headlight Seat Alhambra 2011 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Alhambra, Model: Seat Alhambra 2011Pages: 385, PDF Size: 7.92 MB

Page 111 of 385

109

Lights and visibility

● Damaged blades: A film of water on the damaged blades may lengthen

the activ ation time, r

educe the washing intervals or result in a fast and con-

tinuous wipe.

● Insects: insects on the sensor may trigger the windscreen wipers.

● Salt on roads: in winter, salt spread in the roads may cause an extra

long wipe when the w

indscreen is almost dry.

● Dirt: dry dust, wax, coating on glass (Lotus effect) or traces of detergent

(car wa

sh) may reduce the effectiveness of the rain sensor or make it react

more slowly, later or not at all.

● Cracked windscreen: the impact of a stone will trigger a single wipe cy-

cle w

ith the rain sensor on. Next the rain sensor detects the reduction in the

sensitive surface area and adapts accordingly. The behaviour of the sensor

will vary with the size of the damage caused by the stone. WARNING

The rain sensor may not detect enough rain to switch on the wipers.

● If necessary, switch on the wipers manually when water on the wind-

sc r

een obstructs visibility. Note

● Clean the sensitive surface of the rain sensor regularly and check the

b l

ades for damage ⇒ fig. 70 (arrow).

● To remove wax and coatings, we recommend a window cleaner contain-

ing alcoho

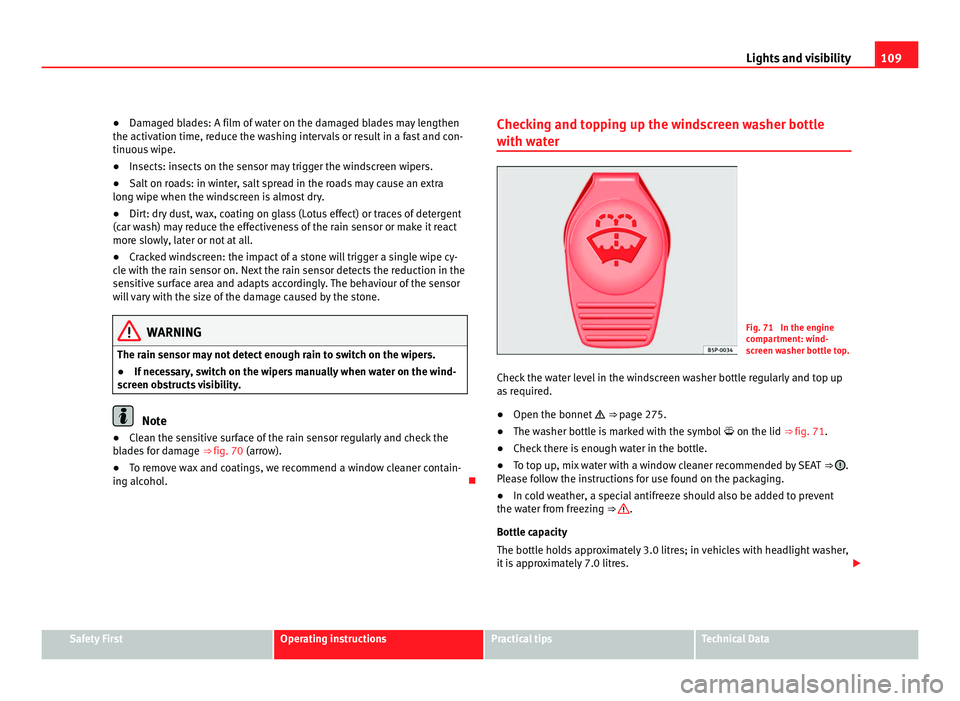

l. Checking and topping up the windscreen washer bottle

with wat

er Fig. 71 In the engine

comp

ar

tment: wind-

screen washer bottle top.

Check the water level in the windscreen washer bottle regularly and top up

as r

equired.

● Open the bonnet ⇒ pag

e 275.

● The washer bottle is marked with the symbol on the lid ⇒ fig. 71.

● Check there is enough water in the bottle.

● To top up, mix water with a window cleaner recommended by SEAT ⇒ .

Ple a

se follow the instructions for use found on the packaging.

