wheel bolts Seat Altea 2007 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2007, Model line: Altea, Model: Seat Altea 2007Pages: 302, PDF Size: 9.17 MB

Page 232 of 302

Checking and refilling levels

230Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 201.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the prescribed torque of the wheel bolts is too low, they could loosen

whilst the vehicle is in motion. Risk of accident! If the tightening torque is

too high, the wheel bolts and threads could be damaged.Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.

Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒page 228, “New tyres and wheels” determines the

following speed limits ⇒ :

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 228, “New tyres and wheels”.

altea_ingles_0706.book Seite 230 Mittwoch, 30. August 2006 3:48 15

Page 233 of 302

Checking and refilling levels231

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

The maximum speed for the winter tyre s must not be exceeded. Otherwise,

this could lead to tyre damage and thus, an accident risk.

For the sake of the environment

Fit your summer tyres in good time. They are quieter, do not wear so quickly

and reduce fuel consumption.Snow chainsSnow chains may be fitted only to the front wheels, and only to certain tyre

sizes ⇒page 270.

Snow chains must have fine-pitch links which do not protrude more than 9

mm, including tension device.

Remove wheel hub covers and trim rings before fitting snow chains. For safety

reasons cover caps, available in any Authorised Service Centre, must then be

fitted over the wheel bolts.

WARNING

Observe the fitting instructions provided by the snow chain manufacturer.

Caution

You must remove the snow chains to drive on roads which are free of snow.

Otherwise they will impair handling, damage the tyres and wear out very

quickly.

Note

In some countries, the speed limit for using snow chains is 50 km/h. The legal

requirements of the country should be followed.

altea_ingles_0706.book Seite 231 Mittwoch, 30. August 2006 3:48 15

Page 234 of 302

If and when

232If and whenTools, tyre repair kit and spare wheelVehicle To ols

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•

Jack*

•

Hook for removing wheel covers* or hub caps*

•

Box spanner for wheel bolts*

•

Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.

•

To wi ng e ye

•

Adapter for the anti-theft wheel bolts*

Some of the items listed are only prov ided on certain models / model years,

or are optional extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts. It is impossible to tighten the bolts with the torque

required, risk of accident.

•

The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads, risk of injury.

•

Use the jack only on firm, level ground.

•

Never start the engine when the vehicle is on the jack, risk of accident.

•

I f wo r k is t o b e ca r r i e d o u t un d e r n ea th the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

altea_ingles_0706.book Seite 232 Mittwoch, 30. August 2006 3:48 15

Page 236 of 302

If and when

234

Note•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the ve hicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

–Pull off the hub cap. Also refer to ⇒page 235, fig. 172 .

– Slacken the wheel bolts .

– Raise the car with the jack in the corresponding zone.

– Ta k e o f f the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner.

–Replace the hub cap.

