brake Seat Alhambra 2016 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2016, Model line: Alhambra, Model: Seat Alhambra 2016Pages: 324, PDF Size: 5.93 MB

Page 6 of 324

Table of Contents

Parking distance warning system* . . . . . . . . . . 211

Park Assist system* (Park Assist) . . . . . . . . . . . 214

Rear assist* (Rear View Camera) . . . . . . . . . . . . 217

Cruise control* (Cruise control system -

C C

S)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Lane Assist system* . . . . . . . . . . . . . . . . . . . . . . 222

Blind spot detector (BSD) with parking assis-

tant (R

TA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Traffic signal detection (Sign Assist)* . . . . . . . . 230

Tiredness detection (recommendation to take

a break)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Dynamic Chassis control (DCC)* . . . . . . . . . . . . 233

Tyre monitoring systems . . . . . . . . . . . . . . . . . . 234

Towing bracket device . . . . . . . . . . . . . . . . . . . . 237

Driving with a trailer . . . . . . . . . . . . . . . . . . . . . . 237

Advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Care and maintenance . . . . . . . . . . . . . . . . . . . . 247

Accessories, replacement of parts and modifi-

cations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Caring for and cleaning the vehicle interior . . . 253

Caring for and cleaning the vehicle interior . . . 258

Notes for the user . . . . . . . . . . . . . . . . . . . . . . . . 263

Checking and refilling levels . . . . . . . . . . . . . . . 264

Filling the tank . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Selective catalytic reduction* (AdBlue) . . . . . . 270

Working in the engine compartment . . . . . . . . 272

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Windscreen washer reservoir . . . . . . . . . . . . . . 284

Vehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Wheels and tyres . . . . . . . . . . . . . . . . . . . . . . . . 288

Tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Winter service . . . . . . . . . . . . . . . . . . . . . . . . . . . 296 Technical data

. . . . . . . . . . . . . . . . . . . . . . . . 298

Technical features . . . . . . . . . . . . . . . . . . . . . . . 298

Important information . . . . . . . . . . . . . . . . . . . . 298

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Engine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

4

Page 26 of 324

The essentials

Turning on/switching off the ignition, glow

p lug

s

reheating

● Switch ignition on: Turn the key to the 2position.

●

Switch ignition off. Turn the key to the 1position.

●

Diesel vehicles : The glo

w p

lugs reheat

when the ignition is switched on

Starting the engine

● Manual gearbox: press the clutch pedal all

the way

down and move the gearbox lever in-

to neutral.

● Automatic gearbox: Press the brake pedal

and move the sel

ector lever to the P position

or into N.

● Turn the key to the 3 position. The key au-

t om

atic

ally returns to the 2 position. Do not

pr e

s

s the accelerator.

Start-Stop System*

When you stop and release the clutch pedal,

the Start-Stop system* turns off the engine.

The ignition remains switched on.