● In cold weather, a special antifreeze should also be added to prevent

the water fr

om freezing ⇒ .

Bottle c ap

acity

The bottle holds approximately 3.0 litres; in vehicles with headlight washer,

it is approximately 7.0 litres. Safety First Operating instructions Practical tips Technical Data

Page 239 of 385

237

Trailer towing

For the sake of road safety, SEAT recommends using the maximum allowed

dra wb

ar load. The handling of the combined vehicle and trailer will be poor

if the drawbar load is too low.

The drawbar load increases the weight on the rear axle, reducing the vehicle

carrying capacity.

Gross combination weight

This figure refers to the combined weight of the loaded vehicle and loaded

trailer.

Loading the trailer

The combined vehicle and trailer must be balanced. Use the maximum

drawbar load authorised and do not overload the front or the rear of the

trailer:

● Distribute loads in the trailer so that heavy objects are as near to the

axle a

s possible or even above it.

● Correctly secure the trailer load.

Tyr

e pressure

Inflate the trailer tyres according to the manufacturer's instructions.

Inflate the towing vehicles tyres to the maximum ⇒ page 293.WARNING

Exceeding the maximum authorised axle load, drawbar load or the gross

comb in

ation weight of the towing vehicle and trailer could cause a seri-

ous accident with severe consequences.

● Never exceed the specifications.

● With the actual load on the front and rear axles, the maximum axle

load shou

ld never be exceeded. The weight on the front and rear should

never exceed the gross vehicle weight. WARNING

If the load moves, the stability and safety of the vehicle and trailer com-

bin ation w

ill be seriously affected and this could result in a serious acci-

dent.

● Always correctly load the trailer.

● Always secure loads correctly with suitable and undamaged attach-

ment rope or s

traps.

Driving with a trailer Adjusting the headlights

When to

w

ing a trailer, the front of the vehicle may rise and so the dipped

beam headlights may blind other drivers. Use the headlight range control to

lower the cone of light. If you do not have headlight range control, have the

headlights adjusted by a qualified dealership. Vehicles with high-intensity

discharge lamps adapt automatically and do not require adjustment.

Details of driving with a trailer

● If the trailer has an overru

n brake, apply the brakes gently at first and

then, firmly. This will prevent the jerking that can be caused by the trailer

wheels locking.

● As of the combined vehicle and trailer mass, braking distances will be

great

er.

● Select a low gear before driving down a steep hill to use the engine

brakin

g effect to slow down the vehicle. Otherwise, the braking system

could overheat and fail. Safety First Operating instructions Practical tips Technical Data

Page 245 of 385

243

Vehicle maintenance and cleaning

Washing the vehicle The longer substances such as insects, bird droppings, resinous tree sap,

ro

a

d dirt, industrial deposits, tar, soot or road salt and other aggressive ma-

terials remain on the vehicle, the more damage they do to the paintwork.

High temperatures (for instance due to strong sunlight) further intensify the

corrosive effect. The vehicle undercarriage should also be thoroughly wash-

ed at regular intervals.

Automatic car washes

Always observe the instructions provided at the automatic car wash. The

standard precautionary measures prior to entering the car wash should be

taken to avoid damage to the vehicle (close all windows, fold in exterior mir-

rors). If the vehicle is fitted with additional components (spoiler, roof-rack,

aerial...), check with the car wash supervisor whether these can enter the

car wash ⇒ .

The v ehic

le paintwork is so durable that the car can normally be washed

without problems in an automatic car washing tunnel. However, wear and

damage to the paintwork will depend on the type of car wash used. SEAT

recommends the use of car washed without brushes.

To remove traces of wax on windows and to prevent wiper blades from

scratching, please observe the following ⇒ page 245, Cleaning windows

and exterior mirrors.

Washing the car by hand

When washing the car by hand, use plenty of water to soften the dirt first,

and rinse off as well as possible.

Then clean the vehicle with a soft sponge, glove or brush using only slight

pressure. Start at the roof and work downwards. Special car shampoo

should only be used for very persistent dirt.

Rinse the sponge or glove thoroughly and often.

Wheels, sills and similar should be cleaned last. Use a second sponge for

this. WARNING

Sharp components on the vehicle may cause injury.

