lock Seat Alhambra 2017 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Alhambra, Model: Seat Alhambra 2017Pages: 320, PDF Size: 6.88 MB

Page 48 of 320

The essentials

Fitting hubcaps

B ef

or

e mounting the full trim, the anti-theft

wheel lock must be threaded into position

››› Fig. 68 2 or

3 . Otherwise it will not be

po s

s

ible to mount the full hubcap.

● Press the trim against the wheel so that the

spac

e for the valve fits over the tyre valve

››› Fig. 68 1 . Make sure that the hubcap is

c orr

ectly

fitted all the way around the wheel.

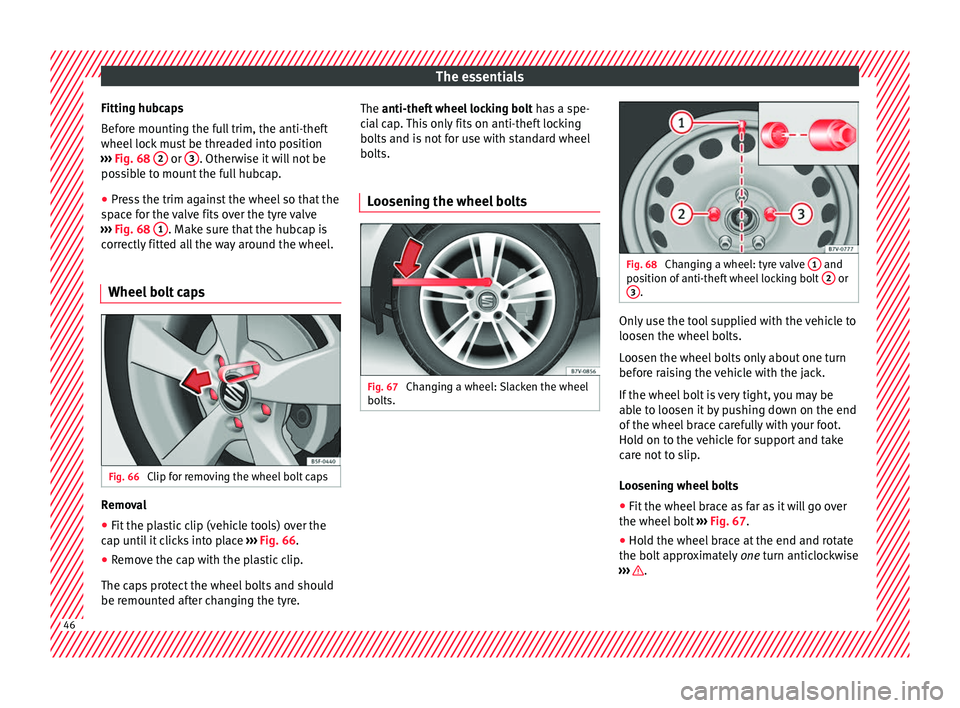

Wheel bolt caps Fig. 66

Clip for removing the wheel bolt caps Removal

● Fit the plastic clip (vehicle tools) over the

c ap u

nti

l it clicks into place ››› Fig. 66.

● Remove the cap with the plastic clip.

The caps

protect the wheel bolts and should

be remounted after changing the tyre. The anti-theft wheel

locking bolt has a spe-

cial cap. This only fits on anti-theft locking

bolts and is not for use with standard wheel

bolts.

