light Seat Altea 2011 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Altea, Model: Seat Altea 2011Pages: 317, PDF Size: 8.87 MB

Page 243 of 317

Checking and refilling levels241

Safety First

Operating Instructions

Practical Tips

Technical Specifications

•When the engine is warm or hot, the cooling system is pressurised! Do

not unscrew the cap on the expansion tank when the engine is hot. This is

a burn injury risk.Caution

•When mixed with other additives the colour of G12 will change to brown.

If this occurs you should have the coolant changed immediately. Failure to do

so will result in engine damage!•If a lot of coolant fluid has been lost, wait for the engine to cool down

before putting in cold coolant. This avoids damaging the engine. Large

coolant losses are an indication of leaks in the cooling system. See a special-

ised workshop immediately and have the cooling system checked. Other-

wise, there is a risk of engine damage.

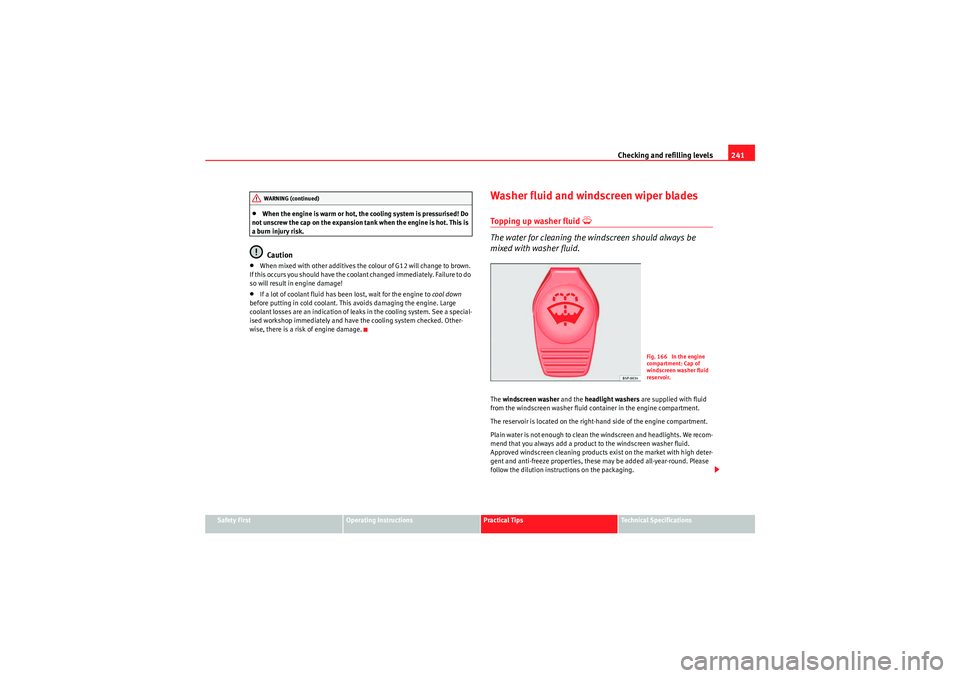

Washer fluid and windscreen wiper bladesTopping up washer fluid

�Y

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washers are supplied with fluid

from the windscreen washer fluid container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING (continued)