● Protect arms and hands from sharp edges when cleaning the vehicle

under c

arriage or the interior of the wheel hubs. WARNING

After the vehicle has been washed, the braking effect will be reduced

(and the brakin

g distance increased) due to moisture (and ice in winter)

on the brakes.

● Dry the brakes and remove ice by braking carefully. Ensure that you

are not end

angering other road-users or breaking traffic regulations in

the process. CAUTION

● The temperature of the water must not exceed +60°C (+140°F).

● To av

oid damage to the paintwork, do not wash the vehicle in full sun.

● Do not use rough sponges or similar which could damage the surface to

cle

an away the traces of insects.

● Never wipe the headlights with a dry cloth or sponge, always moisten

first

. It is best to use soapy water.

● Washing the vehicle in low temperatures: When washing the vehicle

with a hose, do not

direct water into the lock cylinders or the gaps around

the doors, tailgate, or sunroof. Locks and seals could freeze! CAUTION

To prevent damage to the vehicle, please observe the following before en-

terin g

an automatic car wash :

● Compare the distance between the vehicle wheels and the distance be-

tween the guide-rai

ls of the car wash to prevent damage to the wheels and

tyres! Safety First Operating instructions Practical tips Technical Data

Page 269 of 385

267

Checking and refilling levels

Closing the tank cap

● Screw on the tank cap clockwise until it you hear it click into position.

● Press the tank flap until you hear it click into place. The tank flap must

be flush w ith the body

contour. WARNING

Do not continue refilling once the fuel nozzle has switched itself off. The

fuel t

ank may be filled too much. As a result, fuel may spurt out and spill.

This could lead to a fire, explosion and severe injuries. CAUTION

● Always remove any fuel spilled on the vehicle paintwork immediately to

av oid d

amage to the wheel housing, the tyre and vehicle paintwork. For the sake of the environment

Spilt fuel can contaminate the environment.

Refilling precautions Information on bulb replacement

⇒ pag

e 326.

Checklist

Never work on the engine or in the engine compartment if you are not famil-

iar with the operations to be carried out, the applicable safety standards

and especially if you do not have the instruments, liquids and tools neces-

sary ⇒ page 275, Working in the engine compartment! Have the work car-

ried out by a Technical Service if you are uncertain. Check the following reg-

ularly, preferably when you refuel:

● Windscreen washer fluid level ⇒ pag

e 105

● Engine oil level ⇒ pag

e 279 ●

Engine coolant level ⇒ p

age 283

● Brake fluid level ⇒ pag

e 183

● Tyre pressure ⇒ pag

e 293

● Vehicle lighting required to guarantee road safety:

Indicator

s

Side lights, dipped headlights and full beam headlights

Rear lights

Brake lights

Rear fog light ⇒ page 97 WARNING

Not following the checklist prepared for your own safety could lead to ac-

cident s

and severe injuries.

● Always follow the check list and perform the necessary operations.

Fuel Introduction You will find a factory-fitted sticker containing information on the type of

fuel

f

or your vehicle on the inside of the fuel tank flap.

Additional information and warnings:

● ⇒ Bookl et Maintenance Programme

● R

efuelling ⇒ pag e 264

● En

gine and exhaust system management ⇒ page 228

–

–

–

–

–

Safety First Operating instructions Practical tips Technical Data

Page 329 of 385

327

If and when

Several warning and control lamps should light up for a few seconds when

the ignition is sw

itched. This signals that the lamp is working properly. They

will switch off after a few seconds.

Checking the bulbs of a trailer

For vehicles with the factory fitted trailer system, certain trailer lights are al-

so controlled if the socket is correctly connected.

A fault on a trailer turn indicator is indicated on the instrument panel by the

indicator blinking twice as fast ( or ) ⇒ page 95.

● General fault of all indicators on one side.

● Fault in one tail light (on some models, also the registration light).

● Fault in two brake lights. WARNING

If the warning lamps and messages are ignored, the vehicle may stall in

traffic, or m a

y cause accidents and severe injuries.

● Never ignore the warning lamps or text messages.