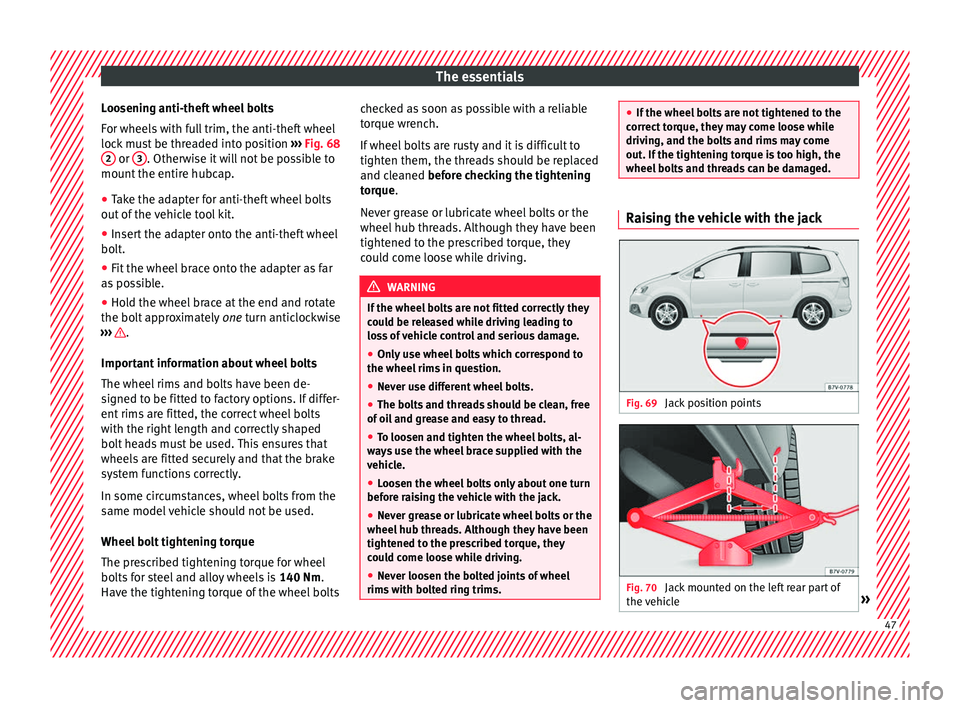

Loosening the wheel bolts Fig. 67

Changing a wheel: Slacken the wheel

bo lts. Fig. 68

Changing a wheel: tyre valve 1 and

pos ition of

anti-theft wheel locking bolt 2 or

3 .

Only use the tool supplied with the vehicle to

loo

sen the wheel

bo

lts.

Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

If the wheel bolt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt

››› Fig. 67.

● Hold the wheel brace at the end and rotate

the bolt ap

proximately one turn anticlockwise

››› .

46

Page 49 of 320

The essentials

Loosening anti-theft wheel bolts

F or wheel

s

with full trim, the anti-theft wheel

lock must be threaded into position ››› Fig. 68

2 or

3 . Otherwise it will not be possible to

mou nt

the entir

e hubcap.

● Take the adapter for anti-theft wheel bolts

out of the

vehicle tool kit.

● Insert the adapter onto the anti-theft wheel

bolt.

● Fit

the wheel brace onto the adapter as far

as po

ssible.

● Hold the wheel brace at the end and rotate

the bolt ap

proximately one turn anticlockwise

››› .

Impor t

ant

information about wheel bolts

The wheel rims and bolts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 140 Nm.

Have the tightening torque of the wheel bolts checked as soon as possible with a reliable

torque wr

ench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

torque.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

cou l

d be released while driving leading to

loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to

the wheel rims in que

stion.

● Never use different wheel bolts.