››› in Ignition lock on page 186

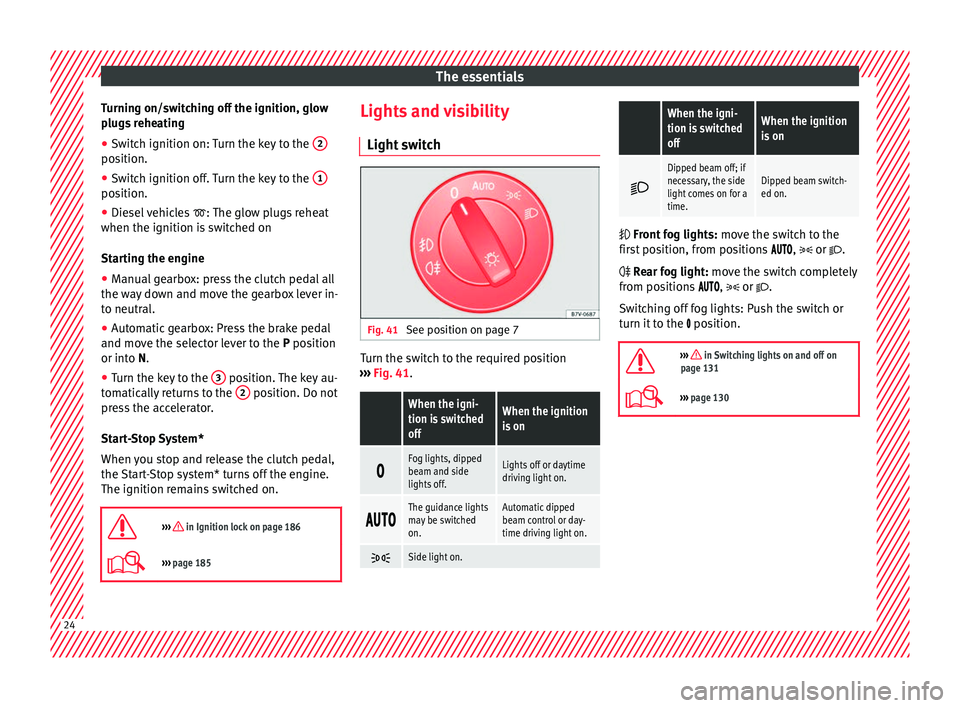

››› page 185 Lights and visibility

Light sw

it

ch Fig. 41

See position on page 7 Turn the switch to the required position

› ›

›

Fig. 41.

When the igni-

tion is switched

offWhen the ignition

is on

Fog lights, dipped

beam and side

lights off.Lights off or daytime

driving light on.

The guidance lights

may be switched

on.Automatic dipped

beam control or day-

time driving light on.

Side light on.

When the igni-

tion is switched

offWhen the ignition

is on

Dipped beam off; if

necessary, the side

light comes on for a

time.Dipped beam switch-

ed on.

Front fog lights:

mov

e the switch to the

first position, from positions , or .

Rear fog light: move the switch completely

from positions , or .

Switching off fog lights: Push the switch or

turn it to the position.

››› in Switching lights on and off on

page 131

››› page 130 24

Page 34 of 324

The essentials

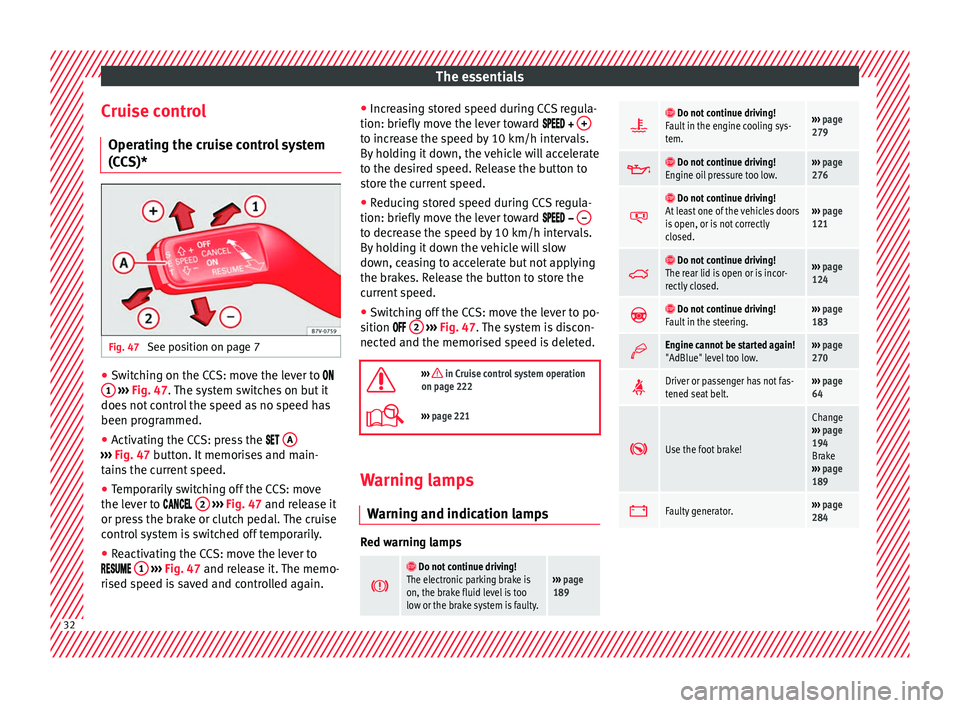

Cruise control Oper atin

g the c

ruise control system

(CCS)* Fig. 47

See position on page 7 ●

Switching on the CCS: move the lever to

1

› ›

› Fig. 47

. The system switches on but it

does not control the speed as no speed has

been programmed.

