lock Seat Altea 2014 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Altea, Model: Seat Altea 2014Pages: 321, PDF Size: 4.52 MB

Page 201 of 321

199

Intelligent technology

Electronic Stability Control (ESC)*

The ESC reduces the risk of skidding by braking the wheels individually.

The system uses the steering wheel angle and road speed to calculate the

changes of direction desired by the driver, and constantly compares them

with the actual behaviour of the vehicle. When irregularities occur, for exam-

ple, if the vehicle begins to skid, the ESC brakes the appropriate wheel au-

tomatically.

The forces acting on the braked wheel bring the vehicle back to a stable

condition. If the vehicle tends to oversteer, the system will act on the front

wheel on the outside of the turn.

Steering manoeuvre recommendations

This is a complementary safety function included in the ESC. This function

aids the driver to better stabilize the vehicle in a critical situation. For exam-

ple, in case of sudden braking surface with varied adherence, the vehicle

will tend to destabilise its trajectory to the right or to the left. In this case,

the ESC recognises the situation and assists the driver with a counter steer-

ing manoeuvre from the power steering.

This function simply provides the driver with a recommended manoeuvre in

critical situations.

The vehicle does not steer itself with this function, the driver has full control

of the vehicle at all times.

WARNING

● Remember that not even the ESC can defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

● Always adapt your driving style to suit the condition of the roads and

the traffic situation. The greater safety provided by the ESC should not

encourage you to run any risks.

CAUTION

● To ensure that the ESC works correctly, all four wheels must be fitted

with the same tyres. Any differences in the rolling radius of the tyres can

cause the system to reduce engine power when this is not desired.

● Any modifications made to the vehicle (for example, to the engine,

brake system, running gear or to the combination of wheels and tyres) may

affect the operation of the ABS, EDL, ESC and ASR.

Anti-lock brake system (ABS)

The anti-lock brake system prevents the wheels locking during braking

⇒ page 197.

Electronic differential lock (EDL)*

The electronic differential lock helps prevent the loss of trac-

tion caused if one of the driven wheels starts spinning.

EDL helps the vehicle to start moving, accelerate and climb a gradient in

slippery conditions where this may otherwise be difficult or even impossi-

ble.

The system will control the revolutions of the driven wheels using the ABS

sensors (in case of an EDL fault the warning lamp for ABS lights up)

⇒ page 83.

At speeds of up to approximately 80 km/h, it is able to balance out differen-

ces in the speed of the driven wheels of approximately 100 rpm caused by a

slippery road surface on one side of the vehicle. It does this by braking the

wheel which has lost traction and distributing more driving force to the oth-

er driven wheel via the differential.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 213 of 321

211

Trailer towing

Note

● Towing a trailer places additional demands on the vehicle. We recom-

mend additional services between the normal inspection intervals if the ve-

hicle is used frequently for towing a trailer.

● Find out whether special regulations apply to towing a trailer in your

country.

Ball coupling of towing bracket*

Depending on the model version, the spherical head on the trailer hook

may be stored in the tool box.

The ball coupling is provided with instructions on fitting and removing the

ball coupling of the towing bracket.

WARNING

The towing bracket ball coupling must be stored securely in the luggage

compartment to prevent them being flung through the vehicle and caus-

ing injury.

Note

● By law, the ball coupling must be removed if a trailer is not being towed

if it obscures the number plate. Driving tips

Driving with a trailer always requires extra care.

Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slowly to allow

for the unbalanced weight distribution.

Speed

The stability of the vehicle and trailer is reduced with increasing speed. For

this reason, it is advisable not to drive at the maximum permissible speed

in an unfavourable road, weather or wind conditions. This applies especially

when driving downhill.

You should always reduce speed immediately if the trailer shows the slight-

est sign of snaking. Never try to stop the “snaking” by increasing speed.

Always brake in due course. If the trailer has an overrun brake, apply the

brakes gently at first and then, firmly. This will prevent the jerking that can

be caused by locking of trailer wheels. Select a low gear in due course be-

fore going down a steep downhill. This enables you to use the engine brak-

ing to slow down the vehicle.