altea_ingles_0706.book Seite 234 Mittwoch, 30. August 2006 3:48 15

Page 237 of 302

If and when235

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as

possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

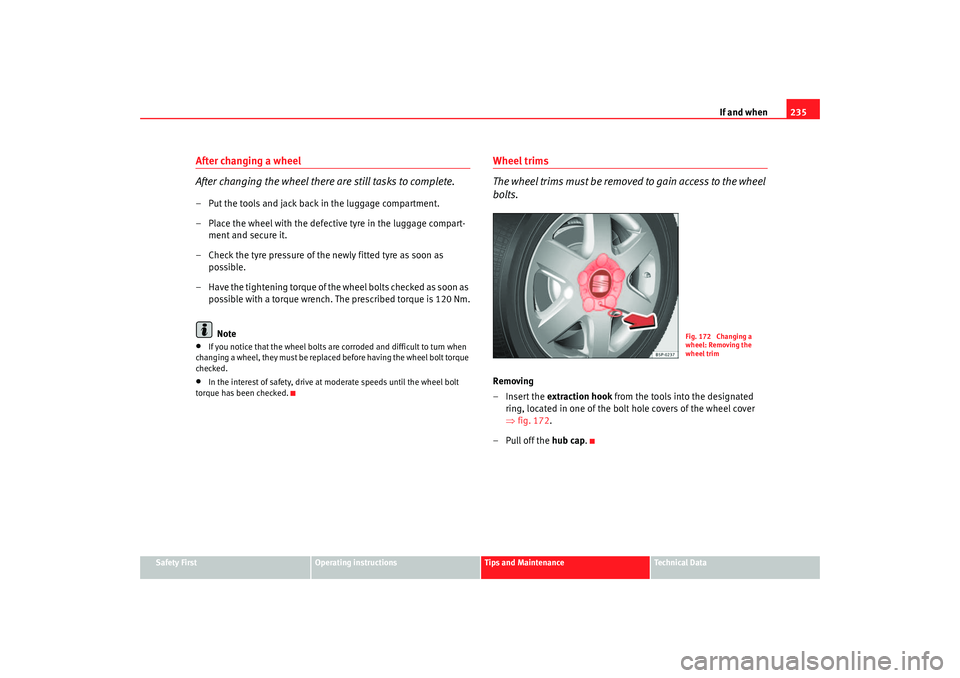

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

–Insert the extraction hook from the tools into the designated ring, located in one of the bolt hole covers of the wheel cover

⇒fig. 172.

–Pull off the hub cap .

Fig. 172 Changing a

wheel: Removing the

wheel trim

altea_ingles_0706.book Seite 235 Mittwoch, 30. August 2006 3:48 15

Page 238 of 302

If and when

236Wheel covers*

The wheel covers must be removed for access to the wheel

boltsRemoving

– Remove the wheel cover using the wire hook.

– Hook this into one of the cut-outs of the wheel cover.

Fitting

– Fit the wheel cover onto the wheel rim by pressing it firmly. Put

pressure initially on the point of the cut out for the valve. Then

press the wheel cover onto the steel rim so that it engages all

round.

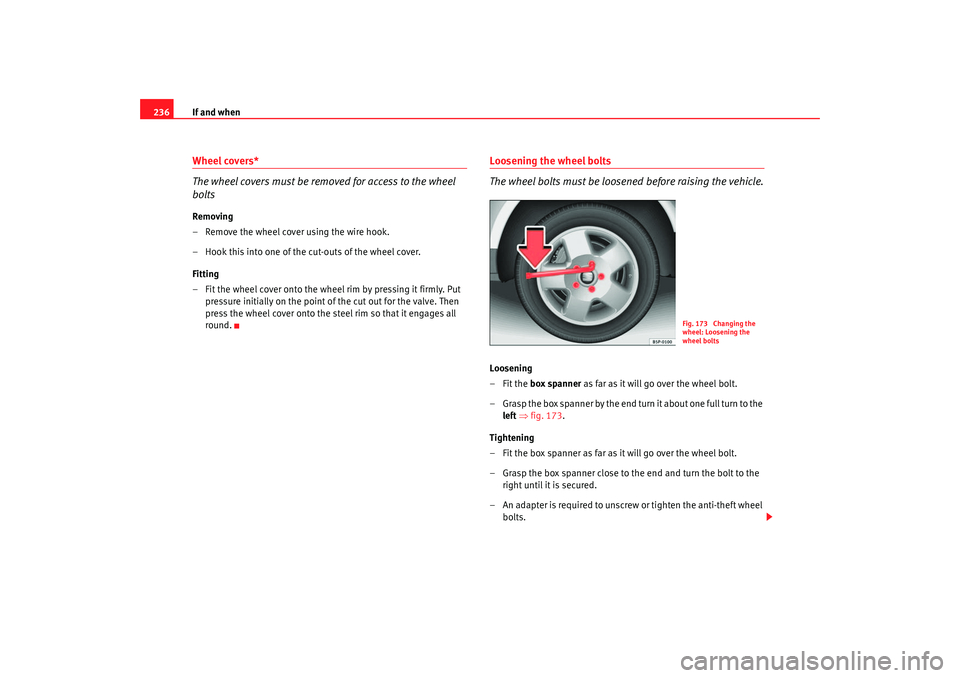

Loosening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner by the end turn it about one full turn to the left ⇒ fig. 173.

Tightening

– Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner close to the end and turn the bolt to the right until it is secured.

– An adapter is required to unscrew or tighten the anti-theft wheel bolts.