● Activating the CCS: press the A ›››

Fig. 47 butt on. It

memorises and main-

tains the current speed.

● Temporarily switching off the CCS: move

the lev er t

o 2

› ›

› Fig. 47 and release it

or press the brake or clutch pedal. The cruise

control system is switched off temporarily.

● Reactivating the CCS: move the lever to

1

›

› ›

Fig. 47

and release it. The memo-

rised speed is saved and controlled again. ●

Incre

asing stored speed during CCS regula-

tion: briefly move the lever toward + to increase the speed by 10 km/h intervals.

B

y

ho

lding it down, the vehicle will accelerate

to the desired speed. Release the button to

store the current speed.

● Reducing stored speed during CCS regula-

tion: briefly mov

e the lever toward – to decrease the speed by 10 km/h intervals.

B

y

ho

lding it down the vehicle will slow

down, ceasing to accelerate but not applying

the brakes. Release the button to store the

current speed.

● Switching off the CCS: move the lever to po-

sition 2

› ›

› Fig. 47

. The system is discon-

nected and the memorised speed is deleted.

››› in Cruise control system operation

on page 222

››› page 221 Warning lamps

W arnin

g and indic

ation lamps Red warning lamps

Do not continue driving!

The electronic parking brake is

on, the brake fluid level is too

low or the brake system is faulty.››› page

189

Do not continue driving!

Fault in the engine cooling sys-

tem.››› page

279

Do not continue driving!

Engine oil pressure too low.››› page

276

Do not continue driving!

At least one of the vehicles doors

is open, or is not correctly

closed.››› page

121

Do not continue driving!

The rear lid is open or is incor-

rectly closed.››› page

124

Do not continue driving!

Fault in the steering.››› page

183

Engine cannot be started again!

"AdBlue" level too low.›››

page

270

Driver or passenger has not fas-

tened seat belt.›››

page

64

Use the foot brake!

Change

››› page

194

Brake

››› page

189

Faulty generator.›››

page

284 32

Page 35 of 324

The essentials

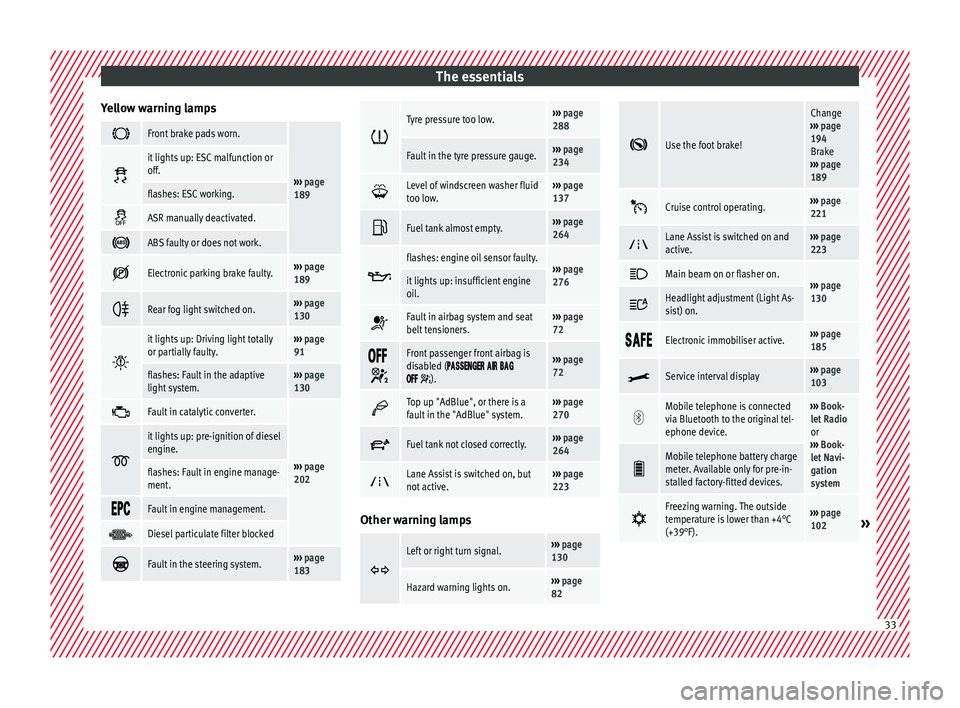

Yellow warning lamps Front brake pads worn.