Fig. 166 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

Altea_EN.book Seite 241 Donnerstag, 2. September 2010 2:00 14

Page 247 of 317

Checking and refilling levels245

Safety First

Operating Instructions

Practical Tips

Technical Specifications

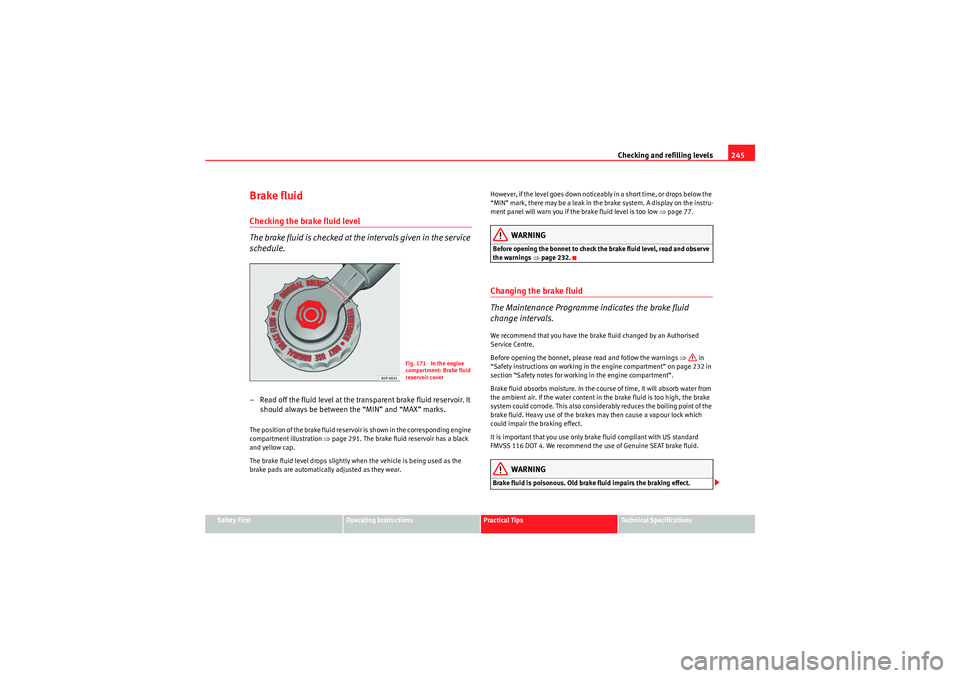

Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.The position of the brake fluid reservoir is shown in the corresponding engine

compartment illustration ⇒page 291. The brake fluid reservoir has a black

and yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear. However, if the level goes down noticeably in a short time, or drops below the

“MIN” mark, there may be a leak in the brake system. A display on the instru-

ment panel will warn you if the brake fluid level is too low

⇒page 77.

WARNING

Before opening the bonnet to check the brake fluid level, read and observe

the warnings ⇒page 232.Changing the brake fluid

The Maintenance Programme indicates the brake fluid

change intervals.We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒ in

“Safety instructions on working in the engine compartment” on page 232 in

section “Safety notes for working in the engine compartment”.

Brake fluid absorbs moisture. In the course of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also considerably reduces the boiling point of the

brake fluid. Heavy use of the brakes may then cause a vapour lock which

could impair the braking effect.

It is important that you use only brake fluid compliant with US standard

FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

Fig. 171 In the engine

compartment: Brake fluid

reservoir cover

Altea_EN.book Seite 245 Donnerstag, 2. September 2010 2:00 14

Page 249 of 317

Checking and refilling levels247

Safety First

Operating Instructions

Practical Tips

Technical Specifications

charge. Never short the battery terminals. High-energy sparks can cause

injury.

•A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.•Keep children away from acid and batteries.•Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.•Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.•When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.•Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.•Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0 °C.•Ensure that the vent hose is always connected to the battery.•Never use a defective battery. This could cause an explosion. Replace a

damaged battery immediately.Caution

•Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.•Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

•If the vehicle is left standing in cold conditions for a long period, protect

the battery from freezing. If it freezes it will be damaged.Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries.– Open the engine bonnet and the battery cover ⇒ in “Safety

instructions on working in the engine compartment” on

page 232 ⇒ in “Warnings on handling the battery” on

page 246.

– Check the colour display in the "magic eye" on the top of the battery.

– If there are air bubbles in the window, tap the window gently until they disperse.The position of the battery is shown in the corresponding engine compart-

ment diagram ⇒page 291.

The “magic eye” indicator, located on the top of the battery changes colour,

depending on the charge state and electrolyte level of the battery.

There are two different colours:•Black: correct charge status.•Transparent/clear yellow: the battery must be replaced. Contact a

specialist workshop.

WARNING (continued)

Altea_EN.book Seite 247 Donnerstag, 2. September 2010 2:00 14

Page 252 of 317

Wheels and tyres

250

2. The tyre pressures should only be checked when the tyres are cold. The slightly raised pressu res of warm tyres must not be

reduced.

3. Adjust the tyre pressure to the load you are carrying.Tyre pressure

The correct tyre pressure is especially important at high speeds. The pressure

should therefore be checked at least once a month and before starting a

journey.

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given are for cold tyres. Do not reduce the

slightly raised pressures of warm tyres ⇒.

