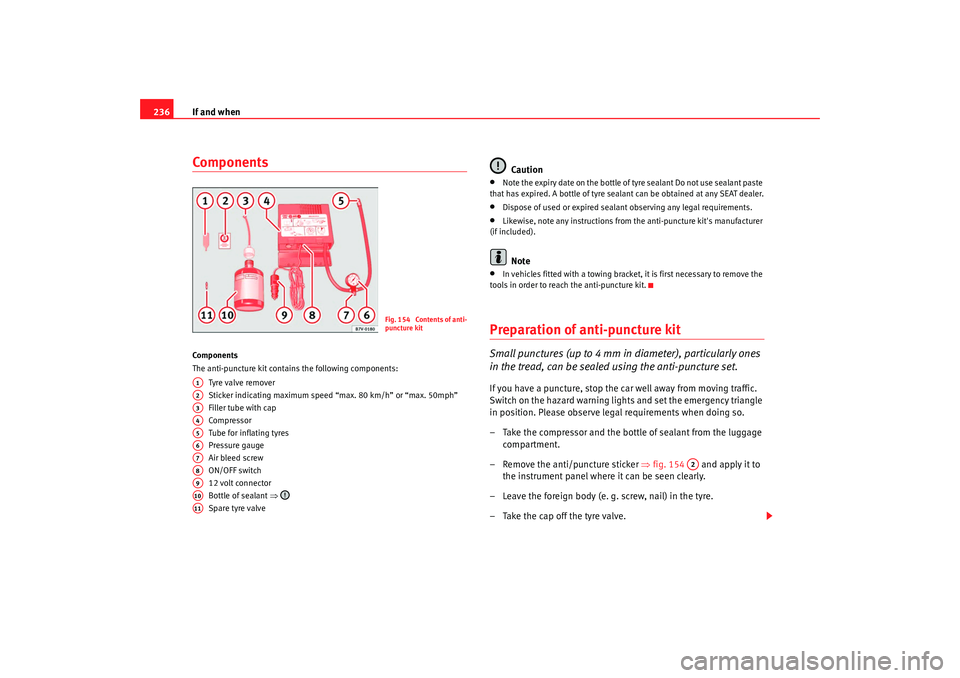

236ComponentsCo mp on e nts

The anti-puncture kit contains the following components:

Tyre valve remover

Sticker indicating maximum speed “max. 80 km/h” or “max. 50mph”

Filler tube with cap

Compressor

Tube for inflating tyres

Pressure gauge

Air bleed screw

ON/OFF switch

12 volt connector

Bottle of sealant ⇒

Spare tyre valve

Caution

•

Note the expiry date on the bottle of tyre sealant Do not use sealant paste

that has expired. A bottle of tyre sealant can be obtained at any SEAT dealer.

•

Dispose of used or expired sealant observing any legal requirements.

•

Likewise, note any instructions from the anti-puncture kit's manufacturer

(if included).Note

•

In vehicles fitted with a towing bracket, it is first necessary to remove the

tools in order to reach the anti-puncture kit.

Preparation of anti-puncture kitSmall punctures (up to 4 mm in diameter), particularly ones

in the tread, can be sealed using the anti-puncture set.If you have a puncture, stop the car well away from moving traffic.

Switch on the hazard warning lights and set the emergency triangle

in position. Please observe legal requirements when doing so.

– Take the compressor and the bottle of sealant from the luggage compartment.

– Remove the anti/puncture sticker ⇒fig. 154 and apply it to

the instrument panel where it can be seen clearly.

– Leave the foreign body (e. g. screw, nail) in the tyre.

– Take the cap off the tyre valve.

Fig. 1 54 Conte nts of ant i-

puncture kit

A1A2A3A4A5A6A7A8A9A10A11

A2

alhambra_aleman.book Seite 236 Montag, 23. M‰ rz 2009 1:12 13

Page 240 of 285

If and when

238

WARNING

•

Do not allow the sealant to get onto your skin or into your eyes. Risk of

injury.

•

Keep children away from the sealant.

Changing a wheel Preparation

You must park the vehicle correctly before changing a tyre.– If you have a flat tyre or puncture, park the car as far away from the flow of traffic as possible on a flat surface.

– Switch off the engine. Switch on the hazard warning lights.

– Apply the handbrake firmly and engage a gear or put the selector in the P position.

– Chock the wheel opposite the wheel being changed with a stone or similar object.

– If you are towing a trailer, unhitch it from your vehicle.