›››

page

189

it lights up: ESC malfunction or

off.

flashes: ESC working.

ASR manually deactivated.

ABS faulty or does not work.

Electronic parking brake faulty.›››

page

189

Rear fog light switched on.›››

page

130

it lights up: Driving light totally

or partially faulty.›››

page

91

flashes: Fault in the adaptive

light system.››› page

130

Fault in catalytic converter.

›››

page

202

it lights up: pre-ignition of diesel

engine.

flashes: Fault in engine manage-

ment.

Fault in engine management.

Diesel particulate filter blocked

Fault in the steering system.›››

page

183

Tyre pressure too low.›››

page

288

Fault in the tyre pressure gauge.››› page

234

Level of windscreen washer fluid

too low.›››

page

137

Fuel tank almost empty.›››

page

264

flashes: engine oil sensor faulty.›››

page

276it lights up: insufficient engine

oil.

Fault in airbag system and seat

belt tensioners.›››

page

72

Front passenger front airbag is

disabled (

).

››› page

72

Top up "AdBlue", or there is a

fault in the "AdBlue" system.›››

page

270

Fuel tank not closed correctly.›››

page

264

Lane Assist is switched on, but

not active.›››

page

223 Other warning lamps

Left or right turn signal.›››

page

130

Hazard warning lights on.››› page

82

Use the foot brake!

Change

››› page

194

Brake

››› page

189

Cruise control operating.›››

page

221

Lane Assist is switched on and

active.›››

page

223

Main beam on or flasher on.›››

page

130 Headlight adjustment (Light As-

sist) on.

Electronic immobiliser active.›››

page

185

Service interval display›››

page

103

Mobile telephone is connected

via Bluetooth to the original tel-

ephone device.›››

Book-

let Radio

or

››› Book-

let Navi-

gation

system

Mobile telephone battery charge

meter. Available only for pre-in-

stalled factory-fitted devices.

Freezing warning. The outside

temperature is lower than +4°C

(+39°F).›››

page

102» 33

Page 37 of 324

The essentials

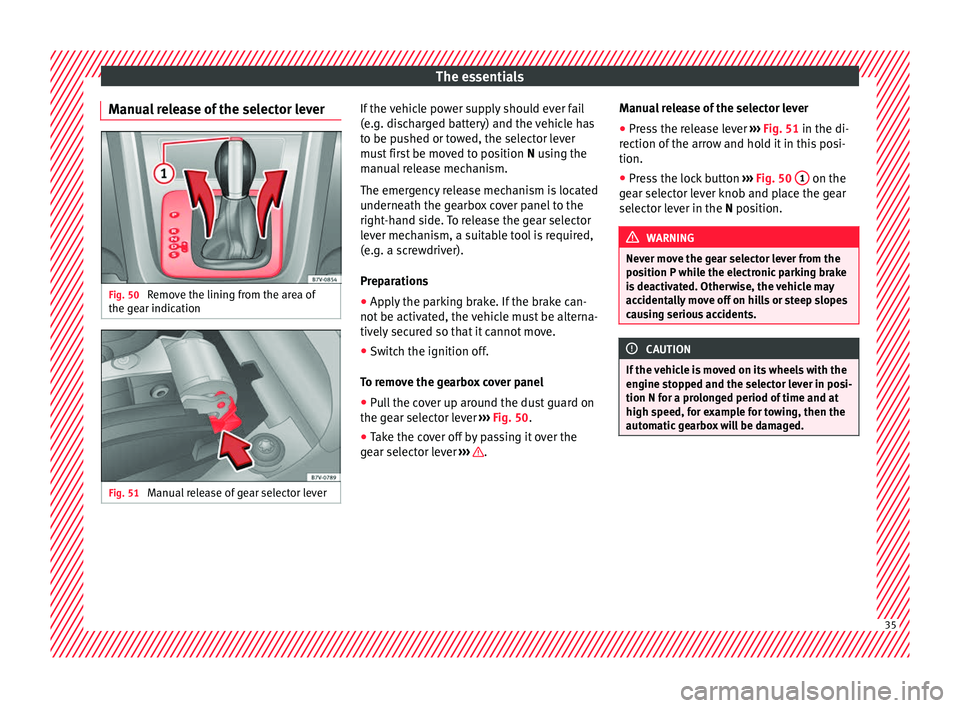

Manual release of the selector lever Fig. 50

Remove the lining from the area of

the g e

ar indic

ation Fig. 51

Manual release of gear selector lever If the vehicle power supply should ever fail

(e.

g. di

s

charged battery) and the vehicle has

to be pushed or towed, the selector lever

must first be moved to position N using the

manual release mechanism.