● The bolts and threads should be clean, free

of oil

and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

way

s use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before r

aising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub thre

ads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bo

lted ring trims. ●

If the wheel bo

lts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

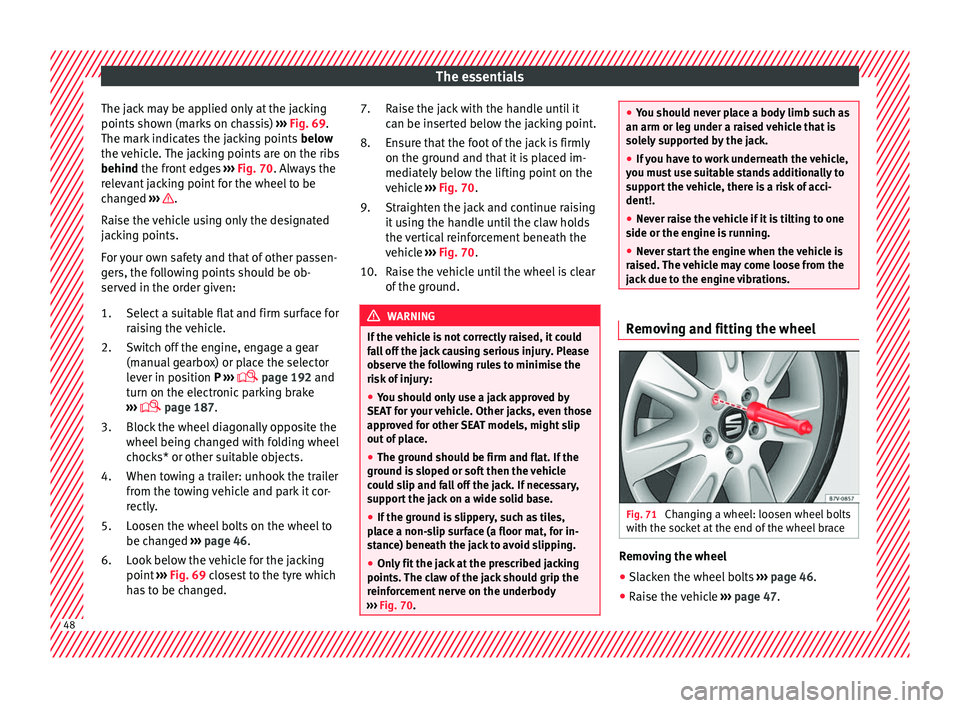

wheel bolts and threads can be damaged. Raising the vehicle with the jack

Fig. 69

Jack position points Fig. 70

Jack mounted on the left rear part of

the v

ehic

le » 47

Page 50 of 320

The essentials

The jack may be applied only at the jacking

points sho

wn (m

arks on chassis) ››› Fig. 69.

The mark indicates the jacking points below

the vehicle. The jacking points are on the ribs

behind the front edges ››› Fig. 70. Always the

relevant jacking point for the wheel to be

changed ››› .

R ai

se the

vehicle using only the designated

jacking points.

For your own safety and that of other passen-

gers, the following points should be ob-

served in the order given:

Select a suitable flat and firm surface for

raising the vehicle.

Switch off the engine, engage a gear

(manual gearbox) or place the selector

lever in position P ›››

page 192 and

turn on the electronic parking brake

››› page 187.

Block the wheel diagonally opposite the

wheel being changed with folding wheel

chocks* or other suitable objects.

When towing a trailer: unhook the trailer

from the towing vehicle and park it cor-

rectly.

Loosen the wheel bolts on the wheel to

be changed ››› page 46.

Look below the vehicle for the jacking

point ››› Fig. 69 closest to the tyre which

has to be changed.

1.

2.

3.

4.

5.

6. Raise the jack with the handle until it

can be inser

ted below the jacking point.

Ensure that the foot of the jack is firmly

on the ground and that it is placed im-

mediately below the lifting point on the

vehicle ››› Fig. 70.

Straighten the jack and continue raising

it using the handle until the claw holds

the vertical reinforcement beneath the

vehicle ››› Fig. 70.

Raise the vehicle until the wheel is clear

of the ground. WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 70. 7.

8.

9.

10.

●

You shou l

d never place a body limb such as

an arm or leg under a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

jack due to the engine vibrations. Removing and fitting the wheel

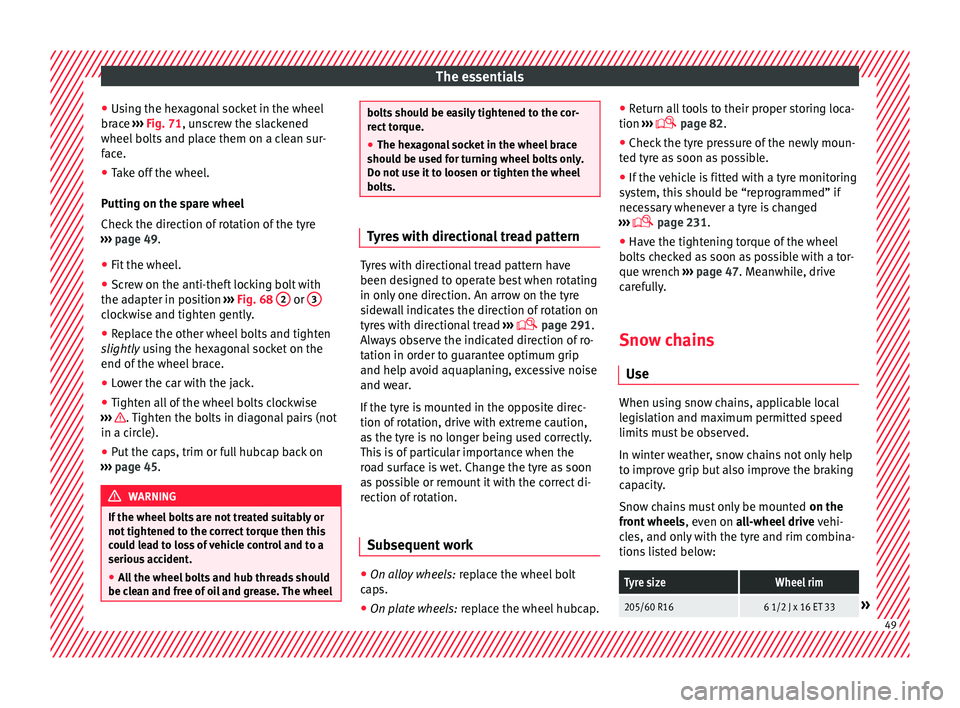

Fig. 71

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Removing the wheel

● Slacken the wheel bolts ››

›

page 46.