● Stop the vehicle safely as soon as possible. CAUTION

Failure to heed the warning lamps and text messages when they appear

ma y

result in faults in the vehicle. Note

A fault in the LED on the tail lights will not be indicated. However, if the fault

affects al

l the LEDs then this will be indicated by the indicator . Information for replacing bulbs Checklist

To r

ep

lace a bulb, carry out the following operations always in the order giv-

en ⇒ :

Park the

vehicle a safe distance from traffic and on suitable ground.

Connect the electronic parking brake ⇒ page 183.

Turn the light switch to position 0 ⇒ page 95.

Move the gear lever into the neutral position ⇒ page 95.

Automatic gearbox: Move selector lever to position P ⇒ page 174.

Stop the engine and remove the key from the ignition ⇒ page 170.

Manual gearbox: Select a gear ⇒ page 174.

Wait until all of the passenger compartment lights are turned off

⇒ page 95.

Allow the corresponding bulb to cool. Visually inspect fuses to see if any are blown ⇒ page 322.

Replace the bulb according to the instructions ⇒ . Bulbs should only

be rep l

aced by new identical models. Bulb information is displayed on

the bulb socket or on the bulb itself.

In general, never touch the bulb glass directly. The heat of the bulb

would cause the fingerprint to evaporate and condense on the reflector.

This will impair the brightness of the headlight.

Check if the new bulb is working. If the bulb is not working, it may not

have been correctly fitted, it could be damaged or the connector may

not be correctly connected.

Every time a bulb for the headlights is replaced, visit a specialised

workshop to check the headlights.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Safety First Operating instructions Practical tips Technical Data

Page 330 of 385

328

If and when WARNING

Failure to follow the checklist prepared for your own safety could lead to

acc ident

s and severe injuries.

● Always complete the operations given in the checklist and observe

the genera

l rules of safety. CAUTION

Always remove and fit headlights carefully to avoid damage to the paint-

work and other

vehicle parts.

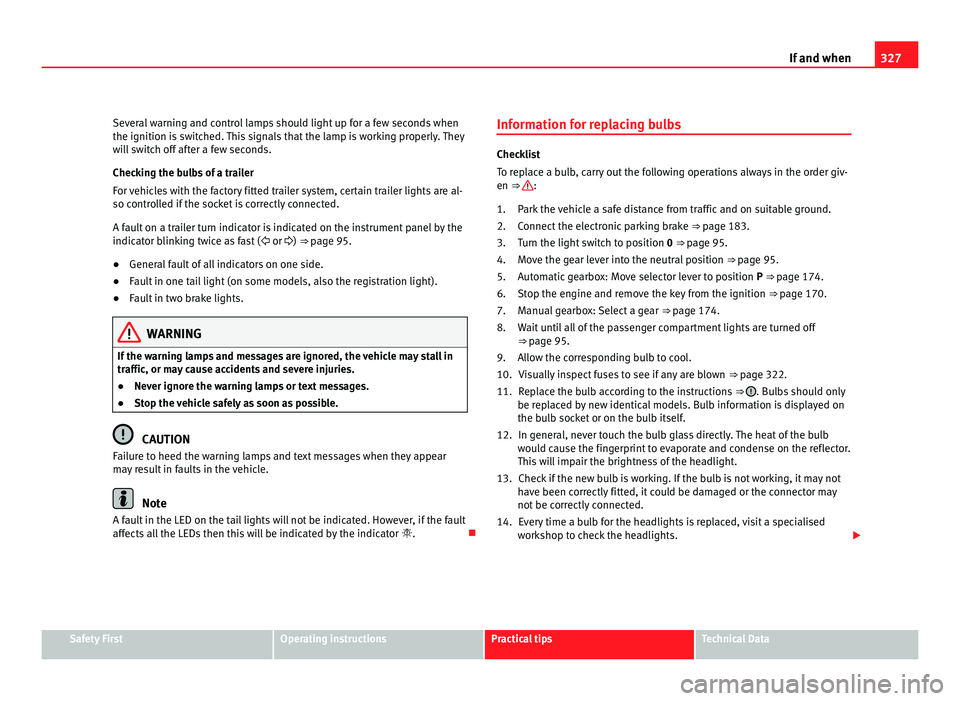

To replace halogen headlight bulbs Fig. 203 In the engine

comp

ar

tment: Left-hand

side headlight lining. A dipped beam headlights,

B daytime lights and

C main beam headlights

and side light

s. Fig. 204 Left headlight

There is no need to remove the headlight to replace bulbs.