The emergency release mechanism is located

underneath the gearbox cover panel to the

right-hand side. To release the gear selector

lever mechanism, a suitable tool is required,

(e.g. a screwdriver).

Preparations

● Apply the parking brake. If the brake can-

not be activat

ed, the vehicle must be alterna-

tively secured so that it cannot move.

● Switch the ignition off.

To remo

ve the gearbox cover panel

● Pull the cover up around the dust guard on

the gear sel

ector lever ››› Fig. 50.

● Take the cover off by passing it over the

gear sel

ector lever ››› .Manual release of the selector lever

●

Press the release lever ››

›

Fig. 51 in the di-

rection of the arrow and hold it in this posi-

tion.

● Press the lock button ›››

Fig. 50 1 on the

g e

ar sel

ector lever knob and place the gear

selector lever in the N position. WARNING

Never move the gear selector lever from the

pos ition P whi

le the electronic parking brake

is deactivated. Otherwise, the vehicle may

accidentally move off on hills or steep slopes

causing serious accidents. CAUTION

If the vehicle is moved on its wheels with the

engine s t

opped and the selector lever in posi-

tion N for a prolonged period of time and at

high speed, for example for towing, then the

automatic gearbox will be damaged. 35

Page 43 of 324

The essentials

Brake fluid Fig. 58

Engine compartment: brake fluid res-

er v

oir c

ap The brake fluid reservoir is located in the en-

gine c

omp

ar

tment ›››

page 275.

The level should be between the and

marks. If it is below , please visit a Techni-

cal Service.

››› in Checking the brake fluid level on

page 283

››› page 282 Windscreen washer

Fig. 59

In the engine compartment: wind-

s c

r

een washer reservoir top. The windscreen washer reservoir is located in

the en

gine c

omp

artment ›››

page 275.

To top up, mix water with a product recom-

mended by SEAT.

In cold temperatures, add anti-freeze.

››› in Checking and topping up the

windscreen washer reservoir on

page 284

››› page 284 Battery

The battery is located in the engine compart-

ment

›

›

› page 275. It does not require maintenance. It is checked as part of the In-

spection Ser

vice.