● Raise the vehicle ›››

page 47. 48

Page 51 of 320

The essentials

● Us

in

g the hexagonal socket in the wheel

brace ››› Fig. 71, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

Putting on the s

pare wheel

Check the direction of rotation of the tyre

››› page 49.

● Fit the wheel.

● Screw on the anti-theft locking bolt with

the adapt

er in position ››› Fig. 68 2 or

3 clockwise and tighten gently.

●

Replace the other wheel bolts and tighten

s ligh

tl

y using the hexagonal socket on the

end of the wheel brace.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 45. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel bolts should be easily tightened to the cor-

rect

t

orque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. Tyres with directional tread pattern

Tyres with directional tread pattern have

been des

igned t

o operate best when rotating

in only one direction. An arrow on the tyre

sidewall indicates the direction of rotation on

tyres with directional tread ›››

page 291.

Always observe the indicated direction of ro-

tation in order to guarantee optimum grip

and help avoid aquaplaning, excessive noise

and wear.

If the tyre is mounted in the opposite direc-

tion of rotation, drive with extreme caution,

as the tyre is no longer being used correctly.

This is of particular importance when the

road surface is wet. Change the tyre as soon

as possible or remount it with the correct di-

rection of rotation.

Subsequent work ●

On alloy wheels: repl

ace the wheel bolt

caps.

● On plate wheels: rep l

ace the wheel hubcap. ●

Return al

l tools to their proper storing loca-

tion ›››

page 82.

● Check the tyre pressure of the newly moun-

ted tyr

e as soon as possible.

● If the vehicle is fitted with a tyre monitoring

syst

em, this should be “reprogrammed” if

necessary whenever a tyre is changed

››› page 231.

● Have the tightening torque of the wheel

bolts c

hecked as soon as possible with a tor-

que wrench ››› page 47. Meanwhile, drive

carefully.

Snow chains

Use When using snow chains, applicable local

l

e

gi

slation and maximum permitted speed

limits must be observed.

In winter weather, snow chains not only help

to improve grip but also improve the braking

capacity.

Snow chains must only be mounted on the

front wheels , even on all-wheel drive vehi-

cles, and only with the tyre and rim combina-

tions listed below:

Tyre sizeWheel rim

205/60 R166 1/2 J x 16 ET 33» 49

Page 52 of 320

The essentials

SEAT recommends you ask a technical serv-

ic e f

or f

urther information on wheel, tyre and

chain sizes.

Wherever possible use fine-link chains meas-

uring less than 15 mm (37/64 inch) includ-

ing the lock.

Remove wheel hub covers and trim rings be-

fore fitting snow chains ››› . The wheel bolts

shou l

d be c

overed with caps for safety rea-

sons. These are available from technical serv-

ices. WARNING

The use of unsuitable or incorrectly fitted

ch ain

s could lead to serious accidents and

damage.

● Always the appropriate snow chains.

● Observe the fitting instructions provided by

the snow c

hain manufacturer.

● Never exceed the maximum permitted

speeds

when driving with snow chains. CAUTION

● Remo v

e the snow chains to drive on roads

without snow. Otherwise they will impair

handling, damage the tyres and wear out very

quickly.