Comp l

ete operations only in the sequence given: fig. 203,

fig. 204 A B C

Indicators (small lamp

holder) Dipped beam head-

lights Daylight driving lights Main beam headlights Side lights

1. Always take the checklist into account and take the necessary actions

⇒ pag

e 327.2. Open the bonnet

⇒ page 275.

Page 331 of 385

329

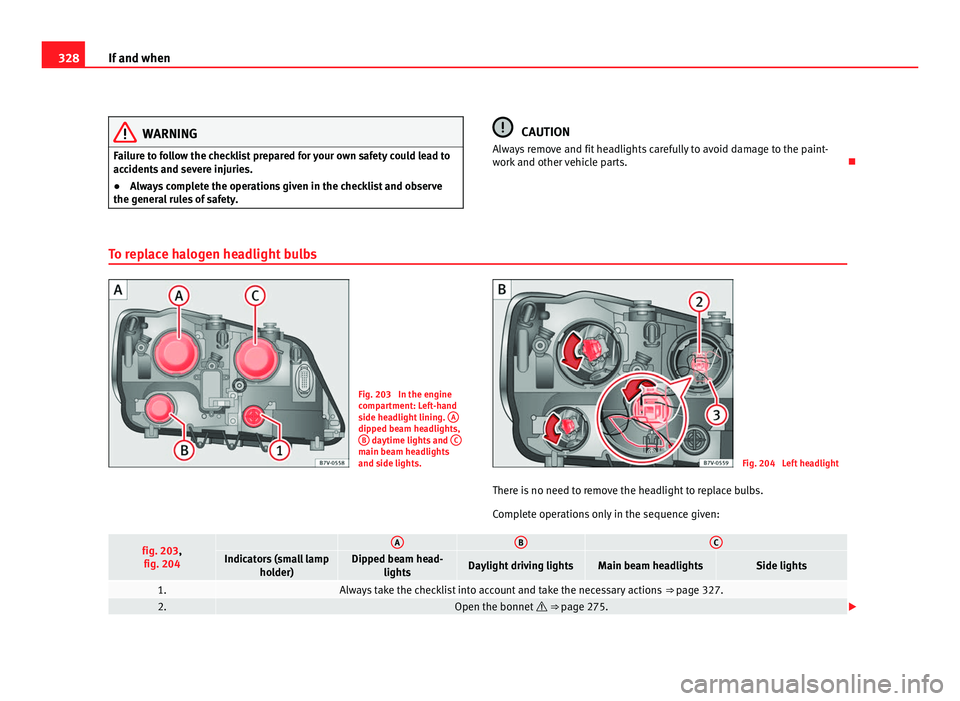

If and when fig. 203,

fig. 204 A B C

Indicators (small lamp

holder) Dipped beam head-

lights Daylight driving lights Main beam headlights Side lights

3. Remove the rubber cover on the rear of the headlight.

4. Rotate the lamp holder

1 to the left all the way

and pu l

l it out back-

wards with the bulb. Rotate the lamp holder to the left all the way and

pul

l it out backwards with the bulb. Press the wire clip down-

war d

s and pull the lamp

holder 2 out with the

bu l

b. Pull the lamp holder

3 out backwards with the

bul

b. 5. Depending on the model, the bulb is removed directly from the lamp holder or it may need to be rotated and then removed.

6. Replace the faulty bulb by a new identical bulb.

7. Place the bulb holder in the headlight and rotate to the right all the way. Place the lamp holder in

the hea

dlight

and pull the

wire clip upwards until it

clicks into place. Place the lamp holder in

the hea dlight

and insert

completely. 8. Insert the rubber cover.