– Remove the spare wheel and the vehicle tools from the luggage compartment.

– All passengers should leave the car. They should wait in a safe place (for instance behind the safety barrier).

WARNING

•

If you have a puncture, stop the car well away from moving traffic.

Switch on the hazard warning lights and set the emergency triangle in

position. Please observe legal requirements when doing so.

•

All passengers should leave the car.

•

Apply the handbrake firmly and engage a gear or put the gear selector

in the P position. Chock the wheel opposite the wheel being changed with

a stone or similar object.

•

If you are towing a trailer, unhitch it from your vehicle.

•

Only use jacks which have been approved for your vehicle by SEAT.

•

Never use other jacks, even if they have been approved for use on other

SEAT models. The jack could slip. Risk of injury.

•

Never start the engine when the vehicle is raised. This may cause an

accident.

•

Never place your body (e.g. arm or leg) underneath the vehicle if it is

only supported by the jack Risk of injury.

•

If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle - Risk of accident!.

alhambra_aleman.book Seite 238 Montag, 23. M‰ rz 2009 1:12 13

Page 254 of 285

If and when

252Towing and tow-startingTow-starting*

The use of jump leads is preferable to tow-starting.We recommend that you do not tow-start your vehicle. Jump-starting

is preferable ⇒page 250.

However, if your vehicle has to be tow-started:

–Engage the 2

nd or the 3

rd gear.

– Keep the clutch pressed down.

– Switch on the ignition.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the gear lever into neutral. This helps to prevent driving into the towing

vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

Caution

When tow-starting, fuel could enter the catalytic converter and damage it.

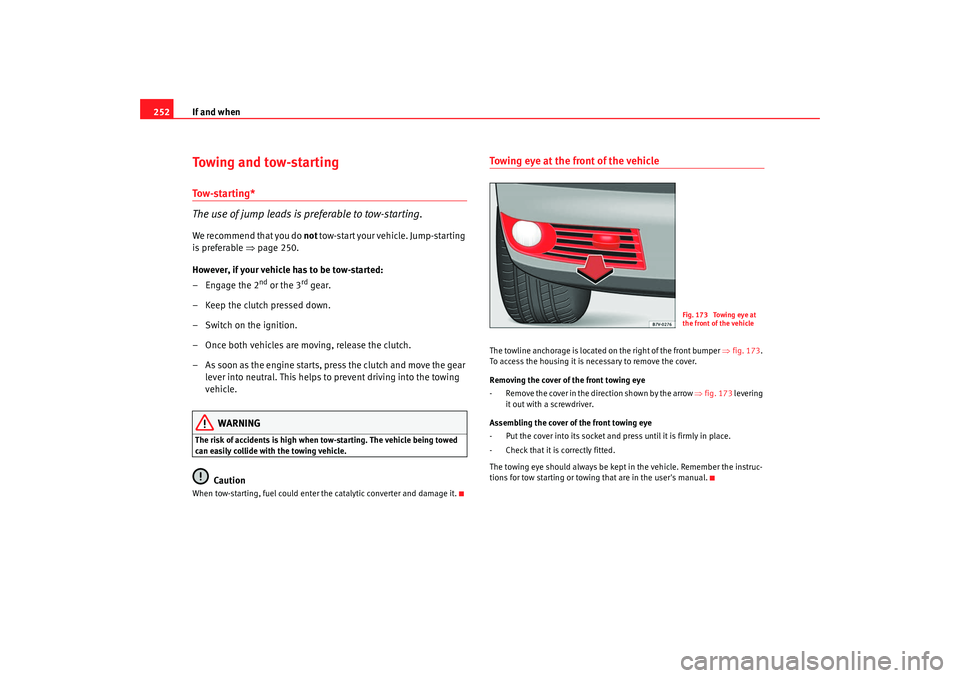

Towing eye at the front of the vehicleThe towline anchorage is located on the right of the front bumper ⇒fig. 173.

To access the housing it is necessary to remove the cover.

Removing the cover of the front towing eye

- Remove the cover in the direction shown by the arrow ⇒fig. 173 levering

it out with a screwdriver.

Assembling the cover of the front towing eye

- Put the cover into its socket and press until it is firmly in place.

- Check that it is correctly fitted.

The towing eye should always be kept in the vehicle. Remember the instruc-

tions for tow starting or towing that are in the user's manual.

Fig. 173 Towing eye at

the front of the vehicle

alhambra_aleman.book Seite 252 Montag, 23. M‰ rz 2009 1:12 13