● Wheel rims may be damaged or scratched if

the chain

s come into direct contact with

them. SEAT recommends the use of covered

snow chains. Note

Snow chains are available in different sizes

acc or

ding to the vehicle type. Emergency towing of the vehi-

cl

e

T

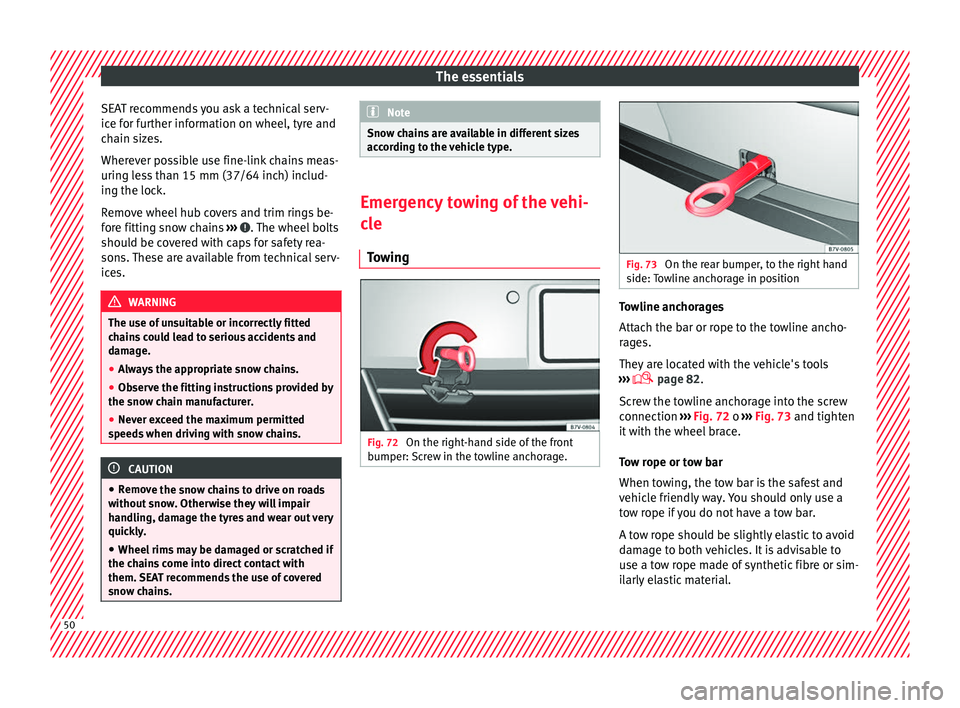

owing Fig. 72

On the right-hand side of the front

b umper:

Sc

rew in the towline anchorage. Fig. 73

On the rear bumper, to the right hand

side: T

owline anchorage in position Towline anchorages

Att

ac

h the b

ar or rope to the towline ancho-

rages.

They are located with the vehicle's tools

››› page 82.

Screw the towline anchorage into the screw

connection ››› Fig. 72 o ››› Fig. 73 and tighten

it with the wheel brace.

Tow rope or tow bar

When towing, the tow bar is the safest and

vehicle friendly way. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to avoid

damage to both vehicles. It is advisable to

use a tow rope made of synthetic fibre or sim-

ilarly elastic material. 50

Page 53 of 320

The essentials

Only secure the tow rope or tow bar to the

t o

wline anc

horage or specially designed fit-

ting.

Vehicles with a factory fitted towing device ,

can only be used for towing with a tow bar,

specially designed to fit on a tow hitch ball

››› page 234.

Towing vehicles with an automatic gearbox

Note the following for a towed vehicle: ● Make sure the gear selector lever is in the N

position.

● Do not

drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km (30 miles).

● If a breakdown truck is used, the vehicle

must

be towed with the front wheels raised.

Note the following instructions for towing

four all-wheel drive vehicles.

Instructions for towing all-wheel drive vehi-

cles

All-wheel drive vehicles can be towed using a

toolbar or tow rope. If the vehicle is towed

with the front or rear axle raised, the engine

must be turned off to avoid transmission

damage.

For vehicles with a double clutched DSG ®

(di-

rect shift gearbox) the instructions for towing

vehicles with an automatic gearbox apply

››› page 51. Situations in which a vehicle should not be

tow

ed

In the following cases, the vehicle should not

be towed but transported on a trailer or spe-

cial vehicle:

● If the vehicle gearbox does not contain lu-

bricant due t

o a fault.

● If the vehicle battery is flat and, as a result,

the electronic

steering lock and electronic

parking brake cannot be disengaged if ap-

plied.

● If the vehicle to be towed has an automatic

gearbo

x and the distance to be covered is

greater than 50 km (30 miles).

››› in Introduction on page 87

››› page 87 Tow-starting

In general, the vehicle should not be started

b

y

t

owing. Jump-starting is much more pref-

erable ›››

page 51.

For technical reasons, the following vehicles

can not be tow started:

● Vehicles with an automatic gearbox. ●

Vehicl

es with the Keyless Access locking

and ignition system, since the electronic

steering lock may not unlock.

● Vehicles with an electronic parking brake,

given that

it is possible that the brake will

not be disengaged.

● If the vehicle battery is flat, it is possible

that the en

gine control units do not operate

correctly.

However, if your vehicle must absolutely be

tow-started (manual gearbox):

● Put it into second or third gear.

● Keep the clutch pressed down.

● Switch on the ignition and the hazard warn-

ing lights.

● Rel

ease the clutch when both vehicles are

movin

g.

● As soon as the engine starts, press the

clutc

h and move the gear lever into neutral.

This helps to prevent a collision with the tow-

ing vehicle.