Note

The images show the left hand headlight from behind. The structure of the

right h and s

ide headlight is symmetric. Safety First Operating instructions Practical tips Technical Data

Page 332 of 385

330

If and when

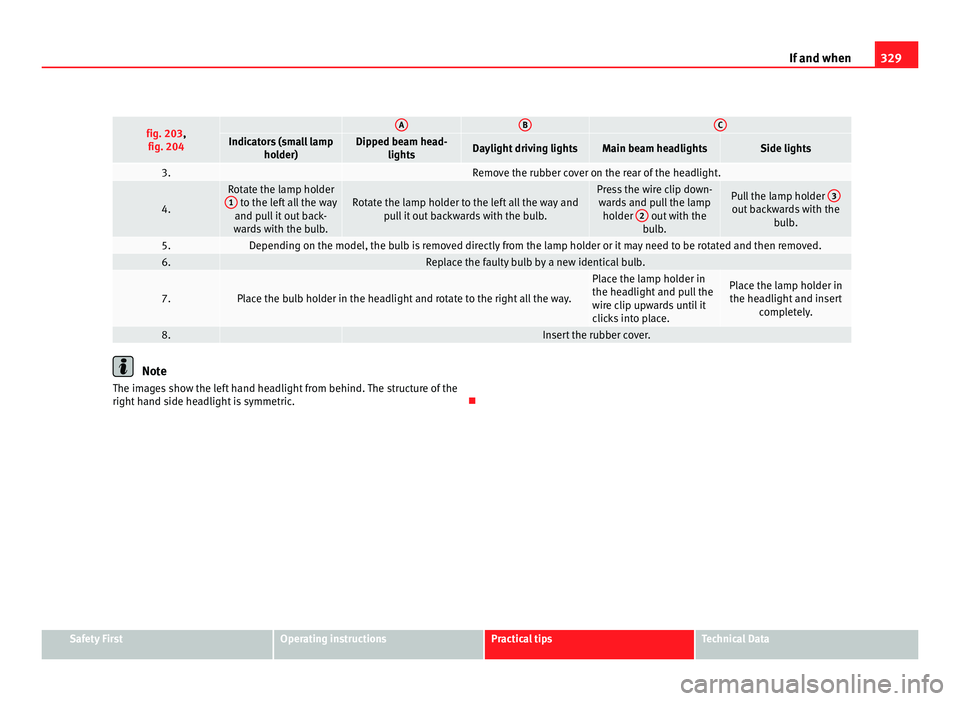

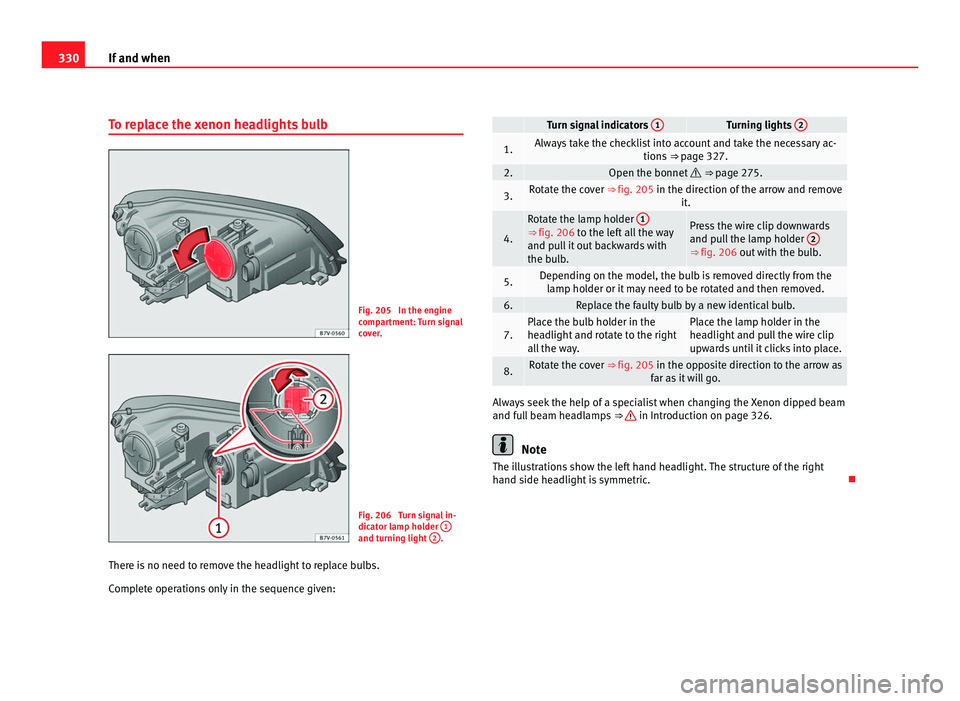

To replace the xenon headlights bulb Fig. 205 In the engine

comp

ar

tment: Turn signal

cover. Fig. 206 Turn signal in-

dicat

or l

amp holder 1 and turning light

2 .