Reheating

At very high temperatures and during prolonged slopes, driving in a low

gear and high engine speed, always monitor the coolant temperature gauge

⇒ page 55.

Electronic Stability Control*

The ESC* system helps to stabilise the trailer in case of skidding or rocking.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 218 of 321

216Vehicle maintenance and cleaning

WARNING

● Wash your vehicle with the ignition switched off.

● Protect your hands and arms from cuts on sharp metal edges when

cleaning the underbody, the inside of the wheel housings etc. Risk of in-

jury.

● Water, ice and salt on the brake system can reduce braking effective-

ness. Risk of accident.

CAUTION

● Never remove dirt, mud or dust if the vehicle surface is dry. Never use a

dry cloth or sponge for cleaning purposes. This could scratch the paintwork

or glass on your vehicle.

● Washing the vehicle in low temperatures: when washing the vehicle

with a hose, do not direct water into the lock cylinders or the gaps around

the doors, rear lid, or sunroof. Risk of freezing.

For the sake of the environment

To protect environment, the vehicle should be washed only in specially pro-

vided wash bays. This prevents toxic, oil-laden waste water entering the

sewerage system. In some places, washing vehicles outside wash bays is

prohibited.

Note

Do not wash the vehicle in direct sunlight. Washing the vehicle with a high pressure cleaner

Be particularly careful when using a high pressure cleaner!

– Always observe the instructions for the high-pressure cleaner,

particularly those concerning the pressure and the spraying

distance.

– Increase the spraying distance for soft materials and painted

bumpers.

– Do not use a high pressure cleaner to remove ice or snow from

windows ⇒ page 217.

– Never use concentrated jet nozzles (“rotating jets”) ⇒

.

– After washing, avoid sudden and sharp braking. “” Dry the

brakes by braking several times ⇒ page 204.

WARNING

● Never wash tyres with a concentrated jet (“rotating nozzle”). Even at

large spraying distances and short cleaning times, visible and invisible

damage can occur to the tyres. This may cause an accident.

● Water, ice and salt on the brake system can reduce braking effective-

ness. Risk of accident.

CAUTION

● Do not use water hotter than +60 °C (+140 °F). This could damage the

vehicle.

● To avoid damage to the vehicle, keep a sufficient distance from sensitive

materials such as flexible hoses, plastic, soundproofing material, etc. This

is also important for bumpers painted in the colour of the bodywork. The

closer the nozzle is to the surface, the greater the wear on the material.

Page 220 of 321

218Vehicle maintenance and cleaning

If possible, use a de-icing spray to remove ice. If you use an ice scraper,

push it in one direction only without swinging it.

Use window cleaner or a silicone remover to clean rubber, oil, grease and

silicone deposits off.

Wax deposits can be removed with a special cleaner available in your Tech-

nical Services. Wax deposits on the windscreen could cause the wiper

blades to judder. Adding a window cleaner that dissolves wax to the wind-

screen washer fluid prevents wiper blades from juddering, but wax deposits

are not removed.

CAUTION

● Never use warm or hot water to remove snow and ice from windows and

mirrors. This could cause the glass to crack!

● The heating element for the rear window is located on the inner side of

the window. To prevent damage, do not put stickers over the heating ele-

ments on the inside of the window.

Cleaning windscreen wiper blades

Clean wiper blades improve visibility.

1. Use a soft cloth to remove dust and dirt from the windscreen wiper blades.

2. Use window cleaner to clean the windscreen wiper blades. Use a sponge or a cloth to remove stubborn dirt. Rubber seals maintenance

If rubber seals are well looked after, they will not freeze so

quickly.

1. Use a soft cloth to remove dust and dirt from the rubber seals.

2. Apply a specialist care product to the rubber seals.

The rubber strips on the doors, windows, bonnet and rear lid will remain

pliable and last longer if they are treated with a suitable care product (for

example silicone spray).

Caring for rubber seals will also prevent premature ageing and leaks. The

doors will be easier to open. If rubber seals are well looked after, they will

not freeze so quickly in winter.

Door lock cylinders

The door lock cylinders can freeze up in winter.

To de-ice the lock cylinders you should only use spray with lubricating and

anti-corrosive properties.