WARNING

•Check the tyre pressure at least once per month. Checking the tyre

pressure is very important. If the tyre pressure is too high or too low, there

is an increased danger of accidents - particularly at high speeds.•A tyre can easily burst if the pressure is too low, causing an accident!•At continuously high speeds, a tyre with insufficient pressure flexes

more. In this way it becomes too hot, and this can cause tread separation

and tyre blow-out. Always observe the recommended tyre pressures.•If the tyre pressure is too low or too high, the tyres will wear prema-

turely and the vehicle will not handle well. Risk of accident!For the sake of the environment

Under-inflated tyres will increase fuel consumption.

Tyre pressure monitoring

The tyre pressure monitoring system constantly checks the

pressure of the tyres.The system uses the speed sensors of the ABS wheels. It operates by

analysing the speed and frequency spectrum of each wheel.

For optimum performance, use genuine SEAT tyres. In addition, check and

adjust tyre pressures regularly.

Whenever the tyre pressures are changed or one or more tyres are changed,

the system should be Reset by pressing the SET switch on the centre console.

The system warns the driver in the event of a loss of pressure by means of

symbols and messages in the instrument panel display. The system uses ESP

⇒ page 199.

Note that tyre pressure also depends on tyre temperature. Tyre pressure

increases about 0.1 bar for each 10 °C in tyre temperature increase. The tyre

heats up while the vehicle is being driven and the tyre pressure will rise

accordingly. For this reason, you should only adjust the tyre pressures when

they are cold (i.e. approximately at ambient temperature).

To ensure that the tyre pressure monitoring system works reliably, you should

check and, if necessary, adjust the tyre pressures at regular intervals and

store the correct pressures (reference values) in the system.

A tyre pressure information label is attached to the inside of the fuel tank flap.

WARNING

•Never adjust tyre pressure when the tyres are hot. This may damage or

even burst the tyres. Risk of accident!•An insufficiently inflated tyre flexes a lot more at high speeds and

causes significant heating of the tyre. Under these conditions, the tyre

bead may be released or the tyre may burst. Risk of accident!

Altea_EN.book Seite 250 Donnerstag, 2. September 2010 2:00 14

Page 261 of 317

If and when259

Safety First

Operating Instructions

Practical Tips

Technical Specifications

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Note

•Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Remove the wheel cover. Also refer to ⇒page 260, fig. 175

– Slacken the wheel bolts .

– Raise the vehicle with the jack at the corresponding area

– Remove the wheel and put on the spare one

– Lower the vehicle.

– Tighten the wheel bolts firmly with the box spanner

– Replace the hub cap.