››› in Checking the electrolyte level of

the vehicle battery on page 286

››› page 284 41

Page 45 of 324

The essentials

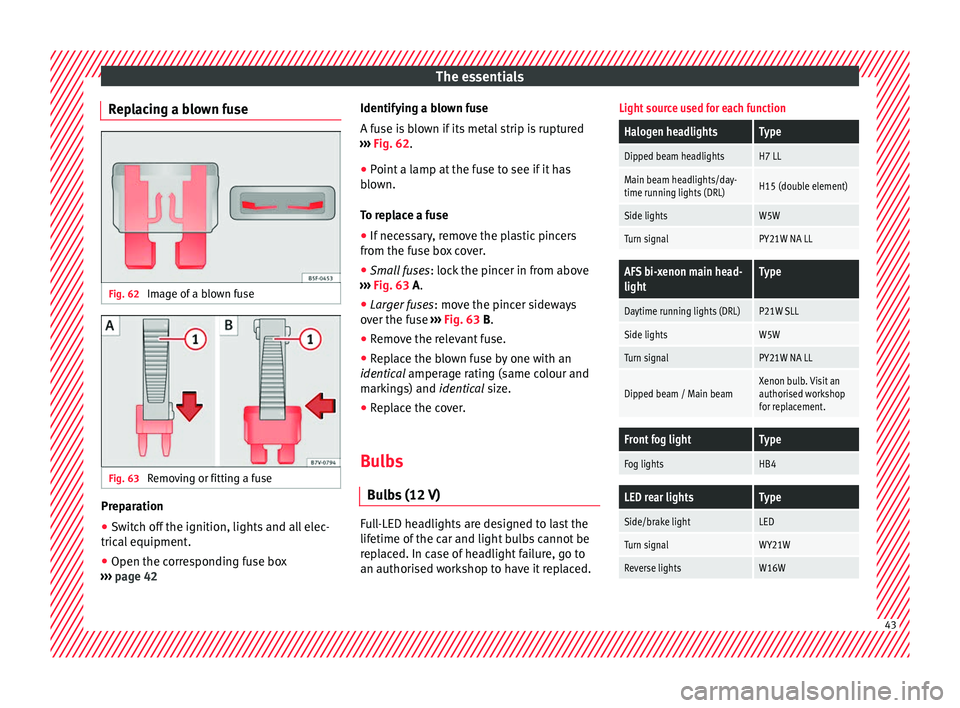

Replacing a blown fuse Fig. 62

Image of a blown fuse Fig. 63

Removing or fitting a fuse Preparation

● Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 42 Identifying a blown fuse

A fuse i

s blown if its metal strip is ruptured

››› Fig. 62.

● Point a lamp at the fuse to see if it has

blown.

T

o replace a fuse

● If necessary, remove the plastic pincers

from the fu

se box cover.

● Small fuses: lock the pinc

er in from above

››› Fig. 63 A.

● Larger fuses : move the pinc

er sideways

over the fuse ››› Fig. 63 B.

● Remove the relevant fuse.

● Replace the blown fuse by one with an

identica

l amperage rating (same colour and

markings) and identical size.

● Replace the cover.

Bulbs Bul

bs (12 V) Full-LED headlights are designed to last the

lif

etime of

the c

ar and light bulbs cannot be

replaced. In case of headlight failure, go to

an authorised workshop to have it replaced.

Light source used for each function

Halogen headlightsType

Dipped beam headlightsH7 LL

Main beam headlights/day-

time running lights (DRL)H15 (double element)

Side lightsW5W

Turn signalPY21W NA LL

AFS bi-xenon main head-

lightType

Daytime running lights (DRL)P21W SLL

Side lightsW5W

Turn signalPY21W NA LL

Dipped beam / Main beamXenon bulb. Visit an

authorised workshop

for replacement.

Front fog lightType

Fog lightsHB4

LED rear lightsType

Side/brake lightLED

Turn signalWY21W

Reverse lightsW16W 43

Page 46 of 324

The essentials

Action in the event of a punc-

t ur

e

Wh

at to do first ●

Park the vehicle on a horizontal surface

and in a saf e p

lace as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select the 1s

t gear.

● Automatic gearbox: Move the sel

ector lever

to position P.

● If you are towing a trailer, unhitch it from

your v

ehicle.