Cleaning chrome parts

1. Clean chrome parts with a damp cloth.

2. Polish chrome parts with a soft, dry cloth. If this does not provide satisfying results, use a specialist chrome cleaning

product. Chrome cleaning products will remove stains from the surface.

Page 230 of 321

228Checking and refilling levels

Checking and refilling levels

Refuelling

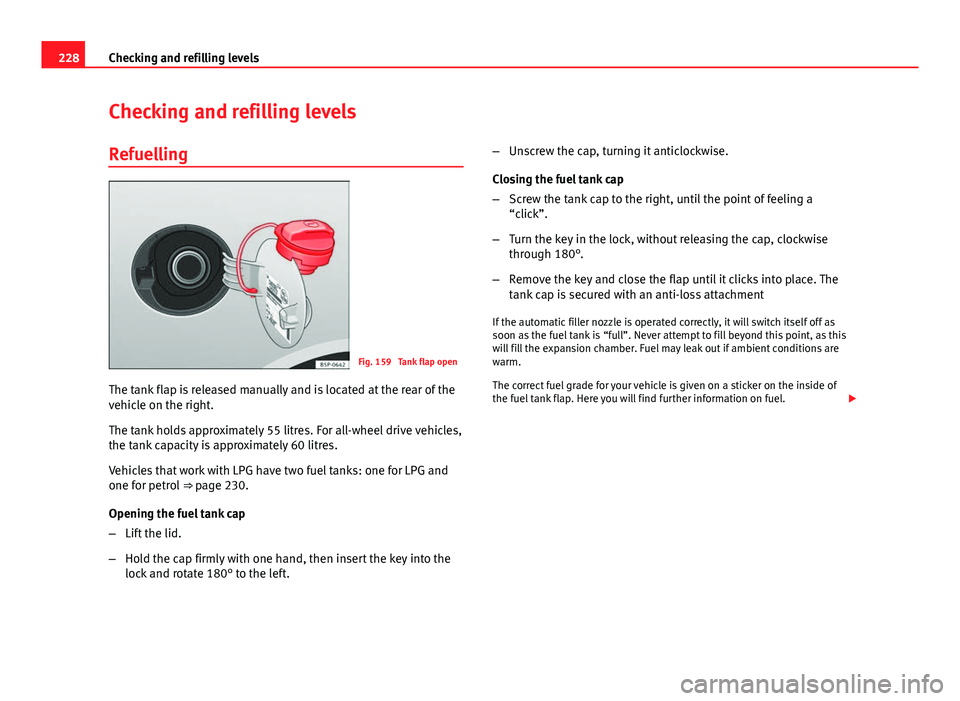

Fig. 159 Tank flap open

The tank flap is released manually and is located at the rear of the

vehicle on the right.

The tank holds approximately 55 litres. For all-wheel drive vehicles,

the tank capacity is approximately 60 litres.

Vehicles that work with LPG have two fuel tanks: one for LPG and

one for petrol ⇒ page 230.

Opening the fuel tank cap

– Lift the lid.

– Hold the cap firmly with one hand, then insert the key into the

lock and rotate 180° to the left. –

Unscrew the cap, turning it anticlockwise.

Closing the fuel tank cap

– Screw the tank cap to the right, until the point of feeling a

“click”.

– Turn the key in the lock, without releasing the cap, clockwise

through 180°.

– Remove the key and close the flap until it clicks into place. The

tank cap is secured with an anti-loss attachment

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the fuel tank is “full”. Never attempt to fill beyond this point, as this

will fill the expansion chamber. Fuel may leak out if ambient conditions are

warm.

The correct fuel grade for your vehicle is given on a sticker on the inside of

the fuel tank flap. Here you will find further information on fuel.

Page 238 of 321

236Checking and refilling levels

WARNING

All work on the engine or in the engine compartment, e.g. checking and

refilling fluids, involves the danger of injury and scalding as well as the

risk of accident or fire.

● Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment. Otherwise, there is a risk of sustaining

burns. Wait until no more steam or coolant is emitted, then allow the en-

gine to cool before carefully opening the bonnet.

● Switch off the engine and remove the key from the ignition.