Altea_EN.book Seite 259 Donnerstag, 2. September 2010 2:00 14

Page 266 of 317

If and when

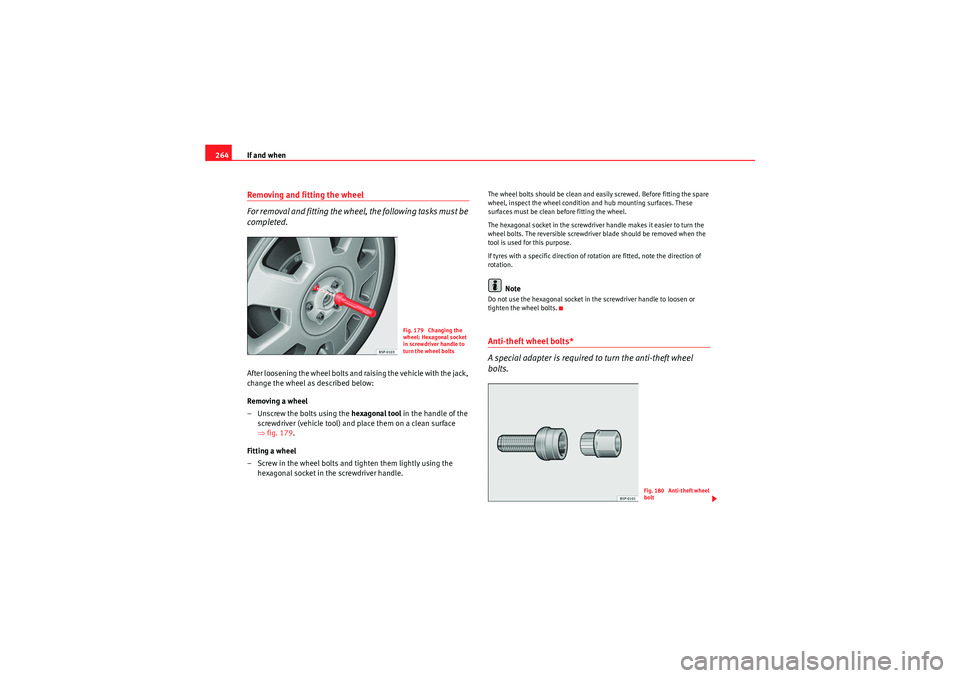

264Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.After loosening the wheel bolts and raising the vehicle with the jack,

change the wheel as described below:

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 179 .

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts. The reversible screwdriver blade should be removed when the

tool is used for this purpose.

If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 179 Changing the

wheel: Hexagonal socket

in screwdriver handle to

turn the wheel bolts

Fig. 180 Anti-theft wheel

bolt

Altea_EN.book Seite 264 Donnerstag, 2. September 2010 2:00 14

Page 268 of 317

If and when

266

For the sake of the environmentIf you have to dispose of a sealant can, go to a specialised waste service or to

a SEAT Technical Service, where the product can be recycled in an appropriate

waste container.

Note

•If sealant should leak out, leave it to dry. This way you can pull it off like a

piece of foil.•Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a specialised workshop.•Seek professional assistance if the repair of a tyre puncture is not

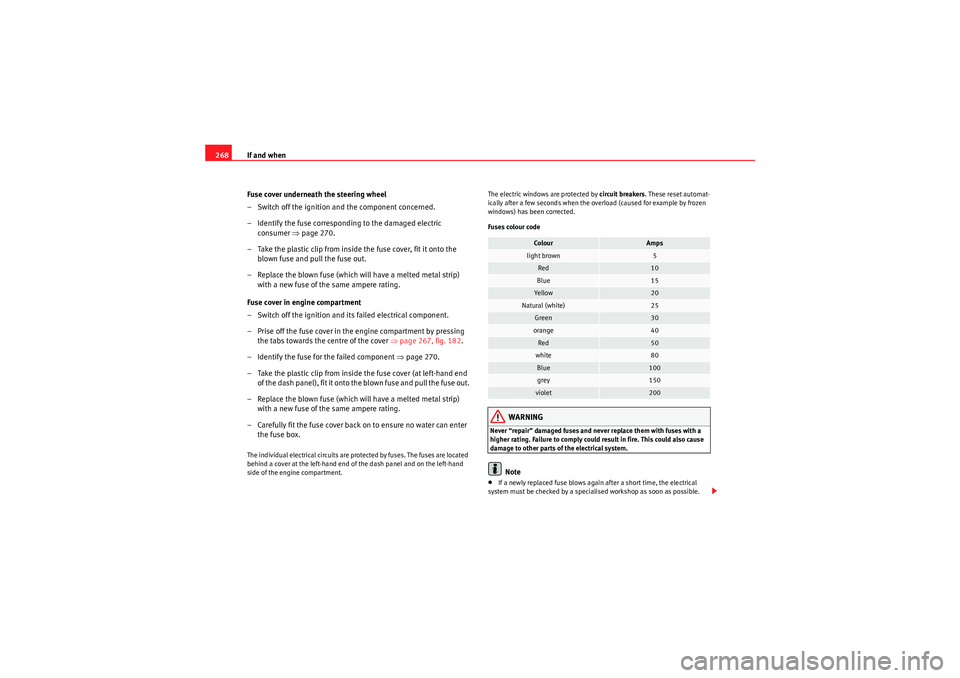

possible with the sealing compound.Preparation work

Certain steps must be taken before repairing a tyre.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible.

–Apply the handbrake firmly.

–Engage first gear, or put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility System “General information and safety notes.”

– Unscrew inflation cap from the affected wheel. –Take the

tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take special care if you have to repair a tyre on a slope.

Note

Please observe legal requirements when doing so.Tyre repair

The following sections describe the procedures for repairing

a tyre.Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power point.

Altea_EN.book Seite 266 Donnerstag, 2. September 2010 2:00 14

Page 270 of 317

If and when

268

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse corresponding to the damaged electric consumer ⇒page 270.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

Fuse cover in engine compartment

– Switch off the ignition and its failed electrical component.