How to jump start

Jump lea

ds If the engine fails to start because of a dis-

c

h

ar

ged battery, the battery of another vehi-

cle can be used to start the engine. Before » 51

Page 55 of 320

The essentials

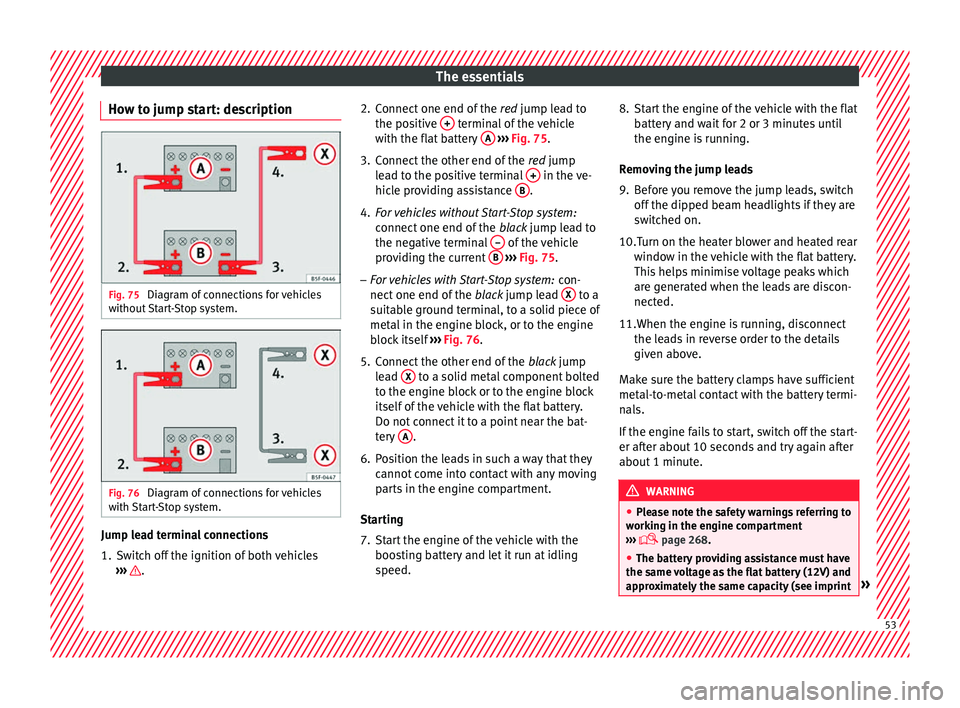

How to jump start: description Fig. 75

Diagram of connections for vehicles

w ithout

Start-Stop system. Fig. 76

Diagram of connections for vehicles

w ith

St

art-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

. 2. Connect one end of the

re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ››

Fig. 75

.

3.

Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ››

Fig. 75

.

– F

or vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 76.

5. Connect the other end of the black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed. 8. Start the engine of the vehicle with the flat

batter

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights if they are

switched on.

10.Turn on the heater blower and heated rear window in the

vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the lea

ds in reverse order to the details

given above.

Make sure the battery clamps have sufficient

metal-to-metal contact with the battery termi-

nals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 268.

● The battery providing assistance must have

the same v

oltage as the flat battery (12V) and

approximately the same capacity (see imprint » 53

Page 60 of 320

Safety

The correct sitting positions for the driver and

p a

s

sengers are shown below.

If your physical constitution prevents you

from maintaining the correct sitting position,

contact a specialised workshop for help with

any special devices. The seat belt and airbag

can only provide optimum protection if a cor-

rect sitting position is adopted. SEAT recom-

mends taking your car in for technical serv-

ice.

For your own safety and to reduce the risk of

injury in the event of an accident or sudden

braking or manoeuvre, SEAT recommend the

following positions:

Valid for all vehicle occupants:

● Adjust the head restraint so that its upper

edge is

at the same level as the top of your

head, or as close as possible to the same lev-

el as the top of your head and under no cir-

cumstances below eye level. Keep the back

of your neck as close as possible to the head

restraint ››› Fig. 80 and ››› Fig. 81.

● Short people must lower the head restraint

compl

etely, even if your head is below its up-

per edge.

● Tall people must raise the head restraint

compl

etely.

● Adjust the seat backrest to an upright posi-

tion so that

your back rests completely

against it. ●

Alwa

ys keep your feet in the footwell while

the vehicle is in motion.

● Adjust and fasten your seat belt correctly

›››

page 64.

Also valid for the driver:

● Adjust the steering wheel so that there is a

dist

ance of at least 25 cm (10 inches) be-

tween it and your chest ››› Fig. 80 and so that

you can hold the steering wheel with both

hands on the outside of the ring at the 9

o'clock and 3 o'clock positions with your

arms slightly bent.