● Keep the vehicle tool kit ready*

›››

page 82.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait in a s

afe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

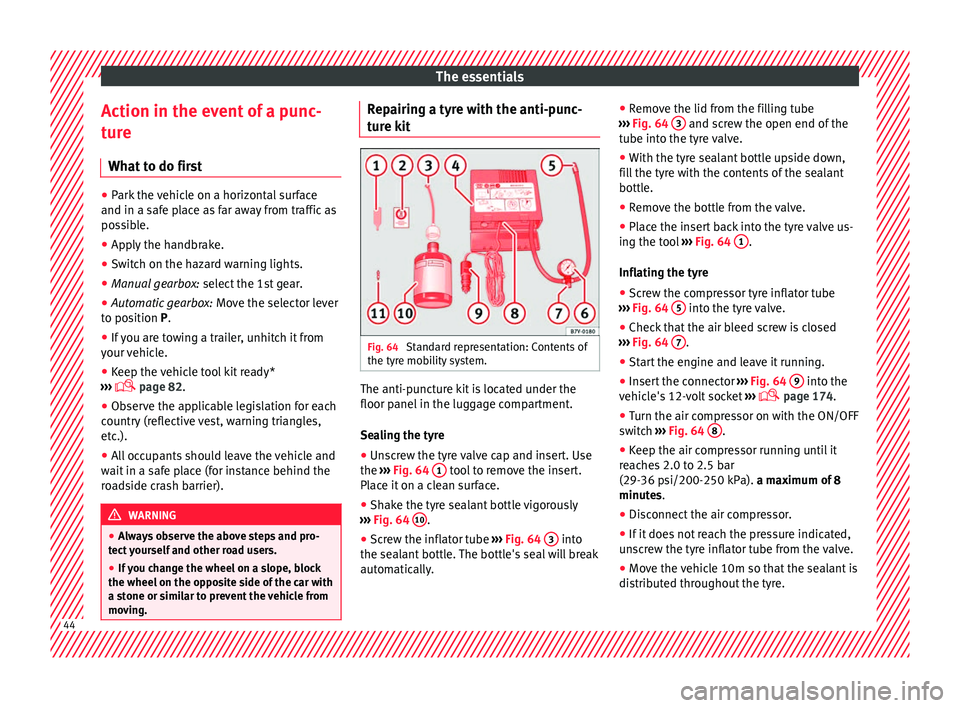

moving. Repairing a tyre with the anti-punc-

t

ur

e k

it Fig. 64

Standard representation: Contents of

the ty r

e mo

bility system. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 64 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 64 10 .

● Screw the inflator tube ››

›

Fig. 64 3 into

the se al

ant

bottle. The bottle's seal will break

automatically. ●

Remov

e the lid from the filling tube

››› Fig. 64 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 64 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 64 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 64 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 64 9 into the

v ehic

l

e's 12-volt socket ›››

page 174.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 64 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). a maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

dis trib

uted throughout the tyre.44

Page 49 of 324

The essentials

Important information about wheel bolts

The wheel rims

and bo

lts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 140 Nm.

Have the tightening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

torque.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

cou l

d be released while driving leading to

loss of vehicle control and serious damage. ●

Only u

se wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free

of oil

and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

way

s use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before r

aising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub thre

ads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bo

lted ring trims.

● If the wheel bolts are not tightened to the

correct

torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

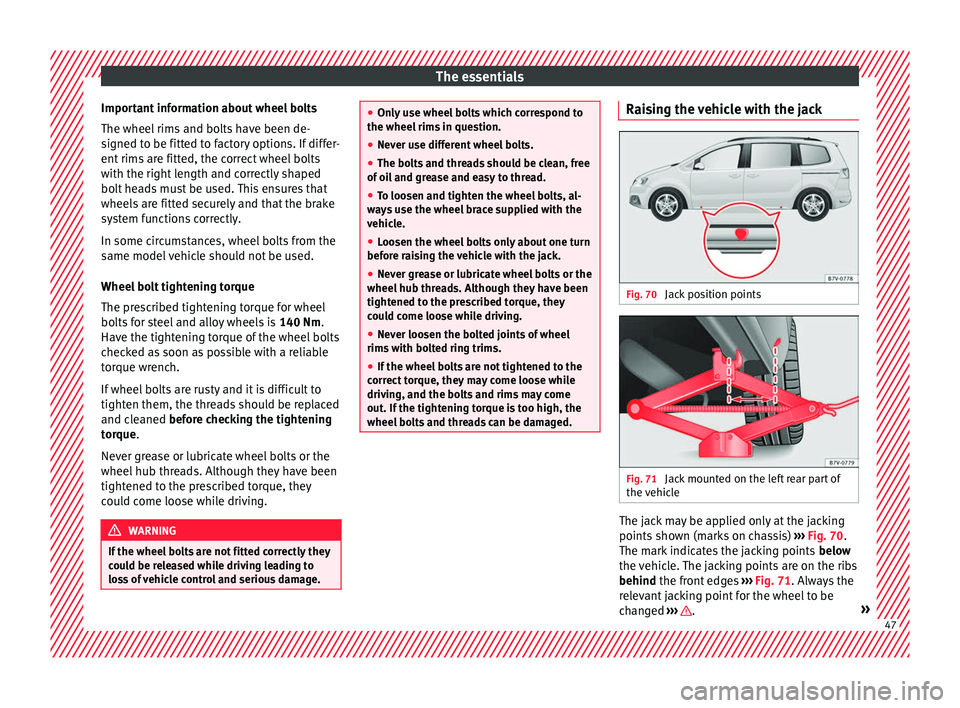

wheel bolts and threads can be damaged. Raising the vehicle with the jack

Fig. 70

Jack position points Fig. 71

Jack mounted on the left rear part of

the v

ehic

le The jack may be applied only at the jacking

points

sho

wn (m

arks on chassis) ››› Fig. 70.