– Prise off the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒page 267, fig. 182 .

– Identify the fuse for the failed component ⇒page 270.

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter

the fuse box.The individual electrical circuits are protected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment. The electric windows are protected by

circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

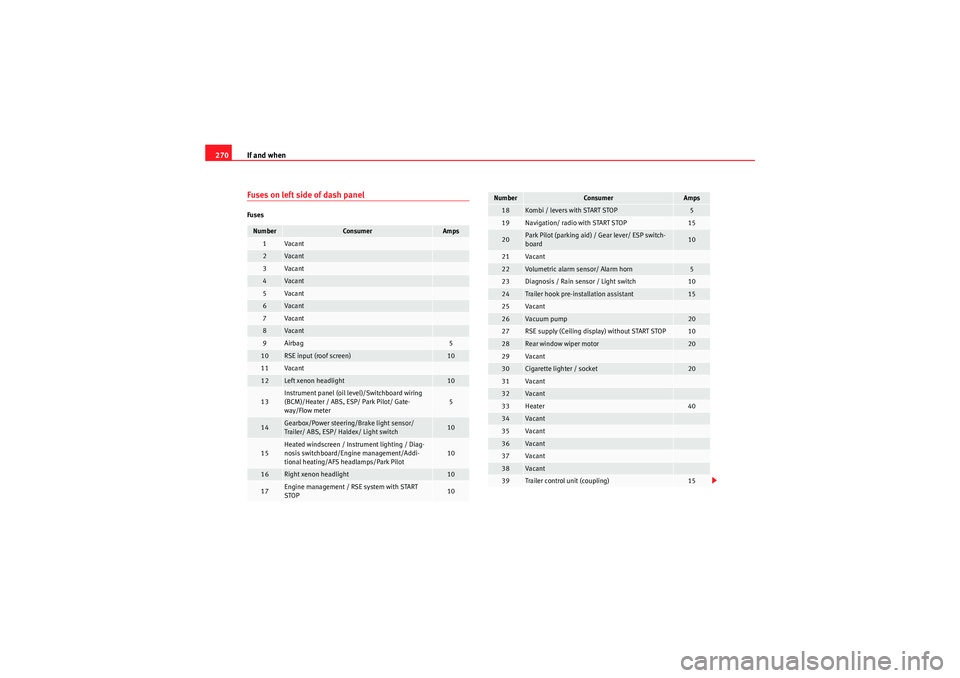

Fuses colour code

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

•If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a specialised workshop as soon as possible.

Colour

Amps

light brown

5

Red

10

Blue

15

Ye ll ow

20

Natural (white)

25

Green

30

orange

40

Red

50

white

80

Blue

100

grey

150

violet

200

Altea_EN.book Seite 268 Donnerstag, 2. September 2010 2:00 14

Page 272 of 317

If and when

270Fuses on left side of dash panelFusesNumber

Consumer

Amps

1

Va ca n t

2

Va ca n t

3

Va ca n t

4

Va ca n t

5

Va ca n t

6

Va ca n t

7

Va ca n t

8

Va ca n t

9

Airbag

5

10

RSE input (roof screen)

10

11

Va ca n t

12

Left xenon headlight

10

13

Instrument panel (oil level)/Switchboard wiring

(BCM)/Heater / ABS, ESP/ Park Pilot/ Gate-

way/Flow meter

5

14

Gearbox/Power steering/Brake light sensor/

Trailer/ ABS, ESP/ Haldex/ Light switch

10

15

Heated windscreen / Instrument lighting / Diag-

nosis switchboard/Engine management/Addi-

tional heating/AFS headlamps/Park Pilot

10

16

Right xenon headlight

10

17

Engine management / RSE system with START

STOP

10

18

Kombi / levers with START STOP

5

19

Navigation/ radio with START STOP

15

20

Park Pilot (parking aid) / Gear lever/ ESP switch-

board

10

21

Va ca n t

22

Volumetric alarm sensor/ Alarm horn

5

23

Diagnosis / Rain sensor / Light switch

10

24

Trailer hook pre-installation assistant

15

25

Va ca n t

26

Va cu um pum p

20

27

RSE supply (Ceiling display) without START STOP

10

28

Rear window wiper motor

20

29

Va ca n t

30

Cigarette lighter / socket

20

31

Va ca n t

32

Va ca n t

33

Heater

40

34

Va ca n t

35

Va ca n t

36

Va ca n t

37

Va ca n t

38

Va ca n t

39

Trailer control unit (coupling)