● The adjusted steering wheel must face your

ches

t and not your face.

● Adjust the driver seat forwards or back-

ward

s so that you are able to press the accel-

erator, brake and clutch pedals to the floor

with your knees slightly angled and the dis-

tance between your knees and the dash pan-

el is at least 10 cm (4 inches) ››› Fig. 80.

● Adjust the height of the driver seat so that

you can e

asily reach the top of the steering

wheel.

● Keep both feet in the footwell so that you

have the

vehicle under control at all times.

Also valid for the front passenger:

● Move the front passenger seat back as far

as po

ssible for optimum protection should

the airbag deploy. Adjusting the steering wheel position Read the additional information carefully

›› ›

page 16. WARNING

Incorrect use of the steering wheel adjust-

ment f u

nction and an incorrect adjustment of

the steering wheel can result in severe or fa-

tal injury.

● After adjusting the steering column, push

the lever ›

›› Fig. 24

1 firmly upwards to

ens ur

e the steering wheel does not acciden-

tally change position while driving.

● Never adjust the steering wheel while the

vehicl

e is in motion. If you need to adjust the

steering wheel while the vehicle is in motion,

stop safely and make the proper adjustment.

● The adjusted steering wheel should be fac-

ing y

our chest and not your face so as not to

hinder the driver's front airbag protection in

the event of an accident.

● When driving, always hold the steering

wheel with both h

ands on the outside of the

ring at the 9 o'clock and 3 o'clock positions

to reduce injuries when the driver's front air-

bag deploys.

● Never hold the steering wheel at the 12

o'clock

position or in any other manner (e.g.

in the centre of the steering wheel). In such

cases, if the driver's airbag deploys, you may

sustain injuries to your arms, hands and

head. 58

Page 62 of 320

Safety

between your knees and the dash panel is at

le

a

st 10 cm (4 inches). If your physical consti-

tution prevents you from meeting these re-

quirements, contact a specialised workshop

to make any modifications required.

● Never drive with the seat backrest tilted far

back.

The further the seat backrests are tilted

to the rear, the greater the risk of injury due

to incorrect positioning of the belt web or to

the incorrect sitting position!

● Never drive with the seat backrest tilted

forw

ards. Should a front airbag deploy, it

could throw the seat backrest backwards and

injure the passengers of the rear seats.

● Sit as far away as possible from the steer-

ing wheel and the d

ash panel.

● Keep your back straight and resting com-

plet

ely against the seat backrest and the

front seats correctly adjusted. Never place

any part of your body in the area of the airbag

or very close to it.

● If passengers on the rear seats are not sit-

ting in an upright po

sition, the risk of severe

injury due to incorrect positioning of the belt

web increases. WARNING

Incorrect seat adjustment may lead to acci-

dents and sev

ere injuries.

● Only adjust the seats when the vehicle is

station

ary, as the seats could move unex-

pectedly while the vehicle is in motion and

you could lose control of the vehicle. Further- more, an incorrect position is adopted when

adju

s

ting the seat.

● Only adjust the height, seat backrest and

forw

ards or backwards position of the seat

when there is nobody in the seat adjustment

area.

● There must be no objects blocking the seat

adjus

tment area.

● Only adjust the height, angle and longitu-

dinal

position of the rear seats when nobody

is in the way.

● The seat adjustment and lock areas must

be kept c

lean. Pedal area

P ed

a

ls Do not allow floor mats or other objects to

o

b

s

truct the free passage of the pedals.

Floor mats should leave the pedal area free

and unobstructed and be correctly secured in

the footwell zone.

In the event of failure of a brake circuit, the

brake pedal must be pressed harder than

normal to brake the vehicle. WARNING

Objects falling into the driver's footwell could

prev ent

use of the pedals. This could lead the driver to lose control of the vehicle, increas-

ing the ri

sk

of a serious accident.

● Make sure the pedals can be used at all

times, with no o

bjects rolling underneath

them.

● Always secure the mat in the footwell.

● Never place other mats or rugs on top of

the original

mat supplied by the factory.

● Ensure that no objects can fall into the driv-

er's footw

ell while the vehicle is in motion. CAUTION

The pedals must always have free and unob-

struct ed p

assage to the floor. For example, in

case of a fault in the brake circuit, the brake

pedal will need to be pressed further to stop

the vehicle. To press the brake pedal down

further will require more force than usual. 60

Page 69 of 320

Seat belts

WARNING

An incorrectly worn seat belt web can cause

sever e or f

atal injuries in the event of an acci-

dent.