There is no need to remove the headlight to replace bulbs.

Comp l

ete operations only in the sequence given: Turn signal indicators

1 Turning lights

2 1. Always take the checklist into account and take the necessary ac-

tions ⇒

page 327. 2. Open the bonnet

⇒ page 275. 3. Rotate the cover ⇒

fig. 205 in the dir

ection of the arrow and remove

it. 4. Rotate the lamp holder

1 ⇒ fig. 206 to the left all the way

and p

u

ll it out backwards with

the bulb. Press the wire clip downwards

and pu

l

l the lamp holder 2 ⇒ fig. 206 out w

ith the b

ulb. 5. Depending on the model, the bulb is removed directly from the

lamp ho l

der or it may need to be rotated and then removed. 6. Replace the faulty bulb by a new identical bulb.

7. Place the bulb holder in the

hea

dlight

and rotate to the right

all the way. Place the lamp holder in the

hea

dlight

and pull the wire clip

upwards until it clicks into place. 8. Rotate the cover ⇒

fig. 205 in the op

posite direction to the arrow as

far as it will go. Always seek the help of a specialist when changing the Xenon dipped beam

and fu

l

l beam headlamps ⇒ in Introduction on page 326.

Note

The illustrations show the left hand headlight. The structure of the right

hand s ide he

adlight is symmetric.

Page 333 of 385

331

If and when

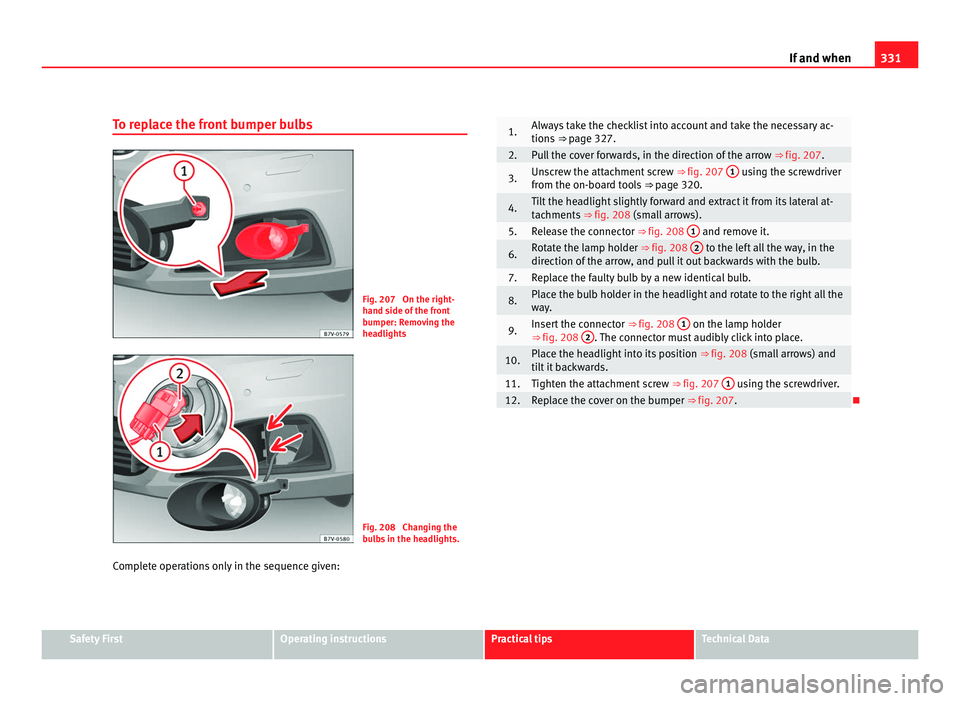

To replace the front bumper bulbs Fig. 207 On the right-

hand s

ide of

the front

bumper: Removing the

headlights Fig. 208 Changing the

bu

l

bs in the headlights.