● Apply the handbrake and move the gear lever to neutral or selector

lever to position P.

● Keep children away from the vehicle.

● Never touch hot engine parts. There is a risk of burns.

● Never spill liquids on a hot engine or on a hot exhaust gas system.

This is a fire hazard.

● Avoid causing short-circuits in the electrical system, particularly at

the points where the jump leads are attached ⇒ page 288. The battery

could explode.

● Never touch the radiator fan. It is temperature controlled and could

start automatically, even when the engine has been switched off and the

key removed from the ignition!

● Do not unscrew the cap on the coolant expansion tank when the en-

gine is hot. If the coolant is hot, the cooling system will be pressurised!

● Protect face, hands and arms by covering the cap with a large, thick

cloth to protect against escaping coolant and steam.

● Always make sure you have not left any objects, such as cleaning

cloths and tools, in the engine compartment.

● If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle, there is a risk of accident!. A

hydraulic jack is insufficient for securing the vehicle and there is a risk of

injury.WARNING (Continued)

● If any work has to be performed when the engine is started or with

the engine running, there is an additional, potentially fatal, safety risk

from the rotating parts, such as the drive belts, alternator, radiator fan,

etc., and from the high-voltage ignition system. You should also observe

the following points:

–Never touch the electrical wiring of the ignition system.

– Ensure that jewellery, loose clothing and long hair do not get trap-

ped in rotating engine parts. Danger of death. Before starting any

work remove jewellery, tie back and cover hair, and wear tight-fitting

clothes.

– Never accelerate with a gear engaged without taking the necessary

precautions. The vehicle could move, even if the handbrake is ap-

plied. Danger of death.

● If work has to be carried out on the fuel system or on electrical com-

ponents, you must observe the following safety notes in addition to the

above warnings:

–Always disconnect the battery from the on-board network. The ve-

hicle must be unlocked when this is done, otherwise the alarm will be

triggered.

– Do not smoke.

– Never work near naked flames.

– Always have a fire extinguisher on hand.

CAUTION

When topping up service fluids, make sure not to mistake them. Using the

wrong fluids could cause serious malfunctions and engine damage!

Page 239 of 321

237

Checking and refilling levels

For the sake of the environment

Service fluids leaks are harmful to the environment. For this reason you

should make regular checks on the ground underneath your vehicle. If you

find spots of oil or other fluids, have your vehicle inspected in a specialised

workshop.

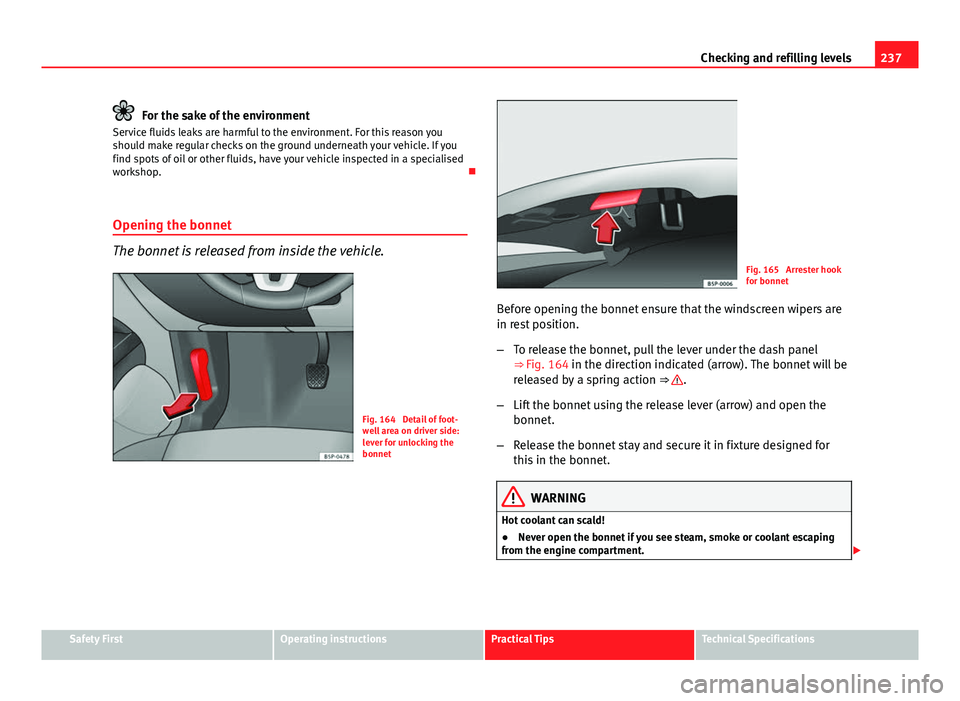

Opening the bonnet

The bonnet is released from inside the vehicle.