● The seat belt cannot offer its full protection

unl

ess the seat backrests are in an upright

position and the seat belt is worn correctly,

according to your size.

● Unbuckling your seat belt while the vehicle

is in motion c

an cause severe or fatal injuries

in the event of an accident or sudden braking. Note

Seat belts with two buckles include a dia-

gram t o sho

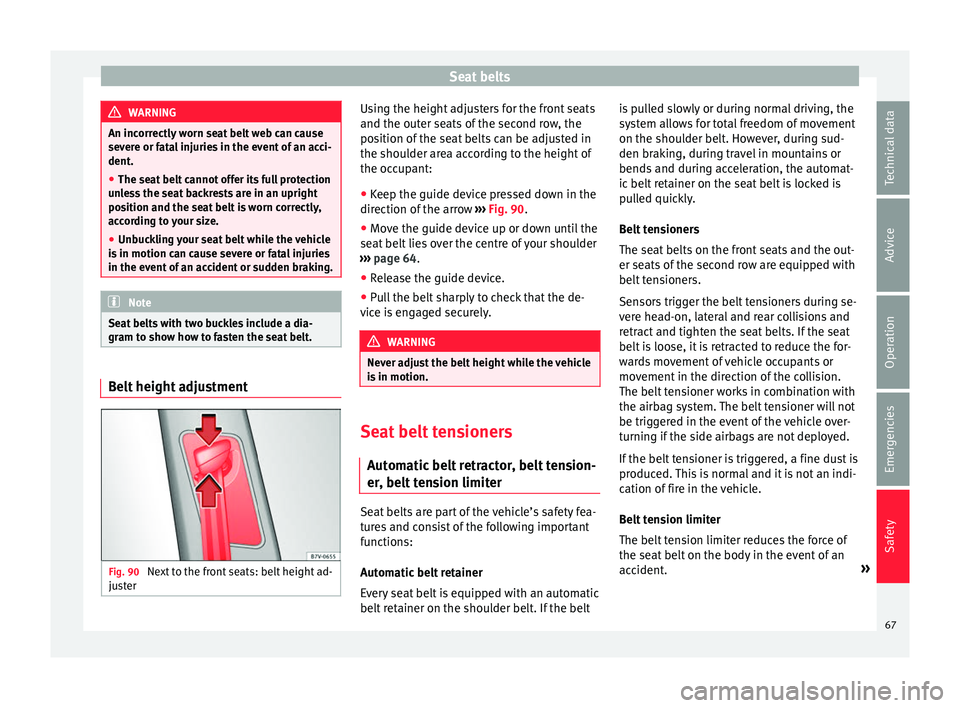

w how to fasten the seat belt.Belt height adjustment

Fig. 90

Next to the front seats: belt height ad-

ju s

t

er Using the height adjusters for the front seats

and the out

er se

ats

of the second row, the

position of the seat belts can be adjusted in

the shoulder area according to the height of

the occupant:

● Keep the guide device pressed down in the

direction of the arr

ow ››› Fig. 90.

● Move the guide device up or down until the

seat belt

lies over the centre of your shoulder

››› page 64.

● Release the guide device.

● Pull the belt sharply to check that the de-

vice i

s engaged securely. WARNING

Never adjust the belt height while the vehicle

is in motion. Seat belt tensioners

Aut omatic

belt retractor, belt tension-

er, belt tension limiter Seat belts are part of the vehicle’s safety fea-

t

ur

e

s and consist of the following important

functions:

Automatic belt retainer

Every seat belt is equipped with an automatic

belt retainer on the shoulder belt. If the belt is pulled slowly or during normal driving, the

syst

em allows for total freedom of movement

on the shoulder belt. However, during sud-

den braking, during travel in mountains or

bends and during acceleration, the automat-

ic belt retainer on the seat belt is locked is

pulled quickly.

Belt tensioners

The seat belts on the front seats and the out-

er seats of the second row are equipped with

belt tensioners.

Sensors trigger the belt tensioners during se-

vere head-on, lateral and rear collisions and

retract and tighten the seat belts. If the seat

belt is loose, it is retracted to reduce the for-

wards movement of vehicle occupants or

movement in the direction of the collision.

The belt tensioner works in combination with

the airbag system. The belt tensioner will not

be triggered in the event of the vehicle over-

turning if the side airbags are not deployed.

If the belt tensioner is triggered, a fine dust is

produced. This is normal and it is not an indi-

cation of fire in the vehicle.

Belt tension limiter

The belt tension limiter reduces the force of

the seat belt on the body in the event of an

accident. »

67

Technical data

Advice

Operation

Emergencies

Safety