Complete operations only in the sequence given: 1. Always take the checklist into account and take the necessary ac-

tions

⇒

page 327. 2. Pull the cover forwards, in the direction of the arrow

⇒ fig. 207. 3. Unscrew the attachment screw

⇒ fig. 207 1 using the screwdriver

from the on-bo ar

d tools ⇒ page 320. 4. Tilt the headlight slightly forward and extract it from its lateral at-

tac

hments

⇒ fig. 208 (small arrows). 5. Release the connector ⇒ fig. 208

1 and remove it.

6. Rotate the lamp holder ⇒ fig. 208

2 to the left all the way, in the

direction of the arr

ow, and pull it out backwards with the bulb. 7. Replace the faulty bulb by a new identical bulb.

8. Place the bulb holder in the headlight and rotate to the right all the

wa

y

. 9. Insert the connector

⇒ fig. 208 1 on the lamp holder

⇒ fig. 208 2 . The connector must audibly click into place.

10. Place the headlight into its position

⇒ fig. 208 (small

arrows) and

tilt it backwards. 11. Tighten the attachment screw

⇒ fig. 207 1 using the screwdriver.

12. Replace the cover on the bumper ⇒ fig. 207.

Safety First Operating instructions Practical tips Technical Data

Page 341 of 385

339

If and when

The vehicles should not touch. Otherwise, current may be allowed to flow

when the pos itiv

e poles are connected.

Connect the clamps so they have good metal-to-metal contact with the ter-

minals.

If the engine fails to start straight-away, switch off the starter after about 10

seconds and try again after about a minute.

Complete operations only in the sequence given.

Jump lead terminal connections

● Switch off the ignition of both vehicles ⇒ page 170.

● Lik

ewise, open the battery cover in the engine compartment

⇒ pag

e 288, or remove the positive pole cap from one side 1)

, in the direc-

tion of the arrow ⇒ fig. 215.

● Connect one end of the red

jump lead to the positive terminal

⇒ fig. 216 + or ⇒

fig. 215 + of the vehicle with the flat battery

A ⇒ .

● Connect the other end of the red

jump lead to the positive terminal + in

the v ehic

le providing assistance B .

● For vehicles without

Start-Stop system: Connect one end of the black

jump lead to the negative terminal - in the vehicle providing assistance

B ⇒ fig. 216.

● For vehicles with St

art-Stop system: Connect one end of the black X jump lead to a suitable ground connection, a solid piece of metal in the en-

gine bloc

k, or t

o the engine block ⇒ fig. 217.

● Connect the other end of the black

jump lead X to a solid metal compo-

nent c onnect

ed to the engine block, or onto the engine block itself of the

vehicle with the flat battery however, connect it as far away as possible from

the battery A ⇒ .

● Place the leads so that they cannot be caught by any moving parts in the

engine c omp

artment. Switching on

●

Start the engine of the vehicle supplying current and let it run at idling

speed.

● Star

t the engine of the car with the flat battery and wait two or three mi-

nutes

until the engine is “running smoothly”.

Removing the jump leads

● Before you remove the jump leads, switch off the headlights (if they are

switc

hed on).

● Turn on the heating and rear window heater in the vehicle with the flat

batter

y. This helps minimise voltage peaks which are generated when the

leads are disconnected.

● With the engines running, disconnect the leads in reverse order to con-

nection.

● Close the battery cover, or replace the positive pole cap 1)

. WARNING

Incorrectly jump starting could cause the battery to explode resulting in

serious injur

y. Please observe the following rules to minimise the risk of

a battery explosion:

● All work involving the vehicle battery and electrical system can cause

corro

sion, fire and serious electric shocks. Always read and take into ac-

count the safety warnings and standards before beginning work on the

battery ⇒ page 288, Vehicle battery.

● Always protect your eyes with suitable working goggles and never

lean o

ver the vehicle battery.

● The jump leads must be connected in the correct order: first the posi-

tive cab

le, then the negative cable. 1)

Vehicles whose battery is not located in the engine compartment ⇒ page 338. Safety First Operating instructions Practical tips Technical Data