Fig. 164 Detail of foot-

well area on driver side:

lever for unlocking the

bonnet

Fig. 165 Arrester hook

for bonnet

Before opening the bonnet ensure that the windscreen wipers are

in rest position.

– To release the bonnet, pull the lever under the dash panel

⇒ Fig. 164 in the direction indicated (arrow). The bonnet will be

released by a spring action ⇒

.

– Lift the bonnet using the release lever (arrow) and open the

bonnet.

– Release the bonnet stay and secure it in fixture designed for

this in the bonnet.

WARNING

Hot coolant can scald!

● Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 240 of 321

238Checking and refilling levels

WARNING (Continued)

● Wait until no more steam, smoke or coolant is emitted from the bon-

net, then carefully open the bonnet.

● When working in the engine compartment, always observe the safety

warnings ⇒ page 235.

Closing the bonnet

– Raise the bonnet slightly

– Release the bonnet stay and replace it in its support.

– At a height of about 30 cm let it fall so it is locked.

If the bonnet does not close, do not press downwards. Open it once more

and let it fall as before.

WARNING

If the bonnet is not closed properly, it could open while you are driving

and completely obscure your view of the road. Risk of accident.

● After closing the bonnet, always check that it is properly secured. The

bonnet must be flush with the surrounding body panels.

● If you notice that the bonnet latch is not secured when the vehicle is

moving, stop the vehicle immediately and close the bonnet properly.

Risk of accident.

Engine oil

General notes

The engine comes with a special, multi-grade oil that can be used all year

round.

Because the use of high-quality oil is essential for the correct operation of

the engine and its long useful life, when topping up or changing oil, use on-

ly those oils that comply with VW standards.

The specifications (VW standards) set out in the following page should ap-

pear on the container of the service oil; when the container displays the

specific standards for petrol and diesel engines together, it means that the

oil can be used for both types of engines.

We recommend that the oil change, indicated in the Maintenance Pro-

gramme, be performed by a Technical Service or a specialised workshop.

The correct oil specifications for your engine are listed in the ⇒ page 239,

Oil properties.

Service intervals

Service intervals can be flexible (LongLife service) or fixed (dependent on

time/distance travelled).

If the PR code that appears on the back of the “Maintenance Programme”

booklet is PR QI6, this means that your vehicle has the LongLife service pro-

grammed. If it lists the codes QI1, QI2, QI3, QI4 or QI7, the interval service

is dependent on time/distance travelled.

Flexible service intervals (LongLife service intervals*)

Special oils and processes have been developed which, depending on the

characteristics and individual driving profiles, enable the extension of the

oil change service (LongLife service intervals).

Page 247 of 321

245

Checking and refilling levels

The windscreen washer and the headlight washers are supplied with fluid

from the windscreen washer fluid container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We rec-

ommend that you always add a product to the windscreen washer fluid. Ap-

proved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING

Any work carried out in the engine compartment or on the engine must

be carried out cautiously.

● When working in the engine compartment, always observe the safety

warnings ⇒ page 235.