The mark indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind the front edges ››› Fig. 71. Always the

relevant jacking point for the wheel to be

changed ››› .

» 47

Page 50 of 324

The essentials

Raise the vehicle using only the designated

j ac

k

ing points.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Select a suitable flat and firm surface for

raising the vehicle.

Switch off the engine, engage a gear

(manual gearbox) or place the selector

lever in position P ›››

page 194 and

turn on the electronic parking brake

››› page 189.

Block the wheel diagonally opposite the

wheel being changed with folding wheel

chocks* or other suitable objects.

When towing a trailer: unhook the trailer

from the towing vehicle and park it cor-

rectly.

Loosen the wheel bolts on the wheel to

be changed ››› page 46.

Look below the vehicle for the jacking

point ››› Fig. 70 closest to the tyre which

has to be changed.

Raise the jack with the handle until it

can be inserted below the jacking point.

Ensure that the foot of the jack is firmly

on the ground and that it is placed im-

mediately below the lifting point on the

vehicle ››› Fig. 71.

Straighten the jack and continue raising

it using the handle until the claw holds

1.

2.

3.

4.

5.

6.

7.

8.

9. the vertical reinforcement beneath the

vehicl

e ››› Fig. 71.

Raise the vehicle until the wheel is clear

of the ground. WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 71.

● You should never place a body limb such as

an arm or leg u

nder a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!. 10. ●

Never r ai

se the vehicle if it is tilting to one

side or the engine is running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

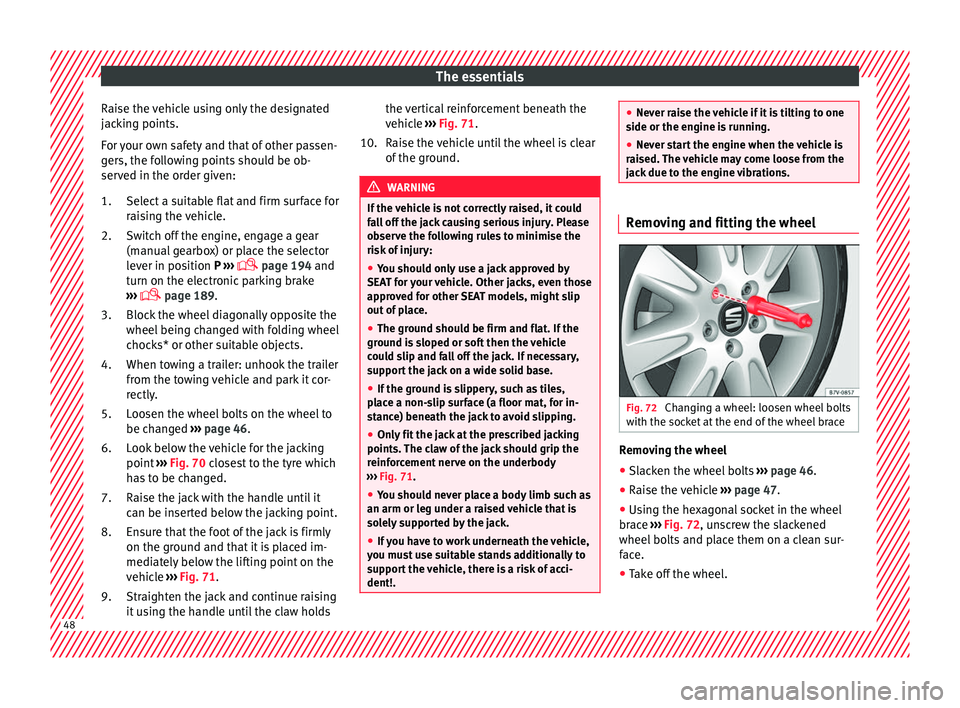

jack due to the engine vibrations. Removing and fitting the wheel

Fig. 72

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Removing the wheel

● Slacken the wheel bolts ››

›

page 46.

● Raise the vehicle ›››

page 47.

● Using the hexagonal socket in the wheel

brace ›

›› Fig. 72, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel. 48