Fig. 173 Changing the

wheel: Loosening the

wheel bolts

altea_ingles_0706.book Seite 236 Mittwoch, 30. August 2006 3:48 15

Page 239 of 302

If and when237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

Loosen the wheel bolts only about one tu rn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in th e screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

altea_ingles_0706.book Seite 237 Mittwoch, 30. August 2006 3:48 15

Page 241 of 302

If and when239

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

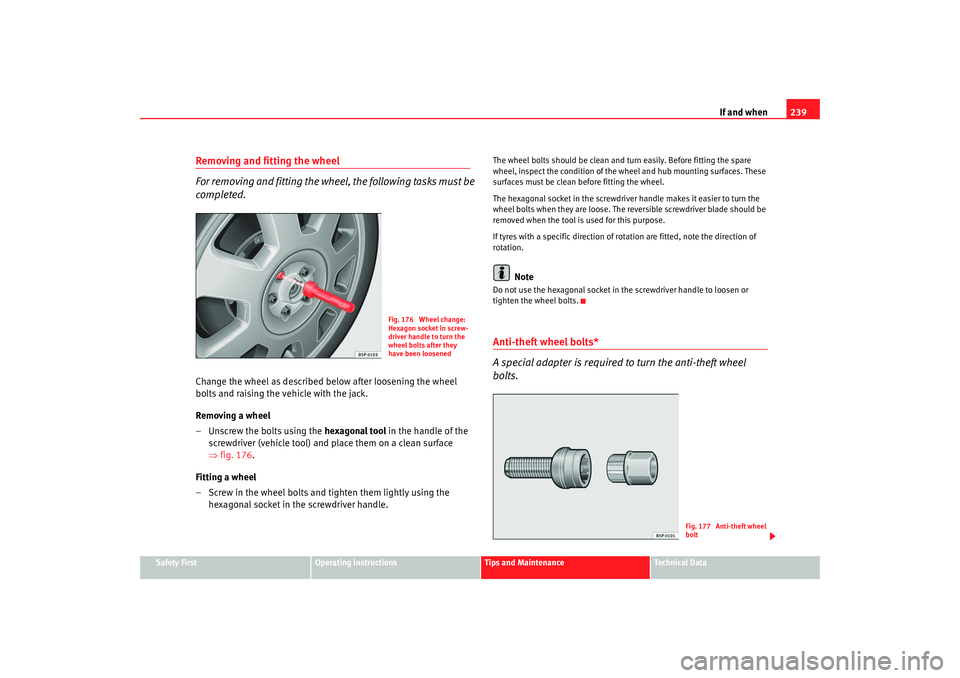

Removing and fitting the wheel

For removing and fitting the wheel, the following tasks must be

completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack.

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 176 .

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the wheel and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdriver blade should be

removed when the tool is used for this purpose.

If tyres with a specific direction of ro tation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 176 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

Fig. 177 Anti-theft wheel

bolt

altea_ingles_0706.book Seite 239 Mittwoch, 30. August 2006 3:48 15

Page 272 of 302

General notes on the technical data

270WeightsKerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for the

weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒.

WARNING

•

Please note that the centre of gravity may shift when transporting

heavy objects; this may affect the vehi cle's handling and lead to an acci-

dent. Always adjust your speed and dr iving style to suit road conditions

and requirements.

•

Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

To w i n g a t r a i l e rTrailer weightsTrailer weights

The trailer weights and drawbar loads approved are selected in intensive

trials according to precisely defined criteria. The approved trailer weights are

valid for vehicles in EU for maximum speeds of 80 km/h (in certain circum-

stances up to 100 km/h). The figures may be different in other countries. All

data in the official vehicle documents take precedence over these data ⇒. Drawbar load

The

maximum permitted weight exerted by the trailer drawbar on the ball joint

of the towing bracket must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow

approaching the maximum drawbar load. The response of the trailer on the

road will be poor if th e drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with an axle

base of less than 1 metre), at least 4% of the actual trailer weight is a legal

stipulation for a drawbar load.

WARNING

•

For safety reasons, you should not drive at speeds above 80 km/h when

towing a trailer. This also applies to countries where higher speeds are

permitted.

•

Never exceed the maximum trailer weights or the draw bar loading. If

the permissible axle load or the perm issible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced ⇒.

altea_ingles_0706.book Seite 270 Mittwoch, 30. August 2006 3:48 15

Page 273 of 302

General notes on the technical data 271

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Snow chains

Snow chains may be fitted only to the

front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•

Check the tyre pressure at least once per month. Correct tyre pressure

is very important. If the tyre pressure is too high or too low, there is an

increased danger of accidents, particularly at high speeds.

•

If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads could be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

altea_ingles_0706.book Seite 271 Mittwoch, 30. August 2006 3:48 15