CAUTION

● Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

● Always use approved windscreen cleansing products diluted as per in-

structions. If you use other washer fluids or soap solutions, the tiny holes in

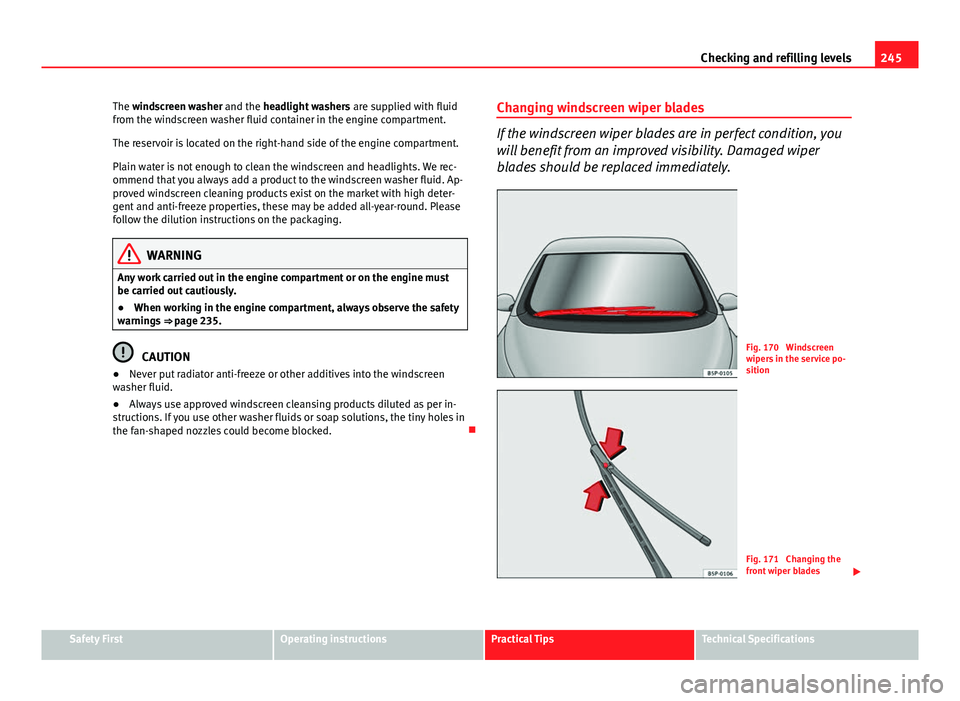

the fan-shaped nozzles could become blocked. Changing windscreen wiper blades

If the windscreen wiper blades are in perfect condition, you

will benefit from an improved visibility. Damaged wiper

blades should be replaced immediately.

Fig. 170 Windscreen

wipers in the service po-

sition

Fig. 171 Changing the

front wiper blades

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 251 of 321

249

Checking and refilling levels

Brake fluid Checking the brake fluid level

The brake fluid is checked at the intervals given in the serv-

ice schedule.

Fig. 175 In the engine

compartment: Brake fluid

reservoir cover

– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.

The position of the brake fluid reservoir is shown in the corresponding en-

gine compartment illustration ⇒ page 297. The brake fluid reservoir has a

black and yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear.

However, if the level goes down noticeably in a short time, or drops below

the “MIN” mark, there may be a leak in the brake system. A display on the

instrument panel will warn you if the brake fluid level is too low ⇒ page 76.

WARNING

Before opening the bonnet to check the brake fluid level, read and ob-

serve the warnings ⇒ page 235.

Changing the brake fluid

The Maintenance Programme indicates the brake fluid

change intervals. We recommend that you have the brake fluid changed by a Technical Serv-

ice.

Before opening the bonnet, please read and follow the warnings ⇒

in

Safety instructions on working in the engine compartment on page 235 in

section “Safety notes for working in the engine compartment”.

Brake fluid absorbs moisture. In the course of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also considerably reduces the boiling point of

the brake fluid. Heavy use of the brakes may then cause a vapour lock

which could impair the braking effect.

Be sure to always use the correct brake fluid. Only use brake fluid that ex-

pressly meets VW 501 14 standards.

You can buy VW 501 14 standard brake fluid in a SEAT dealership or SEAT

Official Service. If none is available, use only high quality brake fluid that

meets DIN ISO 4925 CLASS 4 standards, or USA Standards FMVSS 116 DOT

4.

Using any other kind of brake fluid or one that is not of a high quality may

affect operation of the brake system and reduce its effectiveness. Never use

a brake fluid if the container does not state that it complies with VW 501 14,

DIN ISO 4925 CLASS 4 standards, or USA standards FMVSS 116 DOT 4.

Safety FirstOperating instructionsPractical TipsTechnical Specifications