15

Number

Consumer

Amps

Altea_EN.book Seite 270 Donnerstag, 2. September 2010 2:00 14

Page 273 of 317

If and when271

Safety First

Operating Instructions

Practical Tips

Technical Specifications

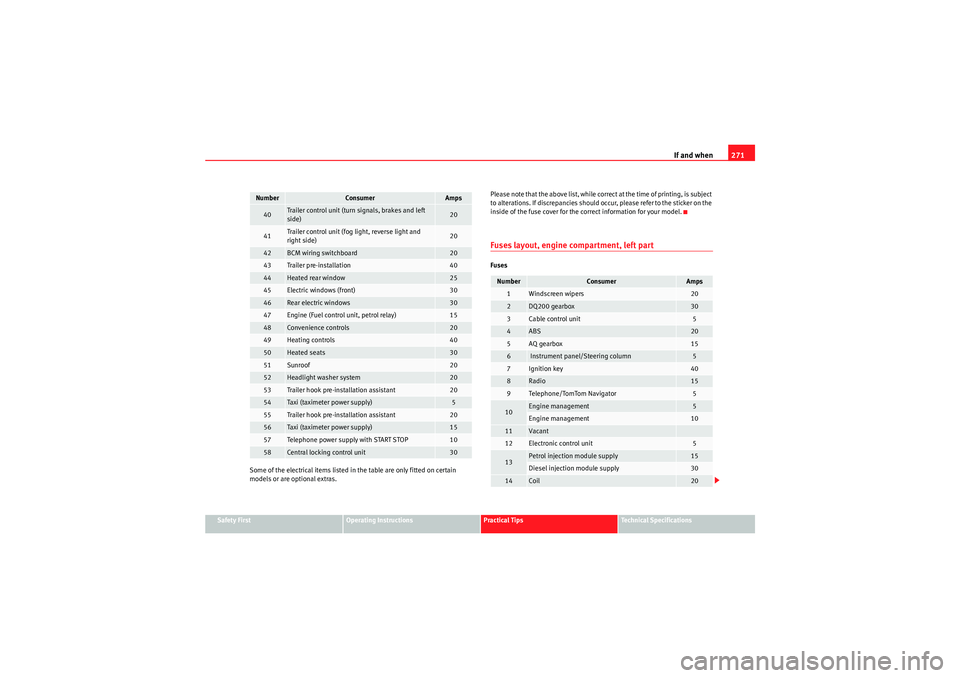

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras. Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should occur, please refer to the sticker on the

inside of the fuse cover for the correct information for your model.

Fuses layout, engine compartment, left partFuses

40

Trailer control unit (turn signals, brakes and left

side)

20

41

Trailer control unit (fog light, reverse light and

right side)

20

42

BCM wiring switchboard

20

43

Trailer pre-installation

40

44

Heated rear window

25

45

Electric windows (front)

30

46

Rear electric windows

30

47

Engine (Fuel control unit, petrol relay)

15

48

Convenience controls

20

49

Heating controls

40

50

Heated seats

30

51

Sunroof

20

52

Headlight washer system

20

53

Trailer hook pre-installation assistant

20

54

Taxi (taximeter power supply)

5

55

Trailer hook pre-installation assistant

20

56

Taxi (taximeter power supply)

15

57

Telephone power supply with START STOP

10

58

Central locking control unit

30

Number

Consumer

Amps

Number

Consumer

Amps

1

Windscreen wipers

20

2

DQ200 gearbox

30

3

Cable control unit

5

4

ABS

20

5

AQ gearbox

15

6

Instrument panel/Steering column

5

7

Ignition key

40

8

Radio

15

9

Te lep ho ne /TomTo m Na viga tor

5

10

Engine management

5

Engine management

10

11

Vacant

12

Electronic control unit

5

13

Petrol injection module supply

15

Diesel injection module supply

30

14

Coil

20

Altea_EN.book Seite 271 Donnerstag, 2. September 2010 2:00 14